Folding bed frame. Do-it-yourself horizontal folding bed. Instructions for creating a wardrobe bed with your own hands (drawings, diagrams and photos) Wardrobe bed with your own hands dimensions

In order to make a wardrobe bed with your own hands, you do not need a lot of strength and skills, but you need to know in advance that all the elements will need to be completed with the highest quality. Currently, at home, only 2 materials are used for such products - chipboard and furniture board, each of which has its pros and cons.

The furniture board is a high-quality glued special technology boards. You can not be afraid for the quality of gluing and pressing, because. they are slightly inferior in strength to the array. In addition to strength, the advantages are ease of use and excellent visual performance of the final products. The downside is the price and the inability to find material in a number of cities.

Chipboard is laminated chipboard, which does not have high quality and excellent external performance. If you work with it correctly, then the service life will be at least half a century. The pluses include compliance and general availability anywhere in the world.

Basic stage of work

- drill;

- jigsaw;

- screwdriver;

- chipboard;

- roulette;

- furniture screws;

- beam 50 * 50 mm.

At the very beginning, you need to make drawings, according to which further work will be carried out. During the development of the drawing, it is necessary to provide for the quality of the fit of the bed to the wall and the elongation in relation to it, the number of beds and the lowering system.

After that, you can start working. At the very beginning, a do-it-yourself wardrobe for the bed is constructed. It is quite simple to make it, but there is one subtlety that many people forget about - this is the strengthening of the structure. The whole process takes place in stages:

- 2 slabs 450*1800 mm and 2 slabs 1124*450 mm and 1 slab 1124*1800 mm are cut out. Narrow and long ones will be on the bottom and top, narrow short ones on the sides, and the latter will be the back wall.

- All panels are fastened together with furniture screws. To do this, a hole of a smaller diameter is initially made with a drill, and only then a screw is screwed in. This order is necessary to prevent possible splitting of the material. The step between the bonding points is 25 cm (it can be increased to 35 cm, but the structure will become weaker). To drill holes, a special drill is used, which immediately prepares a groove for the screw head.

- By inside corners it is advisable to lay a small beam and fix it in a checkerboard pattern. This must be done in such a way as not to break through the body of the resulting cabinet. If there is no certainty that this step will succeed, then it is better not to do it.

Back to index

Fabrication of the frame and mattress

Required materials and tools:

- drill;

- screwdriver;

- jigsaw;

- roulette;

- timber 50 * 50 mm;

- edged board 15*150;

- furniture screws;

- hinges with free play;

- mattress fasteners.

The bed frame is not much more difficult to make. Measurements are made each time on an individual basis, because. Chipboard and furniture board are not always 20 mm thick. After an accurate measurement of the inner perimeter has been made, 2 cm should be subtracted from it from each side, because. otherwise the tree will be too tightly fixed, and at the same time remain motionless.

When making a bed, you must follow the following procedure:

- 4 shields of a previously defined length are cut out, 150 mm wide. From below, the shield should cover the entire surface.

- The panels are fastened together with furniture screws. Joints should be made with a frequency of 25-30 cm. Each joint must be made with high quality so that later there are no complications.

- From the inside, a beam is screwed along the perimeter at a height of 30 mm from the lower side. The frequency of joints is 1 time in 40 cm. A mattress pad will be laid on this beam.

There are several options for making a mattress pad, depending on the desire of the master:

- Screwed onto the mattress topper in 30 cm increments edged board. It turns out qualitatively, conveniently in operation and quickly, but if you need to move the bed, then there are considerable difficulties, because. the design is very cumbersome.

- 1 more rectangle is made from the beam, identical to the finished one, only the new one is not fixed to the frame. Then a cutting board is screwed onto this rectangle. In this case, the mattress pad can be perfectly removed and can be easily carried and replaced, but its price increases by 15-20%.

Taking into account the fact that the bed will rise, the mattress pad must have additional latches, which can be chosen from a huge variety: from simple latch type to more modern plastic ones that respond to a certain directional pressure.

Now the bed is fixed at 2 points to the cabinet at a height of 300-350 mm. The simplest mount depicts a drawing where ordinary hinges are used. The mount should be located strictly at the same level in order to avoid early wear.

At the very end, movable legs are attached. Mounting system - on hinges or bolts, depending on preferences. Only 2 pieces are used. in the corners, because the rest are replaced by cabinet hinges. When lifting, under their own weight, they should go under the base of the mattress pad, i.e. their width should be only 30 mm.

If a person lives in a small apartment, the lack of space becomes a serious problem. The folding bed literally disappears in just a few seconds! By making a wardrobe bed with your own hands, you can solve the issue associated with the shortage square meters: expand the nursery, freeing it for games, turn the guest room into a home office, the living room into a mini-hotel, given the frequent visits of relatives, and the bedroom can become a gym.

About serious and funny

So what is so fascinating about the design of the “invisible” bed? Is it really a bed? Or is it a closet? A huge mattress can be neatly hidden, is it really easy to do? Yes! And the transformer was invented not yesterday, but at least a century ago. According to legend, the inventor of the device, William L. Murphy, lived in one-room apartment in San Francisco. The moral code of those times did not approve of women who dare to enter a man's bedroom, so the savvy guy turned the bed into a closet, and his room into a living room, not forgetting to get a patent for the invention in 1900. However, at this very moment, Thomas Jefferson already had his beds hanging from ropes and hooks in the niches of the bedroom. Murphy is said to have married the very girl who inspired him to transform the apartment.

Changing the living space today is seen as a lifestyle choice, and folding bed-transformer solves multi tasks. Modern versions of various models can have glass, mirrors and beautiful lighting, as well as shelves for computers, TVs and music centers. Some apartment owners decorate the walls above the bed with expensive artwork.

Combination of elegance and ergonomics

Folding bed-transformer can serve up to 60 years! Since the first model, many designs have been created: the bed can be laid out horizontally and vertically, be bunk and have additional functions. For example, beds with tables and models with sofas are popular.

The vertical version of the bed is considered traditional. Horizontal bed is good for narrow rooms and premises with low ceilings, for example, it can be installed in the attic.

After installing the wardrobe bed, the room turns into:

- bedroom-office;

- bedroom-living room;

- children's bedroom.

When deciding to make an “invisible” bed, you should take a closer look at interesting ideas:

- The transformer can be supplemented with comfortable bookshelves.

- The horizontally located folding bed is easily attached to a low modular furniture.

- An interesting solution is when the room is made in a Japanese minimalist style and the built-in bed looks like shoji walls.

- A transformer in a teenager's room can become part of a cozy corner cabinet.

- In a children's wardrobe-bed, it is sometimes convenient to make a bunk bed.

- The transformer can have an unusual image if you make the decor with your own hands. The retro space is adorable!

- A wardrobe bed can appear in an apartment made in any style. For example, with an appropriate solution to its design and decor, it will look good in the sophisticated French atmosphere of Provence. gray sliding doors add the necessary texture contrast.

What do you need to know?

The transformer, which the simplest drawings give an idea of, consists of 4 key components:

- lifting mechanism;

- heavy-duty magnetic clasp that prevents the bed from falling out;

- bed frames;

- closet.

Any modern mechanism, designed for the wardrobe bed, allows for easy folding.

The lifting system can be:

Spring mechanism. Typically, it consists of heavy-duty compressed steel springs in the bed frame that make lifting and lowering easy. But after several years of intensive use, the springs need to be adjusted.

piston mechanism. Unlike spring device, pistons are safer, last much longer and break less.

Each mechanism is designed for a certain weight. A pair of metal springs or a piston lift make it easy and safe to fit the bed box into the frame. A secure latch will keep the furniture in the closed position.

It is important to remember that the mechanism in creating modern bed Murphy is the most important. Installation of equipment is likely to be the most time-consuming part of the work. Only correct installation according to the instructions guarantees the reliability of folding. If the mechanism for the wardrobe bed is purchased in stores furniture fittings, the installation diagram, which is easy to understand, will definitely be attached to the kit.

A person who has ever made a wardrobe or similar large-scale piece of furniture with their own hands probably has all the skills to embed a transformer into a wall.

The manufacturing process of the piece of furniture itself includes:

- creating a cabinet that looks like a frame;

- the bed frame to which the legs are attached.

Beds that are hidden in the closet do not have heavy spring mattress structures. Typically, an orthopedic or regular mattress rests on a wooden platform, wire mesh, or slats and is secured with elastic straps that hold it in place when the unit is folded vertically.

How to make calculations?

To create a bed, the most attractive option is to use a combination of high-end plywood and solid wood. As already mentioned, on the sides of the cabinet, designed to hide the bed, you can add bookshelves, and in upper part frames embed halogen lighting. The front panel of a structure can look as simple as a piece of plywood or as complex as an object. antique furniture.

The height of the legs, sides and the height of the part of the mattress protruding above the sides - total height bed, on which the depth of the cabinet structure depends. Usually it is about 450 mm ( standard height chair) - comfortable to sit down.

Given the thickness of the lifting mechanism, simple calculations can be made. If the mechanism has a thickness of 32mm, then the gaps between the sides of the bed and the sides of the cabinet will be 32mm on each side. Accordingly, the calculation takes into account the width of the bed, the thickness of the sides of the base, the gaps for installing the mechanism and the thickness of the sidewalls of the cabinet.

The height of the cabinet depends on the length or width of the bed.

Work order

The biggest hurdle for many people is finding a place to do carpentry work. Therefore, it is worth considering the issue of assembly in the garage or renting a special room for a while.

To make a transformer, you need to prepare the following tools for work:

- centimeter tape measure;

- building level, square;

- electric drill;

- screwdriver;

- jigsaw;

- grinding machine;

- keys (hex);

- Screwdriver Set.

In addition, you will need quality materials. Based on the size, you need to make a list of them.

A mattress, regular or orthopedic, should be purchased immediately to check the dimensions of the bed frame and wardrobe. Pillows tend to be stored in a closet or chest of drawers rather than on the mattress when hidden.

- Bed frame assembly

The frame consists of 4 boards of the same height, which will serve as the sides of the bed. It is important to create an even rectangle with 90° corners. The frames are connected with glued wooden pins. After the glue dries, in order to finally fasten the sides, self-tapping screws and furniture corners are used. Along the perimeter, you can nail a rail having a section of 100x50 mm, it will serve as a limiter for the mattress.

The base can be made from a single piece of plywood or, for example, it can be knocked down from planks. There are many options. Important! Sometimes additional stiffeners may be needed. At this stage, you can decorate.

- Cabinet frame assembly

The cabinet frame parts are fastened in the same way as the bed frame parts.

When tilting the bed, the wardrobe can simply fall to the floor. To avoid this, you need to attach it to bearing wall using metal corners. Fasteners are placed as high as possible on the sides. If the folding bed is hidden in the structure furniture wall, then the weight of the wall will be a good insurance, in the case when the cabinet is located “at a distance” between the ceiling and the floors, it theoretically cannot fall in any way.

- Bed legs

The legs can be made independently by ensuring their embedding with furniture hinges, and can be purchased together with the mechanism.

- Installation of mechanisms

The spring or piston mechanism is installed according to the manufacturer's instructions.

Compact and multifunctional folding furniture is a great option for small apartment. Often the same room has to be used for different purposes, and the room has to be transformed from one state to another very quickly, so the use of folding furniture is most welcome.

The principle of operation of a folding bed. a - the bed can be easily removed from the cabinet niche; b - bed in the unfolded form.

A folding bed is one of the most popular options for creating a versatile room.

Folding bed options

- Folding. Very convenient option, which allows you to significantly save room space, since the structure can be completely removed. You can make such a bed yourself, just take a regular one. spring mattress, put it in wooden frame and fix the structure with loops to a bar nailed to the wall.

- Bed secretary. This design consists of two bearing racks, to which a folding bed is attached. outer wall in this case, when folded, it will serve as a desk cover.

- Folding bed. A well-known version of the Soviet era. Modern folding beds are more comfortable and compact, they can be easily folded, they can be stored in special bedside tables and lockers.

Hinged design features

Folding structures are horizontal and vertical. If we are talking about a bed for a child, then most often they choose horizontal version, which the child is quite capable of folding on their own. As for the load on the folding bed, it can be absolutely anything, so it is perfect for everyone, regardless of the weight category. Solid wood or chipboard is used as the main material, and obligatory element is lifting mechanism in the form of gas lifts or special springs. It is more rational to use gas lifts, the service life of which is longer than that of springs, and besides, they do not need additional adjustment. You should also take into account such a nuance as fastening the bed, which is possible only if you have thick concrete walls.

Folding bed is a multifunctional piece of furniture. Additional shelves above it and on its sides, cabinets, shelving, you can provide a special compartment for bed linen to further expand the purpose of the sleeping area. If your bed is retracted into a closet, then another similar storage closet will look good next to it. The folding design can fit into almost any interior, regardless of the size of the room and its purpose. The main thing is to carefully work on the stylistic design of the room and correctly select other pieces of furniture. The dimensions must comply with generally accepted standards: the width of a single bed should be 80 cm, a double bed - 160 cm, length - at least 2 m. In accordance with the dimensions, a mattress is selected, the filling of which can be very diverse depending on personal preferences.

Making a folding bed yourself

To build a bed with your own hands, you will need boards, chipboard or fiberboard, plywood, fasteners, a lifting mechanism, hinges, a mattress, belts. First of all, it is worth drawing up a draft of the sleeping area, in which all dimensions will be accurately indicated. The best option there will be a transforming bed that folds into a closet. In this case, its width and length should be slightly less than the width and height of the cabinet. Then we proceed to the manufacture of the frame future bed from boards and chipboard. Please note that the design must be, on the one hand, durable, on the other - light. The front legs of the bed can be made in the form of a solid wall, hinged.

Particular attention should be paid to the installation of the lifting mechanism. As noted above, it is best to use gas lifts as a lift, the power of which is selected in accordance with the weight of the bed. The gas lift is installed in this way: the parts are attached to the sides of the bed and the sides of the cabinet. The next step is to mount the shock absorbers first from the bottom and then from the top. If you decide to make a single bed with a light bed, you can limit yourself to hinged hinges, do not install an additional lifting mechanism. After the construction and installation of the bed frame and the installation of the lifting mechanism, you will only have to lay the mattress and secure it with special belts. The final chord will be the installation of cabinet doors and adjustment of fittings. Your folding bed is ready for use.

Any folding bed is a wonderful design move for both a small room and a spacious room. During the day, the room can be used for rest, study, work, and at night to relax on a comfortable bed. By making a folding bed with your own hands, you will create a unique and original interior while saving significant money.

The theme of lack of space in small apartments always relevant. Lifting furniture allows you to expand the area of \u200b\u200bthe room during the active time of the day, which greatly facilitates the stay of people in cramped conditions. I was interested in learning how to make a wardrobe bed. After reviewing a lot of information on this topic on the Internet, I decided to assemble a transformer bed wardrobe with my own hands. Studied the basic principles of built-in furniture. Made drawings and diagrams of the bed closet. Made lists necessary tool and materials.

Lifting cabinet-bed

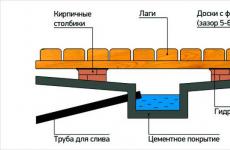

The do-it-yourself wardrobe-bed design project consists of two boxes, one of which is built into the other. Two lifting mechanisms located at the bottom on the sides of the furniture body ensure the movement of the bed from a horizontal to a vertical position and vice versa.

The lifting mechanism is a rather complex technical device. I considered trying to make such a mechanism on my own without special factory equipment a risky business. Therefore, I used purchased factory-made devices.

Tool

Since the work of assembling the folding structure of bedroom furniture is associated with lumber, the appropriate tool was needed:

- jigsaw;

- perforator;

- saw;

- screwdriver;

- confirmatory drill with a crank;

- hammer;

- roulette;

- pencil;

- screwdrivers;

- wrench set

materials

According to the drawings of the wardrobe-bed with dimensions, I ordered cutting MDF sheets in a furniture workshop. In the same place, I ordered the finishing of the ends of all the details of the assembly of the built-in bed. The bottom of a sleeping bed is also a front wall of a case. I also ordered its production in the furniture workshop.

Details of the vertical cabinet of built-in furniture made of MDF 25 mm:

- side panels 45 x 220 cm - 2 pcs.

- top vertical and horizontal panels 45 x 176 cm - 3 pcs.

- bottom wall 50 x 174 cm - 1 pc.

- supporting horizontal panel 45 x 180 cm - 1 pc.

- side walls 43 x 218 cm.

- transverse walls 43 x 174 cm.

- bottom facade 1760 x 2180 cm.

- lifting mechanism with a swivel leg - 2 sets with fasteners;

- metal corners 50 x 50 - 26 pcs;

- frame dowel 10 x 122 mm - 2 pcs.;

- confirmations 50 mm - 16 pcs.;

- screws 30 mm - 40 pcs.

Step-by-step instructions on how to make a wardrobe bed with your own hands

After I brought home the materials and prepared the tool, I started assembling the transformer bed cabinet according to the drawings with my own hands. The work was carried out in stages.

- On the wall, with a pencil, I marked out the markings for fastening the vertical body of the furniture.

- At two points with a perforator, he made holes in concrete wallø 10 mm depth 120 mm.

- Through the holes in the corners, I hammered 2 frame dowels into the wall.

- The vertical body box was assembled from the panels listed in the Materials chapter. In the ends and planes of the mating parts, I drilled holes for the installation of confirmations.

- Having screwed in the confirmations, he set the case in a vertical position.

- With screws, I fixed the mounting brackets screwed to the wall.

- I assembled the bed box, connecting the panels with confirmations.

Cost of materials

At the end of the work, I calculated the costs incurred by me for the manufacture of furniture.

The cost of manufacturing panels for assembling a built-in bed in a closet with your own hands. The area of MDF with a thickness of 25 mm was 11.55 m 2:

- side panels 45 x 220 cm - 2 pieces;

- top vertical and horizontal panels 450 x 1740 mm - 3 pcs.;

- bottom wall 50 x 174 cm - 1 pc.;

- supporting horizontal panel 45 x 180 cm - 1 pc.;

- side walls 43 x 218 cm;

- transverse walls 430 x 1760 mm;

- bottom-facade 1760 x 2180 mm;

The total cutting length of MDF sheets is 20 running meters. Finishing the ends - 34 running meters.

The furniture workshop issued an invoice for payment for materials, for work on cutting and trimming panels:

11, 55 m 2 x 400 rubles. = 4620 rubles;

20 p.m. x 30 rub. = 600 rubles;

34 p.m. x 5 rub. = 170 rubles.

Total: 5390 rubles.

The cost of other materials was:

- lifting mechanism with a swivel leg - 2 sets with fasteners = 3000 rubles;

- metal corners 50 x 50 - 26 pcs. = 52 rubles;

- frame dowel 10 x 122 mm - 2 pcs. = 16 rubles;

- confirmations 50 mm - 16 pcs. = 20 rubles;

- screws 30 mm - 40 pcs. = 5 rub.

The total cost of materials was: 8483 rubles.

Labor costs

The assembly of the transformer bed cabinet was carried out in 2 days.

Such a scheme for assembling a bed closet with your own hands will cost much less than ordering such furniture. To build such a simple, but responsible structure yourself, you must have experience with the above tool.

Photo

For a small city apartment, saving space is extremely important, so folding furniture (transformers) is becoming more and more popular. This usually applies to massive pieces of furniture - beds and sofas. It is far from always possible to single out a separate room for a bedroom, so there is a need to combine such premises as a bedroom and a living room, a bedroom and a nursery. Manufacturers offer variety of options such a situation. You can choose beds that differ in size and shape. But it is not always possible to choose what you want. The way out of the situation is to assemble the bed with your own hands.

For those whose area of the apartment does not allow to put large beds or sofas, furniture manufacturers have come up with a folding bed. During the day, you can fold it and get a sofa, and in the evening - a cozy bed.

The assembly instructions are simple. Today you can find different schemes beds. These models are convenient in that they easily rise after sleep, without taking up any space at all. usable space rooms. During the day it is a cozy sofa with a shelf, and in the evening it is a comfortable bed for relaxing. As a result, it turns out that the space is used as conveniently as possible, and the room is not cluttered with anything superfluous.

Types of folding beds

A folding bed, assembled with your own hands, has a number of advantages:

- It takes up little space, which allows you to free up space in the room for other needs.

- Dust does not collect on the upholstery, as the structure is in the assembled state.

- When assembled, the design is not noticeable, does not interfere, the room can be used as a living room.

These models can be divided into 2 large groups:

A longitudinal folding bed is usually disguised as cabinet doors.

- Cross-folding, which are great for children. By appearance they strongly resemble the shelves in the sleeping cars of trains, that is, they lean to the side. Such beds can be easily disguised as shelves, used as bookcases. The designs of such beds are made single. They are comfortable, take up minimal space even when unfolded.

- Longitudinally folding bed can be double. It is usually disguised as cabinet doors. After use, it rises to the top using a special mechanism. The weight of this design is large, so it is not intended for children. The bed frame can be used in a room where there is enough space to lift it, otherwise you will have to think about another option.

Materials and tools for work

To assemble the bed with your own hands, you need to prepare the following materials and tools:

Tools for making a wooden bed.

- MDF boards with a thickness of 20 mm. They can be ordered already cut into the desired shape and size.

- A sheet of plywood with a thickness of 10 mm or more, which will be used for the bottom. Can be replaced with wooden planks, but the plywood sheet is mounted much faster, it will only need to drill holes for ventilation.

- Fasteners: nails, self-tapping screws, metal corners, plates.

- A special lifting mechanism that will ensure the movement of the bed body.

- A simple pencil, a metal long ruler, a building level, a building corner.

- Sandpaper, drill, screwdriver.

- Screwdrivers, Sander, jigsaw.

The folding bed is assembled simply, today you can find a wide variety of schemes for this. But for this it is necessary to use the drawings showing the assembly order.

Bed assembly: basic steps

The installation itself will be carried out in the following sequence:

Scheme of the folding bed device.

- First you need to draw up a project for such a bed. You can use the many ready-made ones that offer various options. It is enough just to carry out calculations for the future design, substitute the resulting values in terms of dimensions into the already finished drawing. Usually the design is the simplest, it includes a box (mounted to the base), the bottom of the future bed (it is the outer part of the cabinet), a frame for the mattress and the mattress itself. A lifting mechanism is attached to the box, which allows you to raise and lower the structure.

- The assembly of the bed is as follows: 2 side long boards of the frame are fastened transversely, 1 more central board is installed in the middle, which will give the structure the necessary rigidity. Often craftsmen use inner space in order to arrange convenient drawers for bed linen, for pillows that need to be removed somewhere after the bed is folded.

- All fastenings are carried out using self-tapping screws, metal corners and plates, the design should be as strong and reliable as possible. After that, you need to install a mechanism for lifting. It can be purchased at ready-made, it is mounted on the outer edge of the frame. The mechanism should not interfere with the use of the bed, for which it is necessary to first consider how and where it is best to place it.

- After that, the frame for the mattress is mounted, which is a design of a rectangular box and transverse slats. Instead of planks, you can use a solid surface of plywood sheet Well, it all depends on personal preference. But in plywood it is necessary to do round holes for interior ventilation.

- The folding bed is attached to the cabinet structure, the operation of the folding mechanism is checked. The front part is a panel that imitates the surface of the cabinet doors, but it can also be designed in the form of an attractive decorative board with carvings. This panel is attached last, it is securely screwed to the bed frame.

The folding bed is comfortable design, which allows you to save space in small city apartments, where there is a lack of free space.

Such hinged frames can be completely various types, if you have some experience, you can easily assemble them with your own hands. It is only necessary to first decide on the model of the bed, draw up or take a ready-made drawing, and purchase the materials necessary for work.