Sn chemical element name. Alphabetical list of chemical elements. Electronic characteristic of the element

Tin(lat. Stannum), Sn, a chemical element of group IV of the periodic system of Mendeleev; atomic number 50, atomic mass 118.69; white shiny metal, heavy, soft and ductile. The element consists of 10 isotopes with mass numbers 112, 114-120, 122, 124; the latter is weakly radioactive; the isotope 120 Sn is the most common (about 33%).

History reference. O.'s alloys with copper - bronze were already known in the 4th millennium BC. e., and pure metal in the 2nd millennium BC. e. In the ancient world, jewelry, dishes, and utensils were made from jewelry. The origin of the names "stannum" and "tin" is not exactly established.

distribution in nature. O. - a characteristic element of the upper part of the earth's crust, its content in the lithosphere is 2.5 10 = 4% by weight, in acidic igneous rocks 3 10 = 4%, and in deeper basic 1.5 10 = 4%; even less O. in the mantle. O. concentration is associated both with magmatic processes (tin-bearing granites and pegmatites enriched with O. are known) and with hydrothermal processes. Of the 24 known O. minerals, 23 were formed at high temperatures and pressures. The main industrial value is cassiterite SnO 2, lesser - stannin Cu 2 FeSnS 4 (see. Tin ores). In the biosphere O. migrates weakly, in sea water it is only 3 10 = 7%; aquatic plants with a high content of oxygen are known. However, the general trend in the geochemistry of oxygen in the biosphere is dispersion.

Physical and chemical properties. O. has two polymorphic modifications. The crystal lattice of ordinary b-Sn (white O.) is tetragonal with periods a = 5,813 , With=3.176; density 7.29 G/cm 3 . At temperatures below 13.2 °C stable a-Sn (grey O.) cubic structure such as diamond; density 5.85 G/cm 3 . The b a transition is accompanied by the transformation of the metal into powder (see Fig. tin plague), t pl 231.9 °C, t kip 2270 °C. Temperature coefficient of linear expansion 23 10 =6 (0-100 °C); specific heat (0°C) 0.225 kj/(kg K), i.e. 0.0536 feces/(G°C); thermal conductivity (0 °C) 65.8 Tue/(m K), i.e. 0.157 feces/(cm·- sec°C); electrical resistivity (20 °C) 0.115 10 =6 ohm· m, i.e. 11.5 10 =6 ohm· cm.Tensile strength 16.6 Mn/m 2 (1,7 kgf/mm 2)" , elongation 80-90%; Brinell hardness 38.3-41.2 Mn/m 2 (3,9-4,2 kgf/mm 2). When the O. bars are bent, a characteristic crunch is heard from the mutual friction of the crystallites.

According to the configuration of the outer electrons of the atom 5 s 2 5p 2 O. has two oxidation states: +2 and +4; the latter is more stable; Sn(P) compounds are strong reducing agents. Dry and humid air at temperatures up to 100 °C practically does not oxidize O.: it is protected by a thin, strong and dense film of SnO 2 . In relation to cold and boiling water, O. is stable. The standard electrode potential of O. in an acidic environment is - 0.136 v. O. slowly displaces hydrogen from dilute HCl and H 2 SO 4 in the cold, forming SnCl 2 chloride and SnSO 4 sulfate, respectively. O. dissolves in hot concentrated H 2 SO 4 when heated, forming Sn (SO 4) 2 and SO 2. Cold (O ° C) dilute nitric acid acts on O. according to the reaction:

4Sn + 10HNO 3 \u003d 4Sn (NO 3) 2 + NH 4 NO 3 + 3H 2 O.

When heated with concentrated HNO 3 (density 1.2-1.42 G/cm 3) O. is oxidized with the formation of a precipitate of metatinic acid H 2 SnO 3, the degree of hydration of which is variable:

3Sn+ 4HNO 3 + n H 2 O \u003d 3H 2 SnO 3 n H2O + 4NO.

When oxygen is heated in concentrated alkali solutions, hydrogen is released and hexahydrostannate is formed:

Sn + 2KOH + 4H 2 O \u003d K 2 + 2H 2.

Air oxygen passivates oxygen, leaving a film of SnO 2 on its surface. Chemically, SnO 2 dioxide is very stable, and SnO oxide is rapidly oxidized, it is obtained indirectly. SnO 2 exhibits predominantly acidic properties, SnO - basic.

O. does not combine directly with hydrogen; hydride SnH 4 is formed by the interaction of Mg 2 Sn and hydrochloric acid:

Mg 2 Sn + 4HCl \u003d 2MgCl 2 + SnH 4.

It is a colorless poisonous gas t kip -52 °C; it is very fragile, at room temperature it decomposes into Sn and H 2 within a few days, and above 150 ° C - instantly. It is also formed under the action of hydrogen at the time of release to O. salts, for example:

SnCl 2 + 4HCl + 3Mg \u003d 3MgCl 2 + SnH 4.

With halogens, O. gives compounds of the composition SnX 2 and SnX 4 . The former are salt-like and in solutions give Sn 2+ ions, the latter (except for SnF 4) are hydrolyzed by water, but are soluble in non-polar organic liquids. O.'s interaction with dry chlorine (Sn + 2Cl 2 = SnCl 4) gives SnCl 4 tetrachloride; it is a colorless liquid, well dissolving sulfur, phosphorus, iodine. Previously, O. was removed from failed tinned products using the above reaction. Now the method is not widely used due to the toxicity of chlorine and high losses of oxygen.

Tetrahalides SnX 4 form complex compounds with H 2 O, NH 3 , nitrogen oxides, PCl 5 , alcohols, ethers and many organic compounds. With hydrohalic acids, O. halides give complex acids that are stable in solutions, such as H 2 SnCl 4 and H 2 SnCl 6 . When diluted with water or neutralized, solutions of simple or complex chlorides are hydrolyzed, giving white precipitates of Sn (OH) 2 or H 2 SnO 3 · n H 2 O. With sulfur O. gives sulfides insoluble in water and dilute acids: brown SnS and golden yellow SnS 2.

Receipt and application. The industrial production of O. is advisable if its content in placers is 0.01%, in ores 0.1%; usually tenths and units of percent. O. in ores are often accompanied by W, Zr, Cs, Rb, rare earth elements, Ta, Nb, and other valuable metals. Primary raw materials are enriched: placers - mainly by gravity, ores - also by flotation or flotation.

Concentrates containing 50–70% oxygen are fired to remove sulfur and purified from iron by the action of HCl. If impurities of wolframite (Fe, Mn) WO 4 and scheelite CaWO 4 are present, the concentrate is treated with HCl; the resulting WO 3 ·H 2 O is taken up with NH 4 OH. By smelting concentrates with coal in electric or flame furnaces, rough O. (94–98% Sn) is obtained, containing impurities of Cu, Pb, Fe, As, Sb, and Bi. When released from furnaces, draft iron is filtered at a temperature of 500–600 °C through coke or centrifuged, thereby separating the bulk of the iron. The rest of Fe and Cu is removed by mixing elemental sulfur into the liquid metal; impurities float up in the form of solid sulfides, which are removed from the surface of the oxygen. From arsenic and antimony, oxygen is refined in a similar way - by mixing in aluminum, from lead - with the help of SnCl 2 . Sometimes Bi and Pb are evaporated in vacuum. Electrolytic refining and zone recrystallization are relatively rarely used to obtain highly pure O.

About 50% of all produced O. is secondary metal; it is obtained from waste tinplate, scrap and various alloys. Up to 40% of gold is used for tinning tinplate, and the rest is spent on the production of solders, bearings, and printing alloys. Tin alloys). Dioxide SnO 2 is used for the manufacture of heat-resistant enamels and glazes. Salt - sodium stannite Na 2 SnO 3 3H 2 O is used in stain dyeing of fabrics. Crystalline SnS 2 ("gold leaf") is part of paints that imitate gilding. Niobium stannide Nb 3 Sn is one of the most used superconducting materials.

N. N. Sevryukov.

O.'s toxicity and the majority of its inorganic connections is small. The acute poisonings caused by elemental O. widely used in the industry practically do not meet. Separate cases of poisoning described in the literature, apparently, are caused by the release of AsH 3 when water accidentally gets into the waste of cleaning O. from arsenic. The workers of tin-smelting plants, with prolonged exposure to dust, oxides of O. (the so-called black O., SnO) may develop pneumoconiosis, workers involved in the manufacture of tin foil sometimes have cases of chronic eczema. Tetrachloride O. (SnCl 4 5H 2 O) at its concentration in the air over 90 mg/m 3 irritant to the upper respiratory tract, causing coughing; getting on the skin, O. chloride causes its ulceration. A strong convulsive poison is hydrogen stannous (stannomethane, SnH 4), but the probability of its formation under industrial conditions is negligible. Severe poisoning when eating long-made canned food can be associated with the formation of SnH 4 in cans (due to the action of organic acids on the cans of the contents). Acute poisoning with tinous hydrogen is characterized by convulsions, imbalance; death is possible.

O.'s organic compounds, especially di- and trialkyl compounds, have a pronounced effect on the central nervous system. Signs of poisoning with trialkyl compounds: headache, vomiting, dizziness, convulsions, paresis, paralysis, visual disturbances. Quite often develop a coma (see. Coma), cardiac and respiratory disorders with a fatal outcome. Toxicity of O.'s dialkyl compounds is somewhat lower; in the clinical picture of poisoning, symptoms of damage to the liver and biliary tract predominate. Prevention: observance of the rules of occupational health.

O. as an artistic material. Excellent casting properties, malleability, pliability with a cutter, and a noble silver-white color led to the use of O. in arts and crafts. In ancient Egypt, gold was used to make jewelry soldered onto other metals. From the end of the 13th century In Western European countries, vessels and church utensils made of O. appeared, similar to silver, but softer in outline, with a deep and rounded engraving stroke (inscriptions, ornaments). In the 16th century F. Briot (France) and K. Enderlein (Germany) began to cast ceremonial bowls, dishes, and goblets from O. with relief images (coats of arms, mythological, genre scenes). A. Sh. Boole introduced O. into marquetry when decorating furniture. In Russia, objects made of silverware (mirror frames, utensils) became widespread in the 17th century; in the 18th century in the north of Russia, the production of copper trays, teapots, snuff boxes, trimmed with tin overlays with enamels, reached its peak. By the beginning of the 19th century. O. vessels gave way to faience, and the use of O. as an artistic material became rare. The aesthetic merits of contemporary decorative items made of O. are in the clear identification of the object's structure and the mirror-like surface purity, which is achieved by casting without further processing.

Lit.: Sevryukov N. N., Tin, in the book: Brief Chemical Encyclopedia, vol. 3, M., 1963, p. 738-39; Metallurgy of tin, M., 1964; Nekrasov B.V., Fundamentals of General Chemistry, 3rd ed., vol. 1, M., 1973, p. 620-43; Ripan R., Chetyanu I., Inorganic chemistry, part 1 - Chemistry of metals, trans. from rum., M., 1971, p. 395-426; Occupational diseases, 3rd ed., M., 1973; Harmful substances in industry, part 2, 6th ed., M, 1971; Tardy, Les étspan>francais, pt. 1-4, P., 1957-64; Mory L., Schönes Zinn, Münch., 1961; Haedeke H., Zinn, Braunschweig, 1963.

Tin is one of the few metals known to man since prehistoric times. Tin and copper were discovered before iron, and their alloy, bronze, is, apparently, the very first "artificial" material, the first material prepared by man.

The results of archaeological excavations suggest that as far back as five millennia BC, people were able to smelt tin itself. It is known that the ancient Egyptians brought tin for the production of bronze from Persia.

Under the name "trapu" this metal is described in ancient Indian literature. The Latin name for tin, stannum, comes from the Sanskrit "hundred", which means "solid".

The mention of tin is also found in Homer. Almost ten centuries before the new era, the Phoenicians delivered tin ore from the British Isles, then called the Cassiterids. Hence the name cassiterite, the most important of the tin minerals; its composition is Sn0 2 . Another important mineral is stannin, or tin pyrite, Cu 2 FeSnS 4 . The remaining 14 minerals of element No. 50 are much rarer and have no industrial value.

By the way, our ancestors had richer tin ores than we do. It was possible to smelt metal directly from ores located on the surface of the Earth and enriched during the natural processes of weathering and washing out. Nowadays, such ores no longer exist. In modern conditions, the process of obtaining tin is multistage and laborious. Ores from which tin is smelted now, they are complex in composition: in addition to element No. 50 (in the form of oxide or sulfide), they usually contain silicon, iron, lead, copper, zinc, arsenic, aluminum, calcium, tungsten and other elements. Current tin ores rarely contain more than 1% Sn, and placers - even less: 0.01-0.02% Sn. This means that to obtain a kilogram of tin, it is necessary to mine and process at least a centner of ore.

How is tin obtained from ores

The production of element No. 50 from ores and placers always begins with enrichment. Methods of enrichment of tin ores are quite diverse. In particular, the gravitational method is used, based on the difference in the density of the main and accompanying minerals. At the same time, we must not forget that the accompanying ones are far from always an empty breed. Often they contain valuable metals, such as tungsten, titanium, lanthanides. In such cases, they try to extract all valuable components from tin ore.

The composition of the resulting tin concentrate depends on the raw materials, and also on how this concentrate was obtained. The tin content in it ranges from 40 to 70%. The concentrate is sent to kilns (at 600-700°C), where relatively volatile impurities of arsenic and sulfur are removed from it. And most of the iron, antimony, bismuth and some other metals are leached with hydrochloric acid after firing. After this is done, it remains to separate the tin from oxygen and silicon. Therefore, the last stage in the production of crude tin is smelting with coal and fluxes in reverberatory or electric furnaces. From a physicochemical point of view, this process is similar to a blast furnace: carbon “takes away” oxygen from tin, and fluxes turn silicon dioxide into a light slag compared to metal.

There are still quite a lot of impurities in rough tin: 5-8%. To obtain metal of high-quality grades (96.5-99.9% Sn), fire or less often electrolytic refining is used. And the tin necessary for the semiconductor industry with a purity of almost six nines - 99.99985% Sn - is obtained mainly by zone melting.

Another source

In order to get a kilogram of tin, it is not necessary to process a centner of ore. You can do otherwise: "peel" 2000 old cans.

Only half a gram of tin per can. But multiplied by the scale of production, these half-grams turn into tens of tons ... The share of "secondary" tin in the industry of the capitalist countries is about a third of the total production. There are about a hundred industrial tin recovery plants in operation in our country.

How is tin removed from tinplate? It is almost impossible to do this mechanically, so they use the difference in the chemical properties of iron and tin. Most often, tin is treated with gaseous chlorine. Iron in the absence of moisture does not react with it. it combines with chlorine very easily. A smoking liquid is formed - tin chloride SnCl 4, which is used in the chemical and textile industries or sent to an electrolyzer to get metallic tin from it. And again the “circle” will begin: steel sheets will be covered with this tin, they will receive tinplate. It will be made into jars, the jars will be filled with food and sealed. Then they will open them, eat canned food, throw away the cans. And then they (not all, unfortunately) will again get to the factories of "secondary" tin.

Other elements make a cycle in nature with the participation of plants, microorganisms, etc. The tin cycle is the work of human hands.

Tin in alloys

About half of the world's tin production goes to tin cans. The other half - in metallurgy, to obtain various alloys. We will not talk in detail about the most famous of the tin alloys - bronze, referring readers to an article about copper - another important component of bronzes. This is all the more justified because there are tinless bronzes, but there are no “copperless” ones. One of the main reasons for the creation of tinless bronzes is the scarcity of element No. 50. Nevertheless, bronze containing tin is still an important material for both mechanical engineering and art.

The technique also needs other tin alloys. True, they are almost never used as structural materials: they are not strong enough and too expensive. But they have other properties that make it possible to solve important technical problems at a relatively low cost of material.

Most often, tin alloys are used as antifriction materials or solders. The first allow you to save machines and mechanisms, reducing friction losses; the second connect metal parts.

Of all antifriction alloys, tin babbits, which contain up to 90% tin, have the best properties. Soft and low-melting lead-tin solders well wet the surface of most metals, have high ductility and fatigue resistance. However, the scope of their application is limited due to the insufficient mechanical strength of the solders themselves.

Tin is also part of the typographic alloy hart. Finally, tin-based alloys are very necessary for electrical engineering. The most important material for electric capacitors is steel; it is almost pure tin, turned into thin sheets (the share of other metals in steel does not exceed 5%).

Incidentally, many tin alloys are true chemical compounds of element #50 with other metals. Fusing, tin interacts with calcium, magnesium, zirconium, titanium, and many rare earth elements. The resulting compounds are characterized by a rather high refractoriness. So, zirconium stannide Zr 3 Sn 2 melts only at 1985 ° C. And not only the refractoriness of zirconium is “to blame”, but also the nature of the alloy, the chemical bond between the substances that form it. Or another example. Magnesium cannot be classified as a refractory metal, 651 ° C is far from a record melting point. Tin melts at an even lower temperature - 232 ° C. And their alloy - the Mg2Sn compound - has a melting point of 778 ° C.

The fact that element No. 50 forms quite a number of alloys of this kind forces one to take a critical look at the statement that only 7% of the tin produced in the world is consumed in the form of chemical compounds. Apparently, we are talking here only about compounds with non-metals.

Compounds with non-metals

Of these substances, chlorides are the most important. Tin tetrachloride SnCl 4 dissolves iodine, phosphorus, sulfur, and many organic substances. Therefore, it is mainly used as a very specific solvent. Tin dichloride SnCl 2 is used as a pro-grass in dyeing and as a reducing agent in the synthesis of organic dyes. The same functions in textile production have another compound of element No. 50 - sodium stannate Na 2 Sn0 3. In addition, with its help, silk is weighed down.

Industry also uses tin oxides to a limited extent. SnO is used to obtain ruby glass, and Sn0 2 - white glaze. Golden-yellow crystals of olive disulfide SnS 2 are often called gold leaf, which is used to “gild” a tree, gypsum. This is, so to speak, the most "anti-modern" use of tin compounds. What about the most modern?

If we have in mind only tin compounds, then this is the use of barium stannate BaSn0 3 in radio engineering as an excellent dielectric. And one of the isotopes of tin, il9Sn, played a significant role in the study of the Mössbauer effect - a phenomenon due to which a new research method was created - gamma-resonance spectroscopy. And this is not the only case when the ancient metal served modern science.

On the example of gray tin - one of the modifications of element No. 50 - a connection was revealed between the properties and chemical nature of a semiconductor material. And this, apparently, is the only thing for which gray tin can be remembered with a kind word: it did more harm than good. We shall return to this variety of element No. 50 after another large and important group of tin compounds.

About organotin

There are a great many organoelement compounds containing tin. The first of them was received in 1852.

At first, substances of this class were obtained in only one way - in the exchange reaction between inorganic tin compounds and Grignard reagents. Here is an example of such a reaction:

SnCl 4 + 4RMgX → SnR 4 + 4MgXCl (R here is a hydrocarbon radical, X is a halogen).

Compounds of the composition SnR4 have not found wide practical application. But it is from them that other organotin substances are obtained, the benefits of which are undoubted.

Interest in organotin arose for the first time during the First World War. Almost all organic tin compounds obtained by that time were toxic. These compounds were not used as toxic substances; their toxicity to insects, molds, and harmful microbes was used later. On the basis of triphenyltin acetate (C 6 H 5) 3 SnOOCCH 3, an effective drug was created to combat fungal diseases of potatoes and sugar beets. This drug turned out to have another useful property: it stimulated the growth and development of plants.

To combat fungi that develop in the apparatus of the pulp and paper industry, another substance is used - tributyltin hydroxide (C 4 H 9) sSnOH. This greatly improves the performance of the hardware.

Dibutyltin dilaurinate (C 4 H 9) 2 Sn (OCOC 11 H 23) 2 has many "professions". It is used in veterinary practice as a remedy for helminths (worms). The same substance is widely used in the chemical industry as a stabilizer for polyvinyl chloride and other polymeric materials and as a catalyst. Speed

reaction of formation of urethanes (monomers of polyurethane rubbers) in the presence of such a catalyst increases by 37 thousand times.

Effective insecticides have been created on the basis of organotin compounds; organotin glasses reliably protect against x-ray radiation, underwater parts of ships are covered with polymeric lead and organotin paints so that mollusks do not grow on them.

These are all compounds of tetravalent tin. The limited scope of the article does not allow talking about many other useful substances of this class.

Organic compounds of divalent tin, on the contrary, are few in number and have so far found almost no practical application.

About gray tin

In the frosty winter of 1916, a batch of tin was sent by rail from the Far East to the European part of Russia. But it was not silvery-white ingots that arrived at the site, but mostly fine gray powder.

Four years earlier, a catastrophe had occurred with the expedition of polar explorer Robert Scott. The expedition, heading to the South Pole, was left without fuel: it leaked out of iron vessels through the seams soldered with tin.

Around the same years, the well-known Russian chemist V.V. The teapot, which was brought to the laboratory as a case study, was covered with gray spots and growths that fell off even with a light tap by hand. The analysis showed that both dust and growths consisted only of tin, without any impurities.

What happened to the metal in all these cases?

Like many other elements, tin has several allotropic modifications, several states. (The word “allotropy” is translated from Greek as “another property”, “another turn.”) At normal positive temperatures, tin looks so that no one can doubt that it belongs to the class of metals.

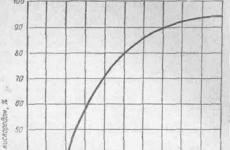

White metal, ductile, malleable. Crystals of white tin (it is also called beta-tin) are tetragonal. The length of the edges of the elementary crystal lattice is 5.82 and 3.18 A. But at temperatures below 13.2 ° C, the “normal” state of tin is different. As soon as this temperature threshold is reached, a rearrangement begins in the crystal structure of the tin ingot. White tin is converted into powdered gray or alpha tin, and the lower the temperature, the greater the rate of this transformation. It reaches its maximum at minus 39°C.

Gray tin crystals of a cubic configuration; the dimensions of their elementary cells are larger - the length of the edge is 6.49 A. Therefore, the density of gray tin is noticeably less than that of white: 5.76 and 7.3 g/cm3, respectively.

The result of white tin turning gray is sometimes referred to as "tin plague". Stains and growths on army teapots, wagons with tin dust, seams that have become permeable to liquid are the consequences of this “disease”.

Why don't stories like this happen now? Only for one reason: they learned to “treat” the tin plague. Its physico-chemical nature has been clarified, it has been established how certain additives affect the metal's susceptibility to the "plague". It turned out that aluminum and zinc contribute to this process, while bismuth, lead and antimony, on the contrary, counteract it.

In addition to white and gray tin, another allotropic modification of element No. 50 was found - gamma tin, stable at temperatures above 161 ° C. A distinctive feature of such tin is brittleness. Like all metals, with increasing temperature, tin becomes more ductile, but only at temperatures below 161 ° C. Then it completely loses plasticity, turning into gamma tin, and becomes so brittle that it can be crushed into powder.

Once again about the shortage of broom

Often articles about the elements end with the author's reasoning about the future of his "hero". As a rule, it is drawn in pink light. The author of the article about tin is deprived of this opportunity: the future of tin - a metal, undoubtedly, the Most Useful - is unclear. It is not clear for one reason only.

A few years ago, the American Bureau of Mines published calculations that showed that the proven reserves of element No. 50 would last the world at most 35 years. True, after that several new deposits were found, including the largest in Europe, located on the territory of the Polish People's Republic. Nevertheless, the shortage of tin continues to worry specialists.

Therefore, finishing the story about element No. 50, we want to once again remind you of the need to save and protect tin.

The lack of this metal worried even the classics of literature. Remember Andersen? “Twenty-four soldiers were exactly the same, and the twenty-fifth soldier was one-legged. It was cast last, and there was a little lack of tin.” Now the tin is missing not a little. No wonder even bipedal tin soldiers have become a rarity - plastic ones are more common. But with all due respect to polymers, they can not always replace tin.

ISOTOPS. Tin is one of the most "multi-isotope" elements: natural tin consists of ten isotopes with mass numbers 112, 114-120, 122 n 124. The most common of them is i20Sn, it accounts for about 33% of all terrestrial tin. Almost 100 times smaller than tin-115, the rarest isotope of element 50.

Another 15 isotopes of tin with mass numbers 108-111, 113, 121, 123, 125-132 were obtained artificially. The lifetime of these isotopes is far from the same. So, tin-123 has a half-life of 136 days, and tin-132 is only 2.2 minutes.

WHY IS BRONZE NAMED BRONZE? The word "bronze" sounds almost the same in many European languages. Its origin is associated with the name of a small Italian port on the Adriatic Sea - Brindisi. It was through this port that bronze was delivered to Europe in the old days, and in ancient Rome this alloy was called "es brindisi" - copper from Brindisi.

IN HONOR OF THE INVENTOR. The Latin word frictio means friction. Hence the name of anti-friction materials, that is, materials "against trepium". They wear out a little, are soft and ductile. Their main application is the manufacture of bearing shells. The first antifriction alloy based on tin and lead was proposed in 1839 by the engineer Babbitt. Hence the name of a large and very important group of antifriction alloys - babbits.

jKECTb FOR CANNING. The method of long-term preservation of food products by canning in tin-plated tin cans was first proposed by the French chef F. Upper in 1809

FROM THE BOTTOM OF THE OCEAN. In 1976, an unusual enterprise began to operate, which is abbreviated as REP. It is deciphered as follows: exploration and production enterprise. It is located mainly on ships. Beyond the Arctic Circle, in the Laptev Sea, in the area of Vankina Bay, REP extracts tin-bearing sand from the seabed. Here, on board one of the ships, there is an enrichment plant.

WORLD PRODUCTION. According to American data, the world production of tin at the end of the last century was 174-180 thousand tons.

TIN (lat. Stannum), Sn, chemical element with atomic number 50, atomic mass 118.710. There are various conjectures about the origin of the words "stannum" and "tin". The Latin "stannum", which is sometimes derived from the Saxon "hundred" - strong, hard, originally meant an alloy of silver and lead. "Tin" in a number of Slavic languages was called lead. Perhaps the Russian name is associated with the words "ol", "tin" - beer, mash, honey: tin vessels were used to store them. In English literature, the word tin is used for the name of tin. The chemical symbol for tin is Sn, which reads "stannum".

Natural tin consists of nine stable nuclides with mass numbers 112 (in a mixture of 0.96% by mass), 114 (0.66%), 115 (0.35%), 116 (14.30%), 117 (7, 61%), 118 (24.03%), 119 (8.58%), 120 (32.85%), 122 (4.72%), and one weakly radioactive tin-124 (5.94%). 124Sn is a b-emitter, its half-life is very long and is T1/2 = 1016-1017 years. Tin is located in the fifth period in the IVA group of the periodic table of elements of D. I. Mendeleev. The configuration of the outer electron layer is 5s25p2. In its compounds, tin exhibits oxidation states +2 and +4 (valencies II and IV, respectively).

The metallic radius of the neutral tin atom is 0.158 nm, the radii of the Sn2+ ion are 0.118 nm and the radii of the Sn4+ ion are 0.069 nm (coordination number 6). The sequential ionization energies of a neutral tin atom are 7.344 eV, 14.632, 30.502, 40.73, and 721.3 eV. According to the Pauling scale, the electronegativity of tin is 1.96, that is, tin is on the conditional border between metals and non-metals.

Information about chemistry

Radiochemistry

Radiochemistry - studies the chemistry of radioactive substances, the laws of their physical and chemical behavior, the chemistry of nuclear transformations and the accompanying physical and chemical processes. Radiochemistry has the following features: work with...

Stark, Johannes

The German physicist Johannes Stark was born in Schickenhof (Bavaria) into a landowner's family. He studied at the secondary schools of Bayreuth and Regensburg, and in 1894 he entered the University of Munich, where in 1897 he defended his doctoral dissertation...

Th - Thorium

THORIUM (lat. Thorium), Th, a chemical element of group III of the periodic system, atomic number 90, atomic mass 232.0381, refers to actinides. Properties: radioactive, the most stable isotope is 232Th (half-life 1.389&m ...

Light non-ferrous metal, simple inorganic substance. In the periodic table it is designated Sn, stannum (stannum). Translated from Latin, it means "strong, resistant." Initially, this word was called an alloy of lead and silver, and only much later pure tin began to be called that. The word "tin" has Slavic roots and means "white".

Metal refers to scattered elements, and not the most common on earth. In nature, it occurs in the form of various minerals. The most important for industrial mining: cassiterite - tin stone, and stannin - tin pyrite. Tin is mined from ores, usually containing no more than 0.1 percent of this substance.

Tin properties

Lightweight soft ductile silver-white metal. It has three structural modifications, passes from the state of α-tin (grey tin) to β-tin (white tin) at a temperature of +13.2 °C, and to the state of γ-tin at t +161 °C. Modifications are very different in their properties. α-tin is a gray powder, which is classified as a semiconductor, β-tin (“ordinary tin” at room temperature) is a silver malleable metal, γ-tin is a white brittle metal.

In chemical reactions, tin exhibits polymorphism, that is, acidic and basic properties. The reagent is quite inert in air and in water, as it is quickly covered with a strong oxide film that protects it from corrosion.

Tin easily reacts with non-metals, with difficulty - with concentrated sulfuric and hydrochloric acid; it does not interact with these acids in a dilute state. It reacts with concentrated and dilute nitric acid, but in different ways. In one case, tin acid is obtained, in the other, tin nitrate. It reacts with alkalis only when heated. It forms two oxides with oxygen, with oxidation states 2 and 4. It is the basis of a whole class of organotin compounds.

Impact on the human body

Tin is considered safe for humans, it is in our body and every day we get it in minimal quantities with food. Its role in the functioning of the body has not yet been studied.

Tin is considered safe for humans, it is in our body and every day we get it in minimal quantities with food. Its role in the functioning of the body has not yet been studied.

Tin vapor and its aerosol particles are dangerous, since prolonged and regular inhalation can cause lung diseases; organic compounds of tin are also poisonous, so it is necessary to work with it and its compounds in protective equipment.

Such a tin compound as hydrogen tin, SnH 4, can cause severe poisoning when eating very old canned food, in which organic acids have reacted with a layer of tin on the walls of the can (the tin from which cans are made is a thin sheet of iron, coated on both sides with tin). Hydrogen tin poisoning can even be fatal. Its symptoms include convulsions and a feeling of loss of balance.

When the air temperature drops below 0 °C, white tin transforms into gray tin. At the same time, the volume of the substance increases by almost a quarter, the tin product cracks and turns into a gray powder. This phenomenon became known as the "tin plague".

Some historians believe that the "tin plague" was one of the reasons for the defeat of Napoleon's army in Russia, as it turned the buttons on the clothes of French soldiers and belt buckles into powder, and thus had a demoralizing effect on the army.

And here is a real historical fact: the expedition of the English polar explorer Robert Scott to the South Pole ended tragically, including because all their fuel spilled out of the tanks sealed with tin, they lost their snowmobiles, and they didn’t have enough strength to walk.

Application

Most of the smelted tin is used in metallurgy for  production of various alloys. These alloys are used in the manufacture of bearings, foil for packaging, food grade tin, bronze, solders, wires, and typographic fonts.

production of various alloys. These alloys are used in the manufacture of bearings, foil for packaging, food grade tin, bronze, solders, wires, and typographic fonts.

- Tin in the form of foil (staniol) is in demand in the production of capacitors, dishes, art products, organ pipes.

- Used for alloying structural titanium alloys; for applying anti-corrosion coatings on products made of iron and other metals (tinning).

- Alloy with zirconium has high refractoriness and corrosion resistance.

- Tin (II) oxide - used as an abrasive in the processing of optical glasses.

- Included in the composition of materials used for the manufacture of batteries.

- By production of paints "under gold", dyes for wool.

- Artificial radioisotopes of tin are used as a source of γ-radiation in spectroscopic research methods in biology, chemistry, and materials science.

- Tin chloride (tin salt) is used in analytical chemistry, in the textile industry for dyeing, in the chemical industry for organic synthesis and polymer production, in oil refining - for decolorizing oils, in the glass industry - for glass processing.

- Tin boron is used for the manufacture of tin, bronze, and other alloys needed by the industry; for tinning; lamination.

1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 2 4p 5 .

Valence electrons are in bold. Belongs to the family of p-elements. Since the largest principal quantum number is 4, and the number of electrons in the outer energy level is 7, bromine is located in the 4th period, Group VIIA of the Periodic Table. The energy diagram for valence electrons is:

Germanium.

1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 2 4p 2 .

Valence electrons are in bold. Belongs to the p-element family. Since the largest principal quantum number is 4 and the number of electrons in the outer energy level is 4, germanium is located in the 4th period, the IVA group of the Periodic Table. The energy diagram for valence electrons is:

Cobalt.

1s 2 2s 2 2p 6 3s 2 3p 6 3d 7 4s 2 .

Valence electrons are in bold. Belongs to the family of d-elements. Cobalt is located in the 4th period, group VIIB of the Periodic table. The energy diagram for valence electrons is:

Copper.

1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 1 .

Valence electrons are in bold. Belongs to the family of d-elements. Since the largest principal quantum number is 4, and the number of electrons in the outer energy level is 1, copper is located in the 4th period, Group I of the Periodic Table. The energy diagram for valence electrons has the form.