Do-it-yourself installation of sewer stations. SPS - sewage pumping station, options and drawing. Key benefits of modular pumping stations

The sewage pumping station (SPS), designed for pumping waste water, is a whole complex of technical devices, which also includes special tanks. Such stations are used in cases where it is not possible to transport wastewater through the sewerage system by gravity. For example, you cannot do without a station if the bathroom is located below the level at which the sewer pipe is mounted.

Today, you can purchase sewage stations of various modifications, which differ among themselves in technical characteristics, and in design, and in the scope of application. That is why, before proceeding with the selection of such installations, if there is a need for them, one should understand their design features, the principle of operation, and also get acquainted with the main types of such equipment and the differences between them.

General information

Depending on the complexity of the design and operational characteristics, sewage pumping stations can be divided into three main categories: simple, medium complexity and complex. It makes no sense to use complex sewage pumping stations for a private house, since such expensive installations are characterized by high productivity, significantly exceeding the volume of wastewater accumulating in a private building. Sewage pumping stations of a complex category are equipped with industrial enterprises, in the process of which a large amount of wastewater is generated.

For servicing private houses, it is advisable to use household SPS, which are compact in size and affordable. When choosing a specific modification of a sewage pumping station for a house, the estimated volume of wastewater, the degree of their pollution, as well as the type of pollution that are present in such waters are taken into account. In addition, it is necessary to take into account the features of the relief of the site where the station will be installed, as well as the depth of the sewer pipes.

Device diagram

Various types of pumping stations for sewerage differ from each other in design, but regardless of their modification, the main elements are a pump and a sealed tank in which waste products are collected. The tank, which is equipped with a sewage pumping station, can be made of concrete, plastic or metal. The task of the pump, with which the sewage station is equipped, is to raise wastewater to a certain level, after which it flows into the storage tank by gravity. After the tank is filled, waste water is pumped out of it and transported to the place of their disposal.

Often, the design scheme of a household SPS includes two pumps, while the second of them is a backup and is used in cases where the main one is out of order. Sewage pumping stations serving industrial and communal enterprises with a large volume of wastewater are mandatory equipped with several pumps. Pumping equipment for SPS can be of various types. So, domestic sewage pumping stations, as a rule, are equipped with pumps with a cutting mechanism, with the help of which the fecal mass and other inclusions contained in the wastewater are crushed. Such pumps are not installed at industrial stations, since solid inclusions contained in the wastewater of industrial enterprises, getting into the cutting mechanism of the pump, can lead to its breakdown.

In private houses, mini pump stations are often installed, the pumps of which are connected directly to the toilet bowls. Such an aesthetically pleasing SPS (a real mini-system equipped with a pump with a cutting mechanism and a small storage tank) is usually installed directly in the bathroom.

Serial models of sewage pumping stations are equipped with polymer tanks, which are buried in the ground, while the neck of such a tank for the pumping station is located on the surface, which facilitates routine inspections, maintenance and repair of the tank, if necessary. The neck of the storage tank is closed with a lid, which can be made of polymeric material or metal, before starting the operation of the pump station. The connection of such a tank to the sewer system, through which wastewater enters it, is carried out using nozzles. In order for the wastewater to flow into the storage tank evenly, a special bumper is provided in its design, and the water wall is responsible for ensuring that no turbulence occurs in the liquid medium.

The equipment of sewage pumping stations for a private house has control devices and automatic control mechanisms. Additional elements that are supplied to industrial sewage pumping stations and installations for servicing the domestic sewage system include:

- a source that provides backup power supply to the equipment that is part of the pump station;

- manometers, pressure sensors, shut-off valves;

- equipment that provides cleaning of pumps and connecting pipes.

How the CNS works

The SPS has a fairly simple principle of operation.

- Waste water from the sewerage system enters the receiving part of the installation, from where it is pumped into the pressure pipeline.

- The wastewater is transported via a pressure pipeline to a distribution chamber, from where it is then pumped to a treatment plant or to a central sewerage system.

In order to prevent wastewater from returning to the pump through the pipeline, the sewage pumping station is equipped with a check valve. In the event that the volume of wastewater in the sewer pipeline increases, an additional pump is turned on at the station. If the main and additional pumps for the sewage pumping station cannot cope with the pumping of the volume of wastewater, then the device automatically turns on, signaling the occurrence of an emergency situation.

The principle of operation of the industrial pumping station provides for the automatic control of such installations, which is provided by float-type sensors installed at different levels of the receiving tank of the station. SPS equipped with such sensors operates according to the following principle.

- When the level of effluent entering the tank reaches the level of the location of the lowest sensor, the pumping equipment remains off.

- When the tank is filled with wastewater to the level of the location of the second sensor, the pump automatically turns on and starts pumping wastewater.

- If the reservoir is filled with drains to the level of the third sensor, then the reserve pump is turned on.

- When the tank is filled up to the fourth (uppermost) sensor, a signal is triggered indicating that both pumps involved in the pump station cannot cope with the volume of wastewater.

After the level of the wastewater pumped out of the tank drops to the level of the location of the lowest sensor, the system automatically turns off the pumping equipment. The next time the system is turned on, a backup pump is activated to pump out waste water from the tank, which allows both pumping devices to be operated in a gentle mode. The work of the station can also be transferred to the manual control mode, which is necessary in cases when maintenance of the pump station or its repair is carried out.

Types of pumping equipment for pumping station

The main and most important element of any sewage pumping station is a pump, whose tasks include pumping out domestic and industrial wastewater, sludge and liquid medium coming from the storm sewer. The main types of pumps that are used to equip the pump station are:

- submersible devices;

- cantilever pumps;

- self-priming pumping equipment.

Submersible pumping equipment related to pressure-type devices, during operation, is constantly in the liquid medium pumped by it, therefore, the body of this type of device is made of materials that are resistant to the aggressive effects of substances contained in wastewater.

Among the advantages of submersible pumping equipment used to equip the pump station are:

- no need for a specially designated place for installation, since such equipment is located in the environment it pumped over;

- high reliability;

- ease of use;

- no need for frequent maintenance;

- the ability to function effectively even at low temperatures;

- spontaneous cooling of the internal elements of the equipment, carried out by the liquid medium pumped by it;

- versatility, which lies in the fact that pumps of this type can be installed on the ground.

With the help of cantilever pumps located on the surface of the earth, the pumping station for industrial purposes is serviced. For the installation of such pumping equipment, it is necessary to prepare a separate concrete site and correctly bring pipes to it, therefore it is best to entrust the implementation of such a responsible procedure to qualified specialists. The advantages of cantilever-type pumping equipment include:

- high reliability;

- ease of maintenance and repair (since the pump is located on the ground);

- the ability to change the performance of the device, which is carried out by replacing the electric motor and other structural elements.

Surface self-priming pumps, which can be used to pump even heavily contaminated media, are used to service sewage pumping stations of industrial and municipal enterprises. If we talk about the advantages of this type of pump, then this should include:

- ease of maintenance, which is provided by a retractable design;

- the possibility of pumping waste water containing solid inclusions;

- the ability to work even at negative temperatures when equipped with a special heating element;

- maximum body tightness, which is ensured by a double mechanical seal;

- ease of installation and dismantling.

In order to carry out the installation of the sewage pumping station, it is necessary to first prepare a pit for placing the storage tank of the station. The depth of the pit to be prepared should be such that the neck of the storage tank protrudes 1 meter above the ground. When preparing the pit, it should also be borne in mind that at its bottom it is necessary to equip a sand cushion 1.5 meters thick. After preparing the pit, a storage tank is placed in it, to which all the necessary pipes are connected. The final procedure of this stage of the installation of the SPS is filling the pit with sand and its layer-by-layer compaction.

Further installation of the KNS consists in adjusting the stroke of the floats, which should be located in the tank at certain levels. So, the first (lowest) float is installed in the container at a level of 0.15–0.3 m from its bottom. The rest of the floats, if the SPS device provides for their presence, are installed in the container with a step of 1.5 meters. You can see how the floats should be located in the SPS tank from the photos, which are easy to find on the Internet.

Level control is carried out using float sensors that ensure timely start and stop of pumps, as well as alarm levels

After the entire SPS structure is assembled, the station is connected to the power supply, for which well-insulated cables are used. A test run of the station, the purpose of which is to check the operability of all its elements, is performed using clean water coming from a water supply system or a storage tank.

A photo of the pump station or a video demonstrating the process of its installation allows you to get an idea of how an assembled station should look like.

Both domestic and industrial sewage pumping stations require regular maintenance to maintain efficiency and extend the life of the equipment used. Maintenance includes the following procedures.

- First, the equipment is inspected and the condition of the pumps, elements of shut-off valves is checked, the values of the parameters, which are reflected in the control panel of the SPS, are checked. If during operation the pumping equipment makes a lot of noise and vibrates, it is removed, inspected, cleaned and washed.

- To clean and flush the pumping equipment, as well as the station body, brushes and ordinary water are used, while no detergents are used. When flushing the pump station using water supplied from a hose, it is important to ensure that the liquid does not get onto the control panel and pressure gauges.

- After dismantling the pumping equipment for inspection, cleaning and flushing, reinstallation should be carried out in such a way that all devices are securely attached to the automatic tube coupling.

- Maintenance of sewage pumping stations also includes checking catchers, which protect pumping devices from large debris entering their interior.

Currently, most industrial enterprises, as well as private residential sectors, are equipped with a sewerage station. This is necessary for the forced drainage of waste and industrial waters. For example, if the bathroom is located below the main one, then the option of removing wastewater by gravity disappears by itself. Let's take a closer look at what a sewage pumping station is and how this device works. In addition, we will consider the key points of equipment installation without the involvement of specialists.

General concepts and information

Currently, three types of SPS are sold, depending on the design: simple, medium and complex. If you want to organize wastewater disposal in a private house, then it hardly makes sense for you to purchase complex sewage pumping stations. Firstly, it is very, very expensive, and secondly, their performance significantly exceeds the amount of wastewater that will accumulate in you. In most cases, the simplest SPS is sufficient, but if we are talking about a large industrial enterprise, then it makes sense to give preference to more complex designs.

Household sewage pumping station: design

Depending on the manufacturer, the equipment of the pump station can be disabled. To put it clearly and briefly, such a pumping station is a sealed tank with a fecal pump. What the storage capacity is for is understandable. Waste products are collected there. The material can be different: concrete, plastic, metal. The task of the pump is to raise wastewater to a certain level, then the outflow is realized by gravity. Often the design includes several such pumps. One is a worker, and the second is a backup, which is needed to support the pump station in working order in case of failure of the main one. In addition, there is a piping system with valves to control the pumps. Pipes can lead to treatment systems or drain water into a central sewer. Another integral part of the design is float switches, almost the same as in toilet cisterns. They work simply - when the drains reach a certain level, the system turns on, water is pumped out.

The principle of operation of the SPS

Let's take a closer look at how the device functions. It should be noted right away that there is nothing complicated. When the wastewater level rises to a certain level, the float switch sends a signal to the receiving tank, into which the waste is pumped. It is worth noting that there are submersible pumps. When they are switched on, the wastewater is sent to the distribution chamber through the pressure pipe. By opening, the water goes either to the treatment plant or to the central sewerage system. To prevent backflow of wastewater into the distribution chamber, a check valve is installed in the latter. This is how SPS works. Sewage pumping stations are equipped with a ladder through which service is carried out. The hatches in the upper part of the unit are sealed, which prevents odors from entering the service area.

Types depending on power

Mini-stations are a very simple device that connects directly to the toilet. Low power pump (no more than 400 W), fecal-submersible, with cutting tools. In fact, this is a good summer cottage solution.

There are also medium SNAs. Sewer systems of this type are equipped with a polymer tank and a submersible pump. They are in the greatest demand due to their high versatility. They are suitable both for summer cottages and for use in an industrial enterprise, in contrast to small and large sewage pumping stations. If the device is intended for domestic use, then most often one pump with cutting elements is mounted. For industrial use, the pumps do not have cutting elements, there are 2 of them.

As for large sewage pumping stations, they are used in large industrial enterprises and in urban sewage systems. In this case, the pumps are multichannel, without cutting tools.

If you decide to choose a sewage pumping station, then be careful. There are several important details that you should always pay attention to. But first, clarify the following points:

- the depth of the system;

- pump performance;

- type of pump (with cutting tools, single-channel or multi-channel travel wheels);

- material from which the SPS body is made;

- case diameter.

You need to understand that today manufacturers make housings from polypropylene and reinforced fiberglass. There are also polyethylene, concrete and steel housings. But the last two are more expensive. Also, the metal will corrode.

In order for the "filling" of the station to serve as long as possible, all its elements must be stainless. If there is seismic activity, then the case must be heavy-duty. For the northern regions, additional insulation is required; it may also be necessary to increase the depth of occurrence. So the sewer will serve faithfully for a long time.

Why is a Grundfos sewage pumping station good?

This manufacturer is considered the market leader in the production of modern SPS. It is worth drawing your attention to the wide range of Danish products. Here you can find both mini-sewerage stations and the modification "wet well", etc. For example, the manufacturer gives a guarantee of about 50 years for the mini-station. This is despite the fact that the installation requires virtually no maintenance. In addition, you can buy a custom-made product.

Let's take a look at the technical characteristics of the Grandfos Integra. The installation itself is quite large, its height can be from 4.5 to 12 meters. The pneumatic cylinders ensure tightness, and the reservoir is made of fiberglass, so it is very durable. Of course, we can safely say that KNS, originally from Denmark, are considered one of the best. This is due not only to the build quality, but also to the use of advanced technology.

How to create a project?

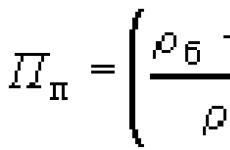

Before proceeding directly to the installation of equipment, you need to calculate everything. And the first thing is water consumption. To do this, you need to take the minimum and maximum costs, as a result, you will get the average. Next, you need to decide on the pump power. To do this, it is worth calculating the height of the effluent rise, taking into account the losses of the heating pipeline and air.

But it doesn't end there. It is also necessary to draw up a general schedule for the operation of the station, and the figure obtained as a result of the functional calculation should be slightly larger than the usual calculation. It is important to understand that there are different pumps. Some are designed to work for short periods of time under load, while others are vice versa. Do not forget about the occurrence of overloads, which the submersible pump must necessarily withstand. The more often they occur, the more powerful the unit is needed. At the final stage, we determine the volume of receiving tanks and we can proceed directly to the installation.

pumping station

Before installing the main equipment, you will need to supply a concrete slab to which the base is attached. Its minimum thickness should be 30 cm. Special anchors can be used for connection. Then you can proceed directly to the installation. To do this, the first step is to dig a pit of the appropriate depth and diameter. If groundwater appears, then you will need to make a foundation. Then you can put the station and fix it to the slab, and then fill the pump station with soil.

In most cases, the installation of a sewage pumping station takes place without any problems. As noted above, for the northern regions, where freezing of the soil is significant, additional insulation will be required. It could be styrofoam sheets or something like that. If we are talking about installing a mini-station, then there will be enough basic plumbing skills. The main thing is to ensure tight connections and correctly. At this point, the installation can be considered complete.

On the advantages of KNS

Of course, it is far from always advisable to install a sewage pumping station. If you have a normal central sewage system, then there is definitely no point in this purchase. However, most of the private sectors are in need of SNA. And this is an obvious fact. Let's look at the main advantages that a sewer station has. Firstly, this kind of construction saves living space very effectively, since the equipment is located outside. Another big plus is the complete automation of the process. After you complete the construction of a sewage pumping station, you can almost forget about this structure. Of course, the installation needs periodic maintenance. SPS is completely harmless to the environment, which is important, especially if the device is installed on an industrial site. Some models have purification filters so that waste water can be sent directly into the ground.

Some interesting points

If you buy a complete sewage pumping station, then its installation is easier to entrust to specialists. They will lead you through the pipeline and make the necessary tests. If you decide to do everything yourself, then be ready to do a good job. It is unlikely that you can do it in a day or even a week, especially if you have to dig the pit by hand. However, you can save a significant amount and gain valuable experience. By the way, as for the equipment prices, Sanicubic (France) with a capacity of 15 kW will cost you about $ 5,000. In this case, wastewater will be sent directly to the ground after treatment. But Homa Saniflux from Germany - the equipment is very expensive, about $ 18,000. Domestic manufacturers supply SPS at a slightly lower price.

Conclusion

So we examined with you typical sewage pumping stations. As you can see, this is a rather expensive technique. However, in some cases, this is the only available exit. Although we can say that many craftsmen themselves make something like a KNS, however, it costs an order of magnitude cheaper. It always makes sense to buy a sewer station in half with a neighbor. This option is extremely relevant for a summer residence or a large private sector. So you can save a significant part of your money, and installation will be easier with third-party support.

Sewage pumping station (SPS) is an irreplaceable assistant in pumping and disposal of waste water. It is rapidly gaining popularity and is gradually displacing drain pits from summer cottages and backyard plots.

Specifications

Structurally, the station is a mechanism consisting of several tanks and pumps, the number of which directly depends on the expected volume of effluents, the degree of their pollution and the type of pollution. The capacity of the station is made in the form of a polymer reservoir dug into the ground. Only the neck is left above the ground, which is due to the need for an audit, repair and, if necessary, measures to clean the tank. The container is closed from above with a lid made of steel or polymers. The most durable containers are considered to be made of fiberglass.

Plastic models have also proven themselves well. Such tanks do not require regular maintenance and can last for at least 50 years. The most budgetary option are concrete and metal containers, the volume of which can reach several cubic meters. There is a pipeline and a baffle inside the tank, which ensures a uniform flow of liquid inside. An equally important structural element is the baffle wall, which prevents flow eddies and contributes to the orderly movement of liquid masses.

Household pumping stations are equipped with one or two pumps, and more serious industrial models can have up to four units of pumping equipment. The type of pumping equipment depends on the place of installation, purpose and operating conditions. So, for home stations, it is more advisable to choose pumps equipped with a grinder. For industrial enterprises and housing and communal services, on the contrary, the installation of cutting devices is not recommended. This is due to the risk of solid waste entering the wastewater, which can cause damage to the devices.

To ensure the flow of liquid masses in one direction, valves and valves are installed in the branch pipes, and in order for the pumping equipment not to idle and turn off in a timely manner - floats. When the level of contaminated masses decreases, the float mechanism lowers, opens the electrical circuit and stops the pump. When the sewage level rises, the circuit closes and the pumps begin to work. This scheme reduces the operating loads on the pumps and extends their service life.

For safety reasons, backup floats are sometimes installed. They are adjusted so that they complete the circuit after the water exceeds a predetermined operating level. Thus, in the event of a breakdown of the main pump, the reserve one will definitely turn on and pump out the accumulated liquid. For a medium-sized station, two main and two backup floats are sufficient.

The installation of the sewage pumping station and the arrangement of sanitary control zones around them is regulated by the norms of SNiPa 2.04.01-85.

In addition to large stationary devices, there are miniature SPS of the "Sololift" type. They are made in the form of a small reservoir, equipped with a pump with a cutting blade, motor, automation and are directly connected to the toilet drain. The installation of this equipment solves the problem of drainage of sewage masses in a private house with a minimum number of residents, and is quite suitable for a family of three. For the operation of the mini-station, it is enough to connect the pressure hose and sewer pipes to the device body and plug it into the socket. Sololifts have a sufficient number of positive reviews and are rapidly gaining popularity among owners of small houses and summer cottages. Mini-stations go on sale completely ready for operation and do not need to purchase auxiliary devices.

Purpose and principle of operation

Sewer stations are intended for pumping rainwater and sewage masses in cases where their movement by gravity is impossible or difficult. This occurs when it is not possible to organize the slope of the drainage pipe, when the place of discharge of sewage and bathrooms is located below the level of receiving collectors or cesspools, as well as when they are located far from the drain source. The stations are widespread in cottage settlements, country estates and industrial facilities, the significant distance of which does not allow them to connect to central sewer networks.

The principle of operation for all SPS is approximately the same. Contaminated wastewater flows into a receiving tank, from which it is pumped into the pressure pipeline system using pumping equipment. Further, the masses end up inside the distribution chamber, from where they go through the pipeline system to the treatment plant or sewer collector. All stations are equipped with a valve that prevents the fluid from flowing back and ensures that it moves in only one direction.

The stations are equipped with an automatic control system. So, monitoring of the level of effluents is carried out by float sensors, which are located at different levels. In the event of a serious accident and failure of both pumps, sensors set to a critical level for the system automatically turn on an alarm, notifying the owners that the system cannot cope with the volume of the sewer mass or is out of order. During repair work or start-up, the station switches to manual control mode.

Stationary mini-stations with a shredder work on a similar principle. At the moment the liquid enters the device, automatic sensors are triggered, which, in turn, start the engine. As a result, the liquid from the tank is pumped into the pressure pipe, through which it goes to the collector. For more efficient removal of sewage, compact stations are equipped with a special impeller, which is engaged in crushing large fragments, which prevents the likelihood of pipe clogging. Usually in the body of the sololift there are from 2 to 5 holes intended for connecting plumbing fixtures: toilets, sinks, sinks and shower cabins. There is an air valve on the upper part of the station, which provides air supply during the operation of the pump, and excludes the breakdown of the hydraulic locks in the siphon of the device.

Types and categories

Sewer stations are classified according to several criteria.

type of instalation

SPS can have vertical and horizontal design. The latter are often equipped with a self-priming pump, which forcibly pumps the contaminated masses into the pump station housing and removes them after cleaning. Sometimes the tank-reservoir can have an additional horizontal compartment on the bottom. This design contributes to an even distribution of sludge deposits on the bottom of the tank and increases the time it takes to fill it.

This, in turn, allows cleaning the tank less often, which significantly saves effort and money.

Vertical sewage pumping stations do not have additional reservoirs and are used for private houses and summer cottages, where their capacity is quite sufficient for timely and uninterrupted discharge of sewage.

Location

By location relative to the surface of the earth, the pump station can be buried, partially buried and have a surface location. Ground stations are represented by mini-installations located in kitchens, bathrooms and toilets. In-depth ones are traditional models with a storage tank dug into the ground, and in partially buried ones, a tank equipped with sensors, a pump and shut-off valves is located in the ground up to the neck. At the same time, the automatic monitoring and control system is brought to the surface.

Equipment management

SPS are equipped with manual, remote and automatic control.

- With the manual method switching on of modular equipment is carried out in manual mode by station workers, who independently check the level of sewage in the tank.

- With remote control data on the state of the system and the height of the liquid level are sent to the control panel. It is very convenient to exercise control over a radio-controlled station: the equipment does not require the constant presence of a person, and in case of a malfunction, it promptly reports it.

- Automatic system control is the most common, and consists in controlling the station using relays and sensors, which can be located both on the station body and next to it on the dashboard.

The most budgetary option are stations with a manual control system. They are installed in country houses and are capable of serving one or two families.

The nature of sewage

Waste water is subdivided into domestic, industrial, storm and sedimentary water.

- For industrial waste tanks and pumps must be made of materials with increased resistance to aggressive chemical substances and high temperatures.

- Storm water drainage stations the sewers are equipped with additional systems for cleaning sand and mechanical debris that rain flows can bring.

- Sewage pumping station for sediment waste It is used in wastewater treatment plants and is equipped with specialized devices for processing sedimentary deposits.

Pumping equipment type

Three types of pumps are installed at the pump station.

- Submersible pumps with a pressure function require complete immersion in water. The devices have a sealed housing, which is made of high-strength, non-corrosive materials. Fecal pumps are efficient and easy to use; they do not need to be additionally fixed or equipped with a platform for them. The device is capable of operating at low temperatures, and its engine is cooled naturally from the surrounding liquid.

- Cantilever pumps are installed in a dry place and are used in large industrial stations. The devices are not suitable for complex modular SPS. Pumps require the construction of a separate site with a foundation, are distinguished by their high cost and reliability. The advantages include ease of access for repair and maintenance, the ability to replace the electric motor with a weaker / more powerful one, and a long service life of the device.

- Self-priming pump for sewage, it is used for pumping highly contaminated liquid and is installed at industrial facilities and housing and communal services. The device is not subject to clogging and is effective in subzero temperatures. Freezing of the device is excluded thanks to a special heating element, which turns on at the moment when the temperature drops and passes the critical mark. This type of pump is recognized as the most reliable and convenient to use. The only drawback of the device is its high cost, which, however, is justified by the high performance and durability of the device.

Installation

Installation of the pump station begins with digging a pit. If you have the necessary tools and at least one assistant, you can dig a hole for the tank with your own hands. The depth is calculated individually and depends on the type of installation and the size of the tank. The optimal position of the tank is considered, in which the tank lid protrudes from the ground by 80-100 cm.

A sand cushion is formed at the bottom of the pit and a reservoir is installed on top. After the tank is installed and leveled, proceed to the connection of the branch pipes and backfilling of the pit. It is necessary to compact the earth around the tank very carefully, tamping each layer in turn. The density of the backfill should be 90% of the natural density of the surrounding soil.

After the tank is firmly in place, begin installing the pumps and adjusting the floats. As an example, floats of the first level are usually located at a distance of 15-30 cm from the bottom of the tank. However, this is the recommended height and can be changed based on the expected amount of drains and the size of the tank. The next float is installed one and a half meter higher than the previous one, after which the installation of the electrical cable begins, grounding is carried out, ventilation is arranged and power is connected.

After all the work has been completed, a test run of the system is carried out using clean tap water. In case of a successful test, you can proceed to the construction of a protective pavilion, and if there is no need for construction, immediately to the commissioning of the station. The pavilion can be built of metal or brick.

Maintenance and operation

Stations need constant monitoring of the state of the main systems. However, when self-servicing the pump station, you should strictly observe safety requirements and clearly understand that it is strictly forbidden to go down into the tank and clean it without personal protective equipment. Poisoning from sewer fumes occurs instantly, and often results in loss of consciousness and death.

Therefore, before proceeding with the inspection of the tank, you should put on a gas mask with a forced supply of clean air and a safety rope. But the best option is to sign an agreement with special services, which will exercise control over the operation of the system.

Scheduled maintenance of the station is carried out on a quarterly basis, and in the case of a large amount of waste water - monthly. During the inspection, the operation of the automation is checked, the pumping equipment is diagnosed and the oil level is monitored, debris is removed from the filters and silt deposits are removed. All work must be carried out in the presence of an assistant, with a rope belay and a respirator.

Maintenance of remote systems is a little easier. Automation of control allows you to monitor the state of the tank without going down into the tank, and in real time monitor the performance of electrical equipment.

Maintenance of the pump station should begin with a general inspection of the state of the valves and checking the indicators of the sensors located on the control panel of automated models. In case of unstable operation of the pumping equipment, the device is removed from the station, washed and subjected to diagnostics. Cleaning of the pump and housing is carried out under the pressure of clean water from a hose using a stiff brush. The use of detergents is undesirable.

When flushing, it is necessary to control the direction and force of the pressure, and prevent drops from falling on the control panel. From time to time, you should check the reliability of the threaded fasteners and, if necessary, tighten the nuts and fasteners. Dismantle the pumping equipment only after the unit has cooled down, while disconnecting the power supply and relieving the pressure in the system.

With careful operation and regular preventive maintenance, sewage pumping stations can serve for more than a dozen years, ensuring uninterrupted drainage of contaminated wastewater and increasing the comfort of others.

An overview of Unipump Sanivort sewage pumping stations, see below.

Thanks to the penetration of modern technologies into various areas, today it is possible to solve many problems with lower costs. And the implementation of some tasks has become easier. The device of a sewage pumping station is the ability to ensure the transportation of wastewater from a private home or office. Thanks to this equipment, a solution to the main problem is provided - the absence of a slope for effective wastewater disposal.

It is not always possible to ensure the transportation of used water and sewage from buildings by gravity due to the absence of a slope. If it is absent or very small, then the use of a natural drain when draining sewage can lead to clogging of the system. The same result can be expected when the system contains small cross-section pipes... Sewerage clogging occurs when inclusions such as:

- sand;

- gravel.

Their presence leads to the fact that the efficiency of flushing fat and other deposits from the pipe walls decreases. Therefore, to ensure effective wastewater disposal, the best solution is to install a sewage pumping station. Its use in private homes and offices for drainage has several advantages:

- ease of maintenance;

- the equipment can operate in automatic mode.

SPS selection

If the owner decided to install a sewage pumping station for efficient wastewater disposal, then when choosing it, it is necessary focus on the following parameters:

- the degree of pollution of wastewater;

- fraction and structure of inclusions.

Classification

Modern SPS are of two types:

- station with a capacity;

- high performance stations equipped with a level sensor.

If we talk about SPS of compact dimensions, equipped with a level sensor, then, in fact, they are small-sized devices that emit a minimum noise level during operation. They can be installed directly behind the toilet or washing machine. Depending on the required power, the sewage station can have several receiver pipes and one outlet valve.

Currently, SPS models are popular with large toilet entrance and several washbasins. Their installation can be carried out in any premises where there are difficulties with the transportation of wastewater. For example, if drainage points are located below the level of the sewer main, then in such cases the only possible and correct solution is to install a sewage pumping station. The use of such equipment provides an opportunity to equip a bathroom and a kitchen with minimal costs.

SPS elements

The pumping station includes three components:

In modern KNS models, the main details made of polymeric materials... This makes it possible to exclude the occurrence of corrosion processes on their surface. With the device of such a system, its installation is carried out in the ground at a certain depth or in a mine equipped in a special way.

Depending on the requirements of the owner, as well as the features of the facility, there may be two pumping units in the equipment of the sewage pumping station. This option is chosen when the pumping station is installed in a private house. If it is located in an office or industrial plant, then it can include up to 5 pumps.

For domestic purposes, several different types of pumps and various mechanisms are most often used. Experts recommend using pumps to create a sewage station, having a cutting edge, thanks to which the clogging of the system with large pollutants stops. The use of such solutions in industrial enterprises can lead to the fact that the pumping station will fail if solid inclusions from plastic and concrete enter it.

Installation of KNS

When performing work on the installation of such pumping stations, they are guided by requirements of SNiP 2.04.01-85... This document contains:

Features of the installation of the pump station

The sewage pumping station should be located at the general level. In this case, the most efficient waste collection will be ensured. When the amount of wastewater has accumulated in the capacity of the station in sufficient quantity and the sensor has triggered, wastewater is released to the place of disposal. The peculiarity of this process involves the installation of a sewer check valve. It is necessary to prevent the return of the water column to the receiver.

Alarm systems high performance sewerage pumping stations can be equipped. It will work in cases when the pumping equipment used in the systems cannot cope with the incoming volume of wastewater. Also, the alarm will be triggered in the event that there is a breakdown of the installations. Some stations may include temperature level sensors, and in addition, meters of the pumped volume of wastewater.

To ensure uninterrupted operation of the sewerage system, pumping stations can be equipped with a backup power source. For the reason that the power of the pumping station is quite high, and the starting currents for pumping equipment are required high enough, it is necessary to install a powerful battery. Therefore, when choosing a power source at the pump station, gasoline generators or diesel-powered units are used. In this case, even in the event of an emergency power outage, the station will function as usual.

SPS service

As part of a high performance pump station there is a filtration system, which is represented by a pre-cleaning tank. It accumulates heavy fractions, as well as large objects. They are there before entering the pumping chamber. Such designs usually provide a trapdoor through which people, using a shovel, provide effective cleaning of the receiver. Due to the fact that not only household waste, but also sewage can enter the pumping station, for efficient operation of the equipment, it is necessary to clean the receiver once a month.

Alternative solutions

Although sewage stations in private homes and offices have been used not so long ago, nevertheless, there is already a large selection of alternative options on the market that are effective and at the same time affordable. One of them - submersible drainage fecal pumps... The main purpose of this equipment is to pump out water from the basement from the basement floor. Also, these pumps can be used to pump out wastewater from cesspools.

If you have purchased such equipment, then with a little modification, you can make a sewer station on your own. To do this, you only need to purchase a container made of polymer material and some plumbing equipment:

- valves;

- fitting;

- sewer pipes.

Models of sewage stations based on fecal drainage pumps are currently available on the market. They are offered in a large assortment. Among the offered models you can find installations, equipped with cast iron knives... Some models have stainless and steel cutting edges. The performance of these systems is very different, so you can choose the right option for your home or office.

Conclusion

Not in all cases, when creating a sewer system, it is possible to arrange a well or bury a container to drain wastewater into the ground. In such cases, the solution to the problem is to install the SPS. With their help, even from a building that has a sewerage system with a slight slope of pipes, it is possible to ensure an effective drainage of used water and wastewater. The market offers large selection of models pumping stations. They vary in cost, performance and size. Therefore, every owner of a private home or office can choose the right equipment.

Often, owners solve the problem of draining wastewater from a building by installing a tank in the basement for temporary storage of wastewater. Here, the best option would be to use a sewer console type stations... In such cases, the container is installed in cabinet furniture in the basement room. A dry installation method is used, which excludes damage to the walls or floor during work. After that, you can connect plumbing fixtures, a washing machine and use them without experiencing any problems with the disposal of used water and wastewater. All effluent will be efficiently discharged from the building and then pumped to the recycling site.

The abbreviation KNS, which is poorly understood for most ordinary people, sounds like a sewage pumping station. Let's take a step-by-step look at what a SPS is, on what principle such stations work and how, in general terms, the unit can be calculated. And with homemade ones, I will show and tell you 3 options for installing the station with my own hands in the photo.

Semi-professional station KNS is an excellent solution for a private house.

What are stations for?

In general terms, sewage pumping stations serve to collect and redirect wastewater to the place of their additional treatment and disposal, for example, to a septic tank of a private house or a common sewer main.

Who might be interested in the station

In fact, the range of application of automatic sewage stations is quite wide, I will voice only the most common options for a predominantly domestic direction.

- If in your multi-storey building there is an ancient, long-obsolete sewage system, which is constantly clogged with any little things, then installing a small station in a plastic case can save the day, because it will turn all the garbage into a homogeneous mass and push it further into the system;

- The story is the same if the house is located in a lowland, and the sewage pit is quite far away. Here, a similar unit is useful in that it can forcibly push the drains over a certain distance;

- The arrangement of small cafes and various offices in the basements and basements of multi-storey buildings has long become the norm, but almost half of such places are located below the level of the city sewage system. Accordingly, a device is needed that will raise the drains to the desired height and send it to the sewer - this is the SPS.

Remember - any SPS station is a volatile complex, since an electric pump is installed there. Many people confuse stations with septic tanks, but this is far from the same thing, although in some models of septic tanks the sewage pumping station is part of the system.

Standard operating principle

A typical project works like this:

- There is a sealed container, the size of this container can be from several liters to several cubic meters. Wastewater flows into this closed tank by gravity;

- When the drains fill the container to a certain level, the filling sensor is triggered and the fecal pump comes into operation. Almost all sewage pumps for sewage pumping stations are equipped with grinders;

- Then the pump pushes the crushed waste into the pipeline. But how high and far the drains can be pushed depends on the power of the pump.

Varieties of aggregates

- In the domestic sector, small stations are in the lead, which easily fit behind a toilet in a regular toilet. The body there is predominantly plastic, and a simple grinder, a filling sensor and the pump itself are installed inside. These devices can push liquid up to 5 - 7 m, which is quite enough for an apartment or office;

The household station can even fit in an apartment toilet.

- In private homes, semi-professional stations are often used. There, a typical project is completed with at least two pumps and a mass of sensors. The price for them is several times higher than for household models, but the capacity there also corresponds to the cost, plus the volume of the receiving tank starts from a cubic meter;

A typical sewage pumping station for private houses may include a wastewater treatment function.

- The so-called modular sewage pumping stations already belong to professional units, they are assembled from separate modules and can be expanded indefinitely, but they are not of interest to us, since they are not used in everyday life and even in large private houses.

The power and dimensions of modular stations do not provide for domestic use.

Modern semi-professional sewage pumping stations for private houses can not only clean and pump household waste, they can even handle storm sewers and drainage systems.

On a semi-professional sewage pumping station in a private house, you can tie a storm drain, drainage and household drains.

Simplest station calculation

Calculation of a SPS station, especially a semi-professional one, is troublesome and here you cannot do without serious knowledge, but there is a simpler instruction, it is, of course, not so accurate, but it is quite suitable for a small private house:

- According to the standards, 1 person uses about two hundred liters of water per day. Count the number of people in your house and add a couple more people to the supply;

- Each unit has technical characteristics, having water consumption data on hand, you can easily select the desired model;

- As for lifting the water to the top, 1 meter of vertical flow is equal to 2 meters of horizontal advance. In other words, if the passport says that the unit can lift liquid to a height of 8 m, then this means that horizontally it will be able to transport liquid by 16 m.

But these are all primitive calculations, suitable only for domestic sewage in a small house, if it is planned to install a sewage pumping station with the connection of a storm sewer and a drainage system, then you cannot do without the help of professionals.

It is better to pay once to a specialist than to understand after purchase and installation that you made a mistake. Moreover, now the calculation with reference to the place will cost 2 - 3 thousand rubles.

3 options for self-installation of the station

Installation of a pump station in the domestic sector is not as difficult as it might seem. Next, we will look at how to install a small plastic station indoors, as well as mount a factory and homemade station for a private house.

Option No. 1. Installation of the station indoors

| Illustrations | Recommendations |

|

Grundfos Sololift 2 parameters.

I took the most popular mini station Grundfos Sololift 2. · The volume of the pumped-over liquid - 8.94 m³ per 1 hour; · Level of liquid ejection vertically - 8.5 m; · Electric power of the pump 620 W; · SPS is equipped with a grinder; · Costs about 18 thousand rubles. |

| .

· Screwdriver; · Perforator; · Hacksaw for metal; · Roulette; · Pencil; · Level. |

|

| ... The floor under the station should be perfectly flat, and most importantly, strictly horizontal. | |

| .

Since the device is behind the toilet, the toilet is connected directly through a separate entrance. And to connect, for example, a sink, you need a separate pipe. And this sewer pipe is exposed with a slope of 3 cm per 1 running meter. |

|

| External drain connection.

Stage 1. Unscrew the side cap. |

|

|

... In the plug, you need to cut a hole for the drain with a knife. |

| ... There is a check valve inside, you need to check its serviceability with your finger. | |

| ... Then we put a soft corrugation on the plug and fix it with a clamp. Likewise, a drain pipe is fixed on the reverse side of the corrugation. | |

| We put the outlet pressure pipe.

Stage 1. The main rule is that the pipeline does not have sharp corners during installation. |

|

|

... The outlet for the pressure pipe in this model can be led out in 2 directions. The photo on the left shows the side outlet. |

|

... If desired, the outlet pipe can be connected from above. |

| ... You need to select one output, and close the unnecessary one with a stub. | |

| ... Then we cut out the inlet hole in the cover. | |

| ... We close the cap and connect the soft adapter through the clamp. | |

| ... The outlet pipe is connected through a tee and in this tee from the bottom there is an emergency drain plug, so it must be tightly closed. | |

| ... We fasten the body of the device to the floor. | |

| ... The toilet is connected in the same way as the side drain, that is, through the corrugation, using a clamp. | |

| ... Now it remains to fix the toilet and connect the unit to the network. By the way, the KNS is connected via an automatic machine. |

Option number 2. How to mount a factory station for a private house

The plant's sewage pumping station is a multifunctional unit, this station provides not only pumping and crushing of effluents, but also the purification of these effluents.

| Illustrations | Recommendations |

|

.

There are quite a lot of such units now, among our models the Astra KNS and the Topas station stand out. Although, in general, both domestic and imported models have similar characteristics. The cost of the station for a house of 6 residents starts at 80 thousand rubles. |

| .

First, a place is determined and a hole is made in the plinth or foundation for a drain pipe with a diameter of 100 mm. We mount the line at an inclination of 3 cm per meter. It is better to take an orange pipe for outdoor work. It is supposed to bury below the freezing of the soil, but it is deep, so it is easier to dig in 50 cm and insulate the line separately. |

|

| ... Naturally, the pit needs to be prepared a little more than the dimensions of the unit itself, about 20 centimeters on each side. In order not to be mistaken, it is better to knock down the template in advance. | |

| ... The walls of the pit need to be strengthened with something, in this case a wooden box and a tamped sand cushion on the floor are enough, since later the station will be insulated and filled up. | |

| ... If the walls are plastic, which happens quite often, then the empty unit weighs up to 100 kg, respectively, 3-4 adult men will easily lower it into the pit. | |

| .

In most stations, a specific tapping point is not indicated, there is simply an area where a drain pipe can be cut. It was not in vain that we first laid the line, and then installed the SPS, it’s easier to get to the desired area. A hole in the wall of the station is cut with an ordinary jigsaw, after which an adapter is inserted there. |

|

| ... There is nothing complicated here, just the pipe is inserted into the socket of the adapter and the joint is sealed with silicone. | |

| ... It is better to solder the joint between the plastic housing of the KNS and the plastic adapter with polypropylene solder using a building hair dryer (500 ° C). | |

| ... The pressure outlet is mounted in the same way, but here a pipe with a diameter of 50 mm is sufficient. | |

| ... The station, as well as the input and output lines, are insulated with foam. For the box, 100 mm thick sheets are enough, the pipes are insulated using semicircular foam cocoons. | |

|

.

Each station model has its own connection features, but the passport must contain detailed instructions. As for laying the cable from the house to the unit, it is advisable to put it in a plastic pipe or at least in a corrugation. The video below in this article shows everything clearly. |

Option number 3. How to make a homemade station

| Illustrations | Recommendations |

| .

There are several options - you can assemble the formwork and fill in a solid reinforced concrete cocoon, but this is difficult and time-consuming. You can take a large diameter steel pipe, weld the bottom and waterproof the container, but this container will be heavy and not cheap. |

|

|

.

It's simple: · We put a submersible pump with a built-in grinder on the bottom of the tank; · From the pump we remove the pipe into the sewer line, septic tank or drain pit; · And we cut the drain from the house into the same container. |

| Procedure.

Stage 1. First, we dig a pit. |

|

| ... We bring the drain from the house and seal the gap. | |

| ... The pressure pipe is cut with an adapter. | |

| .

We hang the submersible pump with a chopper on a rope so that it can be pulled out for maintenance. To connect the pump, we cut a moisture-proof outlet into the board, and for the pump to work, we automatically install a float switch. |

|

| ... Then we act in the same way as in the case of the factory sewage pumping station, that is, we insulate with foam and fill the remaining place with sand. |

Output

The main unit of any sewage station is a fecal pump with a grinder.