What is a carriage: the secrets of Norwegian technology and the characteristics of quality material. Cutting a log house with your own hands - the choice of technology How to cut a bath from a gun carriage

In our article, we will talk about the Norwegian technology for building houses from rounded wooden trunks. We will tell you what a carriage is, what and how it is made of, and consider the design features of the walls. You will also find out what are the advantages and disadvantages of carriage houses.

Houses built from solid logs are considered to be the hallmark of the Russian village. Skillful craftsmen in a wooded area with the help of primitive tools created real masterpieces of wooden architecture. True, as it turned out, not only in Russia they knew how to build houses from long logs. Norwegian carpenters also knew a lot about wooden joints and structures of high reliability, they have long built houses from logs processed in a special way, which were called gun carriages.

Lafette - what is it?

A carriage is a semi-oval log, sawn and planed on both sides so that two rounded planes parallel to each other are obtained. Conventionally, it can be considered a board with rounded edges. The size of this element is usually standard, and is: 240x400 millimeters.

There is also an analogue of the term "carriage" - a gable beam.

As a material for the manufacture of a carriage, you can use any type of construction wood, but most often it is pine.

In contrast to prefabricated glued long lengths, this product is more demanding on the quality of the feedstock:

- For the production of the gun carriage, only high quality wood is used.

- The trunk must have a uniform structure along its entire length, since it is not possible to remove or replace the slightest defects.

- It is possible to process only wood with normal humidity, ranging from 12 to 15 percent.

- In terms of other indicators, the elements of the log house correspond to the well-known rounded log.

1

Features of a log cabin from a gun carriage

In the Norwegian log house, the fastening of logs is carried out by the so-called "Norwegian lock". At first glance, the crowns look like a standard 900 harness, but the secret is hidden inside. A complex cut is only possible for a neat and skilled carpenter.

Showing how to make this cut is quite difficult, as well as teaching from a book. This is the main reason for the small distribution of the mentioned technology. The connection is made for a long time, moreover, this work is highly precise and requires adjustments - among carpenters it is called "furniture".

Why such difficulties? A complex cut has several tasks that subsequently justify the time spent:

- More nested angles increase mechanical reliability.

- The increased contact area between the two elements increases the friction force in the pair.

- The design of the notch contributes to the optimal distribution of the load inside the bundle, it is compacted and strengthened. That is, the load from the weight of the walls is directed to strengthening the connection directly between the crowns.

- Foreign fastenings are excluded: there are no points of excess stress, since the load is evenly distributed throughout the structure.

This "multi-profile" approach when connecting crowns justifies itself. After all, it is obvious that the extra time spent on the log house during the construction process will turn into years and even decades of trouble-free operation in the future. In other words, the Norwegians managed to get the most out of the structural features of the tree trunk, using a reasonable approach and original technology.

1

1

Pros and cons of log cabins

Material advantages

- natural, environmentally friendly raw material - wood. Convenience of processing and installation of other elements (battens, stairs, ceilings, etc.);

- centimeters are not lost indoors. Logs protruding inside the side are one of the main problems of all log cabins built from logs with a round section. But the walls of the gun carriage have appearance like a calibrated bar, they do not require further processing and coating (with the exception of grinding and antiseptic);

- for the assembly of a log house, electricity is not required (with the exception of lighting) and metal fasteners, which reduces the cost of building a house;

- the connection of the crowns strengthens the bond during settlement and an increase in the load on the walls;

- a wood thickness of 240 millimeters is equivalent in thermal conductivity to 380 millimeters brickwork one and a half bricks.

Cons of the material

- complex, expensive and time-consuming construction process. The log house is assembled at the landfill, then marked, and then dismantled for subsequent transportation;

- in 90% of cases it is a unique project to order. That is, the construction will have to be planned in advance, about two years in advance, so that the material can be prepared for it;

- even in the form of a carriage, such a log has all the "wooden" problems: wear due to weathering, freezing, instability to insects, rot and fire hazard. In addition, like any solid wood log house, it needs antiseptic treatment every two to three years and caulking every 3 to 6 years.

It is worth knowing about the houses from the gun carriage

It is often very difficult to find specialists who are able to perform cutting and installation with high quality. In this case, the prefabricated kit has to be transported from afar, and this increases the transportation costs. Although on the other hand, this can be considered as an advantage, because the house can be delivered to any place.

A house built from a gun carriage - perfect option for those who consider solid log structures to be the best. Undoubtedly, in terms of the reliability of fastening and load distribution, the Norwegian cut can be attributed to the best example of an engineering solution. Therefore, European technical thought, along with a thrifty attitude to resources, is rightfully conquering our market, promoting high-quality technical solutions and environmentally friendly materials.

We will send the material to you by e-mail

If you choose quality material for your home, then our review will tell you what a carriage is and what benefits it can bring. This version of lumber is popular in the construction of houses. Similar option is Norwegian technology. In this case, special strong connections are used, which ensure the reliability of structures. So, let's look at the advantages and disadvantages of the carriage, and also study its characteristics.

Luxurious designs from this material presented not only standard projects

First, let's find out what a gun carriage is in construction. This material is logs hewn from opposite sides. In this case, special locking joints are used, which provide high thermal insulation and strength characteristics of the structure. At first, huge boards were used by Scandinavian builders, and then lock fasteners were invented in Norway.

The advantage of such buildings is that they do not need additional insulation, but the thickness is 20-24 cm.The carriage among Russian builders is called double-edged or gable. It can be a sawn log, which is installed in a horizontal plane, and is also used in the form.

How such a structure looks from all sides, you can see in the video:

Now let's figure out what a carriage is in woodworking. For its production, larch or pine wood is used, and the trunk diameter can be from 40 cm. To stiffen the structure, it is necessary to use wooden dowels.

In the manufacture of a carriage, there are certain requirements for quality characteristics:

- When creating the material, high-quality wood is used;

- The table must have a uniform structure without irregularities along the entire length;

- The forest of the optimal moisture index is used - 12-15%.

Mounting procedure gable beam quite laborious. Production takes place in several stages:

- first, the edges are removed from the log. In this case, the butt is marked, and then a layer of wood is removed using a band saw. In this case, additional unedged parts are formed;

- after that, all roughness and a layer of bark are removed from other rounded elements.

Related article:

Why is this material so popular? What are its benefits? How much does a SIP panel house cost? More details in a separate review.

Log cabin from a gun carriage: advantages and disadvantages, main characteristics

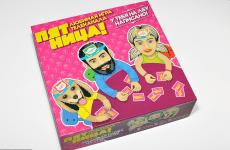

In the photo below, a log carriage from Norway. The main feature of such a log house is the fixation of parts between themselves, which has the name - the Norwegian castle. From the outside, the building looks like a traditional harness. But inside it is a strong and original cut. This mount serves many purposes. Many specially fixed corners increase the strength of the building. A significant area of contact between the two parts increases the friction force in the pair. This technique contributes to the correct distribution of the load within the ligament. In this case, there are no areas of excess stress.

Let's note the advantages of such material:

There are also certain disadvantages of the material:

- complex, expensive and time-consuming construction process;

- construction must be planned for several years in order to prepare material for it;

- every 2-3 years it must be treated with antiseptics, and after 3-6 years caulking should be carried out.

In the table below you can see how much the carriage costs. The price per cube depends on the manufacturer and on the characteristics of the material.

| Photo | Type and characteristics | price, rub. per cube |

|---|---|---|

| Carriage diameter 200 mm, groove width - 140. | 15000 |

| From northern pine. Wall thickness - 190, beam height - 240. | 13000 |

| Carriage of natural humidity. Wall thickness - 140, log height - 140 | 10500 |

For your information! Even the carriage structure is subject to many problems of any wood. For example, the processes of decay, moisture and insect invasion.

The choice of the construction project from the gun carriage

There is a wide variety of carriage designs. Relevant. They are used for permanent residence and as buildings for . They are performed in different styles. The area can vary from 75 to 80 sq.m.

There are classic options with square structures, as well as projects with hipped roofs. Strong buildings are made of cedar. Projects can be completed in, country, modern or chalet.

Exists . Such designs make the building more expensive.

Reliable designs of two-story projects. At the same time, buildings can be made in the Russian style, and not only in the Norwegian or country style. An excellent option is. Such a building does not need a complex foundation.

For your information! Such buildings do not need insulation, since the wall thickness of 20-25 cm keeps heat remarkably.

Carriage houses: original projects and features of buildings

Projects of houses from a gun carriage are distinguished by a thoughtful and concise design. At the same time, the facade part remains in its natural form and does not require additional lining. You can give an unusual color to wood material with the help of impregnations. Such a solution is a mixture of color and antiseptic. Oval hewn logs are a kind of decorative element. Hand-made patterns look great on the gun carriage.

You can do it yourself. At the same time, it is worth considering everything to the smallest detail. Perfect for a setting like this. It will perfectly complement the walls of wood.The inner surfaces of the walls can also be left unfinished.

The table below shows some projects of carriage houses and prices:

| Image | House and company | Description | price, rub. |

|---|---|---|---|

| House 99 sq m (Northern house) | Pine carriage. The project includes a living room, two bedrooms, a terrace, a boiler room, a hall and a bathroom. | 1180000 |

| Pine bath 100 sq. m. (Northern house) | The project consists of a living room, shower room, steam room, hallway and terrace. | 1150000 |

| Building 280 sq.m. (Northern House) | There are several bedrooms, a living room, a wardrobe, a kitchen, a terrace, a bathroom and a hall. | 3900000 |

| Log cabin 8*8 (Srubdom) | Has a six-wall configuration | 1454000 |

| House of Adonijah (Iva) 368 sq. m. | The building has two floors. | 5420000 |

Also, let's see the reviews of the owners of the house from the gun carriage.

Elena, 36 years old. Penza:“We have a house from a gun carriage, so far we have been using it for a year. After the heating began, small cracks began to appear, but this happens in any wooden structure. But since our family likes only wooden buildings, this drawback does not bother us. But the climate: aroma, humidity and air cannot be compared with anything else.”

Evgenia, 43 years old, Yaroslavl:“We are very pleased with the gun carriage structure. There are cracks, but this creates a special charm, as the building is alive and breathing. We have long dreamed of a log house and now we are enjoying it. There is an opinion that such a house does not breathe, but gradually collapses, but this process drags on for many years.”

Maria, 30 years old, Tambov:“The carriage house is very practical. My parents' kitchen in the country was made of timber, so it is already 40 years old and it is holding up well. So in those years there were not even impregnations that are now. About three years ago they built an outbuilding from a gun carriage. As long as we're happy."

For your information! If the carriage is processed correctly, then small cracks will complement decorative look and won't do any harm.

How to make a bath from a carriage

It is popular from a gun carriage with an attic. A building made using this technology has not only a unique look, but can also be stored for decades. Projects of such buildings are developed taking into account the characteristics of this material. The carriage will provide an ideal microclimate indoors and natural humidity. In addition, such buildings are durable and have heat-saving properties.

Features of Norwegian technology

Now let's deal with the technology of the Norwegian carriage cutting. Its feature is the creation of a Norwegian bowl, that is, a special connection method in which water does not penetrate into the structure.At the same time, the pediments are chopped, and the roof has a sleg device. All details are adjusted with great precision. It should be borne in mind that chopped structures also need to caulk gaps and crevices.

The Norwegian cedar carriage has a special interlock connection, which becomes denser over time and does not cause twisting of the logs. Appearing cracks are not a problem, as they do not become through. Such a connection is one of the most durable, reliable and warm. In the process of shrinkage, such a locking device is self-jamming.In addition, a special hidden spike can be used, which is a guarantee of the rigidity of the log house, and also increases the thermal insulation qualities of the structure.

How to make a gun carriage with your own hands

The construction of carriage houses is often made from northern pine. At the same time, its diameter can be 29-37 cm, and after processing - 22-23 cm.The carriage is carried out using special equipment. The supporting part of the carriage is made after marking.

Here are the main stages of work:

- marking should be done only by a specialist. Then the lock is cut;

- a longitudinal groove is marked. In this case, a line is drawn with an adze;

- grinding is performed, which helps to create smooth surfaces;

- also perform cutting corners from the gun carriage;

- All parts are treated with an antiseptic to prevent rotting and mold.

After preparing the material, the building is erected. In this case, a foundation is made, under which a layer of waterproofing is necessarily laid. When assembling the structure, the parts are precisely adjusted to each other. For openings of windows and doors, a groove 50 mm wide is selected. Large beams are selected for mounting the ceiling.

Before finishing, you need to choose a style. Can be treated with translucent surfaces protective compounds. Often used special tinting.

At right approach from the gun carriage you get one of the most reliable building structures. This option is recommended for areas with a cold climate. Unique technology allows you to create durable buildings that will last for tens and even hundreds of years.

Article

To chop log cabins with your own hands means to cut out or cut out corner joints and longitudinal grooves on logs or on a beam. You can do this in several ways.

In the hook

The technology of felling log cabins “in a hook” is divided into 2 types:

- the bowl is selected exclusively up to the middle of the processed log, on one side of the log axis. A semicircular groove is made in the upper part of the logs to the unselected remainder of the prepared bowl;

- hewn inner side logs. When assembling a log house, you get a flat wall, right angles. The inside of the logs is combed off by ¼ of the diameter. The castle is fastened with a spike that clings to an area that is not hewn.

From the gun carriage

The cabin from the gun carriage is also called "Norwegian". A semi-oval log, a two-edged beam is used.

The locks of the Norwegian felling are wedge-shaped. During shrinkage, they are compacted, excluding the appearance large cracks keeping warm. The cost of insulating interventional material is reduced.

This method of making the lock prevents the logs laid in the crowns from twisting.

Canadian felling

Canadian felling is popular due to the preservation of a valuable piece of wood - sapwood. With other technologies for preparing a tree for laying in crowns, this layer is lost.

Blocking, protesta, cylindering remove sapwood, which is only 3-4 cm. The preservation of the sapwood guarantees the protection of the soft internal structure tree.

The Canadian bowl has the shape of a trapezoid.

Advantages of the Canadian felling:

- increase the life of wood;

- minimization of heat losses;

- a room built of wood with a preserved sapwood layer retains the microclimate for a long time;

- moisture protection of internal corners;

- interventional insulation "hidden" in a special insulating channel.

IMPORTANT! Canadian logging is entirely done by hand.

Caulking is not required after shrinkage of a log house driven out using Canadian felling.

Finnish felling

For Finnish felling, coniferous round timber and prepared timber are used. Finnish cutting is similar to traditional Russian cutting.

The grooves are made concave, completely closed, the edges fit snugly. The heater at the Finnish felling is hidden.

Into the bowl

The simplest, actively used by builders method of making log cabins is cutting "into a bowl".

The advantages of the technology are:

- structural stability;

- speed, ease of assembly;

- the ability of a building to retain heat.

Flaws:

- loss of "useful" length of wood is about 1 m. The ends when cutting "into the bowl" protrude beyond the corners of the building up to 30 cm.

You can carry out such cutting with a bowl down or a bowl up. Log assembly technology can become more complicated additional installation spikes.

The marking for cutting is applied with a special, a simple tool- trait. You can make your own carpenter's compass.

In addition to bowls, longitudinal grooves are made oval shape. Interventional insulation is laid in the grooves.

Before, as well as after shrinkage of the log house, caulking is required.

Log cabin from a bar

The technology of felling log cabins erected from wooden beam, simplicity. Prepared timber is easier to mark than roundwood.

The diagram shows options for cutting timber, allowing you to consider how corners and joints are cut.

When collecting the crowns, the beam is fastened with dowels, dowels, spikes.

Timber cutting technologies are divided into:

- felling in half a tree;

- felling in a warm corner;

- cabin in dovetail.

Log cabin in the paw

"In the paw" the log house is assembled with full use usable length wood material. The corners of the log cabins are joined without a protrusion of the ends, which prevents the waste of wood.

After assembly using this technology, it is possible to carry out exterior finish log cabins with facade siding.

To use the cutting "in the paw", careful marking of the logs / timber is required. It is advisable to use a pre-prepared template in order to mark up all the material in the same way.

Photo 7 - Finishing the log house with siding

Felling a log house in the paw video

The video shows how a chainsaw is cutting a log house using the "paw" technology.

felling video

The traditional felling of log cabins “in a hook” is the simplest and looks like this.

$ felling price

The felling of a felling differs in technology, level of complexity. The price of the main types of felling for 1 m 2 today is:

- cutting into a bowl - from $ 100;

- Norwegian felling - from $170;

- Canadian felling - from $120.

An increase in the diameter of logs / timber entails an increase in the cost of work.

The simplest is the "into the bowl" technology. And the most labor-intensive is Canadian felling.

It is well known that Russia has long been famous for the strength of the traditions of wooden housing construction, but this is not the only state where, historically, preference was given to wooden buildings. For example, the traditions of Norway, where their own construction technology was invented wooden houses from a double-edged beam, are in no way inferior to Russian technologies, and in a number of parameters even surpass them. This becomes especially noticeable when combined with a double-edged beam, also called a gun carriage, and a special "Norwegian lock" - a special smooth corner wedge-shaped joint that seals over time and prevents the penetration of wind and water. Thus, having carefully studied this technology, the experts came to the conclusion that with an increase in the shrinkage of the log house, the strength and reliability of fastening increase. Initially, the carriage is considered not only a log, but also a special style of hand-cutting, which has developed in Scandinavia in ancient times and still remains one of the most beloved in Norway, Finland and Sweden. Initially, the construction of houses from a gun carriage was developed as a means of reducing the cost of a log house without compromising the thickness of the log and, as a result, the warmth of the house. The solution was so simple and, at the same time, original that it was soon borrowed by neighboring countries, and then spread all over the world. Its essence was that the pine log was cut off on both sides, and the resulting cut was used to equip the roof and floors. The purpose of this decision was to use the entire array in the process and to abandon additional materials, since the manufacture roof structure and internal partitions also carried out from the gun carriage. In this article, we will consider the main advantages and technology for building houses from gun carriages - the most advantageous Norwegian alternative to traditional Russian buildings from round log.

Carriage houses - a technology that has been proven for centuries

Everything new is a well-forgotten old, and the construction of wooden houses is no exception. Despite the fact that the history of this technology has more than one hundred years, this trend, forgotten for several hundred years, is on the verge of its “second youth”. Industrial development contributes to the fact that many well-known technologies are used in the construction of wooden houses, including profiled timber, and round logs, and frame construction. However, none of them can be described as "tested for centuries." As for the technologies tested for centuries, one of them is the construction technology one-story houses from the gun carriage.

A carriage, also called a double-edged beam, is a log processed by hand cutting so that it acquires a semi-oval shape in which two mutually intersecting parallel planes. In other words, the technology of processing logs in this way involves obtaining logs cut from both sides so that it acquires two flat surfaces. For the manufacture of the gun carriage, cedar or pine logs are used.

Carriage Humidity Levels: Dry and Wet Cart

The construction technology of Norwegian houses involves the use of both wet and dry gun carriages, however, the most optimal material is the last one. Houses built from dry gun carriages are characterized by reliability, high strength and the absence of through cracks, which makes it possible to build an environmentally friendly house that will retain heat even on the coasts blown by cold winds, which was a habitual habitat for freedom-loving Vikings choosing houses from a gun carriage. Despite the impressive thickness and weight of the carriage, it can easily be dried in specialized drying chambers, where they acquire an optimal moisture content that does not exceed 18-22%.

A wet gun carriage, whose humidity index is 35-55%, can also be used to build Norwegian houses from a gun carriage, however, they must undergo long-term natural drying and shrinkage, which postpones the commissioning of the building for some time. In most cases, these processes take place within one to two years. In order to convince you for sure of the advisability of using a dry gun, consider its main advantages.

Advantages of a dry gun:

- In the process of comparing the terms of shrinkage of houses built from a dry and wet gun carriage, experts came to the conclusion that the natural shrinkage of houses built from a gun carriage, characterized by high humidity, carried out three times longer;

- If, before building a house, the material used is dried in specialized drying chambers, the number of cracks that appear during operation is significantly minimized in it;

- The wood of a dry carriage, in contrast to the wet material, is characterized by a higher quality. This is due to the fact that all potentially harmful microorganisms, including mold and bacteria, die during the heat treatment. This significantly improves the quality of the material;

- To build houses from a carriage beam, it will take half the time than when building a building from a wet carriage.

- As for the disadvantages of a dry gun carriage, its only disadvantage is high price compared to wet material.

Houses from a gun carriage photo

Important! During the operation of the log house from the gun carriage, the level of moisture content of the wood is regulated. This parameter does not depend on weather conditions and reflects the processes of self-regulation and stabilization of the humidity level.

Houses made of chopped gun carriage are a classic version of the Scandinavian wooden construction. Carriage is a special material representing a log, which is characterized by the presence of hewn side surfaces, the so-called cheeks. Despite the fact that the houses from the gun carriage retain all the advantages of the classic log house from a round log, from the outside and inside it will be almost flat. This ensures a tighter fit of the logs to each other and increases the thermal insulation characteristics of the building.

Chamber drying of the gun carriage: pros and cons

Forced drying is one of the main components of the woodworking industry. It is equally often used for both boards and timber, however, drying roundwood- the process is much more complicated (in most cases this applies to forests with a diameter of 28-30 cm). The most common type of chamber dryers are convection type designs, significant disadvantage which is considered the deformation of the log and the appearance of cracks. Although there are ongoing developments innovative technologies forest drying, such as drying with microwave radiation, vacuum pulse drying and others, it is still one of the most difficult tasks.

However, if we talk about a half-beam - a carriage used in the construction of houses using Norwegian technology, in this case the situation is different. Due to the fact that it is characterized by a smaller diameter, it is easy to dry. At the same time, it is not at all necessary to dry it to a furniture moisture content not exceeding 8%, since this is quite expensive and impractical. It will be enough to dry the gun carriage up to 18-22%. Upon reaching the specified moisture level, most of the bound and almost all free moisture is removed from the wood. Despite the fact that drying the gun carriage is quite an affordable process, it is much more laborious than drying the board. This is due to the characteristics of the material, which do not allow the use of a hard drying mode, as this will lead to cracking of the wood. When using a too soft mode, a different picture will be observed - upon exiting the drying chamber, the moisture content of the wood will remain at high level. Drying feature that will lead to optimal humidity carriage, is the short stay of the material in the drying chamber, which leads to the drying of the surface layers of wood, while the core remains still wet. The use of wood of natural moisture is an essential condition for the technology of building houses from a gun carriage, since the drying of the material occurs directly in the log house.

Important! The ideal building material for the construction of houses using Norwegian technology is the northern forest, which provides the maximum thermal insulation characteristics of the building. In Russia, such material is Karelian and Arkhangelsk wood, as well as wood from other northern regions characterized by cold long winters. Wood from Finland is no less in demand.

Projects of Norwegian houses from a gun carriage

Design features of houses from a gun carriage

A distinctive feature of the Norwegian log house is a specific method of attaching logs, which is called the "Norwegian castle". The relatively low prevalence of this technique is due to the fact that technological features this method is difficult to describe in words, as well as to learn this from books. In order for this connection to meet all the requirements for it, it is necessary to make a long and careful adjustment of structural elements. What is the reason for this complication of cutting? According to experts, it pursues five main goals, the essence of which will be described below.

Due to this method implies a greater number of cut corners, this indicates its high reliability;

- Between two adjacent structural elements, the contact area increases, and, accordingly, the friction force also increases;

- This technique involves beveling the corner, which determines the impact gravitational force to structural elements. This contributes to the distribution of the load inside the ligament, due to which it is strengthened and compacted. In this regard, we can draw conclusions about the direction of the load on strengthening the connection between the crowns;

- Due to this technology provides for the rejection of foreign fastening elements, there are no points of excess stress, which contributes to a uniform distribution of the load through the tree, which is characterized by relative softness;

- This method of fastening is characterized by the presence of a multi-plane interface and stepped differences that contribute to blocking or, at least, a significant reduction in drafts.

After analyzing these data, we can conclude that such a multidisciplinary approach to the construction of houses using the “Norwegian castle” method can be fully explained by the operational characteristics of the building, which can be built by skillfully combining reason and technology.

Advantages of wooden houses from a gun carriage

The high heat-insulating characteristics of the carriage determine its competitive relationship with glued beams. At the same time, despite the use of even imported material, it costs almost two times cheaper. In addition, the environmental characteristics of a building built from glued beams are in many ways inferior to those of Norwegian houses from a gun carriage. Consider the main advantages of one-story houses from a gun carriage, thanks to which they have become popular in Russia.

- Thermal insulation characteristics- one of the main advantages of Norwegian log cabins, the assembly technology of which involves reducing heat loss. This is due to the peculiarities of the material (the use of a round log with a diameter of 28 to 60 cm), which helps to reduce the number of crowns per unit height of the structure, the number of which does not exceed 8-12 for one floor. Moreover, unlike the traditional Russian log house, which is characterized by a decrease in wall thickness at the joints of the logs, the Norwegian log house is characterized by a uniform wall thickness of at least 20 cm.

Important! If we talk about the thermal insulation characteristics of a house with brick walls, its thermal conductivity is not able to argue with this indicator for wood. For example, the thermal conductivity of perforated brick is 0.63 W/mK, while the thermal conductivity of wood does not exceed 0.15 W/mK. Thus, if we compare brick house with a wall thickness of 1 meter, and a Norwegian log house, the wall thickness of which is 20-25 cm, they will be characterized by the same thermal conductivity;

- Availability of additional living space, which appears due to the hewn part of the logs, acquiring flat surface. Moreover, the increase in the internal volume of the building is facilitated by the small diameter of the gun carriage - no more than 20 cm. This favorably distinguishes the houses from the gun carriage, the projects of which are presented in this article, from the bulky log walls that steal a significant amount of living space. At the same time, in terms of thermal protection, a 20-cm carriage is not inferior to 30-cm log walls made of round logs;

- Features of assembling houses from a gun carriage require careful selection of building materials, which undergoes multi-stage processing, combining the use of the most modern equipment and manual labor. If the cutting of the side surfaces of the logs is carried out at the sawmill, then it is planed only manually. This guarantees the provision as even as possible and smooth surfaces walls, which greatly simplifies and minimizes interior decoration;

- A complex system of connecting crowns ensures the absolute resistance of houses from a gun carriage to deformation. Features of the "Norwegian castle" provide reliable fixation of logs in the nests, so that they do not change their position. In addition, due to the unique design of the "Norwegian castle", the shrinkage of the structure and the shrinkage of wood contribute to even greater self-jamming of the crowns of the log house under its own weight. This system guarantees the absolute absence of gaps and 100% thermal protection;

- Long service life of the building ensured by the design features of the building. The roof and walls of the house from the carriage are a single whole, that is, the wall is a continuation of the roof, which is so dense that it allows you to securely fasten the walls of the building;

- High aesthetic characteristics. Carriage recognized ideal material for those who are true connoisseurs of the beauty and environmental friendliness of natural wood. Carriage structures are characterized by an ideal appearance and are rightfully considered the pride of their owner. Due to the fact that Norwegian houses look solid and reliable, they enjoy growing popularity among consumers everywhere. At the same time, the owner of the house from the gun carriage may not worry that the building will lose its thermal insulation characteristics;

- Savings on building and finishing materials- another advantage of the houses from the gun carriage. Unlike a log house, fewer elements are needed to build a reliable log house. Moreover, the gun carriage design eliminates additional insulation and soundproofing, as they are obviously at a high level. No need for external and interior decoration clapboard or block house walls, which also helps to reduce construction costs.

Important! One of the interesting varieties of carriage buildings are houses made of half carriage - logs that are hemmed only on one side (the inside of the building). The use of such material will not only facilitate the process of finishing the house, but also allow you to create original interior dwellings. The appearance of the building from the outside will resemble the traditional log house, while the hewn inner surface logs will contribute to the expansion of usable living space, which makes such a structure twice as profitable.

How to build a house from a gun carriage: assembly features

After reviewing the projects of Norwegian carriage houses and evaluating the size of the construction budget, you can safely proceed to the process of building a house. In the process of erecting such buildings, northern pine is used - affordable and relatively inexpensive construction material. If the trunk diameter is 28-36 cm, then after processing the diameter of the finished material will be 21-22 cm.

Important! As for pre-processing, it includes the following steps:

- Manufacture of a gun carriage using specialized equipment;

- Log cutting followed by marking on it, which should be carried out only an experienced craftsman, since the quality of the connection of logs and subsequent performance characteristics building.

The next stages of work:

- After marking the log with a line, which is performed by a carpenter using special tools, it is necessary to cut out a lock - a Norwegian bowl. This stage the work is quite complex and subtle and must be carried out with a certain experience;

- Using a line, a longitudinal groove is marked, which is selected using an adze - an ax characterized by a special shape;

- Next, grind the notches, which is necessary in order to ensure maximum density and smoothness of the joints;

- The final stage in the preparation of building material is its treatment with an antiseptic. To do this, use specialized compounds that have antiseptic characteristics and prevent the decay of wood and the appearance of mold spots on it.

- Having prepared the material, proceed to the construction of the building. The basis of the structure is the foundation of the tape type, which is a monolithic concrete base. Before proceeding with the assembly of the house, a waterproofing layer is laid on the foundation to prevent damage to the lower rims.

- After that, the assembly of the building is carried out, which takes a long time, as it requires the most durable fitting of parts, which guarantees an accurate connection of the elements of the house. in doors and window openings choose a groove, the width of which is 50 mm, which must be inserted into the guide beam, which is the basis for fastening window frames and door block. This contributes to the safety of doors and windows during the shrinkage of the log house - after that they will "stand" in place, dry completely and will be tightly pressed to the logs, which guarantees the absence of cracks.

- In order to carry out the installation of the ceiling, use wooden beams, characterized by a section size of 150x200 mm. To give the interior of the house an original appearance, in most cases the ceiling is left open.

- As for the decoration of the Norwegian house from the gun carriage, it can be carried out using various stylistic solutions. In most cases, masters recommend giving preference classic version, implying the treatment of walls with translucent protective compounds, preserving their natural beauty. The use of various tints is also welcome, since the treatment with various paints and varnishes will not only increase the degree of protection of the building, but also make it as attractive as possible.

In conclusion, we note that carriage houses are one of the most reliable construction options, which will become the best choice in cold climate regions. The unique technology of connecting logs allows you to build reliable buildings, the service life of which exceeds tens and hundreds of years. The growing popularity of such houses in Norway and the northern regions of Russia once again proves this.

The original technology for building wooden houses from a gun carriage was born in the Scandinavian countries. It was very successfully used by the Vikings, severe natural conditions forced them to invent quite complex, but effective methods construction of reliable and warm houses from natural materials in particular from wood.

What is a carriage

Norwegian gun carriage is a building material made of selected, large-sized wood with a certain taper and helicity of the fibers. For the manufacture of this building material, logs with a diameter of 330 to 350 mm are used, carefully planed and then turned from two opposite sides.

In finished form, the thickness of the logs can be from 200 to 220 mm. The carriage prepared in this way is used in the construction of external and interior walls. The surface of the wall from the carriage is even and smooth. The dimensions of the wood material make it possible to build walls of one floor of 8 or 9 crowns, which positively affects the quality characteristics of the structure, in particular, heat saving and shrinkage.

Used to process logs band sawmill, which allows processing logs with a diameter of up to 60 cm and a length of up to 9 m. The ability to produce building materials of such dimensions is a positive moment, they are in demand in the construction of houses with large spans of floors and long walls.

The use of a long log allows you to save material, and inner space at home can be used with greater benefit. At the next stage, the carriage is given a more aesthetic appearance, its surface is brought to perfect alignment, the planed wood turns out to be very light and smooth, carry out its sheathing finishing materials not required.

For more information about what a carriage is and about the technology of its manufacture, watch the video:

Assembling a log cabin from a gun carriage and its features

The connection of logs in the construction of the house is carried out using a "cunning lock", complex in shape and of high quality in execution. The use of a Norwegian lock makes it possible to connect logs in cuts, which completely eliminates the possibility of freezing corners. When the house shrinks, the castle becomes even more compacted, log cabins from the gun carriage become warmer with age. Temperature in wooden house also depends on the thickness of the walls - the thicker the logs used in construction, the lower the cost of heating the home.

The problem is that with the increase in the thickness of the carriage, its cost increases significantly. But builders are resourceful people, they began to use the slab obtained by cutting logs for laying floors and arranging roofs. Thus, the construction of houses from a gun carriage began to be carried out using the entire array of wood, waste and the need to buy other building materials disappeared.

Roof rafters were also made from carriage, and the roofs were made flat, without attics. Sod with grass served as insulation, and at the same time for finishing the roof. History mentions facts when goats were grazed on the roofs of such houses.

And today during construction traditional house in Norway, only carriages are used, the minimum thickness of logs is 28 cm in diameter, the maximum is about 50 cm. Naturally, such a house looks rich and thorough.

Ways to assemble log cabins

There are several options for performing corner joints, but the most common are performed:

- in the paw, i.e. without a trace

- in a cloud, when after joining the logs residues are obtained, the logs are connected using the so-called. cups.

The Norwegian cup is used in the manufacture of log cabins. Canadian felling of houses is used if the house is built from a round log of natural taper. To improve the qualities of the Canadian log house, wedge-shaped notches are made on the logs, and a special spike is left inside the cup.

When constructing structures of complex shape, they resort to connecting logs into a cup at an angle that differs from a straight one. If the release of logs outside is not provided for by the project, the construction is used in the paw, i.e. the remains of the logs do not come out. If the external outlets of the log walls are not provided for by the project, the logs can be connected through a support post, which can be used as an interior element.

One-story houses from a gun carriage - features of the construction of a log house

The process of cutting joints is quite interesting - only an ax is used for work, such wood processing allows you to fully preserve its quality characteristics. To improve thermal insulation properties walls and give the structure additional rigidity in corner connections the use of spikes and notches is supposed.

The ideal fit of logs is achieved by cutting special longitudinal grooves. Projects of houses from a gun carriage can be intended for both one-story and two-story construction. The details of the log cabin are made by craftsmen, each detail corresponds exactly to the drawing, each piece of the future house is marked, then it is packed and delivered to the customer.

Delivery of a house packed in this way can be carried out at any distance. A log house is assembled on a pre-prepared foundation. During the assembly process, the interventional joints are insulated and dowels are installed. The assembly of the log house is the most important stage of construction. Mistakes and errors made can ultimately lead to disastrous consequences.

Therefore, the assembly of the house should be trusted to people who have sufficient experience in performing such work, best of all - to professionals. It will take a little time for craftsmen to assemble a house - assembling a house with an area of 100 square meters. m usually last about a week.

The assembly of the log house is carried out by the so-called. Norwegian lock, among its main advantages should be called its ability to self-jam during shrinkage and form an extremely tight connection that prevents the gun carriage from turning due to internal stress, whereas with the traditional version of connecting a rounded log, this phenomenon is often observed.

Naturally, natural moisture cannot get into a tight connection with a Norwegian lock, this is:

- reduces to a minimum the possibility of fungal infections,

- reduces the level of heat loss,

- helps to get rid of the problems that arise during the shrinkage of the house.

The assembled frame is covered with a temporary or permanent roof:

- having reached the desired height, the walls are covered with ceiling beams,

- the cover is insulated

- collect truss system and lay the roof.

Naturally, such an attic in the house will be cold and can only be used as a utility room. Nowadays, it is customary to insulate the roof, and design the room itself as an attic, i.e. make it habitable. Often, for the construction of the attic, material is used that is different from that used to build the house itself. It should be noted that this option does not always contribute to increasing the attractiveness of the facade of the house.

Drying occurs when the carriage is already assembled into a log house, during the first year after the construction of the house. The shrinkage of the log house in this case can be about 6%. The material of manufacture, the carriage, is so beautiful that additional decoration of the house is not required. The assembled frame, depending on the preferences of the owner of the house, can be polished.

But its treatment with flame retardants and antiseptics is a must. Experts recommend not saving on these procedures, using modern drugs that are safe for health and are highly effective:

- flame retardants will reliably protect the house from fire, which is extremely important for a wooden structure,

- antiseptics - will prevent the possibility of wood damage by putrefactive infections, fungi and mold, insects.

The first treatment should be carried out during the construction period or immediately after its completion, the second - the next year, or in accordance with the instructions for the use of drugs. Subsequent treatments are preferably carried out every five years.

How to properly care for a house from a gun carriage, look at the video:

Secrets of the Norwegian castle - advantages and disadvantages of log cabins

The original type of connection, the Norwegian lock, is used only for logs of certain parameters: their diameter should be in the range of 30-40 cm. cm.

Properly made groove and tenon allow you to get an ideal connection in terms of strength, which, in the process of drying the material, will become more and more rigid and impermeable.

For more information about the Norwegian castle, watch the video:

Among the main differences of the Norwegian felling are:

- the ability to self-eliminate interventional gaps, i.e. curtaining of outer corners used in Russian technology is not required,

- invisible joints are used to organize undercuts,

- relief cuts do not eliminate cracks,

- logs for the installation of platbands do not need to be cut.

A log cabin has the following advantages:

- its architectural solutions can be quite diverse, such a house looks easy,

- a flat wall 20 cm thick allows you to increase usable area at home, for comparison - Russian felling gives a wall thickness of 25 cm to 45 cm,

- to carry out the installation of all kinds of communications in the house from the gun carriage is quite simple,

- it is also easy to install furniture in it, in particular wall cabinets,

- excellent thermal insulation characteristics of the cup in the cut,

- cost reduction due to the absence of the need to make cuts for window and door openings.

Of the shortcomings that distinguish carriage structures, the most significant is the technology of wood processing - its upper, more stable and durable layer is removed, the soft, inner layer has to be in contact with environment. That is why the number of mandatory operations in the construction of a house includes the antiseptic treatment of logs.

The cracking of wood along the side surfaces affects only the decorative effect of the material, without changing its qualitative characteristics, including heat-shielding ones.

The prevailing opinion is that a house or a bath from a gun carriage retains heat worse than log structures of the same purpose. This is not true. With a wall thickness of 22 cm, which is the standard for a gun carriage, houses are very successfully operated in rather tough climatic conditions with cold winters, and even beyond the Arctic Circle.