How to lay linoleum correctly: the most detailed laying guide. How to lay linoleum correctly - simple and straightforward instructions What to lay linoleum on in an apartment

If you decide to lay linoleum on your own, then it is not difficult to do this without resorting to the help of repairmen. You just need to know what and how should be done. And also what tools you need.

Preparation for laying linoleum.

First of all, you need to free the room from all furniture. An empty room will greatly facilitate your work.

Then we evaluate the available coverage. If you have old linoleum, then take your time to clean it up. It is quite possible to put new linoleum on the old one - the floor will be warmer and softer. However, this is provided that the surface of the old linoleum, or rather the base on which it lies, is flat. Otherwise, you will have to level the basis, but that's another story.

Next, we measure the area of the room. It is better to draw a plan of the room on paper, where you indicate the length and width of the room, door openings, heating pipes, etc. This plan comes in handy when purchasing linoleum. In general, the plan and purchase of linoleum can be done even before emptying the room from furniture, but much more convenient after.

Linoleum it is better to buy in a specialty store where there are normal sellers who will help with the choice, advise which pieces to take. Some stores can help you cut the linoleum to your size.

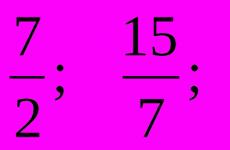

When buying, you need to consider the width of the linoleum. The most common rolls are 2.5 meters, 3.5 meters, and 4 meters wide. If the store has the same linoleum of different widths, choose the width that will allow you to do without any internal seams, i.e. you can just put the linoleum on the floor in one piece.

We lay linoleum.

To do this, roll out the linoleum in the room and cut off the extra centimeters. If you have to lay down several pieces, we lay out these pieces as they will lie.

Linoleum should lie down for several days in order for it to straighten up. It is possible that after keeping it, it will have to be cut a little more in one place or another, because linoleum may increase slightly in size.

It is necessary to leave a small gap between the linoleum and the wall - about a centimeter (it will be closed with a plinth). Then, after the final curing and after the skirting boards are attached, the linoleum will not go in waves.

After the linoleum has rested, you can continue on. The question always arises here: to glue or not glue linoleum to the base.

What can you advise. It is better to glue, of course, but you can not glue the linoleum if the area of the room is small (up to 20 m2) and you have linoleum in one piece. In this case, the linoleum will perfectly squeeze the baseboards. Can be partially glued in passages, for example, at the threshold.

If the area of the room is large or you have several pieces of linoleum, then you will have to glue it. There are many adhesives for linoleum, ask in the store; they do not have much difference.

At gluing linoleum we roll it into a roll in a narrow place. Then we spread the glue with a linoleum comb and slowly, pressing well, glue the roll. It is not necessary to immediately spread a lot of glue so that it does not have time to dry. If the room is large, then it is better to do it together. When the entire area is glued, we glue the piece where the roll was rolled. The seams between the pieces can be repaired with the so-called. cold welding.

After gluing the linoleum, we install the baseboards and return the furniture to the room. Be careful here, it is easy to damage the newly laid linoleum when moving furniture.

Linoleum is a practical and attractive floor covering that can be found in houses, apartments, summer cottages, offices, shopping centers, public institutions ... Almost everywhere. How to lay linoleum, how to do it right - read on.

On what basis

Even when choosing a floor covering, the question arises of what to lay linoleum on. Is it necessary to prepare the base and, if so, how seriously. The answer is simple: linoleum can be laid on any base. The main thing is that it is even, durable and clean. Preparation takes place and can be easy and quick if the ground is level. In this case, the floor is simply cleaned and dried. If the floor is potholed or uneven, preparation takes longer. For correction, a screed or self-leveling mixtures can be used, a dry screed with sheet building material (plywood, OSB, MDF boards) is also used. It all depends on the type of base.

Concrete and wood floor

You can easily lay linoleum on a concrete floor. In general, there may be drops on the surface, the main thing is that they are not local - small and deep pits and bumps are excluded. The swings can be, but smooth. If there are significant irregularities, before laying the linoleum, it is better to fill in the leveling screed.

This topcoat is also laid on a flat wooden floor. Many people think that under it the wood will rot. If the wood is dry, without signs of infection by fungi and mold, then nothing will happen to it. With proper installation, an airtight layer is obtained, so that moisture does not penetrate inside. If there are seams, they are welded, so moisture is unlikely to penetrate them. To prevent water from getting under, choose wide models and press them well to the floor. A more reliable way is to lay a self-adhesive tape for sealing under the linoleum around the perimeter.

If the boardwalk itself is made correctly, with normal ventilation, then it has nothing to rot. If you are very worried, treat the floor with antiseptics before laying the linoleum.

If there are noticeable gaps in the plank floor, they will be visible on the covering over time. If they are small, they can be putty, using sanding to level the surface. Occasionally the floorboards will bend, rising slightly at the edges. It will not work to grind such a floor - there are a lot of nails. In this case, or if the gaps are too large, it is recommended to put sheet material on top of the boards - plywood, OSB, MDF. They are good because they do not have a very large thermal expansion, and OSB does not yet absorb moisture (you can take moisture-resistant plywood), and this is important in humid rooms (in a kitchen, for example).

And fiberboard as a base for linoleum is not a very good option - when the humidity rises, they swell, fiberboard goes in waves. After drying, the original shape is not restored, so that the linoleum laid on top also hunches and wrinkles.

Before laying linoleum, you need to lay or. This is necessary if the plank floor "plays", the boards sag. If you lay the flooring immediately on the boards, it will crack in places of deflection, and quite soon. And this means replacing the floor covering, and problems with the boards are also possible - moisture can seep into the cracks.

This is what it means "with a break in the seams"

When laying any sheet material for leveling the floor under linoleum, it is laid with a gap between the seams - so that they do not coincide (like brickwork). Small seams are left between the sheets, which are then filled with elastic (non-hardening) mastic.

Is it possible to put new linoleum on the old floor

We must say right away that it is advisable to remove the old coating before laying the linoleum. But this can be problematic and then flooring on top of the existing one is allowed. It is true only if the old floor is flat or irregularities can be repaired. New linoleum is placed on the old one, on the tiles, on the parquet. If there are defects in the base - chips, dents, protrusions - they are eliminated, sealed with putty, chipped, the seams between the tiles are rubbed so that the surface is even.

Lay linoleum on parquet, tiles or other linoleum. But only on one condition - the base must be even.

With old linoleum, as with a substrate, there are usually no problems. If there are bumps, they are pierced, filled with glue, the cracks are coated with a repair compound - cold welding for type "C" linoleum or sealant. When laying new linoleum on the old one, there may be another problem - it will turn out too soft and significant indentations may form under the furniture legs.

On the parquet, as well as on the plank floor, it is advisable to lay a substrate made of sheet material - the planks can also "walk", tearing the covering.

To glue or not

Before laying linoleum, you need to decide whether you will glue it or not. There is an opinion that it is not necessary to glue it in houses and apartments. It is pressed against skirting boards, furniture, large-sized appliances, etc. All this "keeps" him in place. Sometimes it works, sometimes it doesn't. Usually works on hard semi-commercial and commercial types of coatings, and does not work on softer - household ones.

It's about thermal expansion. In summer, when it's hot, linoleum expands "crawling" out from under furniture and appliances. In the fall, it shrinks to its previous size, but does not return under the furniture. Waves and bumps are formed. Therefore, the majority agree that it is necessary to fix it.

If not glued, maybe this is the view

Just keep in mind that linoleum either does not need to be glued at all, or glued completely. Glue in some places - almost guaranteed to get humps and bulges after a while.

How to glue

Before laying linoleum, you need to figure out how to glue it. If the room is small, household linoleum is laid in one piece on a smooth base (sheet material, old linoleum, etc.), you can fix it on double-sided tape. It is fixed securely, but due to thermal expansion, humps can form between the adhesive tape. Therefore, if you glue linoleum, then with glue.

There are two types of adhesives:

The first option is more familiar to us, but when changing the coating, we have to suffer for a long time, tearing off the coating and the remnants of glue from the base. The fixation holds it “in shift” no less reliably, but allows it to be easily rebuilt several times (from 5 to 8, depending on the composition).

Fixation

Fixings are used for laying household and semi-commercial linoleum. If we talk about the price per liter, then fixation is much more expensive. But her consumption is much less (100-180 g / square), so gluing one square meter will be cheaper. From all points of view, this is the best option. Here are a few normal clamps to work with:

There are other manufacturers, new products appear every day. But, before buying, please read the instructions carefully. See to it that can be used on your substrate, with your type of coverage.

Linoleum adhesive

It is definitely not worth using glue with a solvent (neoprene). Technologies have changed so that such glue gives a color change (red spots appear). This glue can only crate marmoleum (material based on natural ingredients).

If you decide to use glue, here are the brands that give good results:

If you need to save money, household linoleum "with nap", on a jute or foam base, can be glued on PVA or Bustilat M. If it is placed on concrete, screed or other similar coating, first the glue is diluted with water (1 to 1), this composition is primed (you can do it twice). After that PVA or Bustilat is applied and the coating is rolled "wet".

How to glue the joints of linoleum

There is a special glue to connect the joints of linoleum. It is called "cold welding for linoleum". These are small tubes with a sharp nose, with which the composition is filled directly into the joint. It does not so much glue as it dissolves the adjacent areas of the coating, creating a sealed seam.

There are two types of cold welding for linoleum:

When laying linoleum, naturally, type A is used. Pay attention to the instructions for use. They are of different types and require different drying times.

If you have not previously worked with cold welding for linoleum joints, practice first on scraps. When you have worked out the technology, and you understand what and how to do, you can start gluing the joints in the room.

Another point: the glue for connecting the joints of linoleum until it polymerizes and releases harmful substances. Therefore, windows and doors are opened in the room, providing ventilation. It is better to work with gloves, and a respirator will not hurt.

How to lay linoleum with your own hands

In order for self-laid linoleum to please the eye, not to swell and frown, it is necessary to fulfill several mandatory points. The first is related to the preparation of the foundation. That it should be; but to be even, you already know. In addition, it must be dry and clean. No dust, no grease or other stains. We collect everything with a vacuum cleaner, remove the stains with a suitable means, dry everything thoroughly. We do all this carefully: dust impairs adhesion to the base, debris particles will eventually show through the coating.

The second prerequisite: before laying the linoleum, it must "mature" for some time in a straightened state. Preferably at the place of installation. It is rolled out, left for at least 2 days, but better - for 5-7 days. So he straightens, takes on "working" dimensions. After that, you can start cutting.

How to trim

Let's start with how to cut linoleum. There are two options - knife and scissors. Both, you can work normally, only they must be sharp.

It is more convenient for someone to use a clerical knife, but a boot or sharpened kitchen knife is also suitable, although there are special ones. They have a retractable blade, like office knives, but their handle is curved and the blade almost does not bend.

On a clerical knife, the projections that hold the blade in place must be iron. In this case, the blade is more elastic and there is less chance of the cut going to the side. This is precisely because the blade can "lead" some craftsmen prefer powerful scissors. To make it easier to cut, they make an incision, and then, without making cutting movements, they simply rip the coating along the intended line.

Now about where to trim. Roll out the linoleum so that it goes a little on the walls. If there are several canvases, an overlap of at least 5 cm is made at the junction. If there is a pattern, lay out the canvases so as to achieve a match. Then the junction will not be noticeable.

Linoleum is cut in the corner, the joint remains with an overlap and is cut off after gluing the main part. The canvas is pressed to the floor, cut with a knife or scissors. Please note that if the work is done in a cool room, the high temperature cover will increase in size during the summer. If you cut the canvas close to the wall, a roller forms near the baseboards in summer. Then, at lower temperatures, it can stretch, but in summer it spoils the view. Therefore, when cutting off, retreat from the wall about 1 cm.

Glue to the base

If you decide to lay linoleum without gluing, it is usually fixed along the baseboards with double-sided tape. The same material is glued in the area of the doors. In this case, we turn off the edges, glue adhesive tape on the base. We return the edges to their place, carefully level the coating. After making sure that it lies flat, without distortions and waves, remove the protective tape from the tape and glue the cover.

If you work with glue, you do it a little differently. We twist the cover to half the length. The composition is applied to the floor (strictly according to the instructions). If there is a joint, a strip about 35 cm wide without glue is left on both sides of it. After waiting for the prescribed time, the linoleum is rolled out again, pressed well.

The technology requires a pressure roller - a heavy cylinder (about 50 kg in weight), movably fixed on the handle, which squeezes out the air and presses the coating to the base, ensuring good adhesion. If there is no roller, take a plastic float, which is used at and press everything well with it. You can use a board wrapped in felt or felt, or something similar.

Then the other side is glued. If the canvas was laid in one piece, we can assume that the laying of linoleum is over. It remains to fix the plinth. If there are joints, we continue.

Seam processing

If there are two or more canvases, the seams will need to be processed. There is a simple way - take a T-shaped metal bar and fix it at the junction (attached to screws or dowels, depending on the type of base). The method is not very aesthetic, but reliable. This is exactly what they do if two pieces of linoleum with different colors are joined under the door.

A more aesthetic way is to use cold weld linoleum adhesive. First you need to cut off the excess material at the junction. We take a metal ruler (a level or rule is suitable), apply it at the junction, cut both canvases with a knife along it, remove the extra strips. It is very important to cut through both canvases at once. In this case, if the drawing was chosen correctly, the connection is imperceptible, since the two canvases match perfectly. If the base under the linoleum is hard, you can put something soft under the joint - a piece of felt, linoleum, etc. Then it will be easier to cut both canvases at one time.

We turn off the non-glued parts of the coating along the seam, apply glue, wait, if necessary, for the time according to the instructions, glue the coating in place, roll it with a roller. We wait for the time required for the glue to dry (according to the instructions).

Next, we take cold welding for the joints of linoleum and a wide masking tape. With this tape we glue the joint, then, with a clerical knife, cut it along the joint. This is necessary to protect the coating from accidental ingestion of the composition. It is reactive and will melt the coating, leaving an unsightly stain. Further actions are as follows:

If done correctly, the joint is almost invisible. There is no need to test it yet - several hours are required for the final polymerization. But that's all. Linoleum is laid and you know how to lay it with your own hands.

This article will tell you how to lay linoleum. This is not a technologically complex process, but nevertheless, it must be carried out in accordance with certain requirements, which will ensure high quality, operational reliability and durability of the result.

General preparatory stage

The first thing that guarantees a long service life of the coating is a well-leveled, smooth and thoroughly cleaned dry substrate. The presence of any foreign objects, bumps, cracks is not allowed. The leveling of the base is carried out by means of chipboard (for wooden floors) or a self-leveling screed (for a concrete base).

Suppose you, who are going to lay, and have already purchased it in the store.

Preparation of linoleum consists in its adaptation to the microclimate of the room. Therefore, at least a day before the start of work, he is brought into the room. Works are carried out at an internal air temperature of + 18 ° C and above, as well as a relative humidity of no more than 40-75%. The base temperature should not be lower than + 15 ° С, and the permissible threshold for its relative humidity should not be more than 3%. After acclimatization of the material, the cutting itself begins, while providing a 10-centimeter margin along the contour of the room and 6-8 cm at the joints of the canvases. Measurements are made across the largest width and length of the room. For the final leveling of the linoleum, the resulting pieces are spread and left for another day. Linoleum should lie down:

At this stage, you can prepare the necessary tools:

- metal ruler;

- brush and vacuum cleaner;

- massive scissors;

- spatulas;

- building level;

- sharp knife complete with spare blades;

- roller;

- adhesive or double-sided tape;

- glue for joints.

Preparation of the base

Depending on the initial state of the base, the type of old coating, even before laying the linoleum, a number of technological operations are performed. So, if you have a wooden floor:

- provide verification of the fastening of floorboards;

- make sure that the heads of the nails are "recessed" flush with the plane of the floor;

- fasten fiberboard (plywood);

- putty the joints between the sheets.

When covering with tiles, the joints are filled and smoothed with cement mortar. If there is an old linoleum, then it must be completely removed, and the base must be leveled. The concrete surface is leveled with or using ready-mixed mixtures.

Preparation of linoleum

In addition to adapting the material to the existing climatic conditions of the room and its preliminary leveling, it is important to correctly orient the canvas relative to the dimensions of the room. Linoleum is laid so that the pattern applied to it is parallel to the long side of the room. With a large room width, when the size of one strip of linoleum is not enough, they monitor the coincidence of the pattern of adjacent strips. In this case, the pile of the base of the material should be oriented in one direction.

To ensure the maximum density of joints when preparing linoleum, adjacent canvases are laid with an overlap (6-8 cm).

Cutting is done as follows:

- a ruler is placed on top of the overlap;

- two layers of material are cut simultaneously.

To avoid a mistake, which will no longer be possible to correct, the cutting is performed in small sections. At the same time, the correctness of the cut is constantly monitored. In the corners, the linoleum is cut diagonally, thereby ensuring a snug fit of the material. The overlap on the wall along its entire length is left 8-10 cm.

Laying linoleum

Depending on the area of the room, the intensity of movement, one of the methods of linoleum flooring is chosen. This could be:

- free styling;

- flooring with double-sided adhesive tape;

- laying with glue fixing.

Free laying is suitable for small rooms (up to 20m 2). However, this type of flooring is less preferable from the point of view of its reliability. It is more expedient to provide additional fastening with adhesive tape. The main attention is paid to the places at the entrance and the joints of adjacent canvases. However, this method can only be used for light use of the floor.

The most reliable and durable option is gluing linoleum over the entire area. For this, a number of sequential operations are performed:

- half-turn the dry-laid canvas;

- an adhesive is applied;

- return the linoleum to its original position, while simultaneously controlling the correct laying;

- gently using a roller, the canvas is smoothed in the direction from the middle to the edges.

For convenience, glue should be applied to small areas.

For a snug fit of linoleum to the wall, it is sequentially pressed along the entire perimeter with a spatula. Excess material is removed with a knife, cutting off the material along the base of the walls:

Next, carry out similar actions with the other half of the piece. After that, they proceed to the through-cut along the joint of the strips, remove the scraps, turn off the edges of the resulting joint, apply an adhesive composition along the seam and, pressing, lay the coating in place. The resulting joint will be almost invisible.

Sealing joints between adjacent strips of linoleum

After at least 12 hours, the joints between adjacent strips are sealed, for which a special compound for soldering the seams is used.

First, the joint of two strips is wiped from dust:

Then, on both sides along the joint, stretch masking tape:

Then they pass along the seam of the linoleum pieces with a special colorless compound, "cold welding":  Full operation of the coating is possible only after a technological break specified by the manufacturer.

Full operation of the coating is possible only after a technological break specified by the manufacturer.

That's all. Today we have seen how to lay linoleum in our apartment.

Linoleum is one of the most popular, budgetary and easy-to-install floor coverings. Anyone who wants to simply study the instructions and prepare the necessary devices to independently perform the linoleum flooring. The result is a beautiful and unpretentious floor covering. Modern linoleum can imitate the textures of a wide variety of materials, which allows you to choose flooring for a room decorated in any design style.

For self-laying linoleum on the floor, you will need the material in question and additional accessories.

- Putty.

- Glue.

- Double-sided adhesive tape.

- Reiki for arranging joints.

- Nails.

- Sharp knife.

- Ruler.

- Yardstick.

- Marker.

- Notched trowel.

- An ordinary small spatula.

- Hot welding tools.

- Special skating rink.

- Scissors.

The given set can be reduced depending on the chosen method of fixing the flooring. In this moment, you will be able to navigate after studying the further provisions of the instructions.

Base device

Regardless of whether you will lay linoleum on a wooden or concrete base, the surface needs careful preliminary leveling.

First step. Carefully seal up any visible cracks with putty.

Second step. Sand the filled surface.

Step three. Carry out local repairs to the collapsed screed areas with a suitable concrete mortar. If the damage is large and there are many of them, fill in a new concrete screed, having previously got rid of the old layer. Let the screed dry.

Fourth step. Pour a special self-leveling mixture onto the screed. At this stage, follow the instructions specifically for your mixture.

First step. Buy plywood sheets with a thickness of at least 0.5 cm.

Second step. Lay the plywood on the floor and attach the sheets to the base with self-tapping screws so that the heads of the fasteners are recessed into the material.

Step three. Putty the seams between the plywood sheets.

Quite often, home craftsmen have a question: is it possible to mount a new flooring on an existing linoleum? In theory, this is possible. However, for the successful implementation of such an idea, you need to remove the baseboards and carefully stretch the old linoleum.

As a result, you can spend more time on such preparation than on dismantling the coating and leveling the base.

Most experts agree that before laying new material, the surface must be cleaned of any kind of old coatings. Otherwise, the decision is yours.

The base is carefully leveled and free from any kind of contamination. Move on to further work.

First stage. Measure all sides of the room to determine maximum width and length.

Second phase. Try to determine the width of the linoleum so that the number of seams in the flooring is minimal. Do not forget to add to the calculated values a margin of the order of 10-20% for the selection of the picture. The specific stock is determined according to the complexity of the pattern.

You also need to add 10 mm of margin on each side to compensate for possible unevenness of the walls.

Stage three. Draw a floor plan on paper. It will help you calculate the required amount of material faster and more conveniently.

Stage four. Head to a specialty store with your plan and calculations.

Linoleum is divided into material for household, semi-commercial and commercial use. Additionally, the coating is classified according to the intensity of use. All these points are reflected in the marking of the coating, with which the consultant should help you figure it out.

After delivering linoleum to your home, do not rush to immediately unpack it, especially if the weather is cold outside. Leave the material in the room for about a couple of days to allow it to adapt to the ambient temperature.

Spread a roll of material around the room and leave it on for a while. This will give the coating the opportunity to mature and take the shape of the base. After that, you can proceed directly to the flooring of the material, however, first read the important recommendations of specialists so that the work goes with the least effort, and the finished coating is of the highest quality.

What you need to know for successful linoleum flooring?

When performing repair and finishing work, professionals adhere to a number of important recommendations. Consider them and you, performing linoleum flooring with your own hands.

Observe the required temperature and humidity conditions. Specific recommendations are given on the packaging or in the instructions for the material. Be sure to check them out. Violation of the manufacturer's recommendations will lead to quick peeling of linoleum with parallel decay and destruction of the base.

Do not lay linoleum on an uneven base. Open joints of reinforced concrete panels and joints of prefabricated screed elements are also prohibited.

Linoleum is laid in the last stages of room renovation... Wooden plugs are pre-installed in the walls for installation of skirting boards. The nests for these elements are created at a height of about 15-20 mm from the floor surface with an average pitch of 1 m.

Linoleum flooring can only be performed on a pre-primed base. Any tool can be used to apply the primer.

The joints of individual linoleum canvases are usually fixed using cold welding. This material contributes to obtaining a compound with high strength characteristics. To get perfectly smooth joints, the linoleum sheets are first laid with a slight overlap, and then the excess material is cut off along the construction line. If desired, the joints can be decorated with moldings - special decorative plates.

A step-by-step guide to linoleum flooring

First step. Cut out the linoleum according to the pattern.

Second step. Spread the canvases on the floor of the room and let them sit for two days. During this time, creases and dents should disappear. It is important that the room is not colder than +18 degrees.

Step three. Remove leveled linoleum from the floor. Clean and prime the substrate thoroughly. Let the primer dry and apply the special adhesive to the floor using a notched trowel. Let the glue soak for the time specified by the manufacturer in the instructions.

Fourth step. Place a strip of linoleum on the floor, flatten it and flatten it firmly with a trowel. It will allow you to get rid of excess air under the decking. Start attaching linoleum from any wall.

In the end, you just need to isolate the seams, install decorative strips if desired and mount the baseboard.

Seam insulation rules

Hot and cold welding methods can be used to fix the seams. The specific method is selected taking into account the type of flooring and the complexity of the seams. Hot welding allows for higher strength seams. It is used in the installation of commercial and, as a rule, semi-commercial linoleum. At home, simple cold welding is usually sufficient.

It is carried out using a special compressor. It blows air onto the tools. The function of the bonding material is performed by special filler rods.

Welding of seams is performed after the adhesive composition used to connect the linoleum to the base has dried, i.e. in about a day.

Much easier to implement. Such seam insulation does not require the use of any special equipment.

There are two types of cold welding adhesives: for newly laid floorings and for floorings that have been installed a long time ago. The second glue has a thicker consistency. The principle of operation is the same for both types of glue.

The mechanism of action is extremely simple: you fill the seam space with glue, a special composition melts the edges of the canvases, which leads to their reliable fixation.

Features of installation of antistatic linoleum

There is a separate type of coating in question known as antistatic linoleum. This material is produced in the form of tiles, which are fixed with glue. When dry, the coating retains its conductivity.

Antistatic linoleum is laid using a different technology. First you need to apply static conductive copper strips to the base. These strips are connected into a single structure and connected to a common grounding system.

When laying antistatic linoleum, it is important that the tiles adhere as closely as possible to the substrate. The air from under the deck is removed using a special heavy roller weighing 65-70 kg.

When trimming and trimming the material, be careful not to hit the copper strips. Exceptionally hot welding is suitable for the processing of joints. The air temperature in the process of performing such welding rises to several hundred degrees.

The welding cord is available in a variety of colors. There are even fluorescent cords. Choose a specific option, taking into account the design of the room and your own preferences.

Linoleum belongs to the category of the least whimsical materials to maintain. However, this material still requires some attention from the owner.

To prevent the flooring from fading and cracking, do not use active cleaning agents to wash the linoleum. It is better to use formulations specially designed for cleaning this material.

Before arranging furniture, it is advisable to put on special soft caps on its legs, which will not allow heavy elements of furniture to leave holes in the linoleum and more serious damage.

Now you know how to lay linoleum yourself. Follow the instructions given, and you can make repairs no worse than a professional master, spending, at the same time, exclusively on the purchase of the necessary materials and accessories.

Linoleum - the coating that everyone likes

Happy work!

Video - DIY linoleum flooring

Although this flooring is universal, it is very important to properly prepare the subfloor for it, because over time the linoleum will take over, and all the unevenness of the base will become visible. It's impractical, and it looks messy.

Laying linoleum on a wooden floor. Often such a floor hides defects that invariably come out after laying linoleum. To prevent this from happening, take a closer look at its surface.

Depending on the degree of wear, gaps form between the floorboards. They must be carefully filled with acrylic filler. Have you noticed any differences in height? They should be leveled using a planer. One or more boards may need to be replaced.

Sink in the protruding heads of screws and nails, and then putty all visible indentations.

Remember that after the linoleum is laid, the wooden floor will still be in use. And if there is a problem in it, it will be difficult to get to it. It is better to spend time preparing than dismantling the finished coating.

Linoleum is an artificial and non-breathable material, under which various kinds of bacteria can form. It is advisable to treat your wood floor with an antifungal antiseptic to protect it from mold and damp damage.

For additional protection of the tree, it is worth treating it with linseed oil, and then opening it with varnish. With such care, your wooden parquet will still serve you, even when the linoleum gets tired.

If the floor is excessively worn out and has irreparable defects (for example, lack of floorboards, bulging), it will be correct to cover it with sheets of moisture-resistant plywood. The panels are easily attached with self-tapping screws, which must also be buried and puttyed.

For a well-prepared base, even thin linoleum is suitable, it is cheaper and easy to fit, but just as easily and wears out.

Laying linoleum on a concrete floor. Use a spirit level to check for unevenness. Pay attention to all the bumps, pits, and crevices. If such defects exceed 20% of the total area, then you won’t be led: you will need a screed.

Then apply a self-leveling mixture with a layer of no more than 2 cm so that the surface is perfectly smooth.

This is not a necessary step, however, once you take it, you will understand how important attention to detail is. Make sure all joints between floor and ceiling are clean and crisp.

Concrete is a cold material and will affect the comfort of the new floor. Therefore, it is worth laying a heat-insulating substrate made of foam or izolone, where on one side there is a heat-reflecting foil.

On a well-prepared floor, the coating lays down evenly, is easily trimmed, and such work turns into a pleasant pastime, and not into a tedious procedure.

New linoleum flooring on top of the old one. Can this be done? Not always. Namely, only if the original coating has retained its integrity. Knowing the tendency of linoleum to crack, if there are drops and irregularities of more than 2mm on the old floor, even the substrate will not save the new coating from damage.

Old linoleum contributes slightly to thermal insulation, but it must be strong enough to provide a good base. Most often, new linoleum spreads when the old one is already torn to shreds, bent and broken. Such a coating should be removed without regret, since the loss of time on its "preparation" is not worth the effort.

Moreover, if the rough layer is rubbed in places or has cracks, then this is not critical. The main thing is the absence of sharp drops.

If you decide to eliminate the detected defects, then it is better to do it like this:

- Outline the damaged place with straight lines with a pencil

- Cut the damage with a stationery knife under an iron ruler

- Glue a whole piece of linoleum into the resulting hole, minimizing joints

- Remove the joints on the floor with silicone sealant and smooth the surface with a spatula, allowing the material to dry. Instead of a sealant, you can use liquid nail glue. Pressing properly on the joint, let the glue spread over a large area.

- When the minor repairs are finished and the glue has dried, thoroughly clean the surface. She is now ready for flooring.

To prepare old linoleum, the first step is to remove the skirting board. Remove the connecting strips, if present.

Flooring - step by step instructions

An important aspect when choosing - try to select the width of the material so that it fits in one piece. If this is not possible, consider the joints in such a way that they can be hidden. To do this, on a piece of paper, sketch out the perimeter of your room with all the protrusions, pipes, etc. and take measurements. Add 5cm allowances to the results obtained, just in case, suddenly the walls are uneven.

Step-by-step instructions on how to lay linoleum:

- The desired temperature in the installation room must be stable and exceed 18 degrees. Humidity - no more than 60%.

- Before you start laying it is good to let the linoleum "settle" for a day. The fact is that it is made of elastic material and reacts to temperature changes, narrowing and expanding, and if it is frosty or hot outside, the roll needs to take the temperature in your house.

- Stage of placement of sheets. Place them with some overlap against the wall, which you will then cut off. You can also start cutting by attaching a flat factory edge to the corner (if you know for sure that the wall is straight), and leave a gap of 5-10mm, you then attach it with tape. In this case, trimming is performed only along the rest of the walls.

- If the room is spacious and there are several sheets of cover, first align the seam and position it where you think it should be. Dock the drawing and don't forget about the overlap.

- Now place the material around the perimeter and as such it should lie down again. A couple of days is better this time.

- Secure the factory edge near the edge of the wall.

- Cut off large pieces of linoleum, leaving 3-5cm in reserve.

- The moment has come for a clean cut. In each corner, the material is brought to the wall as much as possible and the joint is marked with a pencil. Move along the perimeter, marking a clipping line every 25cm.

- Connect the marks with a straight line and cut. Remember that the coating stretches over time, so you should leave 5-10mm gaps around the perimeter of the room. If this is not done, waves will appear on the floor.

If there are several strips, then before finishing cutting, take the first strip of material and secure it with tape along the end, which is closer to the center of the room. Now trim it with rough allowances. Attach the second to the first one and connect them with tape at the overlap. Similarly, you need to cut this sheet. It is only when the flooring is centered and docked that the final trim is carried out.

If the room has a protruding corner, then cutting should start from it. First, a rough fitting is done, and then it is cut clean.

Bonding methods

Do-it-yourself linoleum laying can be free and with special glue. Free is suitable for small rooms with an area of 20-25m² and consists in fixing the covering with plinth and thresholds in doorways. If the room is spacious, glue is required. Gluing provides greater security at increased floor loads.

An intermediate method of fastening is considered to be double-sided masking tape, which, although less reliable than glue, can be easily removed if necessary.

In fact, there are several adhesives for linoleum and each has its own testimony. The general requirement is that the subfloor surface must be primed. Apply glue to the floor underneath the neatly folded back material. It is better to distribute it with a spatula. Then smoothly smooth the linoleum from the middle to the edges, releasing excess air with a soft roller. For the second sheet, the procedure is repeated.

Bonding joints is a very important point. It is necessary to make sure that they are tightly pressed against each other and do not bully. In 90% of cases, the method of cold welding is used for this - gluing with colorless silicone glue:

- The first goal is to make both edges perfectly flat, as the welding is butt-to-butt. If the edges are factory-made, there are no problems; otherwise, you need to trim them manually. Join the two stripes along the pattern, marking a seam line over both pieces with a pencil.

- Cut two layers of linoleum under the ruler at once and remove the scraps.

- To weld, stick masking tape at the joint, which will prevent the glue from staining the rest of the surface, and cut it along with a knife.

- Without too much pressure on the tube, apply glue to the weld. The glue should go in and out of the joint.

- Squeeze both edges and after 20-25 minutes the masking tape can be removed.

When the work is over, take care of changing the skirting boards. As a rule, they are installed one week after laying the floor, when it is completely straightened. For uneven walls, it is better to use plastic skirting boards. To prevent linoleum from bending in doorways, fix it to the floor using a special flat sill and self-tapping screws.