Fuel injection valve: fuel pressure is under control. solenoid valve

searching results

Solenoid shut-off valve - general information, removal and installation Citroen Xantia /

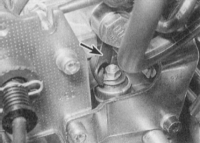

Solenoid shut-off valve - general information, removal and installation Try to prevent dirt from getting inside the injection pump! General information Protective cap for the electromagnetic shut-off valve(TNVD Bosch) Removing the protective cap of the contact connector of the electromagnetic shut-off valve (TNVD Lucas) The valve is located at the end face of the high pressure fuel pump. The valve serves to cut off the fuel supply when the ignition is turned off. When a valve opens or a wire breaks, it ...

The action of the high pressure fuel pump (TNVD) Renault 19 /

Fuel pump action high pressure(injection pump) In the figure, the Bosch injection pump is shown on the left, the Roto injection pump is on the right. The solenoid control shut-off device (2) interrupts the fuel supply to the pump when the ignition is off. If you want to crank the engine with the starter, you must disconnect the electrical contact (1) so that the engine does not start. Further, the numbers indicate: 3 - cam disc "manual throttle control rods" for turning on the microswitches for exhaust gas recirculation and full load; 4 - exhaust recirculation microswitch...

High pressure fuel pump (TNVD) Volkswagen Golf III /

3.9.4. High pressure fuel pump (TNVD) Fig. 3.18. Details of the high pressure fuel pump: 1 - drive shaft; 2 - fuel supply; 3 - valve overpressure fuel pump; 4 - fuel supply control lever; 5 - centrifugal regulator; 6 - drain hole for fuel.; 7 - fuel cut-off valve; 8 - fuel supply to the nozzle; 9 - distributor plunger; 10 - lifting disk; 11 - injection regulator (for clarity, expand by 900); 12 - roller ring; 13 - low pressure fuel pump High pressure fuel pump, ...

High pressure fuel pump (TNVD) Opel Omega /

5.3.8. High-pressure fuel pump (TNVD) GENERAL INFORMATION High-pressure fuel pump the shut-off valve on the injection pump opens the fuel supply when the ignition is turned on. It should be checked if the engine does not start ...

Volkswagen Golf III engine stop solenoid valve /

3.9.8. Solenoid valve shutdown of the engineThe engine is switched off by means of an electromagnetic shut-off valve, which interrupts the supply of fuel to the injection pump when the power supply to it is turned off. Shortly before diesel fuel enters the distributor plunger fill port, it passes the engine stop solenoid valve. When the key for turning on the instruments and the starter is turned to the first position, voltage is applied to the valve and fuel enters the injection pump. When the key is turned to the “O” position, the voltage supply to the valve is stopped. Stop valve...

Checking/replacing the fuel cutoff solenoid valve Mazda 323 /

Checking / replacing the solenoid valve for stopping the fuel supply The solenoid valve on the high-pressure fuel pump opens the fuel channel when the ignition is turned on. It should be checked if the engine does not start or continues to run after the ignition is turned off. PERFORMANCE ORDER To include and switch off ignition. The solenoid valve should click audibly at the same time. If the valve does not click, check with a voltmeter to see if voltage is applied to it when the ignition is on. If no voltage is applied, find and repair the f...

Renault Kangoo coded solenoid valve /

Coded solenoid valve On these vehicles, to replace the solenoid valve and its coded chip (A), the injection pump must be removed. REMOVAL Place the pump on a workbench and remove the protective bracket (B). The bracket is secured with sheared bolts, which can be removed as follows: - using a small chisel or punch, hit the tapered heads of the bolts (C), (D) and (E) several times to loosen the bolts; - the bolt (E) using tool Mot. 1372 drill a hole with a 4 mm diameter drill...

Removal and installation of the electromagnetic shut-off valve Skoda Felicia /

Removal and installation of the electromagnetic locking valve See the preventions given in the Section the General information and precautionary measures. At the time of the preparation of this Manual, replaceable shut-off valves were not produced individually (separately from the injection pump). In case of problems, contact the car service specialists. REMOVAL PERFORMANCE ORDER 1. The locking valve is established in a back part of TNVD. 2. Disconnect the negative cable from the battery. ...

Removal and installation of high pressure fuel pump Opel Astra /

Removal and installation of high-pressure fuel pump Do not allow dirt to enter the pump and fuel lines. Models 1.7 l SOHC PERFORMANCE ORDER Disconnect a negative wire from the battery. Remove a gear wheel of a drive of the pump (the Engine see the Head). Turn out nuts of union connections and remove fuel tubes (Removal and installation of fuel nozzles see). Release the clamp (1) securing the contact connector of the injection pump control module to the engine, disconnect the connector. Care...

High pressure fuel pump (TNVD) Renault 19 /

High-pressure fuel pump (TNVD) High-pressure fuel pump Bosch atmospheric diesel (47 kW) disassembled 1 - drive gear; 2 - front bracket of injection pump; 3 - device for starting a cold engine; 4 - rear bracket of injection pump; 5 - thermoelement of "fast" idling; 6 - solenoid control shutdown device; 7 - fuel outlet; 8 - high pressure pipelines to nozzles; 9 - connecting pipeline between nozzles; 10 - nozzle...

Fuel pump (TNVD) Isuzu Trooper /

5.9.1. Fuel pump (high pressure fuel pump) GENERAL INFORMATION Details of high pressure fuel pump of diesel engines S223 and S223-T 1 - electromagnetic shut-off valve 2 - fuel line 3 - hollow bolt of fitting 4 - bracket 5 - bypass fitting 6 - fitting bolt 7 - sealing ring 8 - high pressure plug 9 - sealing ring 10 - actuator bracket 11 - fast idle actuator 12 - tachometer sensor (or plug with sealing ring) 13 - bolt 14 - front cover...

Checking, removing and installing the fuel shut-off valve BMW 5 (E39) /

Check, removal and installation of the fuel locking valve The electromagnetic fuel locking valve at TNVD opens fuel supply at inclusion of ignition. It must be checked if the engine does not start or does not stop after turning off the ignition. CHECK 1. Turn the ignition switch on the steering wheel on and off. The solenoid valve should click distinctly. 2. If there is no click, disconnect electrical wire. Attach the battery cable to the pr...

Design features Nissan Almera /

5.8.1. Design features The electrical circuit of the engine control system (ECS) is presented at the end of the book. The system includes an ECU, the main information parameters of which are the coolant temperature, fuel temperature, engine speed, TDC and the position of the fuel supply drive. Rice. 3.47. The numbering of the conclusions of the block of wires of the connector of the ECU of the CD20E engine (rear view) Fig. 3.48. The location of the diagnostic connector block The computer is a microprocessor with digital programming ...

Diagrams 1-5 Mercedes-Benz Sprinter /

18.1. Diagrams 1-5 Diagram 1 Diesel fuel injection system with exhaust gas recirculation system (601 engine series 901, 902, 903 and 904) A) ECU for the exhaust gas recirculation system (output<15>) 6H J31 Output<15>, protected by a fuse 7J J265 Output<15>3H K34 Auto Power On Relay...

Diesel Fuel Supply - Ford Mondeo Basic Design /

Diesel engine fuel supply - basic design In contrast to petrol engines, injection systems in diesel engines operate with high system pressures. Fuel pumps, including control peripherals, are fundamentally different from their petrol pumps. In technical terms, diesel engines distinguish between in-line high pressure fuel pumps, plunger fuel distribution pumps, Common-Rail systems and a pump injector. Under the hoods of both Mondeos with diesel engines, plunger distributors supply fuel directly to the combustion chambers ...

Removal and installation of electrical components of the Opel Astra power system /

Power System Electrical Removal and Installation 1.7L SOHC Models Air Mass Sensor (MAF) The Intake Air Temperature (IAT) sensor is integrated into the MAF sensor. PERFORMANCE ORDER Switch off ignition and disconnect an electroconducting from the gauge. Release the clamps, disconnect the electrical wiring from the sensor and remove the sensor from the vehicle. Installation is in the reverse order. Make sure that the sensor and air ducts are securely fixed. ...

Audi A3 engine electrical system /

Electrical equipment of the engine GENERAL INFORMATION Specifications ATTENTION Individual characteristics are also given in the text of the Chapters and, if they are mandatory, are highlighted in bold type Ignition / engine management system AEH Simos AGN Motronic M3.8.5 Spark plugs Engine, designation Type EH, AGN NGK BKUR 6 ET–10 or AUDI 101000033AA AGU Bosch F7LTCR or AUDI 101000051AA Wrench size 16 mm Glow plugs Beru GN 855 Bosch 0 250 202 022 Champion CH 171 AGU Motronic M3.8.3 AQA Motronic ME7.5 Interelectrode...

The invention relates to engine building, in particular to fuel supply systems of internal combustion engines. EFFECT: invention makes it possible to improve the manufacturability of the metering valve design. The solenoid metering valve is installed in the low pressure line of the injection pump of the battery fuel system and consists of an electromagnetic drive and a spool pair. The spool of the spool pair is driven to the closed position by the armature of the electromagnetic drive, which overcomes the force of the compression return spring. Its body is made detachable, one part of which, being part of the body of the electromagnet, performs the function of an electromagnetic drive armature. The electromagnet is closed by an external casing with a separate clamping flange. The other part of the housing (sleeve) directly contains the spool with a return spring, and the spool is made with a locking edge for fuel misfire. 2 w.p. f-ly, 4 ill.

The invention relates to engine building, namely to the production of fuel supply systems, in particular to fuel dispensers for high pressure fuel pumps (TNVD).

Dosing devices for fuel supply systems are widely known. For example, EP 1467085 7, F02M 55/04 protects "Fluid Dispensing Device and Method for Assembling the Same". However, this dispenser is mainly applicable to gasoline injectors, i.e. at the final stage of fuel injection (in the high pressure zone). A similar purpose has a technical solution "Device for regulating the discharge pressure of a pump, for example, for supplying fuel to an internal combustion engine", protected by ROBERT BOSCH GmbH (DE) patent RU 2247258 C2, F02M 63/02. Although this device is widely used (patented in many countries and regions), it is still applicable only in the high pressure zone of the injection pump.

Closest to the claimed technical solution is the "Valve for fuel injection in the internal combustion engine", protected by BOSCH patent US 6626151 BB 7, F02M 59/46 (see figure 1). In the high pressure pump for common rail system, this solenoid metering valve has its outlet directed to the low pressure line and its inlet is in communication with the high pressure side. In the housing 1, the piston (spool) 2 has the possibility of axial movement. The spring 3 working in compression displaces the piston (spool) 2 in open position, and the armature of the electromagnet 4 shifts the piston (spool) 2 to the closed position and thus maintains the specified value of the fuel supply in the low pressure line before the stage of its injection by the injection pump plunger pair (not shown). The disadvantage of this design is that the piston body (spool) is also an integral part of the electromagnetic drive, and this can lead to a deterioration in the traction characteristics of the electromagnet when using, for example, piston body materials with certain properties meeting the requirements for wear resistance. In addition, a single (one-piece) housing that combines an electromagnetic drive with a spool pair is labor-intensive in production and, in the event of failure of one or another part, requires the replacement of the entire device, which unnecessarily increases operating costs.

The aim of the present invention is to eliminate these shortcomings while improving the manufacturability (cheaper) design of the metering valve.

This goal is achieved by the fact that the proposed electromagnetic metering valve installed in the low pressure line of the injection pump of the storage fuel system, consisting of an electromagnetic drive and a spool pair, the spool of which is driven to the closed position by the electromagnetic drive armature, which overcomes the force of the compression return spring, is characterized in that its the body is made detachable, one part of which, being part of the body of the electromagnet, functions as an armature of the electromagnetic drive, and the solenoid is closed by an external casing with a separate clamping flange, and the other part of the body (sleeve) directly contains a spool with a return spring, and the spool is made with a shut-off edge for fuel misfire in the form of a triangular groove or directly on its end surface.

The design of the proposed electromagnetic metering valve is shown in the drawing, where figure 2 shows in axial section a variant with a spool pair having a closing edge of the spool in the form of a triangular groove, figure 3 is a variant of a spool pair with a closing edge made directly on the end of the spool, and figure 4 shows the edge of the spool in the case of its execution according to figure 2.

The proposed electromagnetic metering valve (see Fig.2 and 3) consists of a casing of the electromagnet 1, pressed against the housing of the injection pump (not shown) with a separate flange 2, simultaneously fastening the sleeve 3 of the spool 4 with the inner housing 5 of the winding of the electromagnet 6. The outer end and a small cylindrical the protrusion of the inner body 5 center the electromagnetic drive with the sleeve 3 of the spool 4 when the entire solenoid valve is fixed on the injection pump housing (or on the engine housing) with a flange 2. A return spring 7 is placed inside the spool 4. The armature of the electromagnet 8 through the rod 9 interacts with the spool 4, which has cut-off edges 10 (see figure 2 and 4) and 11 (see figure 3). The sleeve 3 has a through transverse hole 12 passing through its axis for supplying fuel from a booster pump (not shown) through the central cavity of the spool 4 into the low pressure line (not shown).

The proposed electromagnetic metering valve works as follows. The control signal from the electronic unit (not shown) is applied to the winding 6 of the electromagnetic drive. As a result, there is a linear movement of the armature 8 proportional to the value of the applied signal and the effect of the armature rod 9 on the control spool 4. With an increase in the control signal, the rod 9 of the armature 8, overcoming the force of the return spring 7, extends from the housing 5 of the electromagnetic drive and moves the spool 4 to a certain position, reducing the flow area formed by the locking edge 10, 11 of the spool 4 and the bore or hole 12 on the sleeve 3 of the spool 4.

In the spool pair shown in Fig.2, an adjustable flow area is formed between the edge of the bore on the sleeve 3 of the spool 4, made in the area of the hole 12, and the groove 10 of the spool, made in the form of a triangle (see Fig.4), and in a pair, shown in figure 3, an adjustable flow area is formed between the hole 12 and a sharp edge 11, made directly on the end face of the spool 4.

The fuel supplied from the booster pump enters through the holes 12 on the sleeve 3 to the locking edge 10, 11 of the spool 4 and, having passed through the control flow area, exits through the axial hole at the end of the sleeve 3, thereby maintaining the set value of supply to the low pressure line before the stage of injection of fuel by a plunger pair of injection pump.

The use of a spool valve with a locking edge 10 (figure 4) is preferable in cases where accurate proportional control of the metered fuel is required at low maximum flow rates, and the locking edge 11 is preferable for low requirements for control accuracy, but higher maximum fuel flow rates.

The described design of the proposed electromagnetic metering valve is simple (technological) in the manufacture of its individual parts (especially the spool bushing), in the assembly and installation of the entire assembly on the high-pressure fuel pump (or on the engine), and during operation it allows you to repair the electromagnetic drive and the spool pair separately, which significantly reduces costs throughout life cycle products.

1. An electromagnetic metering valve installed in the low pressure line of the injection pump of the storage fuel system, consisting of an electromagnetic drive and a spool pair, the spool of which is driven to the closed position by the electromagnetic drive armature, which overcomes the force of the compression return spring, characterized in that its body is made detachable, one part of which, being part of the body of the electromagnet, performs the function of an armature of the electromagnetic drive, and the electromagnet is closed by an external casing with a separate clamping flange, and the other part of the body (sleeve) directly contains a spool with a return spring, and the spool is made with a locking edge for fuel misfire.

2. Electromagnetic metering valve according to claim 1, characterized in that the locking edge of the spool is made in the form of a triangular groove.

3. The solenoid valve according to claim 1, characterized in that the locking edge of the spool is made directly on its end surface.

The operation of your car for the longest period depends entirely on how high-quality components are used in its production and repair. You will not always be able to buy spare parts that will be characterized by high quality and a significant resource. Only by using the services of real professionals in their field, you can count on the impeccable quality of the purchased spare parts. We can offer our customers a variety of variety of options valves for the high pressure fuel pump (TNVD), which fully comply with the high modern requirements. Our company works directly with manufacturers that supply high-quality components - this allows us not to unreasonably raise prices for all catalog items, attracting new customers and cooperating with many on an ongoing basis. We are ready to become a reliable partner that will ensure not only the quality of the supplied components, but also the speed of their delivery.

The advantage of using a high pressure fuel pump valve

The fuel pump serves to evenly distribute the fuel as it is delivered, and the valves have various functions that prevent excessive pressure from building up, as well as reducing the amount of fuel that enters the engine.The high pressure pump check valve assists in preventing the ingress of diesel fuel. We can offer customers of our services valves that are suitable for various models cars and tractors - both with battery and direct injection. You can order high-quality components using the online form, as well as by contacting our managers by phone.

Injection pump pressure reducing valve reliably protects against excessive fuel supply, regulates its injection in diesel engines various brands. Valves of this kind perform their function effectively if they are produced by reliable manufacturers. We cooperate directly with trusted companies, we always organize a thorough quality control of equipment.

Solenoid bypass valve - variety of assortment, reliability of supplies

Bypass magnetic valves offered by us fix the fuel supply and with the help of an electromagnet make this process as rational as possible. The equipment we recommend is characterized by high efficiency and significant resource.

We are also ready to offer to purchase reliable and functional sensors High pressure fuel pump, the installation of which will help to record all the changes that occur with the fuel pump.

Among the variety of equipment sold by us, you are sure to find what you need to repair your vehicle. For most cars, even the least common brands, we can provide high quality spare parts.

The assortment includes models of KamAZ high-pressure fuel pump valves, characterized by a significant resource, as well as a fairly affordable cost. During working hours, consultations with specialists on issues related to the equipment sold by us are possible. We have tried to create a comfortable and reliable service.

The undeniable advantages of our online resource

On our online resource, visitors can quickly and easily purchase necessary equipment. This is facilitated by the interface provided by us, the possibility of using such an effective tool as the filter of characteristics, which perfectly saves time. All numerous types of valves, as well as other equipment, we try to keep in stock.

It is possible to purchase the following equipment:

· solenoid valves high pressure fuel pump;

· injection pump pressure valves;

· metering valves high pressure fuel pump;

· dispenser for injection pump;

· high pressure fuel pump regulator valves;

· Bosch high pressure fuel pump valves.

Also, all our consumers can easily and comfortably get the required advice - the professional masters of our online store will quickly and efficiently help their customers in solving the most important problems.

Terms of purchase and delivery

Among all the variety offered, there are also fuel shut-off valves - many of the proposed equipment modifications will help you in the repair various kinds transport. You can contact us in a variety of ways: this can be done using Email, and such a well-established method - to leave a request for the further quick response of our specialists. We can offer consumers the possibility of wholesale sales of the equipment offered. You will be satisfied with quite affordable cost and excellent delivery conditions - everything will be carried out in necessary deadlines.You can also call us - we are always in touch, this is our important advantage. High pressure fuel pump solenoid valves have high performance All equipment comes with manufacturers warranties.

Maintaining a constant fuel pressure in the injection pump of diesel engines is a prerequisite for the operation of this unit and the entire power system. Pressure constancy is achieved by using bypass (reducing) valves - read the article about these parts, their types and design, operation and replacement.

What is an injection pump bypass valve

(reducing valve) - a high-pressure fuel pump assembly for diesel engine power systems, adjustable valve(hydraulic choke) to drain excess fuel and maintain required pressure fuel in the pump.

The bypass valve performs several functions:

- Drain excess fuel from the pump;

- Removal of air trapped in the fuel system;

- Maintaining a constant fuel pressure inside the pump (in the channels of the pumping sections of multi-section injection pumps and in the housing of the distribution injection pumps).

The pressure reducing valve is an automatic hydraulic throttle - a device that creates resistance to fluid flow and has the ability to change the intensity of this flow depending on the hydraulic pressure. In a certain pressure range, the bypass valve is closed or creates a high resistance to fluid flow, when a certain threshold pressure is exceeded, the valve opens and dumps excess fuel from the pump, preventing a further increase in pressure.

The bypass valve is part of the low pressure section of the injection pump, it works automatically and only needs to be adjusted to set the threshold.

Types, design and principle of operation of the injection pump bypass valve

First of all, it should be noted that today there are several types of valves that provide fuel bypass into the injection pump:

- Bypass (reducing) valve in multisection pumps;

- Bypass (reducing) pressure control valve inside the housing (at the inlet to the pump section of the fuel priming pump) in the fuel injection pump of the distribution type;

- Bypass throttling valve in distribution type pumps.

Each valve has its own design features and occupies a certain place in the high pressure fuel pump.

Bypass valve in multi-section high-pressure fuel pumps. This valve is installed in the front wall of the pump housing, it is connected to the fuel supply channels from the fuel priming pump to the delivery sections. Structurally, the valve is very simple: it is based on a body, inside of which there is a spring-loaded locking element in the form of a ball or disk. The body can be of two types:

- Bolt. The valve is made in the form of a bolt, inside of which a locking element is located, and two or more holes are made on the walls to drain fuel into the return line. The bolt is screwed into the pump housing, it holds the connecting nipple, to which the return line is connected;

- Union. The valve is made in the form of a fitting, inside which a locking element is located. The fitting is screwed into the pump housing, and to external thread return line is connected.

general information

|

Protective cap for the contact connector of the electromagnetic shut-off valve (TNVD Bosch)

|

Removing the protective cap of the contact connector of the electromagnetic shut-off valve (TNVD Lucas)

|

|

The valve is located at the end of the injection pump. The valve serves to cut off the fuel supply when the ignition is turned off. When the valve opens or its power wire breaks, starting the engine becomes impossible, since the fuel simply does not enter the injectors. The same result is caused by jamming the valve plug in the “locked” position. If the valve is stuck in the “open” position, the engine will not stop after the ignition is turned off. |

|

In the event of shutoff valve failure, a temporary start of the engine can be made by removing the valve (see below), removing the plunger with spring from it and replacing it without internal components. The wire should be wrapped in such a way that it does not come into contact with the ground. In order to turn off the engine after such a start, you will have to use the manual stop lever on the injection pump (see Power supply system - diesel models), or turn off the ignition in gear.

|

PROCEDURE |

|

|

Installation

Installation is in the reverse order. Don't forget to replace the sealing washer/valve ring. Make sure that the required tightening torque is observed.

If the fast idle drive cable has been disconnected, adjust it (see Removal, installation and adjustment of the fast idle speed sensor).