"New biotechnologies": try the future taste. The method of industrial production of larvae of indoor flies and fertilizers and who invented this technology of feed production

About the unique experience of creating our own production of feed protein correspondents of the magazine " Agrotechnology and technology"The organizers of promising business told.

Already, the livestock and poultry production of many countries is lacking for feed protein, the main sources of which are legumes of crops, meat and fish flour. Fish flour is an important component of bird feed, pigs and fish, but its cost is steadily growing from year to year, and the increase in production is limited. All this forces scientists and agricultural producers to look for alternative sources of protein. However, the history of the project began completely from other purposes and tasks.

Dispose of eco

"Creating a company in 2015, we planned to engage in scouting and transfers of advanced innovative technologies in the APK," says Igor Abalakin, Technical Director of Entroprotek. - Then one of the industry leaders set us the task - to find an effective solution to the problem of avoiding bird litter. During the work, various technologies were worked out: from active composting to pyrolysis. In the process of finding the optimal option, we found out that in Japan, pork manure is processed by a biological method - with insects. And the fact that insects are a rich source of protein, only rooted our interest. And we decided: why not try to recycle a bird litter? "

The company's experts began to study technology more. A test batch of larvae was acquired, the necessary conditions for breeding were created and the first laboratory population was obtained. Further laid the first processing experiments. "The technology has confirmed its effectiveness even in working with such severe raw materials as bird litter," continues Igor Abalakin. - However, it quickly became clear that there are a number of technological difficulties for the industrial implementation of such a project. With a more complete immersion in the issue of organic waste utilization, we found out that there are companies specializing in the processing of food losses and food waste (PPO) in Europe and North America. So, exploring their experience, at the end of 2016, we equipped our own laboratory with a total area of \u200b\u200b45 m² to work out the PPO processing technology. "

The technology applied by Entroprotek is based on the ability of the insect larvae Black Lionck (Hermetia Illucens) to recycle plant organic waste. This makes it possible to maximize the use of food products as efficiently possible, returning to the supply chain of agricultural animals and birds the necessary feed protein obtained from biomass larvae. "The main advantage of technology is its environmental safety and man, - emphasizes the company's technical director. - The results of the study of black lionics at the Institute of Ecology Problems and Evolution, A. N. Seversow (IPEE RAS) confirmed that this type of insects do not tolerate infections, is not capable of surviving in the absence of necessary conditions, and when entering the external environment, dies. In addition, our production conditions exclude in the environment of hazardous and harmful substances in the environment, both through ventilation and through wastewater. "

Live technology

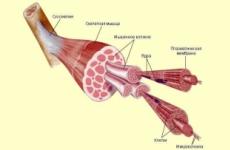

Imago flies (adults) are contained in special insectaries. Inshectaria device prevents insects into the external environment. For vital activity and high insect productivity, a certain microclimate is supported (temperature, humidity, lighting). Egg-layers are taken periodically, which are placed in an incubator, where the process of hatching and planting larvae occurs. In parallel, organic waste comes to the warehouse: substandard grain and food products from retail chains. Waste is released from packaging, grind and pass the homogenization process (bringing to a homogeneous state). At the next stage, larvae grown in the incubator are added to the substance. The container with waste and larvae is placed in the processing shop, where all the conditions necessary for the favorable existence are supported. Within two weeks, the larvae processes the substrate in which there are. At the end of this period, with the help of sieving, the branch of the larvae is separated from the product processing product - compost, which is a valuable organic fertilizer. The larvae is sent to drying and grinding, after which the protein feed product is obtained. In general, the technological stages of the breeding and content of black lionics are similar to the stages in the poultry farming: obtaining incubation eggs, incubation, growing and fattening.

"All sections of technology are worked out in a pilot scale," explains Igor Abalakin. - Research Center for Toxicology and Hygienic Regulation of Biopreparations (NIC TBP FMBA) has developed an experimental regulation for our bioperism technology, as well as the technical conditions for the production of protein feed additive and zoocompost. In the course of assessing the impact of bioperism technology to confirm the environmental safety and procedure for the state environmental examination, numerous studies on the study of the amino acid profile, microbiological indicators, nutritional value of our products were carried out. In addition, the tests of protein feed additives on aquaculture, bird and pigs showed high efficiency of the product. Also, Entroprotek products are of interest among owners of unproductive and exotic animals: lizards, turtles, hedges, iguan, as well as combat and ornamental bird breeds.

Perspective direction

While the analogues of similar production of protein flour in Russia are not. Entroprotek has already built an experienced workshop for industrial production in the Penza region with a permeability of up to 15 tons of food waste per day. Production is mechanized, the technological lines for the acceptance of waste, the preparation of the substrate, thermal processing of biomass insect larvae in order to obtain various products (feed protein, entomological fat, chitin, zoohumus). "Our scientific core conducted hundreds of experiments with the goal of a set of statistics on individual types of waste and the development of a unique recipe for each of them," Igor Abalakin shares. - A separate branch of the project development is genetic research and breeding work on the improvement of the Muhi populations of the populations of the Flys at our disposal.

The technology received a patent, four applications relating to individual parts of the whole process, now on the experts of the Federal Institute of Industrial Property (FIPS), in developing more than 25 applications. Compliance certificates were obtained on all products. Currently comes to the completion of the procedure for the state registration of a feed additive in Rosselkhoznadzor.

Not only one procedure is not completed - state registration of a forage additive. Certificate of registration will allow the company to enter the wholesale sales of feed producers.

This is the history of the Entrepreneurs of Igor Istimina, who built the most real mill farm. Igor explains why flies - it is not really disgusting, as the larvae helps to survive small piglets and chickens and why should a small larvae in the production of insect larvae should ever appear on each poultry farm.

In childhood I had one oddity. More precisely, I had a lot of oddities, but now I will tell only about one. I really liked flies. Parents hung in our country house Velcro from insects, and periodically fell by half immobilized, unfortunate and dying flies on the table. I picked up and put them in a transparent box with air holes - it was a hospital. When the next insect, despite all my efforts, still dying, I seem to be very frustrated. I also liked to plant a fly to my hand and look like she crawls her - her hand was nice-shovel. You probably saddled, reader? My parents were also shrieled. And they said: "Julia, do you even imagine where they went to these legs?"

- You know, Julia, people are very much believe in different stereotypes, "says Igor Ibomin, the founder of the company" New Technologies "- a small farm, where the larvae of the flocks are breeding to create environmentally friendly biocos and fertilizers. - When you tell people about flies, they immediately imagine all sorts of uncleanness, toilet and rot. But, first, if there were no these insects, our planet would have been covered by a multi-kilometer layer of corpses, because they would recycled much more slowly. And in general, studies have long proved that there is an antimicrobial environment around each flies.

Yes, this insect climbs on the garbagers, but then it is thoroughly my paws, on which there are thin chitines. These hairs allocate a microcreen that disinfects everything. And the larvae flies in Napoleonic times were used to clean the employment wounds - they perfectly remove non-frozen fabrics and retain lively intact. The microscipe is rich in immunomodulators, and healing happens faster. In America, this method is sometimes used in surgery today.

Until 2014, Igor Istomin was engaged in household appliances, but with the onset of crisis times decided to sell his business and start some new promising business. Friends offered him together to build a small plant for the production of worship, and Igor put money from the sale of business in this enterprise.

"Actually, before, even before starting trade in household appliances, I was a coach for swimming," says Igor. - So good. So biology was close to me, I understood it well in it. It seemed to me that the production of fish wrath is somehow superficially, the removal of larvae can give the world much more than just a feed for fish. I began to study this topic deeper, my sons helped me, and as a result, by 2015, we made the first experienced batch of excellent feed protein, and in January 2016 we demonstrated it in Moscow at the exhibition at the VDNX.

As Igor Istomin explains, he did not have to invent any new technology - everything has already made nature. Flies live in the world for more than twenty million years - they survived the Ice Age and many other natural cataclysms, unlike Mammoths, Dinosaurs and Mauritius Dream. So, in the body of this insect there is something that contributes to survival.

"In the wild, animals, birds and fish eat something, throw away the waste of digestion, and in the end they die," explains Istomin. - As soon as it happens, the hordes of flies are arrived at the place of death and put eggs. And from eggs, larvae are hatched, which quickly recycle these waste. At the same time, the larvae themselves become excellent feed for other animals, and recycled waste is a great fertilizer for plants. Nature has ever invented us. We simply took this mechanism and placed it under the roof - we decided to see what would happen if you make my own company.

On any agricultural enterprise, be it a poultry farm or fishing plant, quite a lot of waste is formed. For example, the pardee of the bird is five to seven percent - the chickens periodically die due to weak immunity or something they break. Even in enterprises there are always food and vegetable waste, and they all deliver a lot of hassle - they must be stored, disposed of, add special acidifiers, so that in two years these waste turned into fertilizers and it was possible to take them into the field. If all this does not do, there may be problems with environmental services. As Igor Istomin explains, his "Mushying Farm" can become an ideal example of waste-free production, and then there will be no money and time to utilize waste at agricultural enterprises.

"We are divorced by a fly called Lucilia Saesar, this is an ordinary green sinanthropic fellow fly," explains Igor. "However, we call it just a Luce." We have an insectarian with cells where adult flies live and constantly goes the crossing of different types and generations. On average, each fly lives from twenty-one to twenty-four days, so those insects that live in our insectaries have never seen the outside world and differ markedly from those that you meet in nature. For example, they have a much big egg production, because here, we have different generations constantly cross in a closed environment.

In each cell, insectares live about two hundred thousand individuals, on the farm, five such cells, that is, in total about a million flies.

They feed on sugar and dry milk and drink water. Each cell is a small box - Igor calls it "Lunchbox" - with minced meat inside. "New technologies" cooperate with a poultry farm, which specifically gives those birds that did not manage to survive.

"There are small holes in Lanchboxes," says Igor Istomin. - Flies - they are shy. Therefore, they fly there to multiply, and make masonry on mince. Every day a technologist comes, takes lunchboxes with masonry and puts new ones. And old - with masonry - tolerates in the output shop.

In the output shop there are special cabinets with trays where employees of the enterprise place masonry and add more fresh meat. Then the larvae appear from eggs and feed them. During the growth of the larva, flies a lot of ammonia, so each closet is connected to ventilation, the air from which when exiting the street passes through a special microbiological filter.

In four days, each larva increases in three hundred fifty-four hundred times, and one grams of larvae need two hundred meat grams.

They have no stomach, so it would be wrong to say that they eaten this meat. They allocate larval juice on meat, which is rich in enzymes and nutrients. Under their influence, the meat is rapidly decomposed and turns into Cashitz, and then the larva misses the resulting substance many times. Due to this it grows, and the resulting substrate is enriched with enzymes and becomes useful.

After three to five days, when the larvae grows, together with the resulting meat substrate are taking into a special shop. To separate the grown larvae from the substrate, all together fall out on a fine mesh - the larvae is covered through it, and the dry fibrous mass, which once was minced, remains on the grid.

Then the substrate is collected in bags and leave for a day. At a temperature of 65 degrees, it burns out under the influence of anaerobic bacteria. Then it is dried and crushed.

- It turns out a beautiful organic fertilizer, "Igor Ibomin boasts. - It kills in the soil of all sorts of bugs, which eat the roots of plants, and the crop increases twice. At the same time, it is enough to add to the ground just a pinch of such a substrate.

So far, in one department of the enterprise from recycled meat makes a fertilizer, in the other department of the larvae turn into food: they are treated, clean and dried at a temperature not more than 70 degrees to preserve the nutrients and not destroy the protein. Then crushed. It turns out fatty flour with a high content of protein and lipid acids - BLK, protein-lipid concentrate.

"The BLK has natural polymers Melanin and Hitin," says Igor. - They help strengthen immunity. For example, the piglets are the most difficult period - this is a transition from maternal milk to ordinary feed. Often the gastrointestinal system of the faster than animals does not cope, they are sick and dying. If in seven days before the translation of the feed to be started to add to the milk block, by half graam for every kilogram of weight, and then add it already to food for another ten days, then the result will get one hundred percent. Pigs will stop sick. And if you add a little block in the food dog or a cat, it will improve immunity and it will be easier to pass molting, the activity will increase.

Today, in most agricultural industries, animals receive proteins in the form of fish flour. But over the past fifteen years, it has rise in price in eight times, and stocks of fish in the world gradually dry out, because it turns out that animals compete for her with a man. At the same time, the need for industries in animal proteins is colossal - in Russia, their annual deficit is about a million tons. It turns out, you need to urgently look for alternative sources of this protein. And Igor Istomin believes that he found such a source.

"Imagine if on each poultry farm was a small workshop like the one we did if he says." - It is not necessary to pay for utilization, and here, in my own production, it would be possible to make excellent food. It would give and reduce the incidence. In Russia, such technology began to be invented in the 70s of the last century, but all this was at the level of scientific research and remained within the framework of laboratories. We try to bring it into real life.

True, it turned out that it was not so easy to establish waste-free production in Russia - there is simply no regulatory framework for this. At first, it was not possible to certify the product - firms that they do, simply did not know how to work with dried larvae. Then it turned out that according to the law, biological waste should be burned, to be buried or undergo thermal processing. No other processing methods are provided. So you have to demonstrate a new technology once again and prove to everyone that it works.

So far, Igor Inturity's enterprise remains unprofitable: so that it began to make a profit, you need to expand the area and hire more workers. In the meantime, only power is enough for the production of experienced parties - they are sent to plants and factories as probes, so that you can test a new feed and compare it with fish flour.

- Now there are already several enterprises, ready to buy a BLK. Moreover, fish flour costs from 80 to 120 rubles per kilogram, depending on the quality, and our product is 100 rubles. That is, he has every chance to displace the flour. But so that production it is not at a loss to us, we need to produce for eight or ten tons of blocks per month, and while only one is obtained.

We are looking for investors and really hope to get a state grant for research. But with investors it is difficult - you know yourself, it's more interesting to buy ready milk than a cow that will give it milk. So today from commerce us is separated by about 12,000,000 rubles and six months of work. But when everything succeeds, we want to do something like Showerma - let the owners of the factory come and look, as everything is arranged here, and such a waste processing modules are ordered. We will come and build the same in their enterprises - it turns out something like a franchise. And the seed fund will continue to be with us. And we are good, and enterprises, and nature, and the state.

Finally, Igor Istomin asks me, if I had ever seen pickled beetles in banks - in Asia, you can buy in supermarkets in Asia, and people are periodically eaten. I answer that I not only saw, but also tried it - nothing special.

"You see," Igor sighs. - There, in the East, people have already understood what we cannot understand. After all, from the larvae, you can make excellent protein additives useful for people. We have several familiar athletes who buy our BLK and knead themselves with honey for breakfast. But these are athletes. And mostly people are afraid to try. All stupid stereotypes.

Rips on the button to subscribe to "how it is done"!

If you have a production or service that you want to tell our readers, write Aslan ( [Email Protected] ) and we will make the best report that will see not only the readers of the community, but also the site How it is done

Subscribe also to our groups in facebook, VKontakte, Odnoklassniki and B. google + Pluswhere the most interesting from the community will be laid out, plus materials that are not here and video about how things are arranged in our world.

Jim on the icon and subscribe!

Use: The invention relates to the field of animal husbandry and agricultural ecology, in particular, to obtain protein feed and fertilizer. SUMMARY OF THE INVENTION: Fresh manure of agricultural animals populate the eggs of the room flies in the amount of 0.5 g per 1 kg. Previously in one tenth of the manure prepared for processing, the calculated amount of room flies. The larvae hatched from eggs is kept for two days. Prior to their transition to the state of active life. Then brings the rest of the manure and maintained for 3.0 - 3.5 days. before it is complete processing. The settlement of fresh manure with eggs of the room flies is carried out daily in an amount of from 0.4 to 0.5 g per 1 kg of manure.

The invention relates to the field of animal husbandry and agricultural environment, in particular to obtain protein feed and fertilizers. There is a method of cultivating the larvae of a room flies on native pork manure to obtain feed biomass larvae and fertilizer in the cultivator. The essence of the method is reduced to the following. In a special room, called the cultivator, contain containers with pork manure, into which the eggs obtained in the reproductor are made daily. On each kilogram of manure make 0.5 g of eggs. The larvae is hatched from eggs, which in five days processes the entire volume of manure, turning it into a nutrient substrate suitable after processing for use as fertilizers. During the same period, biomass of larvae reaches its maximum value. The resulting mass of larvae is separated from fertilizers and subjected to further processing to obtain feed. The resulting substrate is also subjected to further processing for the preparation of commercial fertilizer. Applying this method of processing manure from the next amount of the mass of the manure coming on processing, it is possible to obtain in five days by an average of 8-10% of biomass of larvae and 40-45% of fertilizers. The described method of obtaining biomass of the larvae of room flies and fertilizers in the cultivator for the processing of manure is adopted by us for the prototype into the task of research included an increase in the productive possibilities of the method, reducing the production time of products in a cultivator and a decrease in its working volumes and areas. It was solved by developing a method for 2 stage cultivation of larvae, when larvae in the first stage of eggs are grown for 2 days in the pre-component, and then over the next 3 days in the cultivator to the maximum growth of their biomass. The essence of the proposed method is that the pre-calculated amount of indoor fly eggs (0.4 0.5 g per 1 kg of manure) is made in 1/10 part of the manure prepared for processing. The larvae hatched from eggs contain in this mass of manure for 2 days. During this period, the larvae increases significantly in the amount and are included in the stage of active life. The period of growing two daily larvae is called predification. On the third day, the larvae, together with a mass of recycled manure, is transferred to the rest of the manure, which in the next 3 3.5 days is fully processed into the nutrient substrate suitable for the preparation of fertilizers, and the larvae reaches the maximum possible weight of their biomass. At the same time, the time of the main production process of obtaining commercial products is significantly reduced, no non-recycled components remain in the manure and the total area of \u200b\u200bthe cultivator is significantly reduced. Example of implementation 1 (optimum). Studies were carried out by comparing the processing conditions 1 with manure known and proposed method. In the pre-component for the first two days, 10 kg of manure was placed, in which the calculated rate of household eggs was made for processing 100 kg of manure (40 g of eggs per 10 kg of manure). The entire work area, occupied by manure in the pre-component, was 0.4 m 2. Within two days, the whole mass of the first 10 kg of manure was completely recycled into the substrate, the larvae were actively moving in search of food, which there was practically no in the mass of recycled manure. After that, on the third knocks, the larvae with a mass of recycled manure was introduced into fresh manure, which for the next three days completely recycled to the nutrient substrate for the preparation of fertilizers. In this case, the area for the placement of the manure was 6 m 2 (at the rate of 100 kg of manure 2 m 2 to day). According to a known method, 40 g of eggs were added daily for five days (the manure was laid with a layer of 8-10 cm), the processing of larvae was submitted for 5 days, the required area 2 m 2. The entire area of \u200b\u200bthe cultivator, occupied for five days, was 10 m 2. The manure placed in containers during the first two days was recycled by no more than 5 7% of its mass. The manure of third day was recycled with larvae by 30 40% of its original mass. Manure with the processing of larvae for four days was revised by 75,85% of the manure, which has been recycled for five days, was completely redesigned to the nutrient substrate. Thus, if the method used is currently required to process 100 kg of manure per day 2 m 2, and in 5 days 10 m 2 2, then according to the proposed method, the total working area of \u200b\u200bthe pre-component and cultivator for the processing of 100 kg of manure per day does not exceed 6, 5 m 2. The economy of the working area of \u200b\u200bthe cultivator in this case is at least 30% in addition, the substrate obtained after the processing of manure by two-sufficient larvae has the best loose-raised mass in which the components of non-recycled manure are completely lacking. The proposed method of cultivation of the larvae of the room flies was tested in the farm Dubrovitsy of the All-Russian NiMi of the Livestock with a positive result in 1994. The proposed method of organizing a cultivator can be widespread use in the creation of waste-free enterprises for industrial processing of native manure of farm animals on pigholders and poultry farms to obtain environmentally friendly feeds and fertilizers Guaranteeing the sanitary welfare of the environment from pollution and infection by waste of animals.

Claim

The method of industrial production of larvae of indoor flies and fertilizers, which includes the settling of fresh manure of farm animals with eggs of room flies in an amount of 0.5 g per 1 kg, the release of larvae from manure after the exit of the larvae from eggs and the processing of manure, characterized in that in one tenth A part of the manure prepared for processing makes the calculated amount of indoor fly eggs, hatched from eggs of larvae for two days before their transition to the state of active livelihoods, and then brought to the rest of the manure and kept for 3.0 3.5 days to Its complete processing, and the sequestment of fresh manure with eggs of the room flies is carried out daily in an amount of 0.4 0.5 g per 1 kg of manure.

In 2021, the Belgorod region intends to open a black lionink protein production plant in the Belgorod region. The design capacity at the initial stage is predicted in 300 tons of flour per month, with a by-product will become a zoocompost, recycled with larvae. It is noteworthy that the flour coming on pet food and fish, manufacturers intend to supply abroad, where its cost is much higher than inside the country.

Not easy choice

Such production today appear in our country, but nobody decided to grow a black lion's larvae in Russia. Such a project exists only in Holland. Belgorod manufacturer of vitamin supplements, as well as feed - for fish of valuable breeds and for pets, the first will be used to grow exotic insects in the chernozem strip. The joint project of the company and Belgorod Technological University named after Shukhov won a grant of 217 million rubles. Experienced product samples will be developed for these funds, while the cost of production is lower than that of the Dutch.

The head of the Department of Higher Education and Science Department of the Department of Internal and Personnel Policy of the Region, Natalia Shapovalova notes that the project is implemented within the framework of the Scientific and Educational Center - one of the five first in the country.

Subsidy at 217 million rubles was allocated within the framework of the National Project "Science", "she explains. - Passed competitive selection of projects. A total of 138 applications were filed. Of these, 45 best projects have chosen.

The director of the company Sergey Liman emphasizes: the interest in the insects in the manufacturers of feed is incomplete.

Vegetable protein will never be a full-fledged substitute for a protein of animal origin, whoever spoke, - Sergey Liman notes. - In the preparation of animal feed, we are widely used by waste - blood, bones, feathers. Even the bristles will make a sharp and then process. The flour, resulting from pork waste, is added to the feed birds, poultry waste is recycled in pigs for pigs and so on. At the same time, all these additives are quite difficult to assimilate the organism of the animal. Of course, the highest quality flour remains a fish: for example, an inexpensive fish is processed for trout. But we all understand: fish in the ocean is not so much.

Looking for different ways to obtain protein feeds and scientists, and investors makes the growing need for meat products. Sergey Liman leads to the example of foreign flour producers from the May beetle or locust.

From the locust, it turns out the best in the quality of flour, "he notes. - But if you open this production, somewhere this locust must be grown, create special conditions for its habitat. Can you imagine if unforeseen and all these insects happen in a free environment?

All these subtleties in investors and scientists had to take into account even at the stage of selection of insects for research. On the fly, black lioninka decided to stop for the simple reason that the insect itself in black earth latitudes is not dangerous for anyone: when a person from the larva turns into a fly - she does not drink and does not eat. Only produces larvae that are easy to control. In addition, they grow rapidly.

Insects and their familiar

Sergey Liman about black lionke can tell infinitely.

This fly is good because it has never been noticed in the entire history of study, so that its population decreases due to any epidemics, he explains. - A certain protective substance is produced in the black lion's body, a kind of antibiotic. This allows them not to hurt. For us, it is also good - no need to worry about how to protect tribal insects.

Together with scientists, manufacturers intend to create their own technology for obtaining protein masses

Fly in the photo looks quite similar to the usual room, but Sergey Liman emphasizes her uniqueness.

Indoor flies can carry many diseases. Yes, and worshipers that are used in such industries, grow long. And these larvae are becoming such that they can be recycled in flour, "says the investor. - Well, if you look at the face of the face, you can see that it, so to speak, face - pearl color. Very nice!

In addition to the "spectacular appearance" of the insect, among the advantages of flies - high productivity. Larisa from one individual is very much.

I will try to explain our choice on the example from the pig-breeding industry, "Sergey Liman continues. - If one sow brings six piglets, and the second - immediately 14, what are you buying? Of course, the second, even though she is expensive. - So we are interested in this fly, and no other.

At the same time, at the initial stage of tribal larvae will have to be purchased from Dutch partners. According to Limana, there are enough buckets. It is important then to provide them with greenhouse conditions for growth and turning into flies.

Cheaper than partners

All the technology of growing larvae, like the equipment, could be brought from the same Europe, together with tribal insects.

But we believe that you need to create our production technology - it will be easier and cheaper than foreign, - Sergey Liman is sure.

The first Vice-Rector of the University of Yevgeny Yevtushenko adds: the most 217 million, obtained as a result of the project competition, will be sent to the scientific and technological support of the project. Laboratory equipment, devices, research - all this will be used to make a grant means so that it can be possible to completely release a prototype product. But the plant will be built at the expense of the investor.

Our employees will engage in the automation of the entire cycle, creating a comfortable environment for insects, explains Evgeny Yevtushenko. - The specialists of the most different profile will be required. For example, for the new factory, our scientists intend to develop and implement a new system of technical vision.

So far, no country university is preparing specialized personnel for such industries, but the company does not consider it a problem.

The principle of working with larvae is the same as on any livestock enterprise, - notes Liman. - So, we will need to just train specialists in place.

The first storage, larvae and flour, as well as new flies in the gubkin intend to get already in 2021. In parallel, the company will work on the production of premium feed for pets. Part of the flour from the larvae will be used there, and the remaining products will try to sell abroad.

And how are the neighbors

Lipetsk project of the company "New biotechnologies", where the larvae of indoor flies are processed in the fodder protein, received support in the amount of three million rubles from the regional fund to promote the development of small forms of enterprises in the scientific and technical sphere.

Any scale.

Types of waste used: nulls, litter, case of chickens, meat and fish raw materials.

Why does the population of Russia be poisoned by poisonous gases from landfills and what to do about it? The cost-effective solution to the problem of "methane" landfills and protein feeds for fish farming with biotechnology.

The article covers the current problems of the accumulation of waste in landfills, the reasons for the resulting the formation of a poisonous gas at the "Narrow" polygon in Volokolamsk and subsequent poisoning of people, considered the process of formation of landfill gas and proposed new profitable methods for recycling (processing) of food waste ...

In this article, we tried to explain to our readers in a simple and accessible language, which represents the methods of disposal of chicken litter and various nurses using larvae flies. To answer the question of what the uniqueness and advantages of such technologies for processing litter and manure.

And why so cheap and unique eco-friendly technologies, scientifically based since the 60s of the last century, have not yet taken their definitely worthy place in the agrarian sector of the economy?

Our company offers high-performance equipment for growing flies of flies on various organic waste.

In this section you can familiarize yourself with its technical characteristics and place an order ...

This material consistently describes the stages of the implementation of the alleged project for the processing of litter. Also, there is also preliminary information on the planned production of organic waste processing in the form of a litter (scheme, calculation of the area, the configuration of the premises, the performance data and purpose of the premises), and will also affect the economic efficiency of such production and financial remuneration for the implementation of the project.

The material was prepared on the basis of one of the queries of our client to prepare a working draft for the construction of a similar enterprise, in order to process 75 tons of litter to provide a duck farm with animal protein protein to replace fish flour in the diet of the bird.

Information on how to create a profitable business with a profitability of 700-800% with the help of technologies for the cultivation of worshi.

Learn about the secrets of business on breeding and selling larvae flies, as well as about the difficulties with which you may encounter starting this business.

Currently, China has reached the leading position in the world in the biological utilization of food waste and waste of agricultural production using a black lionink larvae.

The several largest investment companies in China with the full support of the Government of the PRC invested huge funds in the construction of such processing industries.

Humanity produces food waste daily and regardless of whether those are suitable for eating or unsuitable, food waste has a significant amount of residual nutritional elements that have become unavailable to man and most animals due to low quality, and poor taste attractiveness. . But larvae flies black soldiers indifferent to the taste of their food - they eat all that they will be given.

![]() Growing black lining larvae on food waste and receiving feed protein, fertilizer and chitin

Growing black lining larvae on food waste and receiving feed protein, fertilizer and chitin

The advantage when using black lionic larvae is their ability to significantly reduce the content of harmful bacteria in organic waste, such as manure. For its mass decreases by 50%, and nitrogen concentration decreases by 62%. This is important because the excess of nitrogen from the manure is washed away with rains in the soil and reservoirs, and they pollute them very much. In addition, the rapid feeding of the larvae of the black lionish waste makes it possible to eliminate the appearance of unpleasant odors from the excess manure and marks, as well as the formation of methane gas, poisoning the atmosphere.