Water heating in a wooden private house. The best options for heating a wooden house with electricity. Distinctive features of pumping systems

In Russia, severe cold sets in during the winter, so having high-quality water heating in a private home is simply necessary. This system has superiority over the others, since over all the years it has already managed to show its best side. Stove and fireplace heating today are no longer so efficient - this is just a tribute to our rich history.

In a cold and snowy winter you can’t do without heating...

The principle of operation of water heating

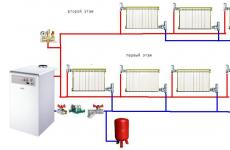

Water heating of a private home has gained such popularity because it is essentially a simple mechanism. There is a closed circuit where the boiler heats the water to the required temperature, the water goes through the pipes to the radiators or radiators in the rooms and gives off heat, after which it returns back to the boiler.

Water heating circuit

In addition to the main elements - boiler, pipes and radiators, the system may also include additional ones. The expansion tank serves to drain excess water that appears during heating. Also, thanks to the tank, there is no oxygen in the system. Another element is the circulation pump. This device serves to maintain a continuous circulation of water in the system; with the help of such a pump, the rate of heating the room temperature increases due to the fact that the water moves faster. The system may also include a pressure gauge, thermostat, air vent, and safety valves.

Choosing heating equipment in a private house

The most important equipment that properly provides water heating in a private home is a boiler.

When purchasing a boiler, a power value of 1 kW per 10 sq.m of space that is heated is usually accepted.

It is also taken into account that the ceiling height is taken to be no more than 3 meters. In addition, the volume of the room, the level of insulation of the house itself, the size of the windows and additional heat consumers are taken into account.

So, given the area that is heated, the boiler power will be equal to:

- 60 – 200 sq.m. – up to 25 kW;

- 200 – 300 sq.m. – 25-35 kW;

- 300 – 600 sq.m. – 35-60 kW;

- 600 – 1200 sq.m. – up to 100 kW.

To equip water heating in a country house or in a private house, you can choose an electric boiler with an area of 30-1000 sq.m. power 3-105 kW. But electric boilers have disadvantages - the high cost of electricity, constant interruptions and fluctuations in electricity, and insufficient power.

Electric boiler

The pipeline must also be selected carefully. Pipes made of different materials are used, each of which has its own advantages and disadvantages. In the old days, steel pipes were the most common. But today they are used less often. After all, such pipes are more susceptible to corrosion processes.

That is why nowadays stainless steel or galvanized pipes are more often used.

Copper pipes are also gaining popularity. They are able to withstand high temperatures and are durable in themselves, which is why copper pipes are the most reliable. But they are not cheap either. In addition, recently it is increasingly possible to find water heating in a wooden house with polymer pipes. Such pipes are made of metal-plastic or propylene (with the participation of aluminum). Pipes made from such materials are durable, resistant to corrosion, and no sediment is deposited inside them. But they have a fairly high coefficient of expansion when heated.

Piping the boiler with copper pipes

What are the heating schemes for a private house?

Water heating schemes for a private house can be single-circuit or double-circuit. A single-circuit system serves only to heat the room. This is a simpler and less expensive system that is suitable if you have a house with an area of up to 100 square meters. Such a system includes a single-circuit boiler and atmospheric exhaust, single-pipe distribution with pipes made of steel or polymers, cast iron, steel or aluminum radiators.

Single-circuit and double-circuit water heating system

A single-circuit heating system can be improved by using two-pipe wiring, adding a circulation pump, and thermostatic valves on radiators.

If you want to equip a single-circuit system for heating water for domestic needs, then reconsider the installation of a gas water heater or boiler. In another case, you can make a dual-circuit system, which is designed not only for heating, but also for heating water.

A double-circuit water heating system for a private house is a very convenient option.

Here the boiler is comfortable for hot water needs for a family of no more than 4 people. The water must be tap or softened; hard water from a well is not suitable. You can equip two single-circuit systems, the first of which will be “responsible” for heating the premises, and the second – for heating the water. Thanks to this system, in the summer you will only use the water heating system, and only 25% of the boiler power is spent on it.

Pipe routing

A water heating system for a private house involves the use of three piping options - a single-pipe system, a two-pipe system and a collector system.

A single-pipe system is a system where the heated coolant (water) from the boiler sequentially flows from one battery to the next. Such a system has one big drawback - it is very difficult to control the wiring, since when water access to any of the radiators is blocked, the others are also blocked.

Single pipe system

In a two-pipe system, each radiator has a hot and cold water pipe. So, with such a system, water heating at home can be regulated very conveniently.

Two-pipe heating system

Another system is a collector system. It is also called radial. Here the mechanism works in this way: from the collector (which is a device that collects water) two pipes are supplied to each heating device - forward and return. Thanks to this, you can simply install a system with hidden pipe wiring, you can maintain a certain temperature regime in a separate room and regulate it.

If you have a two-story house

Today, water heating schemes for a two-story house are very different. This can be a collector system or a two-pipe distribution. Single-pipe wiring (one in which the radiators are connected in series) is now less commonly used for both water heating schemes for a one-story house and a two-story house.

A two-pipe scheme for a two-story house is a universal and practical option.

Each heating device has two pipes for supplying and discharging water. Experts advise doing this: install a control valve in front of each radiator.

A collector circuit in a two-story house is quite an expensive proposition. Water heating of a two-story house with such a system, despite this, is also popular. After all, there is a clear advantage here - the installation of the pipeline is hidden, so the interior does not deteriorate. In this case, the boiler is placed on the first floor, the expansion tank on the second. The pipeline is located under the floor, ceiling or window sills, so there is an excellent opportunity to hide it.

The collector system is also very effective because there is a control valve installed on each radiator. This is very convenient, since depending on your needs you can set your own climate.

Collector heating system of a two-story house

Alternative methods of water heating of a private house

In addition to traditional heating using a heating boiler, there are other types of water heating for a private home. Such modern systems are effective as the main heating systems of a house, or additional ones.

Very often today you can hear such a phrase - “warm floor” system. In principle, heated floors are the same water heating of private houses, which can also be used as an addition to the main heating. Warm floors have advantages - there is a large heat transfer area. Indeed, in this case, the floor of the room is practically a large radiator. And the air warms up correctly in this way - it’s warm below, and a little cooler above.

Warm water floor

Thanks to the heated floor system, you can reduce the operating temperature of the coolant (no more than 55 degrees Celsius). You can also set the thermal power within the required limits.

The disadvantages of a heated floor system are that such a system is difficult to install, and if the renovation is already completed, this is impossible, or you will have to raise the floor or deepen it.

Another option for alternative water heating is baseboard heating. In fact, baseboard water heating of houses is a cross between a radiator system and a heated floor. In this case, heating equipment is placed around the perimeter of the room at the baseboard level. Thanks to this, both the walls and the floor are heated evenly. The air in the room is also uniform. With such a system, water heating of a country house or private house will allow you to furnish the interior without large radiators, and all this without heat loss.

Baseboard heating

Conclusion

Thus, before you decide to install water heating in your private home, you should choose the appropriate option - traditional heating using radiators or modern methods. Each system has advantages and disadvantages, so when designing heating it is best to invite specialists who will be able to take into account all the details.

Previously, the main source of heat in the house was the Russian stove, but now times are completely different. Today, owners of country houses and cottages can purchase modern equipment with good power and performance. Heating in a wooden house is arranged in different ways, because the choice of technologies and equipment is huge. We will look at the most common options.

Gas heating is a popular method

If it is possible to connect to a main pipeline, using natural gas would be a profitable solution. This type of fuel is the most economical because its cost does not greatly affect the budget. To organize a complete system, you need to purchase a boiler that will heat the coolant, metal-plastic pipes, radiators, expansion tank, circulation pump, shut-off and control valves, and fasteners. Also, we must not forget about the safety group, consisting of a safety valve, an air vent, and a pressure measuring device. It is located in close proximity to the boiler and exercises control, ensuring trouble-free operation of the system.

Gas heating must be installed by specialists, because there are many nuances in this process

Gas heating in a wooden house has many advantages:

- efficiency – heating equipment has high efficiency and has excellent technical characteristics. The boilers are equipped with automation, which greatly simplifies the operation process. The range of equipment is huge, so owners of private housing can select boilers according to several criteria: dimensions, power, type of heat exchanger, design features (closed and open combustion chamber), design (floor and wall);

- main gas practically does not pollute the environment, and combustion products are removed using a chimney;

- reliability – the system is equipped with automatic devices that react with lightning speed to emergency situations;

- complete autonomy - there are boilers whose operation does not depend on the electrical network.

Heating a wooden house with gas is always popular, despite the presence of certain disadvantages. Disadvantages include strict fire safety requirements. First of all, we mean the arrangement of a separate room in which the equipment will be located.

This is important to know: wood is affected by temperature changes. For this reason, “sliding” fastenings and compensators are used during installation work.

What are the benefits of electric heating?

Bringing a highway to a site is expensive, so many homeowners are looking for other options. The use of liquid fuel boilers is not suitable for everyone, because a special container is needed to store diesel fuel. But heating a wooden house with electricity is a worthy solution to the problem. What is the rationale for this? There are many arguments:

- boilers operating on electrical energy have a number of significant advantages. This includes operational safety, compactness, efficiency, noiselessness, and environmental friendliness. Electric boilers fit perfectly into the interior as they have an elegant appearance. In addition, the equipment is equipped with automation. With the help of “smart” devices, the temperature in the rooms is regulated, energy saving is ensured and control is carried out from a distance;

Electric boiler "Dakon Daline PTE" connects to any heating systems

- water heating - double-circuit boilers are used for this purpose;

- large selection of radiators - heating batteries for a wooden house are presented in a wide range: aluminum, steel, bimetallic. Leading manufacturers pay close attention to product quality and develop interesting ideas. Aluminum batteries last a long time and have fast heat dissipation. Steel radiators are affordable, while bimetallic ones can withstand high pressure.

When considering options for heating a wooden house with electricity, you need to say a few words about the use of heaters. Basically, electrical appliances are used as additional sources. They are classified according to the nature of heat transfer. Electric heating in a wooden house is provided using different heaters:

- Oil radiators - they do not irritate the respiratory system.

- Convectors are portable devices whose operating principle is based on the passage of air from the bottom panel to the top through a heating element.

- IR devices are heaters that have a positive effect on the body.

Convectors "Zilon" take up minimal space and provide instant heating

Heating with solid fuel is a proven method

If there is no gas main nearby, and electricity is not suitable due to the high cost, there is no need to worry. Heating a wooden house using a boiler that runs on wood or coal is an excellent option. For many years, our ancestors used these types of fuel to create a comfortable atmosphere in their homes. Therefore, there is nothing shameful here.

It is worth paying attention: it is better to entrust the installation of heating in a wooden house to specialists with relevant experience and knowledge. But if a person has practical skills, he can do everything on his own.

Solid fuel boilers of the Buderus brand are suitable for use in gravity and pump systems

The heating system in a wooden house is installed in several stages:

- project development - a series of calculations are performed, power and other parameters are determined;

- selection of equipment, materials, components;

- preparation of the boiler room - this room must comply with safety standards;

- boiler installation;

- laying a pipeline - the heating circuit in a wooden house can be single- or double-circuit;

With double-circuit wiring, two pipes are supplied to each heating device: with cold and hot water

- installation of radiators - devices are mounted in the wall and connected to the pipeline;

- commissioning - the system is checked for leaks.

This heating option is a completely autonomous system, so it is widely used in areas where there are problems with gas and electricity. Solid fuel boilers are conventionally divided into four groups: pyrolysis, classic, universal, long-burning.

The heating system for a wooden house with a solid fuel boiler is often used, because modern equipment has significant advantages:

- safety;

- reliability of operation;

- long service life;

- controlling the combustion process.

This is important to know: such boilers have some disadvantages. We are talking about periodic reloading of fuel and the need for a room for storing firewood, coal or pellets.

Gas holders are a good alternative

How to heat a wooden house if it is not connected to a central gas supply system? There is a worthy answer to this question: you need to use a metal tank designed for storing liquefied propane-butane. Such containers are made of high-strength steel coated with an insulating agent. Shut-off and control valves are installed on the top cover of the tanks, consisting of a fill level indicator and valves.

Heating a wooden house using a gas holder is an excellent solution, because such a system is completely autonomous. Other advantages should also be mentioned:

- safety – metal tanks are certified for use in our country;

- good performance - gas tanks are installed in a horizontal position, which increases the area of fuel evaporation;

- aesthetics - the container is located underground. The tank lid can be decorated with artificial stone;

- a gas holder for heating a house is best suited because it does not require frequent refueling;

- environmental friendliness - when using steel containers with fuel, the environment is not heavily polluted.

This is important to know: installation and regular maintenance of tanks must be carried out by qualified specialists.

Gas holder heating - reliable, affordable and safe

The disadvantage of this method is the high cost of equipment and installer services. But if people have no other choice, this method is quite acceptable.

Regardless of the chosen option, to ensure that the system functions stably and there are no unpleasant surprises, it is better to entrust the heating installation in a wooden house to professionals. Specialists use time-tested schemes, select high-quality materials and perform their work competently.

Video: heating a wooden house

The main element of the heating system in a private house is the boiler. Despite the increased popularity of fireplaces and Russian stoves in country wooden houses, they are mainly used as an additional source of heat.

The heating system can be of various types: gas, liquid fuel, solid fuel, electric. If there is a gas main in the village, users give preference to boilers that run on gas fuel.

Heating gas boiler:

- has high efficiency;

- is economical;

- does not always require the equipment of a special boiler room;

- is easy to use;

- does not require labor-intensive care.

The use of a liquid fuel boiler requires the installation of an area for placing containers with diesel fuel, as well as the presence of a road for the access of special vehicles. The operation of solid fuel devices is extremely labor-intensive. It is necessary to manually load firewood or coal, and also carry out regular cleaning yourself. To store fuel reserves, it is necessary to equip a special place or outbuilding. In addition, solid fuel and liquid fuel boilers must be installed in an insulated boiler room.

Electric boilers are easy to use. Equipment can be installed in the kitchen, hallway, or bathroom. But in order to heat a large country house, considerable expenses will be required. To summarize, I would like to say that in our country the most common and profitable fuel is gas.

Qualified installation of heating in a wooden house

Our company’s specialists have been installing communications in wooden houses for decades. We know about all the nuances associated with the installation of a heating system in log buildings. The heating installation service in our company includes a full range of works:

- development of a design scheme taking into account standards;

- calculation of the required boiler power;

- selection of equipment and consumables;

- installation, installation of equipment;

- system launch, testing.

It is very important that the design of the project is carried out by engineers. This will allow you to take into account all the nuances of a country house, calculate the required power and list of equipment, eliminating unnecessary expenses. Installation of the system should also be carried out by professionals who have experience working in wooden houses. Only a competent and responsible approach to the issue can guarantee the reliability and durability of the heating system in your wooden house.

You can place an order for the service at any office of our company (Moscow, Krasnodar, Kirov); we install communications in wooden houses throughout the Russian Federation.

Until recently, heating in a wooden house was organized using a brick stove. It was this that was the main source of heat and was almost the main place inside the building.

Today everything has changed a lot. Thanks to the active development of technology, any owner of a wooden house will be able to implement a heating system that will satisfy all his needs. The main thing is to know what to choose and what nuances to pay attention to.

First of all, the house can be heated using an autonomous structure with forced or gravitational (natural) coolant circulation. Each of these methods has its own advantages and disadvantages. In addition, there are situations when it is better to use one or another variety.

Advantages and disadvantages of natural circulation

Gravity pumping is entirely based on the laws of physics. More precisely, the coolant moves through the pipeline due to the difference in weight between cooled and heated water.

A hot liquid has a much larger volume, but much less mass. Accordingly, it rises up the riser, moves further through pipes that are laid at an angle, and is pumped into heating radiators, where it is cooled.

Before making a final choice in favor of a certain type of fluid circulation in the system, you need to consider the pros and cons of each heating option

The list of advantages of such a solution should include ease of installation. A system with natural circulation lasts much longer and is stable. At the same time, the absence of a pump allows you to get rid of excess noise and ensure independence from the availability of electricity.

As for the disadvantages, this kind of solution can only be used when heating a small house. In addition, the system requires laying large-diameter pipes, which significantly increases the cost of organizing a home heating system.

When choosing natural circulation, you need to take a responsible approach to installation - errors will lead to a serious decrease in the speed of pumping the coolant

Distinctive features of pumping systems

To make water move faster through the pipes, it is cut into the heating system. With its help, you can move the media with virtually no loss of temperature. As a result, a wooden building warms up much faster, which saves a considerable amount of fuel.

The main advantage of forced circulation is that the area of the heated house can be practically unlimited. At the same time, the owner is given the opportunity to control the amount of heat and the speed of the pump. The disadvantages of this solution are the dependence of the system on the availability of electricity and the high noise level of the equipment.

When installing a heating pump, you can use pipes of small diameter. This allows you to save on the purchase of plumbing fixtures

Types of thermal media

To transfer heat from the generator to the heated room, water is most often used, which has been heated to a certain temperature and circulates through a pipeline.

Today, this is the most affordable and simple solution. Correctly, you can organize a high-performance system that does not require any special care.

In addition to water heating, in a private wooden house the following is used:

A combination option is also often used. A well-designed scheme makes it possible, without spending a lot of money, to build a system that will completely warm up the house in a matter of hours.

If water is used as a heat transfer agent, it must first be filtered. This will significantly increase the service life of heating equipment

Criteria for choosing a heat generator

There is simply a huge selection on the market - domestic and foreign manufacturers offer a wide variety of models. From such an assortment, a buyer with any income level will be able to choose something for himself.

In order not to make a mistake when buying a boiler, you need to check what type of fuel is most available in the region. It is also important to correctly calculate the power of the equipment.

Advantages of gas units

The vast majority of owners of wooden houses opt for gas equipment.

The popularity of wall-mounted ones is due to the fact that such fuel is one of the cheapest in many countries. In addition, with its help you can organize a completely autonomous and maintenance-free heating system.

The list of advantages of gas boilers needs to be supplemented:

- High efficiency. Even a low-power device generates more heat than its counterparts running on other types of fuel.

- Easy to use. No need to worry about where the fuel will be stored. At the same time, using such equipment is easy - you only need to set it up once.

- Durability. A high-quality gas unit will last at least 15 years.

The main disadvantage is the need to obtain special permission to install it. All other disadvantages are completely offset by advantages.

If you need to heat a large house with an area of more than 100 m2, then it is better to refuse a gas boiler. In this case, it will be an economically unprofitable solution

Diesel component in the system

Diesel-powered equipment has become increasingly popular over the past few years. First of all, they are cheap to maintain and easy to install.

At the same time, there is no need to organize a complex chimney design - many models run on light heating oil. The only thing required is to organize the pipe outlet in the form of a sandwich. It has a special turbine that pushes out air.

If you have decided to install a diesel boiler, you need to understand that this heating method will be expensive. After all, the efficiency of this equipment varies from 75 to 85%, which is a rather low figure.

Also, a diesel-powered unit requires constant monitoring. If it is left for at least a week, it will lead to problems. Indeed, due to the low quality of fuel, the equipment may stop. As a result, the water in the pipes will freeze and burst.

Even despite all the advantages of a diesel device, it should only be installed if this is the only available way to organize a heating system

Solid fuel boiler

This type of equipment is as popular as gas equipment. Great demand is due to the efficiency and environmental friendliness of solid fuel boilers. After all, such a device is the cheapest device to operate. At the same time, it burns renewable fuel and is highly energy efficient.

There is an impressive selection on the market. Savings in this matter are not always justified - having decided to buy the cheapest model, you need to be prepared for the appearance of soot, soot and come to terms with the need for frequent cleaning.

The only disadvantage of solid fuel boilers is the need to allocate space for storing fuel, which is required for its operation quite a lot

Electric heat generator

Equipment that uses current in its operation is the only solution for those regions where centralized communication systems are not installed. Most often it is used as an additional option.

Today, manufacturers offer a wide range. Models with power from 6 to 30 kW are available on the market. Such a wide range of performance allows you to order the device for a wooden house of any size.

Advantages of the equipment:

- small dimensions;

- operational safety;

- complete autonomy;

- cheapness;

- Efficiency approaching 100%.

But keep in mind that electricity is the most expensive energy carrier. Therefore, even despite the low cost of the unit, operating such a system will be expensive.

Electric boilers are completely safe for a wooden house. But to avoid problems, you need to install a meter and select a cable with a calculation of 8 amperes per 1 mm 2 of its cross-section

Power calculation rules

To determine the optimal performance of the boiler, it is not at all necessary to seek help from a specialist. To do this, you only need to determine the amount of heat loss. Knowing this value, it must be multiplied by the area of the house and the resulting number will be the required power.

If the building is not insulated in any way, then heating one square meter will require from 130 to 200 W. For buildings with old windows and a facade that is covered with material that does not allow cold to pass through, the optimal value will be 90-120 W/m2.

As for houses with good thermal insulation of attic and basement floors, plastic double-glazed windows, insulated doorways, properly arranged air exchange, then 50-80 W/m2 will be enough to heat them.

Subtleties of radiator selection

Radiators are one of the most important components of the system. After all, they distribute heat throughout the living space. Therefore, their choice should be taken with full responsibility, and not buy the first product you come across.

Batteries are divided into categories depending on their design and the material from which they are made. Since a wide assortment can drive an unprepared buyer into a dead end, before going to the store it is necessary to understand the advantages and disadvantages of each type.

Aesthetics of aluminum structures

Such products appeared in Italy more than 35 years ago. Since their invention, heating systems have immediately become popular and won the recognition of professionals.

When choosing a heating radiator, first of all you should familiarize yourself with the material of the sections. The heat transfer of the battery, its service life and weight depend on it

And this is not at all surprising, because these structures are distinguished by their lightness, high heat transfer, and attractive design. But they are poorly resistant to corrosion and are susceptible to airing.

Aluminum batteries can be cast or extruded. The first type is a monolithic structure, and the second is a blank formed by a press, from which finished products are subsequently cut.

Cast structures are considered more reliable and durable. In other respects, their analogues are in no way inferior to them.

Aluminum batteries are relatively lightweight. This makes them easy to transport and connect, something you can do yourself

Panel steel radiators

Steel is an excellent heat conductor. Therefore, batteries made from it are considered the most effective and are recommended for installation by all specialists. In addition, they are a monolithic structure, which greatly simplifies installation.

Provided they are used in a house or country house with an autonomous heating system, they have no disadvantages. If all recommendations are followed, the service life can reach 30 years.

Batteries of this type are often supplemented with heat exchangers. But this in no way affects the appearance of the structure.

Good old cast iron

Cast iron radiators were first used more than a century ago. But even today they have not lost their relevance and are actively installed in heating systems.

The reason for this is its ease of maintenance and simply enormous service life - cast iron will faithfully last for about 50 years. At the same time, it retains heat well. The products take a long time to heat up, but after turning off the heating they will heat the room for a long time.

Taking into account all their advantages, they have only one insignificant disadvantage - it is heavy. Thus, the weight of one section can reach 6 kg, and the weight of the entire battery can be 36 kg.

Even in comparison with bimetallic and aluminum products, cast iron structures are a good and universal solution with many advantages

Tubular radiators made of steel

Tubular batteries, as a rule, are classified as products in the highest price segment. They fully comply with all quality standards and have a number of advantages over their analogues.

First of all, such structures can easily withstand sudden changes in pressure, and in the event of a heat cut, the battery will not become air-filled.

Also, tubular radiators have a smooth surface both outside and inside. Thanks to this, they have an attractive appearance, due to which they will harmoniously fit into any interior.

Tubular radiators made of steel are an expensive proposition. But at the same time, they last for about a quarter of a century, which completely pays for the costs.

Modern bimetallic structures

These types of batteries are made from an alloy of aluminum and steel. These metals have completely different characteristics, and as a result of their combination, a material with excellent performance is obtained.

More precisely, these radiators show high thermal conductivity and can easily withstand water hammer. Provided that they are well assembled, they last about 50 years. But they are quite expensive.

Even despite the high price, it is better to spend money once and buy a bimetallic radiator from a reliable supplier. Thanks to its long service life, it will fully justify the investment.

Built-in floor convectors

This heating device is a tube made of copper and aluminum through which the coolant moves. The main advantage is the ability to build them directly into the floor.

In this case, the structure does not take up precious residential square meters, but at the same time warms the building well. The only thing that comes out is the decorative grille or panel.

If installation is carried out incorrectly, drafts may form inside the room. In addition, you need to carefully monitor the cleanliness of the heating element - air flows carry dust well.

It is better to choose a floor convector made of copper, steel or aluminum. In this case, the structure will last a long time, and the house will warm up almost instantly

Heating system piping

The main task of the pipes is to transfer the coolant from the boiler to the radiators. There are many types of them - they are divided into categories depending on the material.

Pipelines are:

- polymer;

- steel;

- copper.

The latter variety is resistant to high temperatures and high pressure. Currently, copper pipes are the most reliable and safe. Thanks to this, they can be hidden in the wall. But they are quite expensive.

Nowadays, heating pipelines are most often assembled from metal-plastic or polypropylene products. They are characterized by ease of installation and resistance to corrosion. The elements are connected to each other using soldering. Their disadvantage is their low hydraulic resistance.

To install a steel pipeline, it is necessary to hire a welder - it will be problematic to cope with the work yourself. In addition, such structures are susceptible to corrosion.

Drawing up a heating scheme

Since water is predominantly used as a heat carrier, the schemes discussed below will be based on this factor. The essence of this kind of heating system for a wooden house is that the liquid is heated in a boiler and passes through pipes into radiators, where it is cooled. Next, the water returns to the heat source.

Installation of a one-pipe system

The choice of scheme largely depends on whether a system with gravity or forced coolant pumping is used. In addition, when drawing up a project, you need to take into account the number of circuits.

When organizing a single-pipe building heating system, it is almost impossible to regulate the temperature. It will be different in any case. The farther from the boiler, the lower the temperature

The advantage of creating one heating circuit is ease of installation. If you stick to the plan, you can quickly get the job done without involving a professional.

The single-pipe system allows you to save plumbing fixtures. And in order to maximally equalize the temperature throughout the entire circuit, it is necessary to increase the number of radiator sections that are connected at the end. To speed up the water flow, it is recommended to install a pump.

You should choose a single-pipe system only if it is possible to install the boiler below the level of the radiators. Otherwise, water will not circulate through the pipes

Subtleties of organizing two-pipe heating

A system with two circuits allows you to maintain the same temperature in all radiators, which will have a beneficial effect on heating efficiency. The disadvantage of this solution is the high consumption of materials.

The diagram of a two-pipe house heating system is also suitable for heat generators that run on solid fuel. The only thing that needs to be adjusted in this case is the pipeline material

When implementing a two-pipe project, each radiator must be equipped with shut-off valves. Such elements will allow you to adjust the temperature in each room.

If the boiler will be installed in the basement, then the best choice is a system with bottom wiring (the diagram is presented below). This solution is ideal for wooden houses where a gas boiler is used as a heat generator.

Conclusions and useful video on the topic

Video #1. Organization of a simple inexpensive boiler room:

Video #2. Heating a wooden house with an area of 120 m2:

Video #3. Nuances of pipeline laying:

The heating system is the heart of any home. Therefore, the owner of the building is faced with the task of competently designing and correctly installing such an important element. If you put in a little effort and take into account all the tips given above, then installing a heating system will not cause any connection difficulties or operational problems.

Tell us about how you built a heating circuit in your own wooden dacha or in your permanent home. Share useful information that may be useful to site visitors. Please write comments, post photos, ask questions in the block below.

They are becoming increasingly popular due to their availability, speed of construction and ability to create a unique microclimate. Such housing will provide coolness in summer and warmth in winter, if the shrinkage of the house was correctly taken into account when designing the heating system.

Options and features for installing heating in a wooden house

When laying communications, it is necessary to avoid damage to elements of supporting structures so as not to disturb the uniform distribution of loads of walls, floors and roofs. It is also necessary to avoid direct contact of very hot and condensate-covered pipes with wooden surfaces. To do this, insulation is performed both , and . This simple action helps prevent drying or excessive moisture in the wood.

Coolant in the heating system of a private house

The most popular is the one, which is characterized by efficiency, ease of maintenance and long service life. The coolant fluid, circulating through the pipe circuit, brings heat to the heating devices and returns. Water is most often used as the working heating medium. But such a coolant is not suitable for houses that are used as temporary suburban housing for weekends or holidays. When leaving, the heat generator must be turned off. To prevent pipes and radiators from being destroyed in cold weather, you will have to regularly empty and fill the system. This is not only inconvenient and takes up a lot of time that could be spent heating cold rooms, but it is also harmful to the equipment. Fresh water is rich in salts and oxygen, which are the main sources of corrosion and solid deposits on the walls of pipes and heat exchanger.

The way out of the situation would be to use non-toxic antifreeze based on propylene glycol, which retains its properties under strong cooling. Such a working environment is designed to last up to 10 heating seasons, which fully justifies the initial costs. In this case, there is no need to fill the pipes with pure antifreeze; it is enough to use its mixture with water. The proportions of the composition are determined by the actual climatic conditions and maximum winter temperature:

- down to -20C (65% water, 35% antifreeze);

- up to -25C (60% water, 40% antifreeze);

- down to -30C (55% water, 45% antifreeze);

- up to -35C (50% water, 50% antifreeze).

If the mixture for the heating system contains 55-70% antifreeze, the liquid does not freeze at temperatures below -45-65C, which is more than enough even for northern regions.

The main disadvantages of antifreeze coolant include its reduced heat capacity compared to water (by 15%), expansion ability, increased viscosity, fluidity and aggressiveness towards rubber, which is why all detachable connections must be sealed with special stable gaskets. In addition, it is necessary to use boiler equipment that technically provides for the use of an antifreeze solution, more powerful batteries, and abandon some types of polymer and galvanized ones. At the stage of designing heating in a private house, all these issues can be easily resolved and make it possible to obtain a heating system ready for use.

Schemes and installation of heating a wooden house

Heating systems can be with natural (gravity) or forced circulation of the working environment. In the first case, the laws of gravity and the temperature difference between the heated and cooled coolant are taken into account. In the second, the liquid moves due to pressure pumped by a special circulation pump. To deliver heat to heating devices, single-pipe or two-pipe circuits are used.

Scheme of a single-pipe heating system

To better understand the efficiency and working principle single pipe heating system, let's consider its installation using the example of a wooden house with several floors. Let us immediately clarify that the presence of a single circuit provides for the rise of hot water to the highest point of the system due to its lower density and mass compared to the cooled liquid. This provides the initial impulse for gravity flow. Moving along the main line, the coolant sequentially passes through the heating devices, giving each part of the accumulated heat. The uneven distribution of thermal energy between the upper and lower floors is immediately noticeable. For a small one-story wooden house this difference is insignificant, but for spacious and tall buildings it is of key importance. The increased number of sections farthest from the boiler will allow the temperature levels to be equalized.

In order for the cooled working medium to be able to return by gravity to the heat exchanger for heating, the heat generator must be placed below the level of the radiators. The use of a circulation pump eliminates this requirement and makes heating in a private home much more efficient due to the accelerated movement of the working medium.

In a simplified form, the installation of a single-pipe heating system can be described as follows:

- boiler installation;

- installation of expansion tank and radiators;

- laying a pipe line;

- installation of a circulation pump (if necessary);

- connecting communications to devices;

- installation of radiator valves.

To improve the performance of single-pipe heating, special jumpers are used - bypasses, which allow redirecting and redistributing the coolant flow along the riser.

Bellows compensator for heating system

As already mentioned, the main features of installing a heating system are related to the use of wood as the main building material of the house. Even well-dried timber contains a certain amount of moisture and, over time, dries out and can be partially deformed. On the scale of an individual structural element, such changes can be considered insignificant. But given the large areas of wall, floor and ceiling surfaces, shifts become critical and can amount to tens of centimeters. The use of standard communications and rigid fastenings will lead to bends (ruptures) of pipes, destruction of interpipe connections and insulation, and damage to equipment. That is why special expansion joints are installed on main highways, which are equipped with a corrugated surface, are resistant to dynamic loads and have the ability to compress and stretch. Sliding fasteners ensure freedom of pipe movement. An open one often violates the overall aesthetic integrity of a wooden interior, so it is advisable to give preference to hidden installation of communications.

Pipes are laid under the floor, in interfloor ceilings, behind false walls. It is important to accurately determine the location of the pipework in advance. Experts strongly recommend using collectors and equipping communications in such a way that there is not a single joint in the interfloor ceilings and under the floor. This leads to a slight increase in the construction budget, but completely eliminates the risk of leaks in a place inaccessible for prompt repairs.  The material used for coolant lines is high-quality or, which are designed for trouble-free operation for up to 50 years.

The material used for coolant lines is high-quality or, which are designed for trouble-free operation for up to 50 years.

For those that will decorate communications, you should not use soft