The best options for insulating the ceiling of the bath. Thermal insulation of the ceiling of a bath with mineral wool is a rational solution. Ceiling insulation technology

The walls, as well as the ceiling, must be insulated in the bath. It depends on the insulation how long the hot air will remain in the room. As follows from the laws of physics, hot air tends upward, while cold air takes its place. If the ceiling in the bath is cold, then the warm air is instantly cooled, which further contributes to the formation of condensation and water droplets on the ceiling. You can avoid all this very simply by pre-insulating the ceiling. This is the topic of today's article.

Insulation materials - there is nothing better than Isover!

In the bath, it is quite possible to do it yourself, without resorting to the services of expensive specialists. The main thing in this is to follow the technological instructions exactly, as well as choose the right material for insulation. Then even inexperienced builders will be able to make a high-quality vapor barrier for the bath room in the shortest possible time.

To begin with, let's talk about heaters, which are considered the most popular and in demand today. The insulation will constantly function in conditions of high humidity and temperature. In this regard, preference should be given to goods that have the following characteristics:

- Resistance to humidity and temperature extremes;

- Quick and easy installation;

- Low level of thermal conductivity, which helps to retain heat inside the room;

- Environmental safety - under the influence of high temperatures, many materials are characterized by the release of harmful and toxic substances. Therefore, it is necessary to buy exclusively pure and safe products;

- Low level of moisture absorption;

- Resistant to microorganisms, including bacteria, fungi and mold.

First of all, it is necessary to highlight such material as isover, which belongs to the category of mineral-containing insulation. Izover is very convenient and simple in the installation process, and also has a fairly affordable price. Depending on the mineral on the basis of which isover is produced, dolomite, basalt, slag and many other heaters are distinguished. This material is produced in slabs and rolls. Today, some improved versions of isover, equipped, for example, with a foil coating, are popular. Due to the presence of foil, it becomes possible to achieve an increase in thermal insulation, since heat is reflected from the surface of the protected ceiling with a cold roof.

At its core, isover is a better and more advanced analogue of glass wool, since the production is carried out using fiberglass. Key features include the following performance characteristics:

- 1. In addition to thermal insulation, izover boasts remarkable properties in terms of sound insulation. Therefore, it can be used not only to protect the ceiling, but also the walls.

- 2. Mold is practically incapable of multiplying, since the material is not a breeding ground for such microorganisms.

- 3. Low weight, which makes it possible to independently install the material under the roof without much difficulty

- 4. The composition contains substances such as limestone, soda and sand, which makes it one of the most environmentally friendly and safe insulation materials.

- 5. Isover is a very strong and elastic material that adheres tightly to the wooden frame during installation.

- 6. An important property is durability. Correct installation makes it possible to use the insulation for more than a dozen years without deteriorating its main characteristics.

The only more or less significant drawback is the possibility of using isover only under conditions of a temperature regime not exceeding 300 degrees Celsius. The material itself does not burn, but in the event of a fire it emits a certain amount of smoke. Despite this, home craftsmen prefer to purchase isover, since its advantages many times outweigh this disadvantage.

Polyfoam as insulation - can this polymer be used in a bath?

An excellent alternative to isover is the well-known polystyrene or expanded polystyrene. This material has long established itself as an excellent insulation and insulator. Moreover, foam can be used in a variety of buildings and structures, including baths, living quarters, sheds, as well as for outdoor decoration.

Choosing foam for thermal insulation, the owner of the bath will be able to count on many positive aspects from its use. Its thermal conductivity is at a very low level; in this regard, expanded polystyrene may well compete even with isover. In addition, the insulation is very light, so there should be no problems with installation. The process of processing foam plastic will not cause any problems for novice builders, because special knowledge, as well as special tools, is not required. Any knife, even the most common knife, will work for cutting and leveling.

Having installed expanded polystyrene, you will forget about the need to repair the roof for several decades. This is due to the huge margin of safety, and the insulator feels great in the harshest conditions without any loss in quality. Styrofoam practically does not burn, but it is recommended to buy a special type of polymer treated with flame retardants. Thanks to this chemical, the fire resistance is increased many times over.

In order to objectively evaluate the foam as a heater, it is necessary to note its negative qualities. First of all, let's highlight the weak resistance to ultraviolet radiation. So, under the influence of such rays, the polymer begins to decompose and deform. Therefore, it is imperative to install finishing materials in order to close the polymer from UV rays.

This insulation also cannot be classified as environmentally friendly. This is especially true for materials that have not been treated with flame retardants. When burning, polystyrene foam instantly begins to melt and releases various toxic components. As a result, not only human health, but also his life can be in danger.

Expanded clay - a natural thermal insulation material based on clay

Among the materials that are distinguished by the highest environmental friendliness indicators, expanded clay should be distinguished. This is an excellent natural insulation, which is made on the basis of various clay fractions. Expanded clay is ideal for use in harsh conditions in the bath. Many experts advise using this particular material for the ceiling. Lightweight and plate expanded clay is at the same time a breathable material, which has a positive effect on air exchange in the room.

Advantages of expanded clay:

- This natural substance does not emit any harmful waste, even at high temperatures or after years of continuous use;

- High level of durability - the insulation still performs its main functions during the entire service life of several decades;

- Expanded clay can withstand any temperature extremes. In addition, he is not afraid of high temperatures, since the clay on the basis of which he is produced is subjected to high-temperature firing;

- Remarkable moisture resistance, due to which the roof insulation is not susceptible to dampness and, as a result, it is incredibly difficult for fungus and mold to multiply in such difficult conditions for them.

Expanded clay itself is a fairly cheap material. However, it is better to spend a little more money, but buy fine-grained insulation. It is much easier to work with such a material, moreover, its thermal conductivity is somewhat lower than that of other varieties. But the most important feature is that small rodents, the same rats and mice, will not be able to settle in ceilings covered with similar material. This is a key feature of expanded clay, which compares favorably with all other insulators in the construction market.

Vapor barrier and waterproofing - integral stages of thermal insulation of the ceiling in the bath

Ceiling insulation is far from the only thing that needs to be done to protect the floors of the bath from moisture. Vapor barrier is of great importance, since the ceiling first of all has to be under the influence of hot steam. The absence of a vapor barrier layer contributes to the penetration of steam into the depth of the protective barrier, settling in the form of drops of cold moisture on insulation and sheathing. This negatively affects the quality of ceiling insulation, in addition, the necessary prerequisites are created for the development of various forms of life, as well as the decomposition and decay of wooden beams and boards.

As a vapor barrier, special film materials are usually used. The task of such insulators is to protect thermal insulation from dampness and the destructive effect of moisture. In ordinary rooms, for example, bathrooms, it is advisable to use anti-condensation membranes, which are not expensive. This is a fairly high-quality material that prevents the penetration and settling of moisture on insulation.

However, for a bath, such an insulator is not always suitable, since it requires a better material that can function in conditions of very high humidity and temperature. These include, for example, foil film. This is a special shiny film that must be handled very carefully, even though it is strong. It stretches and is fixed over the entire surface, however, any, even the smallest cut, threatens to reduce the effect of the work to zero.

To protect the ceiling structure from moisture, you can use proven materials, for example, multilayer insulating films or membranes. Such insulators are made on the basis of kraft paper, and one of the sides is foil coated. In this case, saving is not recommended, so give preference to reliable manufacturers. So, the products of Izospan, Megaizol, Folgoplast have been occupying leading positions in the vapor barrier market for a very long time.

No special difficulties are foreseen when working with an insulating membrane. The film itself is overlapped, capturing the previous layer by about 10 cm. Any damaged area must be replaced with another, where there are no mechanical defects or cuts. To fix the film, you can use a special foil tape, due to which the surface will acquire a solid appearance. If you have a construction stapler, then it is better to fix the film with these tools. This contributes to the creation of the most durable and reliable hermetic coating of thermal insulation materials.

Waterproofing is also a very important element of renovation work. Although today vapor barrier films can boast of all the necessary waterproofing characteristics. In any case, waterproofing is required to separate the insulation from the attic. A feature of the installation is that the material is laid from the attic side.

The key difference between waterproofing is to prevent moisture from entering the insulator from the attic. After all, moisture can penetrate in the form of drops from rain, as well as as a result of roof leaks. If the ventilation in the building is low, then water droplets can also form in the attic, having a negative effect on the insulation.

Thus, a competently executed steam and waterproofing protects the insulation materials both from the inside of the bath, where the hot air has the main effect, and from the roof, where raindrops can cause enormous damage to the entire structure.

Ceiling insulation is the most common method

The ceiling insulation method described below is perfect for all types of baths, regardless of the presence or absence of attic spaces. The only condition is the floor beams, since all the main insulation elements will be mounted on the beams.

Wooden structures, which will serve as the main thermal insulation, are recommended to be treated with special antiseptic substances in order to additionally protect them from the destructive action of mold.

The work itself is divided into several main stages. First of all, we install a vapor barrier film on the beams from the side of the bath. As already noted, a membrane equipped with a foil layer is considered the best solution. Due to the ability to reflect heat energy, you can significantly reduce the costs associated with heating the bath and maintaining the temperature at the required high level. The film should be handled very carefully, avoiding cuts and other damage. Having carefully fixed all layers with a stapler, we can consider the vapor barrier successfully installed.

The next important point is the frame or crate. This structure is mounted again from the side of the room. The need for the lathing is due to the fact that it supports the insulation and the vapor barrier film. In the future, the ceiling sheathing is nailed to the frame. Some specialists do not install a crate at the stage of building a bath, but the frame is an ideal solution. For example, additional slabs create a small gap between the ceiling sheathing and the insulation, which has the most positive effect on the heat reflection effect.

The lathing contributes to a tighter fit of the thermal insulation to the membrane, as a result of which the likelihood of condensation is reduced to zero. Naturally, most modern heat insulators do an excellent job with moisture, but constant getting wet leads to a deterioration in their performance.

Now we go directly to the installation of insulation. This is one of the easiest moments in the whole work. It is required to lay materials very tightly, without leaving even the smallest gaps. Slots are absolutely unacceptable, so it is better to put a little more physical effort and squeeze the insulation, rather than leave a small gap after completing the work. It remains only to install the waterproofing of the ceiling, which is mounted from the side of the roof or attic. Again, we need staples and a stapler to secure the film as firmly as possible to wood structures.

The ideal solution would be to install a sub-floor, to which the waterproofing will be attached. However, this is associated with additional costs, moreover, this option is only possible if there is an attic space. Thanks to the subfloor, a small gap remains between the base of the ceiling and the insulation itself, which contributes to continuous air exchange and ventilation.

That's all, you can proceed to the installation of cladding panels on the ceiling. Basically, for these purposes, they choose either lining, although the choice is very, very large.

Clay and straw - folk methods of bath warming

An interesting solution is to use a mixture of straw, clay, sand and sawdust. Such a composition can significantly reduce heat losses, as well as protect the ceiling of the bath. After installing the vapor barrier, proceed to applying the mixture. The correct proportion is very important - three parts of sawdust or ordinary straw are added to two parts of clay, after which the resulting solution is thoroughly kneaded to a state of thick sour cream or river silt.

The resulting mixture is applied with the help of ordinary improvised tools in a layer up to 10 cm. The only problematic issue is the speed of drying, since it can take up to several weeks for the clay to dry completely. In addition, at high temperatures, for example, in summer, during the heat, cracks can form on the drying solution, which can only be repaired with the help of a similar mixture. Finally, a layer of chips or sawdust can be poured over the mixture after it has completely dried, which will only increase the effect of such a "cake", and also further reduce heat losses.

Any bathhouse needs high-quality insulation of the ceiling - warm air, according to the laws of physics, tends to rise up. And if there is no heat-insulating layer on its way, then much more fuel will be needed to warm up the bath and maintain a stable high temperature in it.

But this is not the only problem - in the absence of insulation, condensation will accumulate on the ceiling of the bath, and drops dripping on top of the head and back are unlikely to bring great pleasure to anyone. And the moisture that goes up along with the heat will contribute to the destruction of the ceiling slabs and the supporting roof system. The only way to avoid these troubles is to make high-quality insulation of the ceiling in a bath with a cold roof. And our material will tell you what and how to make it from.

We plan work

Before buying materials and taking up tools, you should carefully plan your actions. A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future.

The first question is whether it is possible to insulate the ceiling in the bath on your own? Or is it worth entrusting this business to a team of builders? The process of insulating the ceiling itself is not something complicated, therefore it is not difficult to perform it on your own, even without having much experience in repair and construction. The main thing is to carefully observe the technology and approach the matter responsibly. The availability of the necessary materials also speaks in favor of self-insulation of the ceiling - they can be found in any large hardware store or on the market.

The second question - what, in fact, needs to be done? Ceiling insulation in a cold bath consists of three stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

As a result, a kind of "layer cake" should be obtained, the lower layer of which is the ceiling covering, and above it, vapor barrier, thermal insulation and waterproofing are sequentially located from bottom to top. More details about why this is necessary and how to do it will be described below. Now is the time to think about the choice of materials.

We select insulation

A melted bath is kept at a very high temperature and humidity. The thermal insulation material must comply with these conditions and, most importantly, not emit harmful substances when heated. In addition, a good sauna heater must be fire resistant. It is undesirable for the thermal insulation material to be too heavy or inconvenient to carry and install. Now let's take a closer look at the materials.

It is the most common type of insulation for baths and private houses; it is a fibrous thermal insulation material that exists in three types:

- glass wool;

- stone wool, which is made from basalt or other rock melts;

- slag wool, made, like cinder blocks, from blast-furnace slag.

The main advantage of mineral wool, in addition to its very low thermal conductivity, is considered to be that it is not a breeding ground for fungi, mold, insects or rodents. This is especially important for a bath located on a private plot. It is also worth noting that this material does not burn, does not change its volume and shape when heated or cooled, and is very easy to install due to its low weight. Mineral wool is produced in the form of rectangular panels or in the form of rolls.

As for the disadvantages, there are two of them - the ability of mineral wool to absorb moisture (especially for slag wool) and the potential harm of the phenols contained in them. Both of these drawbacks can be eliminated if you correctly approach the issue of steam and waterproofing and prevent the contact of mineral wool with the air flow, especially inside the bath.

Important! Small particles of mineral wool can have a damaging effect on the eyes, skin or lungs of a person, therefore, when working with it, you must definitely wear tight clothing and use gloves, goggles and a respirator.

Table. comparative characteristics of different types of mineral wool.

Expanded clay

It is a small clay pebbles with a porous structure. By the combination of its advantages, expanded clay is the most suitable material for insulating the ceiling in a bath.

- Security- it does not burn, is environmentally friendly and does not emit harmful substances into the air.

- Durability- expanded clay does not decompose under the influence of sunlight and does not deteriorate over time.

- This material not an attractive environment for fungi or bacteria.

- Has a low cost and is easy to install.

Also, expanded clay absorbs significantly less moisture than mineral wool, but the need for vapor barrier and waterproofing layers still remains.

Expanded clay

Styrofoam

At one time he was one of the leaders among thermal insulation materials. But even taking into account all its advantages, you should not choose polystyrene as a ceiling insulation in a bath - in a fire, the material burns well, and its smoke is very dangerous for human life and health. It is also capable of decomposing and simply under the influence of high temperatures (and in the bath they are inevitable), therefore, expanded polystyrene can hardly be called a reasonable choice in this case.

Styrofoam

Ecowool

Natural fibrous material made from cellulose with additives that impart flame resistance and protect against rodents, insects and microorganisms. Ecowool is lightweight and has the ability to fill all cracks and gaps. Like expanded clay, it is environmentally friendly and does not emit any substances harmful to humans into the air.

However, ecowool is capable of absorbing a lot of moisture, which worsens its thermal insulation properties. Therefore, when using it, good ventilation under the roof and high-quality waterproofing are desirable. Another disadvantage of its use is the complexity of installation - with the "wet" method of application, special equipment is required.

"Wet" method of applying ecowool

A mixture of cement and sawdust

It is a "classic" material for insulation, which was used even before the appearance on the market of mineral wool or foam. In some cases, clay can be used instead of cement, and straw can be used instead of sawdust.

First, a dry mixture is prepared in the following proportion: one part of cement and one part of lime is taken for 10 parts of sawdust. The resulting dry mass should be poured with one and a half parts of water and a sufficiently thick and homogeneous solution should be obtained. The mixture is spread on the surface and distributed in a fairly even layer.

Important! It is advisable to use sawdust that has been dried for several months or better than a year.

Such a material is very cheap and environmentally friendly, but at the same time it does not have such high thermal insulation as expanded clay or mineral wool. In addition, the process of its manufacture is laborious, and after laying it is required to close the resulting cracks (and they are inevitable).

Materials for steam and waterproofing

For a bath, the vapor barrier of the ceiling is vital, otherwise the rising moisture will not only worsen the thermal insulation properties of the insulation, but also contribute to the development of fungi and mold on the ceiling itself and on the roof rafters. As a material for vapor barrier, specialized films and coatings are used. Particular attention should be paid to anti-condensation membranes. When buying vapor barrier films, it is advisable to choose those on which there is a foil layer.

Important! When working with such films, be careful not to allow any breaks in the vapor barrier material or the foil layer, otherwise its protective properties will significantly deteriorate.

As for waterproofing, you can use for it both special films that can be found in any hardware store, as well as cheaper roofing felt or dense polyethylene.

Common vapor barrier materials: 1. Geosynthetics. 2. PVC membrane. 3. Glassine. 4. Roofing paper. 5. Aluminum foil. 6. Thermofol.

Insulation of a floor ceiling

There are three main types of bath ceilings:

- hemming;

- panel;

- grazing.

Now we will consider the last type and find out how to insulate it and what nuances should be taken into account.

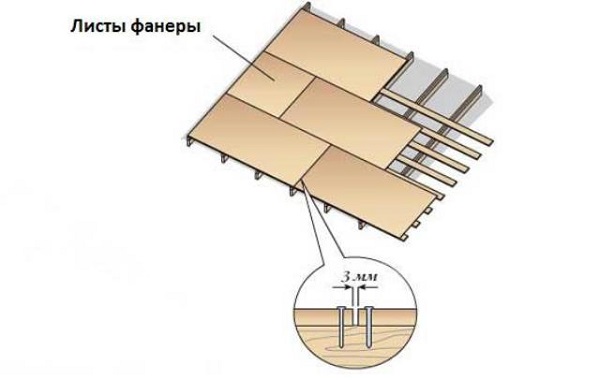

A flat ceiling is usually used for small baths, which are heated quite rarely and seasonally. Sheet pile or simple edged boards are laid on the upper part of the wall, adjusted to each other and fixed, without using support beams. The resulting structure is very simple, but at the same time it is unable to withstand a heavy load, therefore it is impossible to use a thick layer of thermal insulation here.

Important! It is advisable to lay a flat ceiling slightly below the height of the walls in order to leave space for backfilling expanded clay or laying mineral wool. If this is not possible, then sides should be nailed along the perimeter of the ceiling under the roof.

The step-by-step insulation of the bath floor ceiling is as follows.

- From the side of the attic, a vapor barrier film is laid on the flooring so that the foil layer is directed downward. The material should be overlapped by 10-15 centimeters, seams and joints are sealed with foil tape.

- Mineral wool is laid on top of the vapor barrier, expanded clay is poured or a mixture of cement and sawdust is laid, depending on your choice. Please note that it is undesirable to use a layer of insulation that is too thick, since the decking ceiling is not suitable for high loads.

- The layer of heat insulator is closed from above with roofing material, polyethylene film or waterproofing coating, with an overlap and with careful gluing of the joints.

- The final stage will be laying on top of the resulting "layer cake" sheets of plywood or boards.

It makes sense to use a flat ceiling in small baths and in the case when the simplicity and speed of its installation and installation of insulation are important to you. If you plan to make a large enough steam room or arrange an attic under the roof for storing bath accessories, then your choice should be stopped on a false ceiling.

Warming of a false ceiling

Here, not the flooring itself is laid on the upper part of the wall, but support beams made of wooden beams or planks spliced together. And already from below and from above, the ceiling and floor of the attic are laid on the beams. At the same time, layers of steam, hydro and thermal insulation are laid in the space between them.

The very process of insulating a ceiling with a similar design depends on what material you are using. For mineral wool, this happens as follows.

Video - We insulate the ceiling in a bath with a cold roof using mineral wool

The process of warming the hemmed ceiling of a bath with a cold roof looks a little different when expanded clay or a cement-sawdust mixture is used. Let's imagine this in the form of step-by-step instructions.

- From below, a rough flooring of boards is laid on the floor beams. The gaps between them must be treated with a sealant or smeared with a mixture of clay (or concrete) and sawdust.

- A vapor barrier film is laid on the flooring both from the steam room and from the roof, and not only the boardwalk should be covered, but also the beams themselves.

- Expanded clay is poured into the resulting boxes or ecowool is laid.

- Roofing material or other waterproofing material is overlapped on top of the insulation and attached to the beams using a construction stapler.

- Boards or plywood are laid on the waterproofing to form the floor of the attic.

- Lining is laid on the bottom of the rough boards.

If you use a mixture of clay and sawdust to insulate the ceiling, then it is advisable to put a layer of mineral wool on top of the frozen mixture or fill in expanded clay - this will improve the performance of thermal insulation.

Important! The optimum layer thickness of a mixture of clay and sawdust for using a bath in the warm season is 50 mm. If you plan to bathe in it in winter, then you will need to make a layer of insulation of at least 150 mm.

Insulation of a panel ceiling

Such a ceiling design is the most difficult for self-production - first you need to make the panels themselves, and then raise them up and fix them either on the cross beams or directly on the upper part of the walls.

Each of the panels is manufactured as follows.

- A layer of boards, carefully adjusted to each other, is laid perpendicularly on the support bars. This layer will serve as a ceiling for the bath.

- Boards are attached to the inner side of the resulting shield, which will serve as the sides of the panel.

- A vapor barrier material is laid on the boards and sides and fixed with a construction stapler.

- Mineral wool or ecowool is placed in the inner space of each panel. You can also use a cement-sawdust mixture or expanded clay, but in this case, the panel will turn out to be especially heavy.

- On top of the heat-insulating material, a polyethylene film or roofing material is laid, with overlapping joints by 5-10 cm.

- The top layer of boards is laid, which will serve as a floor for the attic.

The resulting panels should be lifted and mounted, while it will not be superfluous to put solid boards on them from above and below, connecting all the panels to each other. The joints between them also need to be insulated with strips of mineral wool scraps. Alternatively, you can take all the same mixture of cement and sawdust.

Advice! The very assembly of the ceiling panels, their lifting and installation is very laborious. Therefore, it is advisable to use some kind of lifting device and work not alone or in a couple, but as a whole team.

The choice of the type of ceiling and the insulation material used should be based on the budget, personal experience of construction work, the area of the bath and how often it will be used.

Video - Ceiling arrangement in the bath

The Russian bath is a unique place for relaxing and revitalizing water treatments and socializing. Strong immunity, beautiful skin and a body free from toxins - these are the results of a constant visit to the bath. However, the effectiveness of bath procedures cannot but depend on the high-quality insulation of the bath.

Everyone has long been accustomed to the fact that it is necessary to insulate the internal surfaces (floors, walls, ceilings) in apartments and houses. However, high-quality insulation of the bath is no less necessary. If it is enough to insulate only the walls in an apartment, then a bathhouse and a private house need careful insulation of the ceiling. The thing is that the heated air becomes lighter and rises up. If the ceiling does not have good thermal insulation, then hot air will pass directly to the roof and heat the air around the house, and this is a waste of heat.

Thermal insulation of the ceiling of the bath with mineral wool- an inexpensive and simple option. If everything is done correctly, then such a ceiling can serve for many, many years.

Technology

Mineral wool is necessary be sure to isolate from water vapor... To do this, it must be closed with a vapor barrier, which must be airtight and waterproof. Today, foil glued at the joints with aluminum tape is often used for vapor barrier. Among the novelties of the construction market is foil-insol, a modern material made on a glass-cloth basis. In addition, glassine, membrane insulation or ordinary plastic wrap are often used.

Mineral wool is necessary be sure to isolate from water vapor... To do this, it must be closed with a vapor barrier, which must be airtight and waterproof. Today, foil glued at the joints with aluminum tape is often used for vapor barrier. Among the novelties of the construction market is foil-insol, a modern material made on a glass-cloth basis. In addition, glassine, membrane insulation or ordinary plastic wrap are often used.

Bath ceiling can be:

- hemmed;

- panel;

- flat.

If the ceiling is hemmed, that is, the boards are hemmed to the floor beams, it is necessary to insulate from the side of the attic. 2 layers of vapor barrier (glassine, roofing material, etc.), a layer of mineral wool, again a layer of vapor barrier are placed on the ceiling.

To make the vapor barrier hermetic, the joints can be glued with foil tape. Next, you can lay boards on the floor of the attic.

In the case of a panel ceiling, each panel is covered with a vapor barrier film, mineral wool is laid on it and closed with a vapor barrier. All this is sewn up with boards.

The easiest way to insulate a floor ceiling... The technology here will be the same as in the case of a false ceiling. To do this, a vapor barrier is rolled out on the boards from the attic, then a layer of mineral wool 200-250 mm thick is placed on it and completely covered with a vapor barrier. Next, the floor is sewn up with boards.

Advantages and disadvantages

Among the advantages of mineral wool insulation you can call what:

Among the advantages of mineral wool insulation you can call what:

- this material almost does not conduct heat and can well insulate a room, including from extraneous sounds;

- mineral wool is fire resistant and cannot cause a fire;

- fibrous insulation lasts a long time;

- the material is inexpensive and easy to use;

- mice, insects and other animals do not start in mineral wool, mold will not appear on mineral wool and putrefactive processes will not go in it;

- mineral wool is completely environmentally friendly and will not harm health;

- mineral wool is durable and resists mechanical stress.

Everything has its downside, and mineral wool as a material for insulating the ceiling of a bath, unfortunately, is no exception. It has few disadvantages when compared to the number of advantages, but these disadvantages are very significant... Consider them:

- mineral wool cannot be crumpled or tamped, because compacted fibers greatly lose their thermal insulation properties;

- mineral wool should be completely isolated from the slightest water vapor, because when wet it will lose all its properties useful for insulation.

So, thermal insulation technology with mineral wool not that hard. It is quite possible to apply it independently and without special construction skills.

A private bath is a great place where it is so nice to take a steam bath in the cold. To quickly heat up and keep the heated air in the bath, you need to qualitatively insulate all its surfaces. Particular attention should be paid to the ceiling, since, according to the laws of physics, warm air masses rise upward.

Conditions of high temperatures and humidity make special demands on the choice of insulation. When carrying out thermal insulation with your own hands, you must also take into account what kind of structure the ceiling has. Depending on this, it can be insulated from the inside or outside.

Sauna ceiling design

In self-built baths, an attic or an attic is usually located on top. This provides additional air space and makes the room warmer. However, this will not be enough to keep the heat in the steam room. The ceiling of the bath should be additionally insulated.

This is most conveniently done from the inside of an attic or attic. Insulating material is positioned taking into account the fire safety requirements. It is especially important to properly close the junction to the chimney.

The distance between the pipe and the insulation should be at least 20 cm. For this, a box of boards is built around it, and from the inside it is filled with fire-resistant material, for example expanded clay or mineral wool.

Access to the ceiling of the bathhouse from above through the attic makes it possible to insulate it in different ways using traditional natural materials or modern insulation. If there is no attic, thermal insulation is installed from the inside of the bath.

- The beams are hemmed with ceiling boards.

- A layer of vapor barrier is laid on top of them (better than foil).

- The space between the beams is filled with insulation: mineral wool, expanded clay, clay with sawdust. Other materials can be used.

- The insulation is covered with a waterproofing film.

- If they walk on the floor of the attic, flooring is made of boards, under which a ventilation gap should remain.

Insulation of the ceiling from the inside

If there is no attic room above the bathhouse, you can carry out insulation with your own hands from the inside. For this, basalt wool is used. At the same time, it is important to ensure that the insulation is protected from moisture penetration.

Advice! For the interior lining of the steam room, wood with a low density is chosen. Alder, linden, cedar or aspen boards not only create a pleasant scent, but also provide good thermal insulation. Pine also smells good, but has a tendency to stick.

Correctly carried out warming of the bath will provide faster warming up and allow more economical use of firewood or electricity for heating. You can place thermal insulation from the inside or from the side of the attic. When building a bathhouse with your own hands, it is better to take care of high-quality insulation in advance.

Every person, without exception, sometimes wants to take a steam bath or relax in a sauna. It is lucky for someone who has their own bathhouse on the site, especially if it is dry there, there are no drafts, it smells like wood. To make it comfortable to carry out all bath procedures in the steam room, insulated walls, floor and ceiling are needed. This will help create a pleasant atmosphere and keep you warm for a long time.

The need to insulate the ceiling in the bath

Even from the school desk, everyone knows that hot steam and warm air go upstairs. This leads to the fact that the floors of the bath will periodically get wet from the effects of condensation, and subsequently rotting and destruction awaits them. As for the dressing room, it is usually always cold and damp there, as a result of which mold and mildew appear in this place. Therefore, before insulating the ceiling in the bath, it is recommended that you familiarize yourself with the basic technologies for the arrangement. It is advisable to think about what kind of insulation is suitable for you specifically, because thoughtful thermal insulation means the absence of dampness and cold now and other problems in the future.

When constructing a bath, the ceiling must be insulated so that the heat in the steam room remains long enough, and the condensate does not accumulate and does not fall in large drops on people. Agree, this brings a lot of unpleasant sensations and does not add comfort.

It is not recommended to impregnate wood with chemicals that protect it from rotting and the spread of fungus, because then you will have to breathe these fumes during bath procedures. It is necessary to protect the natural material from moisture ingress on it with the help of various insulating agents.

Ceiling insulation should be based on three basic principles:

Ensuring the accumulation of steam;

Protection of the attic from moisture (if available, of course);

Prevention of the formation and accumulation of condensation.

The ideal option for insulating the ceiling of a bath is the so-called "layer cake", which consists of three parts: a waterproofing layer, mineral wool, and aluminum foil.

Materials that are better not to be used for ceiling insulation

A bath ceiling that meets all the requirements must be made of high-quality materials that correspond to the purpose, and not every heater is suitable for a bath.

The ceiling should not be made of plastic, fiberboard or plywood. The first material collects condensation. As for the plywood ceiling and fiberboard, under the influence of moisture, these materials swell and, accordingly, deform. And if they are painted or proliferated, then toxic substances will be released under the influence of high temperatures, which is unsafe for humans.

Bath ceiling device

In order to be able to comfortably spend time in the steam room, it is necessary to insulate all surfaces so that the heat does not go anywhere. Before insulating the ceiling in the bath, first, let's get acquainted with its design. It can be either separate or combined with the attic. The ceilings of log or panel baths have a similar design. Their device includes: vapor barrier, filing ceiling material (for example, boards), beams, insulation and rolling sheathing.

The ceiling in a bath without an attic has some difference and requires additional work. Usually, the top of the lining is coated with clay up to 2 cm thick.Then backfill is made, for example, from wood chips and cement mortar with a thickness of about 15 cm.With a sufficient thickness of the insulating layer, condensation on the ceiling will not collect. When it appears, it is necessary to increase the layer of thermal insulation. The joints to the chimney are treated with fire retardant mastics and non-combustible asbestos materials.

Materials for warming the ceiling of the bath

Since ancient times, natural substances such as moss, clay, sawdust, straw, earth or slag have been used as insulating materials. To maintain room temperature, some try to insulate the ceiling of the bath with clay. They smeared all the cracks with it and covered it from above along with wood shavings or moss with earth. This natural protection from the cold was durable and effective, but it is heavy enough and therefore requires a strong overlap. Clay insulation, in addition to its natural qualities, is also good because it does not allow rodents and other pests to breed.

Today, there are various materials that greatly simplify the process of ceiling insulation. What else can you insulate the ceiling of a bathhouse, besides clay and straw? Stone or basalt wool, expanded clay, ecowool, penoizol, etc. are sometimes used as a protective material. Styrofoam is sometimes used. But it must be used with caution, since at high temperatures it emits toxic substances and, among other things, is fire hazardous. It is also not recommended to use glass wool as insulation. It requires special handling and serious protection of the skin, respiratory organs, which is almost impossible to organize at home.

Let's take a closer look at some types of insulation, because the question of what is better to insulate the ceiling of a bath is very difficult to answer unequivocally.

Mineral wool

Mineral wool is a fiber made from rocks - basalt, limestone and dolomite. This insulation ranks first in popularity due to its advantages. Here is some of them:

Durability;

Ease of moisture absorption - hygroscopic;

Fire retardant, high fire resistance.

The thickness of the insulation can be 20-25 mm. By placing it on the vapor barrier, you will achieve the best result.

Expanded clay

As a heater for the ceiling of the bath, you can use expanded clay - a material that has good thermal insulation properties. But at the same time, it absorbs moisture very well, which is its main drawback. Now we will consider how to properly insulate the ceiling of a bath with expanded clay. First of all, it is necessary to make a high-quality vapor barrier from the side of the room.

This requires two layers. The ideal option for the first layer will be a foil film (it should be directed towards the inside of the bathhouse). Expanded clay is poured on top of it, after which two layers of vapor barrier are laid. In this case, the moisture in expanded clay is not terrible, and it will not lose its quality characteristics for keeping heat.

Penoizol

Penoizol is a liquid foam that perfectly fills all free, even hard-to-reach places. In addition, the material does not expand in volume and does not expand upon drying.

If you are puzzled by the question of how to insulate the ceiling of the bathhouse, and there is no extra money, then Penoizol, like nothing else, is suitable for this role. It can be used as insulation, as it is very economical, its price is much lower than the cost of other materials.

Foil insulation

The optimal material for arranging the ceiling is considered to be a heater with foil for a bath, which, in addition to the base layer, also contains a thin coating of aluminum foil. The metal part reflects infrared radiation, preventing heat from leaving the room, that is, the room will not cool down immediately. In addition, a layer of foil is a high-quality vapor barrier, which is simply necessary in rooms with high humidity, which the bath is. The types of insulation include mineral wool with an aluminum coating and polymer foil sheets. The first option is available both in rolls and in slabs. This material is resistant to high temperatures, does not emit toxins and can be easily cut into various shapes. Polymer materials with foil differ from mineral insulation in small thickness and are produced only in rolls.

The main advantage of the listed options is that the metallized surface reflects heat, due to which the walls in the steam room and dressing room are quickly heated. Therefore, in order to reach a certain temperature in the bath, less fuel will be needed, which is very beneficial for the owner of the steam room.

Vapor barrier

Before insulating the ceiling of the bath outside, it is recommended to competently approach the issue of vapor barrier inside. This protects the insulation from getting wet by hot steam that rises from the steam room or washing room. The vapor barrier must be installed hermetically in order to be impervious to moisture penetration. Due to this, high temperatures are not terrible for her.

Foil is often used as a vapor barrier. The joints between the sheets are glued with a special aluminized tape. This is the most effective way to isolate the ceiling of the bath from steam and moisture.

A good option for isolating steam is to use foil insulation. It is a modern material made of fiberglass.

Also, glassine or plastic wrap can be used as protection. Modern membrane heaters isospan and nanoizol also have all the necessary characteristics for arranging a steam room. The main rule: before insulating the ceiling in the bath, it is necessary to provide high-quality vapor barrier.

Types of bath ceiling coverings

There are several types of ceilings in the bath: hemmed, floor or panel. Both the selection of insulation and the method of vapor barrier depend on the types of coatings. Since it is very important to properly insulate the ceiling of the bath, the approach to this process must be appropriate. Consider the main types of floors.

Panel ceiling

It has a simple structure of panels and planks stacked on top beams. This type of ceiling is used very rarely in baths, so it makes no sense to consider the method of its isolation.

Deck ceiling

The ceiling in the form of a flooring is used in steam rooms, saunas and baths, small in size. These are edged or grooved boards that are attached directly to the walls without the use of beams. It is clear that this type of ceiling cannot experience a heavy load, and therefore baths with flooring are used only in a warm period of time, for example, in the summer at a summer cottage.

So how to insulate the ceiling in a bath without the help of professionals? It is very simple to equip this type of coverage yourself. A vapor barrier is rolled out onto the firmly knocked together ceiling boards. A heat-insulating layer of mineral wool is laid on top. Next, you need to re-lay the vapor barrier layer. The thickness of the materials directly depends on the climatic and weather conditions of your residence and on the type of bath roof.

False ceiling

The most popular is the suspended ceiling, especially since it has a large bearing capacity and is cheaper. The top boards are attached to the floor beams, which are solid wooden beams. According to the principle of installation work, the protection of a false ceiling is not much different from a floor covering.

We insulate the ceiling of the bath with our own hands

It is quite possible to do without involving professionals and specialists in this process, because the installation technology is quite simple:

1. Attach the vapor barrier to the ceiling beams. As a protective layer, you can use plastic wrap or foil. This must be done with a stapler.

2. Then we install a ceiling made of boards on the beams.

3. We put an insulating layer of mineral wool or other material on the boards, the thickness of the insulation depends on the minimum outside temperatures.

4. On top of the insulation we cover with a vapor barrier and sheathed with boards. This will be the floor in the attic of the bathhouse, on which it will be possible to walk, because such an overlap can easily withstand the weight of a person.

Thermal insulation of the ceiling of a bath is one of the most important events in terms of importance. Many are mistaken, believing that all options for protecting the steam room from the cold require significant material investments. Some types of insulation can become absolutely free for their owner. What material to use for the ceiling in your own bath, everyone decides for himself, based on his capabilities and personal preferences. This article can only advise which insulation is better, in any case, the choice will be yours.