If you lay the laminate diagonally, what is the consumption. Diagonal laying of laminate: material calculation and installation features. Foundation preparation as a necessary stage of work

The general technology of working with laminate is not particularly difficult and does not cause serious problems for beginners and people without experience in such work. The main difficulty arises when it is required to deviate from standard conditions and lay the coating in a different form.

Such cases include laying the laminate diagonally, when the finishing material is laid at a certain angle, which raises a lot of questions, especially among “home” craftsmen.

Features of this installation method

Traditional methods of working with laminate are universal solutions when visual adjustment of the volume of the room, shifting emphasis to the floor area, hiding some irregularities and a flaw in the interior is not required.

With their help, you can achieve a sane effect when the location of the panels coincides with the direction of natural light. But this is an ideal case, which is not always possible to implement in practice.

Diagonal laying is not so versatile and has its pros and cons, which, with proper skill, can be successfully applied to typical rooms and rooms in the private housing sector.

When laying diagonally, material consumption increases by 15-30%

Among the main advantages of this laying technology, the following points can be distinguished:

- the location of window openings does not always correspond to standard standards, which postpones its own adjustments for working with laminate. The diagonal helps to shift or lay the material so that the light falls in the right direction;

- strong unevenness of the walls or their non-parallelism to each other. Flooring along the room will only enhance the effect of unevenness due to the correct orientation of the panels. The diagonal method of laying the laminate is able to level out small irregularities, thanks to the choice of the desired laying angle and the correct texture of the material;

- small or too tight spaces. Laminate diagonally allows you to visually expand and “stretch” the room, shifting the focus from the correct forms to not quite standard installation, while emphasizing the advantageous design solution and originality of the room.

Among the minuses, one can note some of the complexity of the work and the general cost overrun of the material. That is, without certain skills in finishing, or people who want to save on the total cost of work, you should not resort to such methods.

It is better to get by with proven solutions that practically eliminate any difficulties in the calculations and preparation of the material for direct laying on the surface.

How to calculate the material

Calculating the required amount of material with a standard flooring method does not cause any particular difficulties - you need to know the area of \u200b\u200bthe room in which the laying will be carried out and the area of \u200b\u200bone panel / laminate package. Further, the total area of the room is divided by the area of one panel/package and the minimum required amount of material is obtained.

Diagram illustrating the number of panels and trims when laying diagonally

With a diagonal arrangement, everything is somewhat different. To be more precise, a cut at a certain angle will be required for each end panel in a row, and not through a row, as with a longitudinal or transverse flooring method.

This condition will lead to a relatively increased consumption. Additionally, this can include the cost of damaging the panels during fitting and installation. As a result, it turns out that the amount of material can be 20-30% higher than with classical methods.

In some cases, this is quite true, but we propose not to rely on "maybe", but to carry out real ones. To do this, you will need to use the laying scheme, which is located below.

In the diagram, the rectangular room is divided into 3 sections, which conditionally show the three main stages of laying. That is, first of all, the panels are mounted on the AEC site, then ECFB, and only after that on the BFD.

Laying diagram showing direction of laying laminate panels

As a result, knowing simple geometric formulas and the area of \u200b\u200bthe room, you can calculate the number of trims and the required number of laminate panels. That is, the total amount of material required will be equal to the sum of the area of the panels laid on the surface and the area of the scraps obtained during the work.

Further calculations will be carried out according to the following formulas, based on the fact that laying will be carried out strictly at an angle of 45 degrees and S1 + S2 = 1.42 AC, which in turn is equal to the sum of the areas of the two extreme sections.

For example, we calculate the required material for a typical room 8 m long and 4 m wide. For the calculations themselves, we take a laminate 1 m long and 12 cm wide.

- room area: 8 * 4 = 24 m2;

- trimming area: (1.42 * 4 * 0.12) = 0.682 m2;

- panel area: 0.12 * 1 = 0.12 m2;

- number of panels: (24 + 0.682) / 0.12 = 206.

That is, 206 panels is the minimum required amount of material, which does not include damaged or defective canvases. This point should also be taken into account when purchasing material.

For people who are not too concerned about the total cost of the work, you can not do manual calculations, but use a calculator that is not so accurate, but allows you to get an acceptable result. The form of the calculator can be seen a little higher.

Preliminary steps and instrument preparation

Preparing a surface for laying diagonal laminate flooring is a standard set of activities that includes checking the underlying subfloor for degree of deflection, the presence and severity of subfloor damage, and correcting any problems found.

Basic steps for leveling the concrete base before laying

Conventionally, preparation can be divided into two groups, corresponding to one or another type of foundation:

Without eliminating the existing problems, further finishing and flooring with modern materials will not make sense, since a laminate or parquet board requires an almost perfectly flat plane. This allows you to guarantee the use of the material in the course of 5-7 years without visible problems.

To level differences up to 2-3 mm, a substrate made of natural or foam materials is used, which is spread over the floor area before installing the panels.

Laminate flooring requires an electric jigsaw, hammer, square, tape measure and tamping accessories

Immediately, before laying the laminate diagonally, it is recommended to keep the laminate panels in a warm room for 2-3 days. This will allow the material to acquire a “shape” corresponding to the temperature and humidity in the room.

You can use a hacksaw, a fine-toothed blade, or an electric jigsaw to trim and cut laminate flooring. Marking is more convenient to produce using a square, tape measure and pencil. Installation and padding of panels is carried out using a mallet and a special clamp.

If necessary, you can purchase inexpensive ones that are used for 2-3 laying cycles, after which they are disposed of.

Diagonal laminate laying technology

Technologically, the process of working with laminate with a diagonal arrangement of the coating is different from other types of installation of similar material. The main difficulty, as a rule, is caused by the measurement algorithm for the outer web in the row, which will be described below.

Various types of substrates will level out small flaws in the carrier base

The flooring technology for diagonal laying can be divided into the following points:

- Preparing and cleaning the base. The supporting base is checked for technical conformity. With differences of more than 3 mm per 2 m2, irregularities on the floor surface are eliminated. If necessary, the surface is cleaned from cement deposits, oil stains, paint, abrasive particles and dirt.

- Fitting and laying the substrate. The substrate is laid out on the floor surface. If necessary, the fabric is trimmed to length. The joints between adjacent canvases are glued with paper tape. If desired, a polyethylene film is laid under the substrate, which will play the role of an insulating material.

- Laying the first canvas. Different manufacturers and craftsmen have different recommendations for installing the first canvas. Basically, this is laying from a corner or from the first solid canvas. We recommend that you use the first case, when the installation starts with a corner adjustment.

- Markup algorithm. For marking, it is desirable to use a construction square, which will allow you to accurately measure the angle of 45 degrees. For marking, an ordinary simple pencil is used. Trimming the panel is carried out using an electric jigsaw. Preparation of the panel into the corner is carried out on a solid canvas by marking the desired corners from the starting mark.

- Marking and fitting subsequent canvases. After preparing and trimming the canvas, which is located in the corner, its greatest distance along the outer edge is measured. This distance is plotted on the next panel and sawn off at an angle of 45 degrees. Then the process is repeated.

- Long line marking. For rows where a single blade is mitered on one side only, it is recommended that the correct measurement be taken only after the first blade has been trimmed. For example, the first laminate panel is adjusted, then the required number of solid sheets are laid, and only after that the required distance for the last panel in the row is measured.

After cleaning, you can treat the surface with an antiseptic or primer

The substrate spreads along the length of the room without overlap

The canvas for the corner is marked with the edge of a solid laminate lamella

To mark subsequent canvases, you will need to measure the largest distance along the outer edge of the previous lamella

In a long row, cutting the material at an angle is carried out only from one edge

During the installation process, you should remember about the temperature gap, which should be 1-1.2 cm. For this, you can use special mounting wedges or laminate residues. When mounting the panels, it is not recommended to use a conventional hammer or other tool that can damage the panel groove.

Before laying the laminate diagonally with your own hands, we recommend that you familiarize yourself with the video, which clearly demonstrates the installation of the first canvas, marking and trimming the canvases.

The most popular way of laying a laminate is longitudinal. It is the most simple and economical. This method is often indicated on the instructions that come with the packaging of the coating. Most of those who decide to make repairs on their own try not to deviate from the basic rules of laying. Of course, this is a good option, especially if there are no problems with the layout of the room, and the installation error is several degrees. But what if the room has uneven walls, ledges? In a difficult situation, laying the laminate diagonally is better.

With the classic method of laying laminate boards are located parallel to the walls - along or across the room. Diagonally laminate is laid at an angle of 30 or 45 degrees. The last option is considered the most optimal.

Advantages and disadvantages of diagonal styling

The pros and cons of laying laminate diagonally are ambiguous. It cannot be said that the advantages outweigh the disadvantages and vice versa. The undeniable advantages of this method of installation: an unusual design and the ability to zone the space.

Diagonal laying is the shortest way to a creative and interesting room design. The skills gained during the repair will come in handy to visually smooth out the unevenness of the walls, hide the defects in the layout of the room.

Laminate laid diagonally is a good way to visually expand the room. They are often used by interior designers. This floor looks most impressive in rooms that are not overloaded with furniture and accessories. In this case, the diagonal pattern of the laminate further visually expands the space. It seems that the room really became more spacious.

Here is a photo of the laminate diagonally in various versions:

One of the most important arguments in favor of diagonal installation is that such a floor pattern looks stylish and opens up space for the designer. You can visually enlarge the room and make it lighter, divide the space into separate zones using different styling methods.

How to calculate the right amount of material

Laying laminate at an angle of 45 degrees is technically more difficult than the classic installation method and requires more materials to implement the plan. For this reason, considering the required amount of laminate, add 15-20% to the resulting value. Professionals with extensive experience in laying laminate flooring can reduce unnecessary expenses to a minimum - up to 5%. If you decide to make repairs yourself and have little experience in such work, it is better to play it safe and take more material.

How is diagonal laying carried out

So, how to lay the laminate diagonally? Before starting work, take paper, a simple pencil and a ruler. Draw the layout of the room to scale and sketch out the layout of the boards on the plan. Consider the location of the windows: the boards should be laid so that the sunlight falls on them in parallel. Thanks to this, the seams between the lamellas are almost invisible. You will get a detailed diagram as in this photo:

Then proceed directly to work. In order for the laminate to be laid correctly, it is important to level the subfloor well. This is a mandatory rule when installing any floor covering, regardless of the method.

Floor preparation

From a technical point of view, the preparation of the subfloor for diagonal laying does not differ from the traditional longitudinal installation of laminate boards. There are several stages:

- Pour the concrete screed and wait for the mixture to dry completely. Vacuum the floor, cleaning the surface of dust and small debris.

- The second layer is waterproofing: a primer or a dense polyethylene film.

- A substrate is laid on top of the previous layers: cork, polypropylene, expanded polystyrene, etc. Depending on the material, the substrate sheets are laid butt-to-butt or overlapped.

Laminate installation

You can lay the boards from corner to corner or from window to doorway. In the latter case, try to position the longitudinal joints in the direction of the rays of the sun. You can start installing the floor from the center of the room so that the boards are evenly spaced. Stretch the cord diagonally from one corner of the room to the other. This will serve as a guide.

The first row should be laid out strictly parallel to the guide. Lay the boards from the center to the left. With the diagonal laying method, the end locks are connected first, after which a whole long row interlocks with the next, already fully assembled row. It is best to work with assistants. If you work alone, use the load. This will facilitate the process of connecting longitudinal locks. As soon as you fasten the two rows and put a load on them so that they do not disperse, you can safely continue to work.

The slats are laid according to the brickwork method or in a checkerboard pattern with an offset of at least 30-40 cm. The coating will be stronger and stronger without deforming during operation.

When you reach the walls, do not lay the laminate back to back. Be sure to leave small gaps of 1.5-2 cm. The fact is that with natural fluctuations in temperature and humidity, the laminate will expand and contract. If not done, the floor will swell and cracks may appear. To ensure that the floor is laid evenly, and the distance to the walls is the same everywhere, use small pegs while working. When the laminate is completely laid, get rid of them. These gaps will not spoil the appearance of the floor. They are covered with a plinth, which is attached to the wall.

When making repairs with their own hands, some are faced with the problem of trimming the extreme lamellas. You need to cut the boards strictly diagonally, taking into account the direction of the wall. The cut must be parallel. How to do it correctly and evenly? Measure with a ruler the distance from the topmost corner of the row to the peg between the wall and the boards, in the same way measure the distance from the bottom outer corner to the peg. Transfer the obtained values to the whole lamella. Mark the obtained points and connect them with a line. Clearly cut the panel along it as shown in this photo:

You can cut the laminate with a hacksaw or electric jigsaw strictly from the back.

Whatever technology you decide to lay a laminate, always choose a quality material. Don't skimp on coverage at the expense of quality. Laminate of an average or premium checkout will last much longer than a cheap one. When installing the floor in the kitchen, it is better to choose a moisture-resistant coating. After you have bought and brought laminate flooring into your home, let it rest for at least 48 hours. Observe the temperature regime in the room: not lower than +17, so that the laminate after being in the warehouse gradually “gets used” to the new conditions.

Do not install laminate flooring in damp areas. This material does not tolerate sudden changes in humidity and a large amount of moisture in the air. From this, the lamellas swell and swell. If you have recently plastered walls and other surfaces, it is better to wait with the repair of the floor. It is necessary that the level of humidity in the room returned to normal.

Water must not be allowed to enter the laminate floor, especially if the cheapest material is chosen. The quality of such a coating is the least resistant to any influences. Moisture-resistant panels are not afraid of an accidentally spilled glass of water, but even they will not withstand too much of it.

The laminate is laid only on the substrate and only on a flat base. If these conditions are not met, then it is to be expected that the unevenness of the base will lead to deformation of the coating. The substrate does not allow the laminate to change its structure and is a good heat and sound insulator.

Also, the laminate goes well with any floor heating system. Do not forget about the so-called thermal seams - those same gaps along the walls. It should be borne in mind that in office premises such gaps are much wider than in a living room. The size of the gap is considered simply - 1.5 mm for each meter of the width of the room.

Please note that all tips apply only to rooms with a humidity level of no higher than 65%.

Heavy overall furniture does not allow the floor to “breathe”, preventing the panels from expanding and contracting naturally. In this case, experts recommend increasing the gaps between the coating and the walls by another 1 cm around the entire perimeter.

Inspired by a photo and decided that you want to do the same? Correctly laying laminate flooring at a 45° diagonal is a little more difficult than laying it across or across the room. You will need more accuracy in work and more accurate calculations. This installation option is less economical in terms of money. But in the end, you will get a beautiful and original floor that will stylishly fit into any interior and visually enlarge the space. And this is especially valuable in small rooms.

Development is not only in the technology of manufacturing materials for decoration, but also in the method of their installation. Laminate is a beautiful high quality material. Recently, laying laminate diagonally in an apartment has become popular. This method is suitable for those who want to add zest to their interior, make it more individual. This type of installation will also visually expand the room. You can do the work yourself.

Calculation of the material for this method of laying. Is it true that it needs more than with traditional styling?

For diagonal mounting, it is necessary to calculate the amount of material using a special formula that differs from that used in the straight-line method. You need to take the length of the room and the width and multiply them. To this product it is necessary to add the product of the width of one board by 1.42 times the width of the room.

Mathematically, the formula for the calculation looks like this: AC - the width of the room; CD is the length of the room; 1.42 is the square root of 2; (ACxCD) + (1.42 AC x the width of one board).

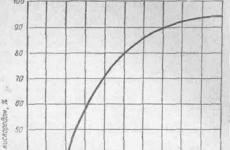

Calculation of the amount of laminate per room

Calculation of the amount of laminate per room When mounting diagonally, you really need more material than with. It's easy to explain. The thing is that in areas where the ends of the panels adjoin the walls, they need to be cut in a certain way. So waste-free production will not work here. It is advisable to take material with a margin of 15-20%.

Laying laminate diagonally can be done by hand.

Laminate laying tool

Laminate laying tool You will need the following tools for this:

- hammer;

- tape measure with a pencil;

- jigsaw;

- padding bar;

- wedges for spacers.

Before you start laying the laminate diagonally, you need to carry out certain preparatory operations. , get rid of the trash. In order to make the surface even, you can use self-leveling compounds. They are very easy to use and give excellent results.

It is better to sweep the floor first, and only then strengthen the floor with a primer.

After that, you need to cover the surface with cellophane. A substrate is placed on it or. Before starting work, it is necessary to hold the material indoors for about a couple of days. So it will not swell and will not shrink.

There are two ways to lay laminate diagonally: from the center and from the corner. Both methods are used quite often, but it is the first that produces the least waste. You can do the work yourself.

Method from corner:

Method from the corner

Method from the corner - If you choose to install your laminate flooring away from the corner, you should start with a solid panel that is cut to the required angle on both sides. It is this panel that will indicate the direction in the future. It is important to remember that the panel must be wedged 10 from the wall in order to compensate for thermal expansion.

- If there is a heating system near the corner in which you start work, then you should start from here. At the junction with the system, you can immediately make a cut. This will make the task easier. From the main panel it is worth moving towards the center of the room. With this laying, the rows will subsequently increase in length. So you should definitely offset the seams by about half the length of the panel. So the reliability will be much higher, and the floor itself will look more beautiful. Watch the tutorial video, you can quickly understand the editing system.

- Panels in each row must be fastened at the ends. The exceptions are the segments that are adjacent to the walls. The row is laid out in its own place, while it is not linked to the previous one too tightly. After that, a measurement is carried out at 2 points. This length is reduced by 10 mm and transferred to the panel to be cut. It is important to note that if the walls are strictly opposite each other, then the angle that remains after trimming should fit exactly on the opposite side. So you will be able not to use up excess material.

- After you have prepared the parts, remove the row from the lock, and then completely assemble it at the ends. And only after that is the clutch with the lock from the last row.

Method from the center:

Method from the center

Method from the center Laying laminate diagonally can be done using the "from the center" method. With this method, you will first need to lay a long prefabricated row. He will give direction in the future. Its installation is carried out in the same way as described in the previous method. After that, it is worth starting the installation of the coating, first to one corner, and then to the other.

This technique is justified for those rooms in which there are external corners.

The first row is better to start from the outer corners on a tangent. After you finish the installation, you will need to remove the spacer bars and attach the plinth to the wall.

How to remove the end panel

Removing the end panel

Removing the end panel Measure the length to the wall. Transfer the measurements to the material. Measure the length from the opposite end. Again transfer the measurements to the material. The points that you have turned out will need to be connected. It is better to cut with a jigsaw from the inside out. So on the front you will not have chips.

Fasten all locks

Fasten all locks To lay them out, you need to fasten all the locks. Place one panel at an angle to the other. Next, press the floor, the lock will snap into place, so you need to fasten all the rows. Now fasten the sides, the more you have made the row, the more difficult it will be to snap it into place. The technology is the same: slightly lift the opposite edge. Install the timber in the lock, press on the floor and snap into place. In order for the panel to enter its position, you can shake it slightly. And to see the process more clearly, turn on the video.

This method of installation in this way has its pros and cons.

Mounting method

Mounting method Its main advantage is beauty. You can easily hide the imperfections of the room. The disadvantages include a greater consumption of material.

If you decide to install the laminate in the apartment, then you can do it yourself.

To do this, just watch the training video. Such a floor will look very unusual and elegant. It will make your room look bigger.

Video

In today's video you will see how to properly lay laminate diagonally in a master class.

Thanks to this material, you will learn a lot of useful things for yourself.

Photo source: laminatekspert.ru, strmnt.com

One way to give your floor a sophisticated look is to lay laminate flooring diagonally. Such an unusual arrangement of panels will attract attention and become the center of the impression of the entire room. In addition, when laying laminate along the walls, you can also visually make the room longer, and when laying transversely - wider.

That is why most often diagonal laying is done in narrow rooms with a non-standard layout. In addition, with the help of unusually located panels, you can shift the direction of view to a specific area of the room. At the same time, alternating between strips of dark and light shades, it is easy to make the interior even more expressive. An example of this use of laying laminate diagonally can be seen in the photo.

The only disadvantage of the diagonal arrangement of the laminate is the more difficult installation compared to the standard laying technology. In addition, much more material is required. This is due to the fact that it is necessary to cut laminate boards much more often, and it is very rare to use trimmings.

Styling features

There are no special difficulties in the technology of laying a laminate diagonally with your own hands. As already mentioned, this method practically does not differ from the standard one. Given this, you need to start the process by leveling the base and laying the substrate. Before starting work, pay attention to how the diagonal lines will be located relative to the lighting in the room. They should lie down so that the sun's rays falling inside are scattered along the panels. This will help hide the joints between the panels and make the floor more solid.

It is also necessary to take into account the air temperature in the room: it should be in the range of 20-26 degrees. Humidity should not be more than 75%. To avoid deformation of the boards during laying, the material is left in the working room for a day. To lay the laminate diagonally with your own hands, use padding - a rectangular wooden beam, with which the panels will fit into the grooves.

There are several ways to lay the laminate diagonally: from the middle of the room or from one of the corners. In the first option, you can significantly reduce the consumption of laminate, which is a big plus. This is due to the fact that after laying the planks from the center, you have two working fields, and if one plank does not fit on one side, you can apply it on the second. Thus, the consumption of slats is optimized, and the workflow is accelerated.

It is also important to control the seams between the board and the wall. For this, special wedges are used. They are installed in existing gaps in order to maintain the laminate in the required position. In the future, this gap will be hidden with the help of skirting boards. The situation is more complicated with areas near doorways. This tutorial video will help you solve this problem.

Diagonal laying without thresholds

Let's consider this process in more detail. In this case, laying the laminate diagonally will be more difficult, but there is a technology that allows you to get a beautiful surface even without joint thresholds.

To do this, laying the laminate in adjacent rooms is carried out in the same direction. This will remove the boundaries and at the same time visually expand the space. Also, to create a more original flooring with your own hands, you can combine several floor coverings. For example, a laminate laid diagonally, which is combined with ceramic tiles, looks great. Very often in this way there is a division of space between the corridor and the bathroom or kitchen.

To obtain an ideal sealing of joints, artificial cork is most often used. In terms of its qualities, it is very similar to mounting foam. It is carefully filled with a construction gun into all gaps, and only then the excess material is cut off after solidification. This material is ideal for use with laminate as it is waterproof and has expansion and contraction properties that are very relevant to the flooring used. In consumer reviews, these positive qualities of the sealant are very often noted.

Material calculation

Laying laminate diagonally has its own algorithm for calculating the required material, since its consumption will be somewhat greater than for conventional installation. For the last option, you just need to measure the area of \u200b\u200bthe room, divide the resulting value by the area of one panel and add 7% to trim.

To lay the panels diagonally, you need to use a completely different calculation method. After multiplying the length and width of the room, you need to add to the result the value of multiplying the width of one board by 1.42 and the width of the room. Let's consider a mathematical interpretation so that you can calculate it all yourself as accurately as possible.

(1.42 x AC x Z) + (AC x CD), where:

- 1.42 - root of two;

- AC - room width;

- CD - room length;

- Z is the width of one board.

To make it easier for you to understand the algorithm of actions, consider this formula using the example of a room with an area of 5 x 7. In this case, the laminate panel will have a length of 1 meter and a width of 0.1 meters.

We carry out the calculation in several steps:

- determine the area of the room: 5 x 7 = 35 m2;

- we calculate the area of spare strips: (1.42 x 0.1 x 5) = 0.71 m2;

- we find the area of one plank: 1 x 0.1 \u003d 0.1 m2.

Now we substitute the found values into our formula:

- we find the total number of material: 0.71 + 35 = 35.71 m2;

- we calculate the final value: 35.71: 0.1 \u003d 357.1 pieces.

The result can be rounded up, resulting in 357. Thus, we found out that it would take 357 laminate panels to lay the laminate diagonally in a 5 x 7 room.

After that, you can go to the store to buy the material and proceed with the installation yourself. To do this, you will need a diagonal laminate laying pattern, which is recommended to be done even before the start of the workflow. This video tutorial will help you.

If your room is narrow or has a non-standard layout, diagonal flooring can solve this problem. The right choice of laminate color and its correct laying in relation to the incident light from the window can transform any, even the most nondescript room.

Laminate is a material with many advantages. Among the advantages are beauty, versatility, resistance to temperature changes, moisture resistance. On the laminate, you can easily walk on heels, move furniture on wheels and ride children's cars.

Laminate retains its functional qualities for a very long time, the main thing at the same time is compliance with certain rules.

The process of laying laminate flooring largely depends on the type of floor on which the work will be done. It doesn't matter what kind of substrate to lay the laminate on, the surface must be flat and dust-free.

Laminate can be laid on a cement screed. To do this, it is important that the screed is even and dry. Therefore, if you decide to lay the laminate on cement, you need to wait at least 7 days before starting work. In winter, if there is no central heating in the room, 3 weeks should pass until the cement floor is ready for further use.

When laying laminate on a cement screed, it is recommended to cover the floor with plastic wrap to prevent moisture from escaping. Also, between the floor and the laminate flooring, you can use a polystyrene substrate, in case you need to insulate the floor.

If the laminate is mounted on a wooden floor, it will not work to level it with cement. In this case, you can use OSB boards to get an almost flawless floor. For insulation, also use a substrate or isolon.

Allow the laminate to sit indoors for a while before starting the laying process. He needs to get used to the temperature of the room.

Diagonal laying of laminate: features of work

Like any job, laminate flooring requires certain skills. The diagonal method is slightly different from the standard installation. The flooring of the boards is not mounted directly, along the wall, but starting from the far corner of the room.

Craftsmen who have already encountered laying laminate on an oblique more than once can do this work without auxiliary means. They can cut laminate by eye, join boards without any problems and easily determine the angle of inclination.

But if for the first time you decide to cover the floor with boards with your own hands, it is better to install beacons on which it will be easier to lay the laminate.

In appearance, the finished floor with diagonal laying of the laminate will look like brickwork.

Key points when laying laminate diagonally:

- The room is visually enlarged. If the floor is made light, the room will become spacious and bright. The motley floor, consisting of a laminate of different shades, will focus on itself.

- With diagonal laying, there is an emphasis on the corner of the room, so in this way you can shift the focus from the walls or other parts of the room to the corner.

- When laying the laminate diagonally, the seams between the boards are not so noticeable.

- If you use laying obliquely throughout the apartment, you can avoid installing thresholds between rooms.

- Laminate does not need to be nailed or screwed. The material may warp or crack.

This method of laminate flooring has significant disadvantages. The consumption of material is greater than with conventional installation. To save money, you can start laying from the middle of the room and move to the corners. Also, the calculation of the material is more difficult to make than with direct laying.

Laminate consumption when laying diagonally

Laying laminate diagonally requires an accurate calculation of the material. Specialists or consultants in hardware stores will help you calculate how many boards will go on the floor in the room. There are times when the calculation is very approximate and then the material may not be enough or there will be more boards than necessary.

You can calculate the laminate consumption yourself by calculating, according to the described scheme, the approximate piece consumption of boards to cover the entire floor. Add 3-4 boards to the amount received in case something gets damaged.

If it is not possible to draw up a detailed diagram of the room, but there is a general quadrature, you can calculate the flow rate as follows. When laying diagonally, add 10-12% to the total area of the room and divide the resulting number by the area of \u200b\u200bone board. Divide the number of planks by the number of laminates in the package.

How to lay laminate diagonally: laying technology

Before you start laying laminate boards, you need to lay the substrate. Roll out the material over the entire surface of the floor, glue the joints with adhesive tape or masking tape. So that when laying the boards, the substrate does not move, you can make a small overlap on the walls, the excess can be easily cut off with an ordinary clerical knife.

Perhaps in order to lay the laminate correctly, you will need a diagram that will show in sequence how it is more convenient and economical to lay the boards.

The diagonal layout of the laminate starts from the far corner of the room, which is located near the window. You can lay a laminate both from right to left, and vice versa - there is no fundamental difference. When installing boards, you need to take into account the angle of inclination, it varies from 30 to 45 degrees.

Progress:

- The first row is assembled from a whole board, the ends of which are sawn at an angle for the correct joint with the wall.

- You can prepare a template according to which the board adjacent to the wall will be cut. According to the template, cut out the next board, connect with the main row along the entire length.

- Collect the next row, connect with the previous one. Using this technology, lay out the entire floor.

- Install plinth. It will hide all errors.

Between themselves, the laminate is connected by special locks. To dock the boards together, you need to bring the board into the lock at an angle of 30 degrees and gently lower it to the floor. If you hear a “click” sound, then you did everything right.

When laying the laminate obliquely, you need to adhere to the indentation from the wall of 20-30 mm. This is done so that the coating does not deform when loaded on it. These indents will later be hidden by the plinth.

Laying laminate diagonally (video)

A high-quality result can be obtained only by observing all the rules of laying. Despite the fact that diagonal laying is a more complex and painstaking process than standard laying, the finished result will exceed all expectations. Thanks to this method of installing laminate, you can transform the room, make it original and beautiful.