Chemical cleaning of column fittings from rust. Acid-free rust converter for the protection of building reinforcement. Degree of metal corrosion

How to remove rust from rebar without harming other materials

Reinforcement is called steel rods with different sections. There are rebar smooth and periodic profile. Manufactured from high strength steels. Reinforcement is used for the manufacture of reinforced concrete, as well as for strengthening metal structures.

Therefore, it is very important that the iron rods covered with ribs and transverse projections are completely free of rust.

How to remove rust from reinforcement if it has penetrated between the protrusions and cannot be mechanically removed

Is rust dangerous for rebar? If light dusty rust has formed on the fittings, it may not even be removed. Thanks to it, the adhesion of metal to concrete occurs. But such a version can lead to the destruction of the reinforced concrete structure if moisture penetrates into the concrete or chlorides appear in the solution, which activate the metal corrosion process. Still, it is better to make a decision before laying concrete than to remove rust from the reinforcement.

mechanically by using metal brush, sandpaper, grinder you can remove the accumulated layer of rust.

Disadvantages: Slow, labor cost, rust is not completely removed.

Application of inhibitors (retarders) of corrosion. The inhibitors contain phosphoric acid and react chemically with the metal. Iron phosphate is formed, which protects the metal from rust.

Disadvantages: for reinforcement, which is poured with concrete, inhibitors cannot be used: the acid will destroy the concrete, like an alkaline environment. Additional costs will be required for another coating of the reinforcement with an anti-acid solution.

Acid-free rust converters. Remove rust from rebar without harming others building materials: the developers of acid-free rust converters took care of this. The composition of such a converter includes vegetable tannins, stabilizers and corrosion inhibitors, and functional additives.

Advantages of acid-free converters:

- does not destroy concrete;

- does not require washing;

- completely replaces mechanical rust removal;

- it is used even with a thick layer of rust up to 150 microns;

- does not contain mineral acids and toxic products;

- fireproof, does not light up;

- guaranteed to protect the metal from the moment of manufacture to use in the next cycle for 18 days.

Applying the acid-free rust converter to rebar is very easy by brush, roller, spray or dipping.

In production conditions, the last two methods are used to process a large volume of reinforcement.

Successful Completion chemical reaction visible in color Brown color rust changes to black.

If a very thick layer of rust is found on the reinforcement, it is necessary to treat the rods with a converter 2-3 times, without waiting until it dries. The effect is bound to be.

The processed reinforcement can be embedded in concrete or painted with paintwork materials after the converter has completely dried.

Buy a tool for cleaning fittings from rust

You can buy a corrosion control agent for fittings on our website or at your local Docker office. You can get full information about acid-free rust converters on our website. Consultants will help you determine the quantity of goods and its cost. Quality assurance guaranteed modern technology production of acid-free rust converters.

In the presence of a urotropin inhibitor. The function of the inhibitor is to prevent the destruction of the metal from acid exposure, but it does not interfere at all with corroding the rusty layer.

It is effective to use a rust converter for these purposes. The agent reacts with the damaged metal layer and transforms it into a brown coating. The composition of such products necessarily includes phosphoric acid, which forms iron orthophosphate from rust, covering the surface of the reinforcement.

To ensure the durability of reinforced concrete and extend the service life reinforced concrete structures, it is necessary to process the reinforcement in accordance with all requirements.

Why rebar processing is necessary

Iron fittings, when exposed to an aggressive environment, undergo oxidation, rust and lose strength. Before laying in concrete, it must be treated with special means. Concrete pouring will not save the reinforcement if it is already subject to corrosion.

Reinforcement made of durable steel is a rather expensive building material. Therefore, it will be much cheaper to use a liquid to remove rust from rebar than to get a poor-quality reinforced concrete structure with rotten rebar inside. Corrosion only begins its journey on the surface, and then completely affects the cross section of the reinforcement.

It is not easy to clean the rebar, because it has helical and profile protrusions. The recesses between them must be cleaned in the most thorough way in order to get as close as possible to building codes.

The best way to protect the fittings is a special rust converter. Such a liquid for removing rust from fittings meets all the requirements, has high protective properties against corrosion.

- Neutral rust converter has strong inhibitors. Removes the layer of rust on the steel surface. It is used in various areas of construction, car repair and in domestic conditions.

- Rust converters containing acid. With their help, chemical process cleaning metal surfaces from rust.

Phosphating converters consist of a solution of phosphoric acid, corrosion inhibitors and additives. When applied to reinforcement or other metal products, rust is converted into a protective cold film, which is a combination of phosphate salts of iron, manganese and zinc (cold phosphating). Such a layer reliably increases the anti-corrosion and weather-resistant qualities of fittings and other metal products.

Advantages of chemical converters:

- carry out pickling, impregnation of metals;

- create a protective film as a result of cold phosphating;

- very simple and easy to apply to the surface;

- have increased adhesion to the metal surface;

- compatible with any brand of paints and varnishes.

How to apply funds correctly

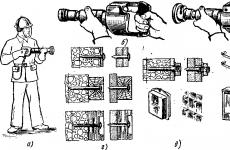

Rust on fittings may appear during its storage in warehouses and during transportation. How to process already rusted fittings. You can do it manually, which requires a lot of physical effort. Under production conditions, they use a mechanical cleaning method - a sandblaster with a vacuum gun, a pneumatic brush, etc.

Facilitates the process of processing liquid to remove rust from fittings. The solution is easy to apply both manually and mechanically. The main thing is that the result meets the technological requirements. The fittings processed by the converter are ready to use. But acid-based rust converters are not suitable for reinforced concrete. Therefore, rust is best removed mechanically. This method is environmentally friendly and reliable.

how to remove rust from fittings without harming other materials

Reinforcement is called steel rods with different sections. There are rebar smooth and periodic profile. Manufactured from high strength steels. Reinforcement is used for the manufacture of reinforced concrete, as well as for strengthening metal structures.

Therefore, it is very important that the iron rods covered with ribs and transverse projections are completely free of rust.

How to remove rust from reinforcement if it has penetrated between the protrusions and cannot be mechanically removed

Is rust dangerous for rebar? If light dusty rust has formed on the fittings, it may not even be removed. Thanks to it, the adhesion of metal to concrete occurs. But such a version can lead to the destruction of the reinforced concrete structure if moisture penetrates into the concrete or chlorides appear in the solution, which activate the metal corrosion process. Still, it is better to make a decision before laying concrete than to remove rust from the reinforcement.

Methods for cleaning fittings from rust

mechanically using a metal brush, sandpaper, a grinder, you can remove the accumulated layer of rust.

Disadvantages: Slow, labor cost, rust is not completely removed.

Application of inhibitors (retarders) of corrosion. The inhibitors contain phosphoric acid and react chemically with the metal. Iron phosphate is formed, which protects the metal from rust.

Disadvantages: for reinforcement, which is poured with concrete, inhibitors cannot be used: the acid will destroy the concrete, like an alkaline environment. Additional costs will be required for another coating of the reinforcement with an anti-acid solution.

Acid-free rust converters. Remove rust from rebar without harming other building materials: the developers of acid-free rust converters have taken care of this. The composition of such a converter includes vegetable tannins, stabilizers and corrosion inhibitors, and functional additives.

Advantages of acid-free converters:

- does not destroy concrete;

- does not require washing;

- completely replaces mechanical rust removal;

- it is used even with a thick layer of rust up to 150 microns;

- does not contain mineral acids and toxic products;

- fireproof, does not light up;

- guaranteed to protect the metal from the moment of manufacture to use in the next cycle for 18 days.

Applying the acid-free rust converter to rebar is very easy by brush, roller, spray or dipping.

In production conditions, the last two methods are used to process a large volume of reinforcement.

The successful completion of a chemical reaction can be seen from the color - the brown color of the rust changes to black.

If a very thick layer of rust is found on the reinforcement, it is necessary to treat the rods with a converter 2-3 times, without waiting until it dries. The effect is bound to be.

The processed reinforcement can be embedded in concrete or painted with paintwork materials after the converter has completely dried.

Buy a tool for cleaning fittings from rust

You can buy a means to combat corrosion on fittings in specialized stores. You can get full information about acid-free rust converters on our website. Consultants will help you determine the quantity of goods and its cost. Quality assurance is provided by modern technology for the production of acid-free rust converters.

Steel reinforcement, like all metal products, can rust over time, as corrosion occurs even from small fumes and humidity.

Before welding work and concreting it is necessary to remove all traces of rust, which can appear even when the reinforcement is stored in good conditions.

Features of removing traces of corrosion

When removing rust, the most important thing is to be careful, as you can damage the surface and spoil the quality of the steel rod, reducing its service life. Since corrosion is most often removed using chemicals or other chemically active substances, they must be applied and removed very carefully, carefully observing the dosage.

Try to choose a gentle cleaner that will only remove the rust layer and not attack the steel surface. Some builders, with small manifestations of corrosion, prefer not to remove it at all, although this, of course, is not entirely true, since under conditions of almost complete tightness of the hardened concrete product during the manufacture of the foundation, rust will spread due to internal evaporation.

Variants of chemical compositions

There are already many ready mixes commercially available, which are used for cleaning the steel surface. Most often, phosphorus-containing inhibitors are taken, which slow down corrosion processes. Phosphorus interacts with the steel surface, forming the thinnest layer of iron phosphate. This layer is like protective film will not allow the steel to collapse from the smallest water vapor, but it is powerless against really strong humidity.

There are acid-based inhibitors, but their use is highly questionable. Concrete has alkaline properties, that is, the opposite of acidic, which means that it will collapse from such reinforcement inside itself. Acid inhibitors are best left for rolled metal, which goes to conventional structures.

home chemistry

To remove small traces of corrosion, improvised substances can be used that do not have such a strong chemical effect as real chemistry, but at the same time contain enough tannin or inorganic acids to stop corrosion processes.

Such substances are table vinegar (not acetic acid!), aqueous solutions of hangover remedies, soda, carbonated water (for example, cola), a mixture lemon juice and table salt. If desired, you can find other options for these sparing mixtures.

Please note that any compositions, even such simple ones, must be applied very carefully. If an abrasive gets between the sponge or cloth with the substance and the metal surface, it can scratch the steel surface, and then corrosion will appear more strongly in this place.

To ensure a long service life of reinforcing bars without corrosion, buy them from a trusted manufacturer who stores rolled metal in a place specially equipped for this.

Purpose:

Reinforcement is an acid-free rust converter that is designed to modify the rust that forms on the surface of ferrous metal before applying coatings or concreting.

Material Armaturite- a complex composition based on vegetable tannins, stabilizers, functional additives and corrosion inhibitors.

Reinforcement is used to transform and stabilize corrosion that forms on the surfaces of reinforcing steels, rolled metal, pipes, steel parts of reinforced concrete structures before applying mastics, paintwork materials or concreting. The tool is able to replace the mechanical method of cleaning the surfaces of metal products from corrosion products.

Armaturite recommended for processing bar reinforcement classes A-I, A-II, A-III, A-IV. It is acceptable to use the composition for the treatment of tightly adhering rust with a thickness of corrosive products up to 150 microns (when applied in two or three layers).

At the interoperational stage of production, the converter provides reliable protection metals for a period of up to eighteen days, provided there is no rain, snow (direct precipitation). The product does not contain toxic substances and mineral acids in its composition, it is not flammable.

Corrosion Converter Armaturite applied in construction industry in the construction of reinforced concrete structures, the production of reinforced concrete products (concrete products), on preparatory stage(when preparing products for implementation painting work), when carrying out restoration and repair work in different areas industrial production and domestic operating conditions.

The composition is also used in the implementation of the current repair of machines, metal structures, mechanisms in order to increase their service life.

Armaturite when applied, it converts iron oxide into inactive corrosive compounds, which are characterized by increased adhesion to metals. The conversion process takes place in a neutral environment (pH 5.0-6.0).

The workpiece does not need to be rinsed after application of the composition with water. Converter improves functional characteristics concrete and extends their service life, provides anti-corrosion resistance, durability, adhesive strength and weather resistance of the system paintwork.

Mode of application:

Reinforcement is applied to a dried surface, previously cleaned of accumulations of dust, oils and loose corrosion. Before use, the product must be stirred. The converter is applied by roller, brush, dipping or spraying. The successful completion of the reaction is indicated by a change in the brown color of the rust to black. The surface, depending on the thickness of the corrosion, is treated one to three times until the rust turns black. The subsequent layers of the composition are applied at intervals of at least fifteen minutes to wet treated surfaces "wet on wet". The application of paintwork or concreting must be carried out after the product has completely dried (from one to those hours, depending on temperature indicators). Temperature regime application: from +4°С.

Consumption:

Converter consumption - 0.1-0.15 kg / m 2 when applied with a brush in two or three layers.

Precautionary measures:

When carrying out work, use individual means protection. In case of contact with eyes, rinse with water.

Storage:

Store the composition in a tightly closed container, protected from heat and direct sun rays. Do not heat. Keep away from fire and moisture. Storage temperature from 0°С to +35°С. After defrosting does not lose its properties. Guarantee period storage - 12 months from the date of production.

The composition is a complex composition based on vegetable tannins, stabilizers and corrosion inhibitors and functional additives.

Converter Armasil designed to stabilize and convert rust from the surfaces of reinforcing steel, pipes, rolled metal, steel elements of reinforced concrete structures before concreting and applying mastics or paintwork materials. Successfully replaces mechanical way cleaning metal surfaces from corrosion products.

In the interoperational manufacturing cycle, the converter reliably protects the metal for a period up to 18 days(in the absence of direct precipitation).

The composition is non-flammable, does not contain mineral acids and toxic substances.

Purpose

rust converter Armasil it is used in the construction of reinforced concrete structures, the manufacture of reinforced concrete products (concrete products), preparation for painting work, during repair and restoration work in various industries and living conditions.

The converter is also used in current repair machines, mechanisms, metal structures in order to extend their service life.

Armasil converts iron oxide into non-corrosive compounds with excellent adhesion to metal. The conversion process takes place in neutral environments (pH 5.0-6.0).

Does not require washing the product with water after processing. Improves the functional properties of concrete and prolongs their service life. Provides adhesive strength, corrosion resistance and weather resistance to paint systems.

Tara

Container 5kg, 40kg.

Attention! The label is equipped protective elements from fakes.

Mode of application

rust converter Armasil Apply to a dry, dust-, oil- and loose rust-free surface. Stir before use.

The converter is applied by brush, roller, spraying or dipping. If the reaction is successful, the brown color of the rust will change to black.

Depending on the thickness of the rust, the surface is treated 1-3 times until the rust is completely blackened. Subsequent coats of transducer can be applied wet on wet on wet surfaces at intervals of at least 15 minutes.

Concreting or painting should be carried out after the transducer has completely dried (1-3 hours, depending on the temperature). environment).

Application temperature: from +4°С.

Consumption

Converter flow - 0.1-0.15kg per 1 sq.m. when applied with a brush in two or three layers.

Precautionary measures

Use personal protective equipment. In case of contact with eyes, rinse with water.

Storage

Store the composition in a tightly closed container, protected from heat, at temperatures from 0°C to +35°C. After defrosting does not lose its properties.

Guaranteed shelf life in the original packaging 12 months from the date of manufacture.