Tower cranes Technical characteristics Table. The main characteristics of tower cranes

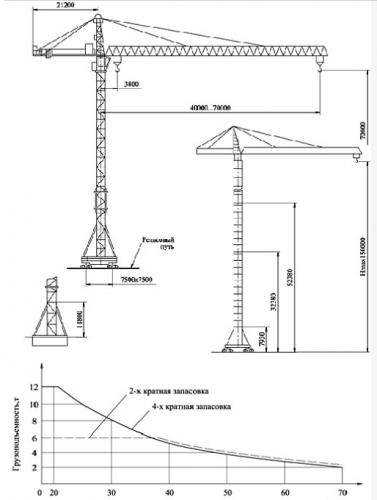

This group includes unified KB-403A, KB-403B, KB-405.1A, KB-411, KB-408, Crane modular system KBM-401 and their modifications. These cranes with the maximum carrying capacity of 8 ... 10 t are designed to perform construction mounting work on the construction of residential, civil and industrial buildings And structures with a height of up to 12 ... 16 floors, have a one-type design and are mobile self-propelled full-turn machines on a rail track with a rotary telescopic tower and the lower arrangement of the counterweight.

The technical characteristics of the cranes of the 4th dimensional group is given in Table. 2.

Cranes modular system KBM-401P These are basic unified modules (mechanisms, cabin, reference device, steensions and arrows section). At the same time, the mechanisms, a cabin, a reference device converted throughout the sizernate row, and the metal structures of the cranes - in all versions within this sizes. By varying the number of modules of the sections of the towers and arrows, it is possible from the same knot modules to receive different crane performances, characterized by cargo, high-speed and high-speed characteristics, departure and type of arrows (Table 1).

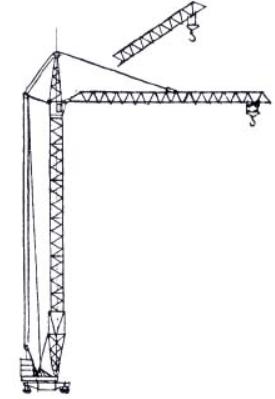

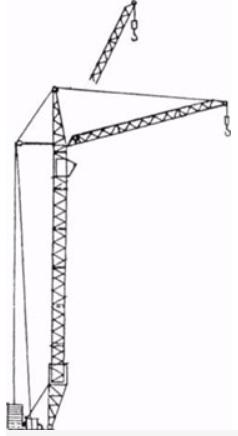

The execution of the KBM-401P crane (Fig. 1) can be used in warehouses, polygons and overloading sites. Cranes are designed to work in the I-Vi wind areas at ambient temperature - 40 ... + 40 ° C.

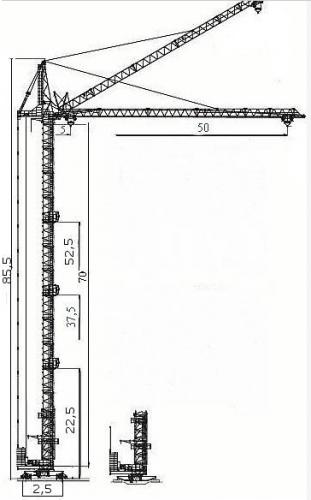

Fig. 1. Tower crane modular CBM-401P system (numbers in circles - performing numbers): a - execution with the beam boom; B - Performance with lifting boom

Cranes KB-405.1A and five versions of the KBM-401P crane are equipped with a lifting boom, CB-403A cranes, KB-403B, KB-408 and 28 crane versions of KBM-401P (including basic model) - a beam arrow with a cargo cart.

Table 1. Technical characteristics of the execution of the tower crane CBM-401P Rzhevsky Crane Building Plant

Commission No. |

Parameters |

|||||||

CargoMart, KN - M |

Maximum load capacity, t |

Maximum lifting height, m |

Maximum departure, m |

Departure at maximum load capacity, m |

Cargo adherence at the maximum departure, t |

Number of sections of the tower |

||

Horizontal arrow H 1 |

Inclined Streth(? \u003d 30 °) H 2 |

|||||||

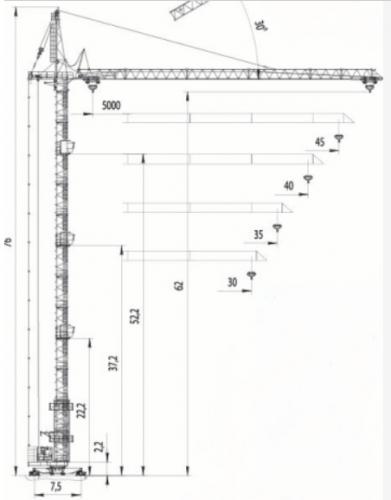

Composite parts of each crane (Fig. 2) are: chassis ring frame 1 of the box 1, Single-row roller reference device 16 with internal gear gear, rotary platform 2, portal 15, tower 14, head 7, arrow 11, cargo truck 9 ( At the cranes with the beam arrow), cargo 6 and boom 5 ropes, broken 8, hook suspension 10, mounting device, unified cabin machine 13 and working mechanisms, counterweights 3, electrical equipment, safety devices and cable drum. Four swivel floors are connected to the chassis frame, and are located diagonally using tubular tips. Each fluger relies on a unified balancing two-wheeled chassis trolley 17 with a carrying capacity of 72 T in KBM-401 and KB-408 and 60 T in the remaining cranes of the group. All running trolleys of the CBM-401 crane are driven (leading). The remaining cranes in the set of carts include two leading and two slave chassis trolleys, and the driving trolleys are located on one rail.

When rounding the path of the inner rail of 7 ... 10 m, the leading running trolleys are located on the outer rail, with a radius of the inner rail, more than 10 m can be placed on any rail. Trolleys are based on P50 crane rails. The pitch and the base of the fourth dimensional group cranes are usually equal to 6 m. The swivel platform is based on the rotting frame through the reference device, on which the cargo and boom winch are installed, the mechanism of rotation, electrical cabinets, counterweight plates. In front of the turning platform, the tower portal is hinged with the help of brackets.

The lattice tower of the cranes consist of the ledge, the upper section, intermediate sections, portal and a movable clip. The towers are struck by the bottom of the intermediate sections as the building is erected. To grow up the intermediate sections of the tower serves lever mechanism Cage extensions (mounting parallelogram) mounted in front of the platform. In the vertical position of the tower is held by two telescopic pins 4. The portal is two triangular farms connected in two tiers of boxed beams. On the belts of the portal are mounted guide rollers holding the tower in a vertical position when extending it. In the upper tier on the beams installed four locks, the purpose for landing on them towers after its extension. Still blocks of the upper tier of the portal together with the blocks of the movable clock and the mounting rope form a mounting polyaste of the tower of the tower of the tower. When extending the tower, one end of the mounting rope is attached to upper strapping Portal, the other is fixed on the drum of the cargo winch, from which the cargo rope is removed. The headband of the tower consists of a metal structure, a strut-up strut and a pull-up mounting rack to lift the arrows to the working position. From above on the ledge installed two boom blocks and the blocks of the cargo mat. Beam arrows Cranes KB-403A, KB-403B, KB-408, KBM-401 - single-private, sectional, made in the form of a triangular farm, on the lower belts of which the cargo truck moves. The movement of the cargo trolley is carried out by a television winch 12, installed in the root part of the boom, and a television rope. With the helper winch and the boom polyspaster, the beam boom can be installed in a horizontal or inclined (at an angle of 30 ° to the horizon) position.

Fig. 2. Cranes of the CB of the 4th dimensional group: A - KB-403B; b - KB-401.5A

All cranes with the beam boom (with the exception of the KB-403A crane) there is an opportunity to move the cargo cart with a load on inclined arrows. At the same time, thanks to the special supply of the cargo rope, the load when changing the departure moves almost horizontally, which facilitates the loading of the cargo, reduces the duration of the working cycle and helps to increase the performance of the crane. Changing the rope supply with horizontal to the inclined arrow is automatically performed. On freight carts, devices are mounted for their automatic locking when the television rope breakage.

The crane lifting arrow of the CB-405.1A of the lattice, triangular section, is made of pipes: the rise, and lowering the boom when the departure changes are carried out by the booler wagon through the shut-off polyspaster. In the root section of the boom, the rope strut is suspended from below, which protects the arrow from the thread when the rope breaks on the minimum departures.

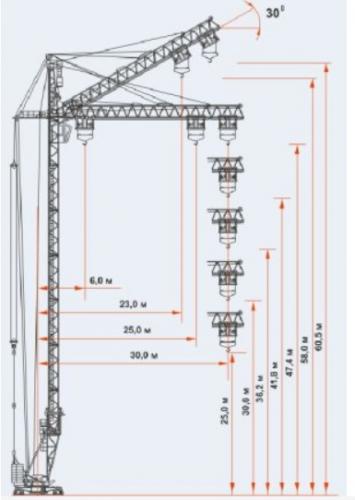

Crane rope supply circuits are shown in Fig. 3. Truck characteristics of cranes are shown in Fig. four.

Fig. 3. Schemes of stocks of ropes of cranes of the 4th dimensional group: a - cargo rope with lifting boom; b - cargo rope cranes with beam boom; in - boom rope; g - television rope; d - mounting rope; 1 - cargo winch; 2 - cargo rope; 3 - boom rope; 4 - Board winch; 5 - television winch; 6 - television rope; 7- cargo truck; 8 - portal block; 9 - mounting rope; 10 - mobile clip block

Fig. 4. Freight characteristics of cranes of the 4th dimensional group:a - Crane KB-408.21: L - with a horizontal arrow; LL - with an inclined arrow; b - kb-405.1a

The unified mechanisms of cranes (Fig. 12) include the boom, cargo and television swabs, a reference-rotary device and a movement mechanism.

Cranes are equipped with one - and two-link cargo winches (Fig. 5, a, b). The main electric motor of the two-link winch is intended for lifting (lowering) cargo of the largest mass, auxiliary - to lift (lowering) cargo of the smallest mass, hook suspension and supplying speed.

The execution of the KB-408 crane is equipped with: two-uniform freight winches with engines alternating current (The main engine with a phase rotor, auxiliary - with short-circuited), single-toted winches equipped with an AC motor with a phase rotor and a brake machine or electric motor direct current with a thyristor converter. The use of a DC thyristor electric drive allows you to expand the speed control range when lifting-lowering the cargo of the maximum mass, significantly increase the speed of lifting small by weight of goods and empty hook.

Fig. 5. Kinematic schemes of unified mechanisms of cranes of the 4th dimensional group: a, b - cargo winch; in - the booler winch; g - telecom winch; D - rotation mechanism; e - the mechanism of movement; 1 - two-stage gearbox; 2.8 - brakes; 3, 4 - electric motors; 5 - television winch; 6 - cylindrical transmission; 7- global gearbox; 9 - three-stage reducer; 10 - toothed crown; 11 - Output gear; 12, 13 - gears; 14 - Chassis Wheel

Each CBM-401 crane version can have three modifications of the cargo winch drive - with two AC motors, with two AC motors and a switchable gearbox, with a DC motor and a thyristor converter.

Board winches (Fig. 5, c) differ from the freight lack of an auxiliary engine. The winch winch (Fig. 5, d) consists of an electric motor, a padding brake, a gearbox, which includes cylindrical and global transmissions, and a rifled drum. Turning off the winch drive in the extreme positions of the trolley is carried out by the end switch.

The turning mechanism (Fig. 5, e) consists of a vertical three-step gearbox of a flange electric motor and a special brake brake. Braking is carried out in three stages: free braking, dynamic braking, final turning of the rotation mechanism. At the crane CBM-401 and its versions have two rotation mechanisms. The mechanism of movement of cranes (Fig. 34, E) includes an electric motor, a gearbox (the same as the television winch), cylindrical gears and chassis wheels.

Board cranes of the KB-404.4 family Designed to carry out construction and installation work when building zero cycles of buildings in housing and civil construction.

In the structures of KB-404.4 cranes, unified nodes and mechanisms of mass produced are widely used. tower cranes.

Composite parts of the cranes: chassis with trolleys, a support-rotary device, a rotary platform with crane mechanisms installed on it, a lifting boom, a cabin cabin, a rack with a troop and ballast. Arrows cranes sectional, rectangular cross section and consist of root, head and three intermediate sections. Cranes can be collected in versions that are characterized by the length of the boom, carrying capacity and cargo moment. Crane KB-404.4 is equipped with a replaceable reference insert that performs the function of the short tower, which allows it to be used also for the construction of low-rise buildings. From the object to the crane object is transported on a rolling trolley with a truck tractor.

The technical characteristics of the booms of the KB-404.4 family is presented in Table. 3.

Table 3. Technical characteristics of arrovar cranes for zero cycle

Parameters |

Machine index |

||

KB-404.4-1 |

KB-404.4-2 |

KB-404.4-3. |

|

|

Load capacity, T. |

|||

|

Hook departure, m |

|||

|

Hook lifting height, m: |

|||

|

without insert |

|||

|

with insert |

|||

|

Working speeds, m / min: |

|||

|

lifting cargo |

|||

|

smooth landing of goods |

|||

|

crane movement |

|||

|

Rotation frequency, min -1 |

|||

|

Cake x base, m |

|||

|

Installed power, kW |

|||

|

without insert |

|||

|

with insert |

|||

|

Manufacturer |

OJSC "Karacharov Mechanical Plant" (Moscow) |

||

Specifications

Table 2. Technical characteristics of KB of the 4th size group

Parameters |

Machine index |

||||||

KBM-401HL |

KB-403A. |

KB-403B. |

KB-403B.4. |

KB-405.1A. |

KB-411-04 |

KB-408.21 |

|

|

Maximum cargo moment, kN · m |

|||||||

|

Multiplicity of cargo polyspaster |

|||||||

|

Load capacity, T: |

|||||||

|

at the maximum departure |

|||||||

|

maximum |

|||||||

|

with horizontal (inclined) arrows: |

|||||||

|

maximum L 1 2) |

|||||||

|

with maximum load capacity: |

|||||||

|

minimal l 3, |

|||||||

|

with lifting arrows: |

|||||||

|

maximum L 1. |

|||||||

|

minimal l 2. |

|||||||

|

Hook lifting height, m: |

|||||||

|

the greatest with horizontal (inclined) arrows H 1 (H 2) |

|||||||

|

the greatest with lifting arrows: |

|||||||

|

at the maximum departure H 1 |

|||||||

|

at the minimum yield H 2 |

|||||||

|

Depth of lowering, m |

|||||||

|

Working speeds, m / min: |

|||||||

|

maximum height load lifting |

|||||||

|

smooth landing |

|||||||

|

cargo truck movement |

|||||||

|

crane movement |

|||||||

|

Rotation frequency, min -1 |

|||||||

|

Cake x base, m |

|||||||

|

The smallest radius of the rounding path, m |

|||||||

|

Installed power, kW |

|||||||

|

constructive |

|||||||

|

counterweight |

|||||||

|

Manufacturer |

OJSC Ukhta Mechanical Plant (Komi Republic) |

OJSC Nizepetrovsky Crane-Building Plant (Chelyabinsk Region, Nizepetrovsk) |

OJSC Rzhevsky Crane Construction Plant (Rzhev, Tver Region) |

OJSC "Karacharov Mechanical Plant" (Moscow) |

OJSC "Nesthetrovsky Crane-Building Plant" |

||

Construction of civil and industrial buildings, the construction of residential multi-storey houses, loading and unloading operations in warehouses, venues and polygons can not be submitted without the use of tower type cranes. They move cargoes, structural elements to the desired point of construction object.

Let's try to figure out what the tower crane is, and we learn its technical characteristics. The article will allow us to find out the parameters of tower cranes, their types and understand where, in which area their use will be most effective. And also find out the price of the "one-armed helper".

The speed of work is determined by the power and capacity of the tower crane. From his speed of movement and weight, which he can raise, depend on the overall rates of construction and construction of buildings. The tower crane video, which can be viewed in below is a cyclic type mechanism.

What is included in the concept of the cycle of the mechanism:

- This is capturing the cargo.

- Move the captured object.

- Unloading at the planned place.

- Reverse mileage.

| Tower crane specifications of this type, its capabilities | |||

| 1 | Height of the tower crane (arrows departure) | meter | 40 |

| 2 | Possible height of arrows lifting with cargo | meter | 150 |

| 3 | Speed \u200b\u200bof lifting goods | meter / min | 10 — 100 |

| 4 | Rotation of the crane design (its frequency) | revolutions / min | 0,2 – 1,0 |

| 5 | Speed \u200b\u200bof movement | meter / min | 10 — 30 |

| 6 | Loading of the freight mechanism with minimal arrows | kg | 7500 |

Tower cranes The characteristics we consider are several types:

- With swivel tower.

- And non-refreshrating design.

Prefabricated design design allows short time Conduct the installation and disassembly of the crane. Translate it to the right place. Speaking of tower cranes as a variety of lifting mechanisms, add that the non-turning tower is divided into three types:

- telescopic version;

- structured design;

- aspirable.

Way to travel

To move in construction site Set rails. For them, the crane can move forward and backward, lifting and delivering the design of buildings or cargo to the desired point of the construction site.

There is a category of cranes, which relies on the outer side of the facility under construction. This is classified as the design of an appropriate type. In some cases, self-lifting mechanisms are used. With an increase in the height of the object under construction, they rise up.

There are except for the cranes under consideration mechanisms on a pneumocole move. Cranes that move on caterpillars and installed on cars.

Device of the tower crane

The design includes:

- reference part;

- cab of control;

- reverse rotary devices;

- tower;

- arrow;

- running frames;

- device for moving by curves;

- rotary platforms;

- stairs and playgrounds.

Stamps of tower cranes

Today it is produced and located on construction sites Many cranes different marks. Photo Tower cranes, which are presented at the end of the article, are most in demand. We are talking about the KB series. It is believed that this series with rotary cabin Most often found on construction sites. It is for them we will stop.

Technical characteristics of tower cranes KB

KB-100 is used in the construction of buildings whose height is 5 to 9 floors. Moves along the rail canvase. KB-100 is an installation with an inclined arrow and a swivel tower. The height of the rise from 21 to 33 meters. Speed \u200b\u200bof lifting 43 m / s.

KB-402 Crane on the rail go and the swivel tower. Can lift loads up to 8000 kg. Arrow departure is 25 meters. Used in the construction of five-storey buildings.

How much is the tower crane?

The tower crane, the price of which, depends on its performance, carrying out the possibilities, the year of issue and the technical condition can be bought by credit funds. Possible purchase in leasing or the acquisition of the ex-used technique. The dispersion ranges from 13897000.00 to 1287000.00 p. The average price of cranes in the Russian Federation is 670000.00 p. Practiced crane rent for a certain period.

Suffice to say that any cranes regardless of the carrying capacity, the speed of movement in demand, without which the construction is impossible high-rise structures. Their use only speeds up the construction of buildings.

Crane "Pioneer" g / n 500, 750, 1000

General

Manufacturers of CJSC "Tver Experimental-Mechanical Plant"

OKP code 483580.

Characteristics

Load capacity, kg 500, 750, 1000

Specifications Lifting height - 50 m, when installed on Earth 4, 5, 6 m. Lifting speed - 0.2; 0.14; 0.74 m / s. Drive power - 4.0; 4.0; 4.25 kW. dimensions 4.2 x 1.78 x 5.4 m; 4.28x1.7x5.4 m; 4.5 x 2.0 x 6.0 m. Mass without k / g, kg - 480; 480; 900. Mass complete, kg - 910; 921; 1790 kg. Rope diameter, mm - 6.9; 6.9; 12. Rope diameter, mm - 6.9; 6.9; 12

The use of the "pioneer" crane is intended for lifting goods with installing it on Earth and overlap of buildings and structures. The crane is a collapsible design.

General

Brand (type) KB - 403B

GOST, TU TU 22-5955-85

Mass, kg 80 500

OKP code 4835421101

Characteristics

Load capacity, t 8

Specifications type - mobile on the rail track with a swivel tower and a beam boom. Cargo moment -120 TM. The height to the axis of the arrow suspension is 43.6 m. The height of the lift with the largest departure, with horizontal arrows - 41m, with inclined arrows - 54.7 m. Maximum departure at a horizontal arrow - 30 m, maximum with inclined arrows - 26.3 m , the smallest departure is 5.6 m. Rise speed (lowering) of cargo - 40 (55) m / min. Smooth loading speed - 5 m / min. Crane movement speed - 18 m / min. Installed power - 77.6 kW. Mass constructive - 50.5 tons

Application is intended for mechanization of construction and installation works when erecting residential and industrial buildings and structures having a lot of mounted elements up to 8 tons

General

Mark (type) KB - 405.2A

GOST, TU TU 22-03821-89

Mass, kg 114 000

OKP code 4835421030

Characteristics

Load capacity (max.), T 9; With minimal arrows departure - 13

Specifications type - mobile on the rail track with a swivel tower and a lifting boom. Cargo moment - 162 TM. The lift height is 63.4 m, with a maximum departure - 51.6 m. The maximum departure is 25 m, the minimum is 13 m, with a maximum load capacity - 18 tons. Load capacity for macasimal fly 25 m - 6.3 tons. Pallet and The base is 6 m. Power of electric motors when the operation of two mechanisms is 45 kW. Ballast - 50 t

Application is intended for mechanization of construction and installation work when erecting multi-storey buildings with a mass of elements up to 9 tons.

General

Brand (type) KB - 408.21

GOST, TU TU 22-28005

Mass, kg 55 700

OKP code 4835421760

Characteristics

Load capacity, t 10 when flying arrows 5 m

Specifications Maximum cargo moment - 200 TM. Lifting height (horizontal arrows) - 54 m. Departure of the horizontal boom - 30 m. Depth of lowering - 5 m. The angle of rotation is 1080 degrees. Seismicity, scores 1-6 by SNiP II-7-81

The use of the tower crane is designed for mechanization of construction and installation work in the housing and civil construction of structures with a height of up to 72.7 meters with a mass of mounted elements up to 10 tons. Model KB-408.21 is a construction mobile full-time tap on a rail with a rotary tower and a beam boom with a cargo cart, providing vertical and horizontal transportation of construction parts and materials. The crane is transported from an object on an object disassembled. Installation is carried out by its own mechanisms and with the help of a car crane

Description Crane Tower KB-408.21 is equipped with a cabin heating system to work in winter time. Manufactured by B. climatic execution V category I according to GOST 15150-69 for areas with ambient temperature from 40 degrees. up to + 40 hail

General

Brand (type) KB - 415

Mass, kg 115 800

OKP code 45354210

Characteristics

Load capacity, t 12

Technical characteristics of cargo moment - 160 TM. Load capacity for max. Relet - 3.2 tons. Loading capacity raised by 30 degrees. - 3.2 tons. Departure arrows - 40 m. Raised arrows raised by 30 degrees. - 35 m. Mass are constructive - 67.8 tons. The mass of the counterweight on the rotary platform is 45.8 tons. The mass of the counterweight is 3 tons. Operating conditions from -40 to +40 degrees. Seismicity up to 6 points

The use of KB-415 is designed for the mechanization of works on the construction of buildings up to 83 m high with a mass of mounted elements up to 10 tons.

General

Mark (type) KB - 415-07

Mass, kg 80 700

Manufacturers Kokhomsky Plant Strommashin

OKP code 45354210

Characteristics

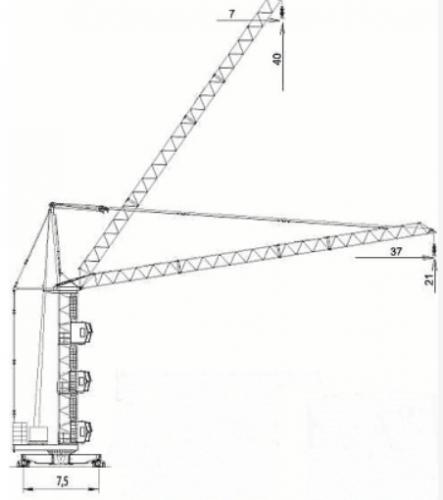

Load capacity, t 10

Technical characteristics of cargo moment - 250 TM. Load capacity for max. Relet - 5 tons. Loading capacity raised by 30 degrees. - 6 t. Departure arrows - 37 m. The departure is minimal - 7 m. The height of the lift is 40 m. The depth of lowering is 5 m. Mass is structural - 42.4 tons. The mass of the counterweight on the rotary platform is 38.5 tons. Operating conditions from -40 to +40 degrees. Seismicity up to 6 points

The use of KB-415-07 is designed for mechanization of work on building buildings up to 40 m high, as well as for the work of the zero construction cycle. Tower crane, low-speed, with a maxim arrow providing an departure to 37 m

Description Crane has the top extension of the tower using the hydraulic equipment of the mounting clip. The installation-dismantling of the crane is made with the feeder with the possibility of defension the arrows in the installation process when working in cramped conditions. In the construction process, the driver's cabin can be rearranged into fixed positions using the mounting rope. Electric equipment of the crane is installed on the rotary platform

General

Mark (Type) KB - 503

Mass, kg 90 000

OKP code 483542.

Characteristics

Load capacity (MAX.), T 28

Specifications type - mobile on the rail track with a swivel tower and a beam boom. Execution of crane- 503. Cargo moment - 280 TM. Lifting height, maximum - 67.5 m. With horizontal arrows - 53 m., Maximum departure - 40 m, minimum - 7.5 m. Load capacity with horizontal arrows - 10 tons. Kalo and base - 7.5 m. Power of electric motors When working two mechanisms - 85.5 kW. Mass constructive - 90 t

The application is intended for the construction of residential, public and industrial multi-storey buildings and structures.

General

Mark (type) KB - 515

Mass, kg 166 600

Manufacturers Kokhomsky Plant Strommashin

OKP code 45354210

Characteristics

Load capacity, t 10

Technical characteristics of cargo moment - 160 TM. Load capacity for max. Departure - 6 tons. Loading capacity raised by 30 degrees. - 6 t. Departure arrows - 40 m. Raised arrows raised by 30 degrees. - 35 m. Mass constructive - 98.6 tons. The mass of the counterweight on the rotary platform is 65 tons. The mass of the counterweight is 3 tons. Operating conditions from -40 degrees. up to +40 degrees. Seismicity up to 6 points

The use of KB-415 is designed for mechanization of works on the construction of buildings up to 95 m high with a mass of mounted elements up to 10 tons. Provides departure up to 50 m.

Description Crane has the top extension of the tower using the hydraulic equipment of the mounting clip. The installation-dismantling of the crane is made with the feeder with the possibility of defension the arrows in the installation process when working in cramped conditions. In the construction process, the driver's cabin can be rearranged into fixed positions using the mounting rope. The electrical equipment of the crane is installed on the rotary platform in the hardware cabin. Possible stationary installation of the crane (on supports)

General

Mark (type) KB - 581

Manufacturers of OJSC "Mechanical Plant" (SN. Petersburg)

OKP code 483542.

Characteristics

Load capacity (Max.), T 10

Specifications Cargo moment 180 - 300 TM. Load capacity during poppy. Relet - 3 tons. lift height, maximum - 56.8 m. The speed of lifting the cargo 10 t - 30 s; up to 2.5 t - 90 s. Arrow 50 - 60 m. Base 6x6 m / m.

The use of tower crane KB-581 is designed for the mechanization of construction and installation work when erecting residential, civil and industrial buildings and structures up to 25 floors with elements building structures Weighing up to 10 tons

Description Tower Crane KB-581 with an upper turn with an arrow departure up to 60 meters is available in mobile and stationary versions. From their predecessors, KB-581 is distinguished by better mobility and lifting capacity, it is easily transported and mounted on the spot (all nodes correspond to the permitted dimensions). Installation used the original system of hydraulic mounting and attachment of nodes. The mobility of the tower crane KB-581 allows 1.5 - 2 times to reduce its preparation time for work. The tower crane KB-581 is produced in six versions. Manufacturer Plant Guarantee - 5 years

General

Brand (type) KB - 585

Manufacturers Kokhomsky Plant Strommashin

OKP code 45354210

Characteristics

Load capacity, t 10

Technical characteristics of cargo moment - 260 TM. Load capacity for max. Departure - 6 tons. Loading capacity raised by 30 degrees. - 6 t. Departure arrows - 40 m. The departure is minimal - 4 m. The depth of lowering is 5 m. Mass are structural - 74.3 tons. The mass of the counterweight is 14.5 tons. Operating conditions from -40 to +40 degrees. Seismicity up to 6 points

The use of KB-585 is designed for the mechanization of works on the construction of buildings up to 66 meters high in free-standing version up to 160 m in the appropriate execution with a mass of mounted elements 10 tons

Description The tower crane, top-turn, with a block arrow providing an departure to 60 m. The faucet is installed on a specially prepared foundation and is attached through special inventory anchors. The faucet has the upper extension of the tower using the hydraulic equipment of the mounting rope. The fastening of the crane to the building is carried out by means of an inventory cover and fastening (manufactured by a separate project). The mounting step is 30 m. Installation and removal of embracing fixing frames into the project position is made by the mounting rope. On the tap of the crane is provided by the mounting drive with a lifting capacity of 1.5 tons for the convenience of mounting-disassembly of the attachment. Electric equipment of the crane is installed on the rotary platform in the hardware cabin

General

Brand (type) KB-314

GOST, TU TU 4835-007-00239913-08

Length, mm 16 500

Width, mm 2,500

Height, mm 4 000

Manufacturers of JSC "Nizepetrovsk Plant of Construction Machines"

OKP code 4835421048.

Characteristics

Load capacity (MAX.), T 5

Specifications The height of the rise in horizontal arrows is 21/27 m. The height of the lift with inclined arrows (20grad) is 41.7 m. Arrow departure with horizontal arrows - 43 m. Arrow departure when raised by 20 degrees. Arrow - 40 m. The load capacity at the end of the boom - 1 tt

Application of tap without hydraulics, operated up to - 40 hails. Transported on rolling trolleys or low-arm trawl in transport dimensions

Description The crane can be operated in the I-III wind areas. When installing an additional central ballast (16 tons), the crane can be operated in I-V wind districts

General

Mark (Type) KB-403A

GOST, TU TU-22-4522-79

Mass, kg 50 000

Manufacturers of JSC "Nizepetrovsk Plant of Construction Machines"

OKP code 4835421048.

Characteristics

Load capacity, t 20

Specifications type - mobile on the rail track with a swivel tower and a beam boom. Execution of the crane with an arrow length - 30 m. Cargo moment - 160 TM. The lift height is the maximum - 49.6 m. With a horizontal arrows - 41 m. The maximum departure is 25 m. The minimum is 5.5 m. Load capacity with horizontal arrows - 8 tons. At maximum departure - 8 m. Krug - 6 m. The power of electric motors when the operation of two mechanisms is 85 kW. Common installed capacity - 116 kW

The application is intended for mechanization of construction of residential, administrative and industrial buildings up to 16 floors with a mass of mounted elements up to 8 tons.

General

Brand (type) KB-571B

Mass, kg 118 000

Manufacturers of JSC "Rzhevsky Crane Building Plant"

OKP code 483542.

Characteristics

Load capacity (MAX.), T 12

Technical characteristics of cargo moment - 250 TM. Load capacity at maximum departure - 2.6 tons. Departure: Maximum - 70 m.; With maximum load capacity - 20.8 m. The speed of lifting the cargo 0-90 m / min; Movement of a cargo trolley 0-60 m / min; Crane movement - 16 m / min. Rotation frequency - 0.7 rpm. Cake x base - 7.5 m. Total weight - 250 tons

Application Tower Crane KB-571B is designed for mechanization of construction and installation work when erecting residential, civil and industrial buildings and structures of various floors with elements of building structures Weight up to 12 tons

Description Crane KB-571B with upper twist with an arrow departure up to 70 meters is available in mobile and stationary versions. In the crane, original mechanisms management systems are applied with the wide use of modern purchased products, including imported. Crane control system Integrated, performs the functions of security requirements, parameter recorder and coordinate protection devices

General

Mark (type) CBM-401pa

Manufacturers of JSC "Rzhevsky Crane Building Plant"

OKP code 483542.

Characteristics

Load capacity, t 10

Specifications Type - mobile (on the rail) full-turn (with a swivel tower). Pitch - 6 m. The radius of the curvature of the inner rail for the curvilinear portion of the path is 10 m. Types of engines - MKAF 225L6 U1, MTKN 412-4 / 24 U1. Power - 55 kW. Rotation frequency - 975 rpm. The speed of lifting-lowering, cargo to 2.5 tons. - 45 m / min., Loads more than 2.5 tons - 30 m / min. Smooth loading speed, max. Mass, no more than 4.8 m / min. Power consumption - 67 kW

The application is intended for the mechanization of lifting and transport work when erecting residential, civil and industrial buildings and structures of various floors with elements of building structures. It is used to work in the I-VI wind areas according to GOST 1451-77 and in the climatic execution "in" category I according to GOST 15150-69 at ambient temperature from 40 degrees. up to +40 degrees. Seismicity up to 6 points inclusive. Crane mode group A4 on ISO 4301 / 1-86. The rear envelope is 4.2 m. The mass of the plates of the counterweight is 50.05 tons. Mobile Mobile Tower Crane KBM-401P

General

Brand (type) KB-586

GOST, TU TU 4835-008-00239913-10

Manufacturers of OJSC "Nizepetrovsky Crane Building Plant"

OKP code 4835421760

Characteristics

Load capacity, T to 10 t

Specifications Maximum cargo moment - 212.75 TM. Load capacity - 5 tons (at 2 "to a multiple source), 10 tons (with a 4-EX of multiple stock). Departure Max. - 65 m. Lifting height (on a reinforced base) - 64 (72) m. The permissible wind speed is 20 m / s. The angle of rotation is not limited. Operating conditions from -40 to +40 C. Management system - frequency regulation

The use of tower crane KB-586 is designed for mechanization of construction and installation work when erecting residential, civil and industrial buildings and structures of elevated floors with a mass of mounted elements up to 10 tons

The Description of the KB-586 is a building stationary atmospal cooler hook electric crane with a non-turning tower and a full-turn beam arrow equipped with a cargo carriage. The height of the freestanding crane is 64 (72) m. With an increase in the height, the valve is attached to the building with special connections. Installation of the crane is carried out by the method of increasing using a hydraulic mounting device.

General

Mark (type) 132 EU-N

Manufacturers LLC "Liebherr-Rusland"

OKP code 45354210

Characteristics

Load capacity, t 8

Max. Lifting height, m \u200b\u200b72.2

Technical characteristics Load capacity at max. Departure - 1700 kg. Tower - 132 ns

The application is intended for the construction of residential, public and industrial multi-storey buildings and structures in cramped conditions.

Description EC-H lifting cranes are economical during transportation, provide fast and easy installation and are advanced in the drive hardware. The class of load of these cranes overlaps the needs of medium and large construction objects. Separate components of the lifting crane can be transported in the order in which they will be collected later. These lifting taps use the modular concept of Liebherr and are equipped with a standard version of the electronic control system (EMS).

From:

1. Purpose and crane device

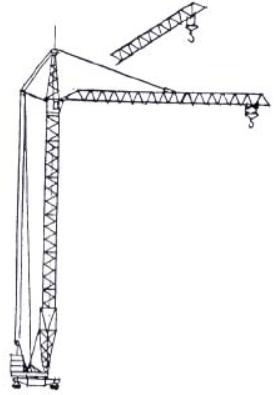

Tower cranes (Figure1) are designedto serve the territory of construction sites of buildings and structures, warehouses, polygons, loading and unloading of materials from transport - when performing construction and installation and loading and unloading work.In this tower crane, work movements are made: a change in departure, raising the boom, turning and movement of the crane. Change the arrows departure, depending on its type, is made either or lowering the boom or the movement of the cargo cart along the arrows.

Figure 1 -Bended crane

The lifting of goods is carried out with the help of a cargo winch, a cargo rope and a hook coil. The rotary part of the crane rotates relatively non-reflective with the help of a rotary mechanism. They are connected by the reference device (Sopr. Oph), which transmits vertical and overturning loads from the rotary part to the non-refining - chassis frame.

The main mechanisms of tower cranes are equipped with special safety devices, called the limiters that are equipped with: the mechanism of cargo lifting, turning the crane, the movement of the cargo cart and the arrow lift. Manage these tap mechanisms is carried out by a crane drive from the control cabin, which is usually installed in the top of the tower construction..

Description and design

To perform basic operations, the crane is equipped with appropriate mechanisms: swans, blocks and polystes.

Tower of Crane general purpose It has either a telescopic design, or lattice, two types: swivel and non-turning. At high altitude, it can be extensive (from above) and the essential (bottom). A hooking suspension is used as the main airproof organ. Such cranes, in the bulk, are made in a mobile version on the rail canvase, and their design allows you to quickly carry out and dismantling and dismantling and further transportation to another object

Any tower crane consists of the following parts:

Tower.

Working boom.

Reference part.

Rotary device.

Cab control.

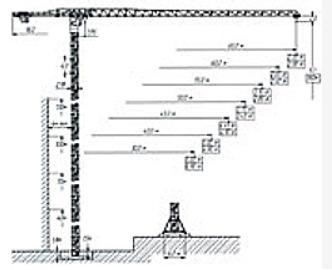

KB-674 - Tower lifting crane (Figure 2), self-propelled, on the rail, full-turn, is intended for the production of construction and assembly work of the main equipment of the main buildings of open and semi-open layouts, as well as residential and administrative buildings and facilities with a mass of mounted elements from 2.5 to 25 tons, refers to the cranes of the 6th dimensional group

Figure 2 -Kb 674

Working boom. As a working boom of a tower crane, a helpful or suspended boom can be applied (with a rigid base from individual thrust or on a flexible rope suspension). Structurally, the arrow can be a beam, lifting or articulated arrow made of pipes (small or big diameter), bent profile or corners. The arrow of the cranes are manufactured by section, which simplifies assembly and transportation, and also provides universality of performances

Tower. Crane tower: swivel, stripped, telescopic, swivel. The tower of the crane is a telescopic (tubular construction made from a large diameter tube), or a lattice design made from a corner or from small diameter pipes.

According to the method of rotation, the tower of the crane can be urgent (with a non-refreshrating tower and a swivel column) and a low-speed (with a rotary platform or with a swivel tower).

According to the assembly method, the tower of the cranes can be carried out with unintended, disassembled on Earth (telescopic and folding), designed from the bottom and extensive from above

The traveling trolleys of mobile rail cranes are divided into drive and unkind. Trolleys are performed on steel beats with flavors that move along a subcrane railway pathway using movement mechanisms

Application

Construction tower cranes of general purpose are used mainly in civil, industrial construction. Construction cranes for high-rise construction are used to build multi-storey civil and industrial buildings big height (up to 150 m or more).

Table 1- Technical characteristics of tower cranes

|

Load capacity, T. |

5-25 (up to 75) |

|

Departure, M. |

25-40 (up to 80) |

|

Height of the lifting, m |

up to 90 for mobile (up to 150-220 - for the attached) |

|

Speed: |

|

|

lifting cargo, m / min |

10-100 |

|

rotation, rpm |

0.2-1.0 |

|

crane movement, m / min |

10-30 |

Manufacture of work and safety guidelines.

1. Manufacture of works by cranes can carry out crane owners or operating organizations that have a special resolution (license) of technical supervision for their operation.Crane owners can allocate them for the production of work on orders to other organizations and citizens (entrepreneurs), which have a license to operate cranes or the resolution of the technician organ for the production of cranes.The permit for the production of works by cranes is issued by the organ auditorium authority to organizations and citizens (entrepreneurs), which have managers, specialists and staff, trained and tested the knowledge of these rules and other regulatory legal acts, as well as conditions for the safe production of work.In cases where the crane is allocated to the Customer who has no license to operate cranes or permissions of the technician body for the production of works, as well as a private person, the safety of work with its use is fully provided by the owner of the crane.The owner of the crane must determine the procedure for the allocation and directions of cranes to customers at the requests of the established form or contracts. At the same time B. specified documents The obligations between the owner and the customer to ensure the safety of the work of work should be distributed.

2. The cranes should be equipped with signs with the designation numbers, passport capacity, the date of the next partial and complete technical examination.

The inscriptions for bridge, console-mobile, gantry and tower cranes should be well visible from the ground or floor of the workshop. Recommended letter size: heighth. \u003e 80 mm, width b\u003e 35 mm.

3. Cranes can be admitted to the movement of goods, the mass of which does not exceed the passport capacity.

4. When operating bridge cranes, a vintage system should be applied from the cabin, in which the crane control is allowed only to the crane driver, which received key in the order installed by the ownera stamp that includes an electric crane control circuit.

5. In the operation of the cranes, managed from the floor, should be

the free passage is provided for the worker controlling the crane.

6. Increases on the crane paths, the gallery of bridge cranes that are in operation should be closed on the castle. Admission of personnel serving cranes, as well as other workers for craneways and passing gallery of existing bridge and mobileconsole cranes for the production of repair or anyother works should be carried out according to the admission, determining the conditions for the safe production of work.

The procedure for issuing outfits and instructives of workers is determined by the owner of the crane. ABOUT upcoming work Must be notified in the record journal of craners of all shifts of the span, the workshop where the work is made, and if necessary - and crane craners of adjacent spans.

- For each workshop (span), not equipped with passing gallery along the crane path, where bridge cranes work,

events on the safe descent of the crane drive from the cab with a forced stop of the crane near the landing site should be developed. These activities should be indicated in the production instructions for craners.

8. Most of the owner's solution can be used to produce construction, painting and other works with

existing on the tap of sites. Such work must be performed

according to a tolerance defining security measures, warning fall from the crane, defeat electric shock, exit on

crane paths, collision of cranes, simultaneous movement

crane and its carts. Using a crane for cargo movement

when performing from its bridge, these works are not allowed.

9. Promotions, equipped with a graon or

magnet, can be allowed to work only when executing

specifically designed for these cases of instructions set out

in the manuals for the operation of the crane and the airproof organ.

10.Nextracted lifting devices as well

fixtures that do not have tags (brand) should not be in the workplace places. It is not allowed in places of production of work unmarked and damaged containers.

11. The owner of the crane or the operating organization should be developed ways to properly sling, hooking and storing cargoes, which must be trained by the soloers.Terminal schemes, graphic image The methods of lines and hooks of goods must be issued on the hands of solingers and craners or posted in places of work. The owner of the crane or operating organization should also be developed by the removal of parts and assemblies of machines moving by the crane on time to their installation, dismantling and repair, indicating devices used at the same time, as well as methods of safe Cant of cargo, when such an operation is performed using the crane. Schemes of the lines and city of cargo and the list of used lifting devices should be given in the technological regulations. Moving the cargo on which the sling schemes are not developed must be made in the presence and under the guidance of the person responsible for the safe productionworks with cranes. The management of river ports is obliged to ensure the production of loading and unloading with the use of cranes according to the technological documentation approved by it.

12. Organizations operating cranes must establish the procedure for exchanging signals between the slingman and the craneman. The recommended sign alarm is shown in Appendix 23. When building buildings and structures, a two-way broadcast connection should be applied with a height of more than 36m. Sign alarm and signal exchange system for radio broadcast communications must be made in production instructions For craners and solingers.In cases where the zone serviced by the crane is not fully viewed from the cabin cabin, and in the absence betweencrane and solid radio or telephone forsignal transmission Crane driver must be assigned a signbody of solingers. Such signals are assigned to faceessential for the safe production of works by cranes.

13. The place of production of works on cargo movement cranes should be covered in accordance with the project production project.

14. The owner of the Crane II operating organization should:

Develop and issue production projects

construction and installation works with cranes, technological maps of warehousing of goods, loading and unloading vehicle rolling stock and other technological regulations;

To acquaint (under the signature) with projects and other technologically regulations of persons responsible for safe productionr. bot with cranes, craners and slings;

Provide solingers with distinctive signs (red dressings on sleeves, well visible crane drivers), means individual protection (protective helmet of the established sample), tested and marked removable lifting adaptations and containers corresponding to the mass and nature of the transported goods;

Sit on the place of production of work a list of main cargo transported by the crane indicating their mass. Crane workers and landlords serving boom self-propelled cranes when conducting construction and assembly works, such a list should beissued for hands;

Ensure the testing of the load capacity of the load capacity within the deadlines specified in the crane operating manual and in the passport of the load capacity limiter;

Determine the procedure for the isolation and direction of the boom self-propelled cranes on objects at the orders of the established form and ensure its compliance;

Set the order of sealing and locking by the lock of protective panels of tower cranes, as well as sealing the limiters of the loading capacity of the boom self-propelled cranes;

Determine the platforms and places of warehousing of goods, equip them necessary technological equipment and devices and instruct craners and soloers relative to the order and dimensions of the storage;

Ensure the implementation of projects for the production of works and other technological regulations in the production of works by cranes;

Provide a good condition of tower cranes located on a construction site in non-working condition. After receiving the message from the Customer on the end of the work (before the start of dismantling), disconnect the crane from the power supply and take measures to prevent the factor in the wind.

15. In order to safely perform work on the movement of goods by cranes, their owner and the manufacturer of work are required to ensure compliance with the following requirements:

At the site of the production of works on the movement of goods, as well as on the crane, there should be no foundation of persons who are not directly related to the work performed;

The entrance to the bridge cranes and the descent from them should be made through the planting platform or in some cases through the passage gallery;

If necessary, inspection, repair, adjustment of the mechanisms, electrical equipment of the crane, inspection and repair of metal structures dol wives disconnect the switch of the introductory device. This requirement should also be performed if necessarystil bridge crane gallery;

- on the bridge cranes, in which the rails rails are located at the level of the gallery flooring, before the service of the service personnel on the gallery, the trolley should be installed in the immediate vicinity of exiting the cabin to the flooring.Construction and installation work must be carried out on the project manufacturing with cranes in which:

The compliance of cranes established by the conditions of construction and installation work on carrying capacity, lifting height and departure (cargo characteristic of the crane);

Ensuring safe distances from networks and air lines of power transmission, locations of city transport and pedestrians, as well as safe distinct distances of cranes to buildings and places of storage of construction parts and materials;

Conditions for the installation and operation of cranes near the slopes of the kittlers; conditions safe work several cranes on one way and on parallel paths;

The list of used loading devices and a graphic image (diagram) of cargo lines;

Places and dimensions of warehousing of goods, driveways; Activities for safe work of work, taking into account specific conditions on the site where the crane is installed, as well as other security measures provided for by SNiP.

Loading and unloading and warehousing of goods at bases, warehouses, platforms must be performed by technological cards, designed taking into account the requirements of GOST 12.3.009-76 "SSBT. Works loading and unloading. General requirements security "and approved in the prescribed manner:it is not allowed to lower the load on the car, as well as lift the goods while finding people in the body or cab cabin. In places of constant loading and unloading of cars and gondolas, overpass or mounted plates for soloers should be installed. Loading and unloading of gondolas with hook cranes should be carried out using the technology approved by the manufacturer of work in which the locations of the solutions must be identified when moving goods, as well as the possibility of youstroke they are on the overpass and hinged platforms. Finding people in the semilesss when lifting and lowering cargo crane is not allowed; Moving the cargo should not be made when people under it. The slings may be located near the cargo during its rise or lowering, if the load is raised to the height of not more than 1000 mm on the level of the site;

The lines of goods should be made in accordance withcXE. mami stopping. For the lining of the cargo intended for the lifting, the slings corresponding to the mass and nature of the lifting goods are applied, taking into account the number of branches and the angle of their inclination; General destination slings should be selected so that the angle between their branches is not exceeded 90 degrees;

The movement of small cargoes should be made in a specifically for this purpose, the possibility of loss of individual goods should be excluded. Lifting bricks on pallets without fence is allowed to produce during loadingand unloading (on land) vehicles;

Moving the cargo, the mass of which is unknown, should be taken only after determining its actual mass;

Cargo or a lifting device when they are horizontalmovement must be pre-raised by 500 mm above the objects of objects;

When moving the boom self-propelled crane with the load, the position of the boom and the load on the crane should be installed in accordance with the instruction manual;

It is allowed to lower the moved cargo only on the place intended for this, where the possibility of falling, tipping or splitting the installed cargo is excluded. The lining of the appropriate strength must be pre-furnished in the installation site in order for the slings to be easily and without damage removed from under the cargo. Installing the cargo in places, for this not intended, is not permitted. The laying and disassembly of the cargo should be performed evenly, without breaking the dimensions established for the storage of cargo and not cluttering passes. Laying of cargo in the half-haul, on the platform should be made in accordance with the established standards in coordination with the consignee. Loading cargo in cars and other vehicles should be made in such a way that it is provided with a convenient and safe lines of it when unloading. Loading and unloading of gondolas, platforms, cars and other vehicles must be carried out without disrupting their equilibrium;

It is not allowed to find people and carry out any work within the movement of goods with cranes equipped with a grab or magnet. The utility workers serving such cranes can be allowed to fulfill their duties only during breaks in the operation of the cranes and after the grab or magnet will be published on the ground. Places of production of work with such cranes shouldbe fenced and indicated by warning signs;

Not it is allowed to use a grant for lifting people or performing work for which the grab is not intended;

By the end of the work or in the break cargo should not remainin suspended state and voltage switchon the the main trolls or flexible cable must be turned off and locked on the lock. Upon completion of the operation of the tower, portal, gantry crane and bridge overhead, the control cabin must be locked, and the crane is strengthened by all anti-theft devices on it;

Cant cargo cranes should be carried out using special devices (tilters) and in specially designated places. The execution of such work is permitted only by a predetermined technology that determines the sequence of operation of the operation, the method of lining the cargo and the instructions for the safe production of work;

When the bridge cranes installed in several tiers should be carried out by the condition of the cranes of the upper tierover cranes located below, only without cargo with a hook raised in the upper working position;

When lifting the cargo, it must be pre-raised to a height of no more than 200-300 mm to verify the correctness of the slingand reliability of brakes;

When lifting the cargo set near the wall, columns, stacks, railway car, the machine or other equipment, there should be no foundation of people between the raised cargoand specified parts of the building or equipment; This requirement should also be performed when lowering and moving the cargo.

16. When working the crane is not allowed:

Entrance to the crane cockpit during its movement;

Finding people near the working boom self-propelled crane in order to avoid clamping them between the rotary and non-turning parts of the crane;

Moving the cargo located in an unstable position or suspended for one horn of the counnogo hook;

Moving people or cargo with people on it. Lifting people with bridge type cranes can be made in exceptional cases provided for by the instruction manualcrane attation, and only in a specially designed and manufactured cabin after developing measures to ensure the safety of people. Such work should be made according to a special instruction agreed with the technical supervision authorities;

Lifting the cargo, filled with land or approached the Earth, laid by other goods, reinforced with bolts or otherwise, bolted with concrete, as well as metal and slag, frozen in the furnace or welded after plum;

Loading the cargo on the ground, floor or rails with a crane hook with the inclined position of cargo ropes without the use of guide blocks that provide the vertical position of cargo ropes;

Liberation with a tap of roped lines, ropes or chains;

Tightening the cargo during its lifting, moving and lowering. For the reversal of long and large-sized cargo during their movement, hooks or deficing of the corresponding length should be used;

Alignment of the moved by hand by hand, as well as amendments for weight lines;

Supplying cargo to window openings, balconies and loggia without special receiving platforms or special devices;

Using end switches as working bodies to automatically stop mechanisms, except for the case when the bridge crane is suitable for the landing site arranged in the end of the building;

Work with disconnected or defective devices safety and brakes;

The inclusion of crane mechanisms while finding people on the crane outside its cabin. Exception is allowed for persons leading inspection and adjustment of mechanisms, electrical equipment and safety devices. In this case, the mechanisms should be included by the Signal of the Inspection Face;

Lifting the cargo directly from its place of installation of the boom winch, as well as the mechanisms of lifting and telescopic boom;

Landing in container raised by the crane, and finding people in it;

Finding people under the arrow of the crane when it is climbing and lowering without cargo.

17. Manufacture of work with rifle self-propelled cranes at a distance less than 30 m from the lifting retractable part of the crane in any position, as well as from the load to the vertical plane, formed by the projection to the land of the nearest wire of airing transmission, which is energized more than 42B, should be carried out by - Dopupus defining secure Conditions Work.

The procedure for organizing the production of works near the power line, the issuance of outfits and admission and briefing of workers should be established by the orders of the owner of the crane and the manufacturer of work. The safety conditions specified in the outfit must comply with GOST 12.1.013-78 "CSBT. Construction. Electrical safety. General requirements." The time of action of the outfit-tolerance is determined by the Organization issued an outfit. The outfit must be issued to crane drivers before starting work. The crane driver is prohibited by the unauthorized installation of the crane for working near the power line, which is being recorded in the track sheet.

The work of the crane near the power line should be made under the direct guidance of the person responsible for the safe production of cranes, which must also specify the crane factor in the crane installation, ensure the execution of the work provided by the outfit and to record the work of the crane driver on the resolution of work.

In the manufacture of work in the security zone of the power line or within the gaps established by the rules for the protection of high-voltage electrical networksThe outfit tolerance can only be issued if there is an organization's permission that operates the power line.

When operating boom self-propelled cranes on existing power plants, substations and power lines, if working with cranes is conducted by personnel operating electrical installations, and craners are located in the state of energy organization, the outfit to work near the conductive wires and equipment is issued in the manner prescribed by industry standards.

The operation of the boom self-propelled cranes under the non-connected contact wires of urban transport can be carried out when the distance between the crane boom and contact wires are at least 1000 mm when installing the limiter (stop), which does not allow to reduce the specified distance when lifting the arrows.

The order of the cranes near the power line made by a flexible cable is determined by the owner of the line.