PPR on scaffolding. Project of the work of work (PPR) on the construction forests of the PPR on the installation of forests

Project production project (PPR)

Project of production of work on the installation of forests of LSPR-200

PPR applicable directly to the installation of the most widely used rack-based appliances made according to the technical conditions of GOST 27321. Forests can be any degree of collection (tubular, frame and frame) and a variety of components of nodular compounds (clamp, hook, wedge or pins); At the same time, racks, frame and frame elements are joined using nozzles.

The PPR consists of textual and graphic parts. The graphic part is represented by the schemes of the danger zone fencing, the installation sequence, forest fastening against the wall.

PPR has the following sections:

1. Explanatory note.

2. The statement of the documents used.

3.1. Preparatory work.

3.2. Main works.

4. Reincarnations for quality and acceptance of work.

5. The need for mechanization, instrument, inventory and devices.

6. Safety and labor protection.

7. Features of forest editing on high-rise buildings, on buildings with balconies (loggias).

8. Technical and economic indicators.

1. Explanatory note

The PPR on the installation of scaffolding for the device of the ventilated facade on the building of the fitness center is designed based on the technical task and the presented source data. As part of the technical task and baseline data: working documentation for the device of the ventilated facade, passport and installation instructions for scaffolding (for example, LSPR-200 frameworks), drawings on the building.

This PPR is designed for the following source data.

LSPR-200 Forests - Power, when the device of the ventilated facade can reach a height of 40 m. The troops pitch in height - 2 m, step of frames along the wall - 3 m, the passage width between the racks is 0.95 m. Regulatory load at an altitude of more than 20 m Not more than 100 kgf / m0 "style \u003d" Background: White; Border-Collapse: collapse "\u003e

Composite parts of forests of LSPR-200

Frame (2x1 m)

Rama with a staircase (2x1 m)

Communication (3.05 m)

Communication diagonal (3.3 m)

Cork-anchor

Clamp deaf, 48x48 mm

Fencing end

Rigel Nastila

The table shows that the weight of the component parts of the forests does not exceed 12 kg and they can be raised by a package to the mounting horizon with a winch or a roof crane with a carrying capacity of not more than 250 kg.

The building is a rectangular shape, the length of the facade is 72.0 m, the height is not more than 40 m.

The facade of the building is mounted by the hinged front system U-Kon with facing elements - ceramic tiles and aluminum profiles. In accordance with this, forests are mounted by the facade in the axes 1-12.

2. Vedency used documents

When developing PPR, regulatory, methodological and reference documents are used, which are listed in the list of references. The text also used links to the following regulatory documents:

GOST 2.601-2006 ECCD. Operating documents

GOST 2.602-95 * ECCD. Repair documents

GOST 9.104-79 * ECCD. Paint coatings. Groups of operating conditions

GOST 7502-98 Rulets measuring metal. Technical conditions

GOST 7948-80 Steel construction plumbers. Technical conditions

GOST 8486-86 * Softwood sawn timber. Technical conditions

GOST 9467-75 * Metal coated electrodes for manual arc welding of structural and heat-resistant steels. Types

GOST 15150-69 * Machines, devices and other technical products. Versions for different climatic regions. Categories, conditions of operation, storage and transportation in terms of exposure to climatic factors of the external environment

GOST 23407-78 Fencing inventory construction sites and construction and installation sites. Technical conditions

MDS 12-41.2008 Mounting equipment for temporary consolidation of prefabricated elements of erected and disassembled buildings.

3. Organization and technology for performing work

3.1. Preparatory work

Instructing workers are made on the order, receptions and rules of assembly and fastening forests to the wall.

Figure 1 is given as an example fragment of the construction plan. The symbols are shown by the forest, the border of the danger zone in the fall of the item from the last yarus of the forests and the temporary fence of the construction site.

https://pandia.ru/text/80/128/images/image003_66.jpg "width \u003d" 35 "height \u003d" 25 "\u003e bearing exterior walls

Scaffolding

the border of the danger zone in the fall of the subject with the yarus of the forests

temporary Forest Installation Fencing

Inspection, monitoring and assessment of the technical condition of the components of the mounted forests. Damaged components are subject to chosen.

Preparation for work, installation and launch of lifting mechanisms (roof crane or winch) for lifting and descent of composite parts of forests. These works are performed according to the instructions of manufacturers of lifting mechanisms.

Preparation of mechanization (manual drilling machines, perforators, traaming, etc.) and tools are prepared, their completeness and readiness for work is checked.

For the installation of forests, a planned and the rammed platform is prepared with which the water removal must be arranged, or a platform with an asphalt concrete coating. If the soil is wet, the rubbing is produced with a slottle of rubble, broken brick, concrete.

Due to (according to the initial data) with a drop of heights up to 400 mm, the field under the facade of the facade in the axes 1-12 are aligned horizontally in the longitudinal and transverse directions. For alignment of the drop of heights up to 500 mm, standard concrete slabs and boards with a thickness of at least 40-50 mm are used.

The scope of work is divided into three captures of 24 m in length along the facade of the building and a height not higher than 40 m. It uses one set of LSPR-200 forests (960 m with dimensions 40x24 m).

The markup of the point of installation of anchor stoppers on the wall of the building is carried out in accordance with the working drawing on the wall or "on the place".

At the initial stage, the wage marking points are determined with such a calculation so that the points do not coincide with the windows of windows. In the coincidence of the point of attachment with the opening in the forest wall, they are fixed to carrying structures (walls, columns, overlap) from the inside of the building with the help of fasteners and fixtures; It is not allowed to mount the forest to balconies, eaves, parapets.

The distance of the installation point of the anchor (dowel) to the opening should be at least 150-200 mm. The horizontal of the extreme points is determined using the level, the points are noted by the indelible paint. For two extreme points, using a laser level and roulette, they define and mark the intermediate points of the installation of anchor plugs. Then, on the extreme points of the horizontal line, the vertical lines are determined. The indelible paint mark the installation points of the anchors (dowels) on the extreme vertical lines.

3.2. Main works

The works are made by the invigays of the 24 m long on the facade of the building and a height not higher than 40 m, starting from the first capture. In the presence of several sets of forests, the device of the ventilated facade and, accordingly, the installation of forests can be carried out with parallel capture.

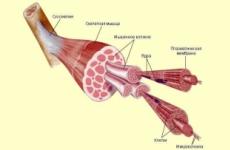

The forests are collected from frames, diagonal ties, shoes with screw control, riglels of flooring and flooring.

Fastening forests to the wall is made by standard anchors (dowels).

The frames increase each other to the necessary height and combine with the help of locks (clamps) horizontal and diagonal connections. Rigels of flooring are hanging out with its brackets on the upper communication of related frames on two top tiers, one of which is worker, the other is a safety. Wooden flooring is stacked on the rigls.

Forest installation is made according to the manufacturer's instructions, on tiers on the length of the capture.

The technological process of installation consists of assembly of the first, second, third and other tiers and fastening them to the wall.

Since the operations of the assembly of the tiers are described in detail in the factory instruction on the installation of forests, here they are not given.

For fastening forests, anchors (dowels) in the wall in the marced points are drilled after four meters in a checker order of the hole, diameter and depth of the corresponding anchors. The fastening strength is checked by calculating (see section 2) and must be tested by selectively using a special instrument.

If the hole is turned erroneously in the wrong place, and it is necessary to drill a new one, then the latter should be from the erroneous at least one depth of the drilled hole. This rule is not necessarily if the erroneous hole is pre-concreted or filled with a similar polymer composition.

Cleaning holes from drilling waste (dust) is made with compressed air.

The dowel is inserted into the prepared hole and burst with a mounting hammer.

On working and insurance tiers, end and longitudinal fences are installed. In places of lifting to a working tier, where diagonal connections are not installed, the longitudinal fences are set.

Dismantling of forests for their permutation to a new invapination is made in the order back to their installation. The descent of the dismantled components of forests is carried out using a winch or a roof crane.

4. Quality requirements and acceptance of work

The quality of forest editing is ensured by the current control of the technological operations of preparatory and basic work, and is also checked at the acceptance of work. According to the results of the current control of technological operations, acts of examination of hidden works are drawn up (on the strength of the fastening of forests to the wall).

In the process of preparatory work check:

The readiness of the wall and structural elements of the building, means of mechanization and tools for the implementation of installation works;

The quality of the components of forests (sizes, lack of dents, bends and other defects of forest elements);

The correctness and reliability of the installation of forest shoes for the base.

In the process of assembly, they check:

The accuracy of the wall markup;

Diameter, depth and purity of holes for anchors (dowels);

The strength of the fastening of anchors;

The verticality of the racks and horizontal relationships, riglels, forest flooring.

When increasing the frames, the gap between pipes and nozzles should not exceed 3 mm.

When laying the flooring, the strength of the consolidation and the absence of the capabilities of shifts is checked.

When accepting the work of the Acceptance Commission, an inspection of mounted forests is carried out in general and especially carefully places of fastening and pairing.

Forests are subject to the presence of an acceptance commission to test by regulatory load for two hours. At the same time, their strength and stability, fastening reliability to the wall, flooring and fences, grounding are estimated.

The railings of the fence must withstand the concentrated load of 70 kgf, attached to them in the middle and perpendicularly.

Bearing horizontal communications must withstand the concentrated load of 130 kgf, attached in the middle.

Acceptance of mounted forests is drawn up with an act of acceptance of work. The act of surveying work is attached to the certificate of hidden work.

The quality of forest editing is estimated by the degree of compliance of the actual parameters and the characteristics specified in the design and regulatory and technical documentation.

The main controlled parameters and characteristics, methods for their measurement and evaluation are shown in Table 4.1.

Table 4.1.

Technological operations | Controlled parameter, characteristic | Permissible value | Method of control and tool |

|

Marking of extreme points horizontally | Accuracy markup | |||

Marking of extreme points vertically | Accuracy markup | Theodolite |

||

Marking of intermediate attachment points | Accuracy markup | Laser level, plumb, roulette |

||

Drilling holes for traffic jams | Depth, Diameter, | screw length +10.0 screw diameter +0.2 mm | Depthionometer |

|

Distance to opening, corner of the building | At least 150.0. | |||

Clean hole | No dust | Visually |

||

Installation of Bashmakov | Lining thickness | Metal ruler |

||

Assembling sections and forest tiers | Deviation from verticality | ± 1.0 mm 2 m height | Plumb, ruler |

|

Deviation from horizontal | ± 1.0 mm for 3 m lengths | Level, ruler |

||

Clearance between the wall of the building and the flooring | No more than 150 mm | |||

Linear dimensions | Up to 50 m - ± 1% | Roulette Laser Disto |

||

Foresting forests to the wall | Effort disintegrating anchor from the wall | At least 300 kgf | Cork Control Device |

|

Laying the flooring | Clearance between boards | No more than 5 mm | ||

Proposals of the boards | No more than 3 mm | |||

Overlapping with joints | Not less than 200 mm | Metal ruler |

||

Forest grounding device | Ground resistance | No more than 15 ohm | Tester Shch4313 |

5. The need for mechanization, instrument, inventory and devices

The need for basic means of mechanization, instrument, inventory and devices is shown in Table 5.1.

Table 5.1.

Name | Type, Mark, GOST, | Technical specifications | Purpose |

Crane roofing | "Pioneer" CJSC "TEMZ" TL-12 | Load capacity 150-500 kgf | Lifting and descent of composite parts of forests, facade elements |

Traction force 250 kgf | |||

Top, cord | From400-1, GOST 7948 Cord three permanent kapron | Mass of a plumb not more than 0.4 kg, length 98 m. Cord length - 5 m, diameter 3 mm | Vertification markup, Vertical Verification |

Laser level | BL 40 VHR SKB "STROYPRIBOR" | Measurement accuracy 0.1 mm / m | Measuring heights |

Laser level | BL 20 SKB "Stroypribor" | Measurement accuracy 0.1 mm / m | Check horizontal planes |

Interskol | Power 1.0 kW, hole drilling diameter up to 25 mm | Hole drilling |

|

Steel roulette | P20UP, GOST 7502 | Length 20 m, weight 0.35 kg | Measuring linear dimensions |

Screwdriver with tip | Screwdriver prof INFOTEKS LLC | Reversible lever | Screwing - unscrewing screws |

Device for pulling a dowel from the wall | Measurement limits 100-500 kgf Dimensions: 1240x1200x175 mm Weight - 7.8 kg | Measurement of forest fastening force to the wall |

|

Fencing of the work of work | Inventory | Safety of work |

|

Grid Protective on Forests | 4.603; 4.504; 4.501.1 Apex firms, vert or other firms | From polymer fibers | Protection against falling objects from height |

6. Safety and labor protection

When organizing and conducting work on the installation of scaffolding should be carried out by the requirements of SNiP 12-03, SNiP 12-04, GOST 12.4.011.

On the forests should be posted a scheme for the placement and magnitude of permissible loads on the forests. It is not allowed to accumulate on the flooring of more than three people.

For the installation of forests, workers who have the right to work at height are allowed. Installers must be secured by safety belts.

Fire safety at workplaces should be provided in accordance with the Rules of PPB-01.

Electrical safety at workplaces should be ensured in accordance with the requirements of Pot R M-016.

When organizing a construction site, a danger zone is established from the fall of items from the height of the forests, in this example from a height - 25 m, equal to 7 m. The danger zone is indicated by safety signs and inscriptions of the installed form in accordance with GOST 12.4.026. A protective grid can be labeled on the forest. The danger zone may not be denoted.

The location and construction of the construction site fence adopted according to the requirements of GOST 23407.

The storage and storage of composite parts of forests, materials, products and equipment should be carried out in accordance with the requirements of standards or technical conditions on forests, materials, products and equipment, as well as SNiP 12-03.

When working in the dark, the construction site, forests, passages and approaches to them should be covered in accordance with GOST 12.1.046. The illumination must be uniform, without blinding the lighting devices.

Forest stairs must be equipped according to GOST 26887. The slope of the stairs to the horizon must be no more than 75 °. Stairs must be with non-slip steps.

Lifting cargo on the forest is carried out by a winch or a roof crane. Lifting cargo on the forest by rifle cranes is unacceptable.

Lightning protection of forests should be arranged with a ground resistance of not more than 15 ohms.

At the time of installation and dismantling of forests, electric wires located closer than 5 m from the forests dealers.

During thunderstorms, snowfall and in the wind, more than 6 points installation or disassembly of forests are not produced.

During the installation and dismantling of the forests, window, balcony and doorways should be closed.

The technical condition of the forests is controlled before each shift and periodic examinations every 10 days. If the forests were not used for a month, then they are allowed to operate after acceptance by the Commission. The results of acceptance and inspection are celebrated in the GOST 24258 accounting log.

Forests are subject to additional inspection after rain or thaw, which can reduce the bearing base ability.

7. Features of forest mounting on high-altitude buildings, on buildings with balconies (loggias)

In Russia's metropolisms, the volume of high-rise (from 30 floors and above) of monolithic reinforced concrete residential and public buildings are growing.

The buildings in the plan have a complex shape with rectangular and oval outlines of walls, overall dimensions: the length of the facade is at least 50.0 m, the width is 30 m, the height is up to 160 m. The thickness of the walls and interoaded floors is at least 200 mm, window and others The openings allow you to mount the reference devices to install forests at the height.

On the facades of these buildings, various works are performed using scaffolding: finishing, insulating, facing and others. The usual tubular, clamps according to GOST 27321 are used, the racks of which are joined using nozzles.

Forests, for example, LSPH-200-60 - rack-made, tier pitch in height - 2 m, the step of racks along the wall - 2.5 m, the width of the passage between the racks is 1.25 m. The flooring shields can fit on all tiers at the same time. Regulatory load no more than 200 kgf / m. Maximum forest height - 60 m.

The forests are mounted from tubular elements: racks and semi-resistance with a diameter of 60 mm, installed in support shoes with wooden lining, longitudinal bonds with a diameter of 48 mm connected with racks using clamps, cross-fastened forests to the wall with metal or polymer plugs (dowels). On the extreme sections of the forests with the help of rotary clamps, diagonal connections are established.

Racks and sequins are joined with nozzles.

Communications are connected with bolts.

The choms are unproofy connects at the right angle of the rack and seal with crossbars and railings. Rotary clamp joins a rack with diagonal connections under an acute or blunt angle.

The design of forests allows you to apply various installation schemes of the forests of the high-rise building depending on the configuration of the walls, the height of the building and other local conditions.

Before the start of installation work, regular preparatory work is carried out.

The forests are mounted on a height of up to 160 m. The installation feature is the use of dual racks, as a rule, to a height of 80 m, and above - single. The distance between the dual racks is taken, as a rule, 300 mm (Fig. 2).

https://pandia.ru/text/80/128/images/image012_31.jpg "width \u003d" 256 "height \u003d" 207 src \u003d "\u003e

Fig.3. Foresting forests to the wall through the window opening

The inventory of the attachment is made, as a rule, from the same tubular elements as forests.

The elongated transverse links of forests are set in the opening, then the longitudinal pipes are placed on them. The fastening of bonds and pipes is carried out using clamps or otherwise.

If the configuration of the walls does not allow to apply the usual installation scheme with the support of the shoes to the ground, the forests are installed on the support devices at the height. The support devices are mounted on overlapping using cantilever beams or on the wall using brackets.

Consider these reference devices.

The reference device at the overlap of two cantilever beams and spacer racks is shown in Fig.4.

https://pandia.ru/text/80/128/images/image014_30.jpg "width \u003d" 173 "height \u003d" 246 src \u003d "\u003e

Fig.5. The reference device mounted on the reinforced concrete wall using the bracket

To install the bracket in the reinforced concrete wall, a hole is done in which the stud is inserted. A rack having an eyelets at the top and at the bottom for a hinge fastening on the studs of stretch marks and beams. Standard shoes are welded to the beam, in which forest rack are inserted and forest installation is carried out.

Details of the bracket are made from steel rental profiles for two options. According to the first embodiment, the rack and beam are made from channels N 10 - N 16 according to GOST 8240, depending on the load from the forests, and stretching from strip steel. And the beam is welded from two channels. According to the second variant, the rack is made of two-corners N 5 - N 9 according to GOST 8509, and the beam is from an 2-channel N 12 - N 18. Stretching steel is used for stretching.

The stretching attachment point on the beam, from the condition of equality of bending moments (economical section of the beam and the smallest weight) should be at a distance of 4/5 of the length of the beam from the wall.

Standard stud for mounting the bracket to the wall - with a thread of at least M18.

Studs in bracket hinges can be structurally identical with a diameter in a non-cross-section of at least 28 mm.

Calculations show that each bracket is withstanding the load from two racks of forests at least 2400 kgf.

Forest installation circuit on a building with balconies (loggias) is shown in Fig.6.

The foundation blocks "href \u003d" / text / category / fundamentnie_bloki / "REL \u003d" BOOKMARK "\u003e The foundation unit of the FB type 200-300 kg.

Checking the strength of forest fastening to the wall show that the pulling force does not exceed the strength of the fastening of the forests to the wall provided by the dowel. In order to increase the strength of forest fastening to the wall, it is arranged an additional point of attachment at the level of extension forest support.

8. Technical and economic indicators

Table GESN 08-07-001 Installation and disassembly of external inventory forests

The composition of the work:

for norms 1-3:

01. Planning the place of installation of outdoor forests. 02. Assembly and installation of inventory forests with devices of flooring, fences, stepladers and running stairs. 03. Disassembly of forests. 04. Recovery repair of forest details at every turn of them. 05. Drawing of ready-made elements of forests from an attribute warehouse on an object and disbuild them from an object to an applicable warehouse.

for norms 4, 5:

01. Assembly and installation of inventory forests with devices of flooring, fences, stepladers and running stairs. 02. Disassembly of forests. 03. Recovery repair of forest details at every turn of them. 04. Drawing of ready-made elements of forests from an attractive warehouse on an object and disbuild them from an object to an attractive warehouse.

Meter: 100 m0 "STYLE \u003d" Background: White; Border-Collapse: Collapse "\u003e

Installation and disassembly of external inventory forests up to 16 m high:

tubular cladding

tubular for other finishing works

suspended

For every subsequent 4 m height of external inventory forests add:

to standards 08-07-001-01, 08-07-001-02

to normal 08-07-001-03

Silver resource | Name of cost element | Units. measured. | 08-07- | 08-07- | 08-07- | 08-07- | 08-07- |

Labor construction workers | |||||||

Medium discharge of work | |||||||

Machines and mechanisms | |||||||

Cars onboard, carrying capacity up to 5 tons | |||||||

Materials | |||||||

Details Wooden forests | |||||||

Details of steel tubular forests | |||||||

Floor shields | |||||||

(Table of GESN 08-07-001 as amended by the change approved by the Order of the Ministry of Regional Development of Russia of 01.01.2001 N 339). |

List of used literature

SNiP 3.03.01-87 bearing and enclosing structures.

SNIP 12-01-2004 Organization of construction.

Snip 12-03-2001 Labor safety in construction. Part 1. Common Requirements.

Snip 12-04-2002 Labor safety in construction. Part 2. Construction production.

Snip II-23-81 * Steel structures.

GOST 12.1.004-91 * PRT. Fire safety. General requirements.

GOST 12.1.030-81 * SSBT. Electrical safety. Protective grounding, zero.

GOST 12.1.046-85 SSBT. Building. Norms of lighting construction sites.

GOST 12.4.011-89 Facility protection means. General requirements and classification.

GOST 12.4.026-81 SSBT. Colors signal and danger signs.

GOST 12.4.059-89 CSBT. Building. Fencing safety inventory. General specifications.

GOST 24258-88 Forming means. General specifications.

GOST 26887-86 sites and stairs for construction and installation work. General specifications.

GOST 27321-87 Forest racks for construction and installation work. Technical conditions.

Decision of the Government of the Russian Federation of April 25, 2012 N 390 on fire regime.

POT R M-016-2001 Intersectoral rules for labor protection (safety rules) during the operation of electrical installations (edited by 01.01.2001).

GOST 380-2005 Steel carbonated ordinary quality. Brands.

GOST 3242-79 Compounds welded. Quality control methods.

GOST 3262-75 * Steel water pipes. Technical conditions.

GOST 8240-97. Steel hot rolled sewners. Sort.

GOST 8509-93 Steel hot-rolled steel corners. Sort.

GOST 10704-91. Steel electric welded pipes. Sort.

Working documentation and instructions on the use of mounted mounting forests for the production of works on the facades of buildings under construction. - M.: Tsniyomtp, 1998.

Project production project (PPR)

Project of production of work on the installation of forests of LSPR-200

The RFP is applicable directly to the installation of the most widely used racking appitable forests, manufactured according to the technical conditions of GOST 27321. The forests can be of any degree of collection (tubular, frame and frame) and a variety of components of nodal compounds (clamp, hook, wedge or pins); At the same time, racks, frame and frame elements are joined using nozzles.

The PPR consists of textual and graphic parts. The graphic part is represented by the schemes of the danger zone fencing, the installation sequence, forest fastening against the wall.

PPR has the following sections:

1. Explanatory note.

2. The statement of the documents used.

3. Organization and technology for performing work.

3.1. Preparatory work.

3.2. Main works.

4. Reincarnations for quality and acceptance of work.

5. The need for mechanization, instrument, inventory and devices.

6. Safety and labor protection.

7. Features of forest editing on high-rise buildings, on buildings with balconies (loggias).

8. Technical and economic indicators.

1. Explanatory note

1. Explanatory note

The PPR on the installation of scaffolding for the device of the ventilated facade on the building of the fitness center is designed based on the technical task and the presented source data. As part of the technical task and baseline data: working documentation for the device of the ventilated facade, passport and installation instructions for scaffolding (for example, LSPR-200 frameworks), drawings on the building.

This PPR is designed for the following source data.

LSPR-200 Forests - Power, when the device of the ventilated facade can reach a height of 40 m. The troops pitch in height - 2 m, step of frames along the wall - 3 m, the passage width between the racks is 0.95 m. Regulatory load at an altitude of more than 20 m no more than 100 kgf / m. The structural components of the forests of LSPR-200 and their weight are shown in Table 1.1.

Table 1.1.

|

Composite parts of forests of LSPR-200 |

|

|

Frame (2x1 m) |

|

|

Rama with a staircase (2x1 m) |

|

|

Communication (3.05 m) |

|

|

Communication diagonal (3.3 m) |

|

|

Shoe |

|

|

Cork-anchor |

|

|

Clamp deaf, 48x48 mm |

|

|

Fencing end |

|

|

Rigel Nastila |

The table shows that the weight of the component parts of the forests does not exceed 12 kg and they can be raised by a package to the mounting horizon with a winch or a roof crane with a carrying capacity of not more than 250 kg.

The building is a rectangular shape, the length of the facade is 72.0 m, the height is not more than 40 m.

The facade of the building is mounted by the hinged front system U-Kon with facing elements - ceramic tiles and aluminum profiles. In accordance with this, forests are mounted by the facade in the axes 1-12.

2. Vedency used documents

When developing PPR, regulatory, methodological and reference documents are used, which are listed in the list of references. The text also used links to the following regulatory documents:

GOST 2.601-2006 ECCD. Operating documents

GOST 2.602-95 * ECCD. Repair documents

GOST 9.104-79 * ECCD. Paint coatings. Groups of operating conditions

GOST 7502-98 Rulets measuring metal. Technical conditions

GOST 7948-80 Steel construction plumbers. Technical conditions

GOST 8486-86 * Softwood sawn timber. Technical conditions

GOST 9467-75 * Metal coated electrodes for manual arc welding of structural and heat-resistant steels. Types

GOST 15150-69 * Machines, devices and other technical products. Versions for different climatic regions. Categories, conditions of operation, storage and transportation in terms of exposure to climatic factors of the external environment

GOST 23407-78 Fencing inventory construction sites and construction and installation sites. Technical conditions

MDS 12-41.2008 Mounting equipment for temporary consolidation of prefabricated elements of erected and disassembled buildings.

3. Organization and technology for performing work

3.1. Preparatory work

Before starting installation work, the following preparatory work must be carried out:

- the working area (as well as approaches to it) is exempt from foreign building structures, materials, mechanisms and construction waste and is protected according to the requirements of GOST 23407;

- Forest installation zone is protected, according to SNiP 12-03, warning signs are established according to GOST 12.4.026 *;

________________

* GOST 12.4.026-76 canceled on the territory of the Russian Federation from 01/01/2003. GOST R 12.4.026-2001. (IUS N 12, 2001). - Note database manufacturer.

- Instructing workers and assembly on the order, receptions and rules of assembly and fastening forests to the wall.

Figure 1 is given as an example fragment of the construction plan. The symbols are shown by the forest, the border of the danger zone in the fall of the item from the last yarus of the forests and the temporary fence of the construction site.

Fig.1. Fragment of the construction plan

Legend

Bearing outdoor walls

scaffolding

The border of the danger zone in the fall of the subject with the yarus of the forests

Temporary Forest Installation Fencing

Inspection, monitoring and assessment of the technical condition of the components of the mounted forests. Damaged components are subject to chosen.

Preparation for work, installation and launch of lifting mechanisms (roof crane or winch) for lifting and descent of composite parts of forests. These works are performed according to the instructions of manufacturers of lifting mechanisms.

Preparation of mechanization (manual drilling machines, perforators, traaming, etc.) and tools are checked, their completeness and readiness for work is checked.

For the installation of forests, a planned and the rammed platform is prepared with which the water removal must be arranged, or a platform with an asphalt concrete coating. If the soil is wet, the rubbing is produced with a slottle of rubble, broken brick, concrete.

Due to (according to the initial data) with a drop of heights up to 400 mm, the field under the facade of the facade in the axes 1-12 are aligned horizontally in the longitudinal and transverse directions. For alignment of the drop of heights up to 500 mm, standard concrete slabs and boards with a thickness of at least 40-50 mm are used.

n1.rtf.

Project manufacturing work on the installation of forestsExplanation of the work project

This project was developed for the installation of forests of LRP-2000-100 at the facility: __________ at the address: ______________.

1. Basic requirements when building forests

1.1. Forests must be registered in the account log in accordance with Annex 3 GOST 24258-88; The log must be stored at the facility. The registration number must be applied in a prominent place on the forest design element or on the tablet attached to it.

1.2. Installation and dismantling of forests should be carried out under the leadership of the person responsible for the production of work.

1.3. It is forbidden to load the forest flooring with materials and products, the weight of which exceeds the allowable passport on the forest - 150 kg / m.

1.4. Forests must be grounded. In the quality of lightning, pipe sections of at least 4 meters long, which are connected to the end of the pipes of the outer upper racks.

2. Device and application rules

Firefire frames.

2.1. Before starting work on the structure of forests, it is necessary:

Set temporary fencing along the border of the danger zone for the period of installation, operation and dismantling of forests. The limits of the danger zone are established according to SNiP 12-04-2002 "Labor safety in construction. Part 2. Construction production, p.10", and its borders are accepted from the external range of forests;

deliver to the place of installation, renovated and equipped, according to the specification, forest elements;

Clean and plan, taking into account the removal of surface water, the bandwidth of 2.5 m along the entire length of the facade. In the case of a bulk soil, the strip must be sealed, and if necessary, the base plate was laid on the planned surface in accordance with the project.

2.2. Forest installation is carried out according to the installation schemes of the project, which indicates the beginning and direction of installation. Forest installation should be started from the corner of the building.

2.3. Forest installation to perform on the tiers specified in the project.

2.4. Work on the installation and dismantling of forests to be carried out by linking of locksters, installers consisting of 4 people, including:

1 person. - 4 solutions;

2 people - 3 div.;

1 person. - 2 breaks.

Works lead in one shift in the bright time of the day.

2.5. Forest installation with different configuration of buildings is carried out in the technological sequence, including:

marking of sites of drilling of nests for anchor and places of installation of support linings;

The layout of the board linings perpendicular to the facade of the building on marking, the size of the section and the length of the linings is taken in accordance with the project (with a lining thickness of at least 50 mm);

Installing supports and screw supports on lining. The distance from the wall to the axis of the inner row of supports and between the rows of supporting spots should be the project. The disconnectope is fixed to the lining of nails or crutches;

Device holes for installing anchors. On the facades, the main part of which are stained glass fastening sites, can be adjusted at the place, with reflection of changes in the project.

Forest installation is performed in the following sequence:

- Stage 1. On the prepared platform, install wooden gaskets and letters, if necessary, jacks. Santers must be in one horizontal plane.

- 2 stage. Install two adjacent frames of the first tier on the spyers, combine them with horizontals and diagonals. After step 2 m (3 m), install other adjacent frames and also connect them. Repeat this operation to the set of the required length.

- 3 stage. Installing the flooring on the first tier of two adjacent sections with the right and left side of the forests.

- 4 stage. Install the frames of the second tier, connect them with horizontal and diagonal connections.

- 5 stage. Install the flooring on the second tier of the first two adjacent sections with the right and left side of the forests.

- 6 stage. Fastening forests to the wall to carry out traffic jams or hooks with hooks through anchor brackets.

- 7 stage. Repeating these stages, score the necessary wood height.

- 8 stage. On the working tier to install fences.

Forest frames establish a plunder. The installation of the frames and fixing the forest to the wall simultaneously with the installation of forests.

Styling the flooring and installation of fences should be performed at the same time.

Dismantling of forests is allowed only after cleaning from the flooring of the remnants of materials, inventory and tools.

Prior to the start of installation, the manufacturer of work is obliged to inspect and instruct workers about the sequence and disassembly techniques, as well as measures that ensure the safety of work.

Dismantling of forests should be started from the top tier in the sequence, reverse installation sequence.

Lifting elements of forest winch.

2.6. Lightning parameters are installed after installing forests to a height of 8 m and then, as forests extend, they are rearranged by overlying tiers each time, tightly attached to lightning parameters must comply with the project.

2.7. Dismantling of forests exercise under the leadership of the person responsible for the production of works in compliance with the rules of installation and dismantling forests and the compliance of forests project.

2.8. To dismantle it only after from the forests and with the flooring, all materials, inventory, tools are removed.

2.9. Before the disassembly, the responsible installation manager should inspect the forests and familiarize workers with the sequence and disassembly method, measures to ensure the safety of work.

2.10. All the first floor doorways on the forest disassembly area must be protected, and the passages are completely fenced.

2.11. After the end of the dismantling of the upper tier, the workers switch to the tier (temporarily loving on it) and finish the disassembly of the framework of the overlying tier, transverse and longitudinal connections are removed. At the same time, the clamps are exempt only from the racks, remaining fixed on cross, connections and other elements of forests.

2.12. Forest elements with blocks and hemp ropes are descended down. The dropping of individual elements of forests from the height is categorically prohibited. Small elements before lowering down, stacked in special boxes.

2.13. When dismantling forests, contacting tubular elements with electrical pipelines is not allowed.

2.14. Forest mounting scheme to the facade of the building coordinate with the manufacturer of forests.

2.15. Places of installation of forests and console beams (OTM +60,300) on the building design to agree with the designers.

2.16. When installing forests on the console sections of the building, perform a redefusion of forest racks on a separate project.

Foresting sequence on the facility

The project provides 3 stages of forest construction:

1st stage

The construction of forests along two facades of the building to the mark +60,300. Forests to install on the construction of the building (erected by the time of installation of forests) in accordance with the passport. Forest installation places to coordinate with building designers.

2nd stage

Dismantling of forests in the sections of the first stage and the installation of them on the 3rd facade for the entire height of the building. Forests to install on the construction of the building (erected by the time of installation of forests) in accordance with the passport. Forest installation places to coordinate with building designers. Before starting installation of forests above the mark +60,300, it is necessary to install console beams (design, dimensions and calculation of beams to perform by a separate project).

Frames are connected to each other (in the places specified in the project) elements of the clamp forests with the device of flooring and the railing of the fence according to the scheme of the sheet N 9 and the passport to the clamp forests. Sections of the framework of frame forests are used only for the passage of staff at the workplace. The accumulation of people and storage of materials on the floor, arranged on the elements of the clamp forests.

3rd stage

Dismantling of forests in the sections of the second stage and the installation of them on two facades of the first stage, above the mark +60,300. Before starting installation of forests above the mark +60,300, it is necessary to install console beams (design, dimensions and calculation of beams to perform by a separate project). Forest installation places to coordinate with building designers.

Frames are connected to each other (in the places specified in the project) elements of the clamp forests with the device of flooring and the railing of the fence according to the scheme of the sheet N 9 and the passport to the clamp forests. Sections of the framework of frame forests are used only for the passage of staff at the workplace. The accumulation of people and storage of materials on the floor, arranged on the elements of the clamp forests.

3. Requirements for complete delivery of forest elements

3.1. Each batch of forests, consisting of a set of elements, is sent to the consumer is complete and is accompanied by a manufacturer's passport, an act of acceptance of the OTB and a complete specification, which indicates the amount and weight of the elements of the stamps.

3.2. Large details of forests leave from the manufacturer without packing, wire in packs weighing no more than 80 kg. Each pack is attached with the mark and the number of elements in a pack. Small details are sent to the container.

3.3. Forest elements sorted by brands are stored in closed rooms or outdoors on a lining under a canopy without touching the soil. The fasteners are stored canned in closed boxes weighing no more than 60 kg.

3.4. Before sending to the object, the forest is equipped with all typical and non-typical elements according to the specification of the draft forests of a particular object. Making forests is made with rejection of forest elements that do not correspond to regulatory tolerances.

3.5. When completing the following regulatory tolerances and requirements:

All wood elements of forests, including flooring shields, handrails, onboard boards, are processed by deep impregnation with flame retardant means;

The geometric dimensions of the flooring shields, cross sections and the location of the crosslocked slats must comply with the project;

Deviations from the design length of forest elements should not exceed in the elements of +2 mm, and in the remaining elements ± 3 mm.

3.6. Installation, dismantling and operation of inventory forests should be carried out by a specialized division (plot), whose duties include:

storage, repair of elements of inventory forests;

Production of non-surface parts;

Passing of forests according to the specification in the composition of the draft forests for a specific object (Table 4);

Installation and disassembly of forests;

Control over the state of forests during operation of mounted forests.

4. Ensuring the quality of the forest device

4.1. The required quality and reliability of the device and the operation of forests should be provided by building organizations by implementing a complex of technical and organizational measures in accordance with the requirements of GOST 27321-87 "Forests of the rack-made powered for construction and installation work", SNIP 12-01-2004 "Construction Organization".

4.2. Production control of the quality of the forest device should include input quality control of the elements of forests, operational control of individual mounting processes or operations and acceptance control of mounted forests.

4.3. When input control of forest elements, their completeness and compliance with the requirements of standards, as well as the availability and maintenance of passports, certificates and other accompanying documents are checked.

4.4. During operational control, compliance with the method of installation of forest elements, the correspondence of the forest device by working drawings, construction standards, rules and standards is checked.

4.5. When acceptable control, the desired quality of mounted forests prepared for operation is checked.

4.6. When accepting forests, the operation is checked:

compliance with the collected frame of the mounting schemes;

correctness of assembly of nodes and matching forest fastening project;

The correctness and reliability of forest is based on the basis;

correct installation and fencing fencing and flooring;

the presence of diagonal bonds and the correctness of their location;

ensuring the safety of forests from possible blows by vehicles;

ensuring water removal from forests;

compliance with the verticality of the installation and reliability of forest fastening to the wall;

The reception of forests should be made under the calculated load located on the work flooring of the upper tier. The load value and its location must comply with the load scheme adopted in the forest project.

4.7. The surface of the soil on which forests is installed, it is necessary to plan, catch and ensure the removal of surface waters.

4.8. During operation, a systematic observation of the state of all compounds, fastenings to the wall, flooring and fences should be carried out. For this daily before starting the shift of the forest, they are examined by a foreman or master, guiding works performed from these forests. At least once every 10 days, the state of the forests should be checked by representatives of the construction organization with fixing the observed defects.

4.9. In all cases of detection of deformations of forest elements, stability disorders and other defects, work from forests should be discontinued before fixing and re-accepting forests.

5. Safety Solutions

5.1. The work at the height in the device and operation of devices are allowed by persons not under 18 years old, for medical reasons for the implementation of these works, trained and instructing in the prescribed manner and corresponding to the certificate. Persons for the first time allowed to fulfill work should work during the year under direct supervision of a more experienced worker.

5.2. Before starting work on the installation of forests, workers should receive an outfit for the production of these works for the period necessary to perform the entire amount of work.

5.3. The mass of assembly elements of forests per desktop (with a manual assembly of the tooling means) on a construction site, should not exceed 25 kg - during installation and dismantling (means of dying) at an altitude and 50 kg - with their device on Earth.

5.4. Forests should be equipped with stairs or ladder for lifting and descending people located at a distance of no more than 40 m from each other, and for forests with a length of less than 40 m should be installed at least two stairs or traps. The top ends of stairs or ladders must be attached to the crossing of forests and openings in forest flooring to exit stairs - fenced from three sides. The angle of inclination of the stairs to the horizon should not exceed 60 °, and the angle of the trap is not more than 1: 3.

5.5. A worker flooring from the side of the external range of forests should have a fence. The height of the fencing on the level of the base of the fence to the top of the horizontal element should not be 1.0 m.

The distance between horizontal elements in the vertical plane should not be more than 0.45 m, between the racks there should be no more than 2 m. Fences and railing of forests must withstand a concentrated load equal to 40 kg applied horizontally or vertically anywhere in the length of the handrail.

5.6. In places of passages to the forest building, protective visors and side solid trimming for the protection of people from falling from above of various items must have, and the protective visor should play for the forest at least 15 m and installed at an angle of 15-20 ° to the horizon. The height of the passages should be at least 1.8 m.

5.7. Forests should be equipped with lightning protection devices and lightning places consisting of lightningness, auxiliary and grounding. The distance between the lightning parameters should not exceed 20 m, and the grounding resistance should not be more than 15 ohms.

5.8. Forests should be securely fixed to the walls of buildings all over the altitude in accordance with the mounting schemes.

5.9. It is forbidden to fix the forests for parapets, eaves, pipes, balconies and other protruding parts. In the coincidence of the fastening of forest racks with openings in the forest wall, it should be mounted on the inside of the building through the openings through devices.

5.10. When working at height, workers must be equipped with safety belts for fastening to reliable parts of the building or forest racks in accordance with the indication of the engineering and technical worker, guiding installation of forests.

Workers - installers must be provided with overalls, special footwear, tested by safety belts, ropes, helmets, etc. means of individual protection.

5.11. During the installation of forests should be provided:

Strength and reliability of structures;

safe working conditions during installation and operation;

stability during installation and operation;

fences and individual means of protection that exclude the possibility of falling workers and materials from height;

Safe transportation of materials.

5.12. When installing (dismantling), forests are prohibited:

Admission of people to the zone where the installation or disassembly of forests is made.

Casting people on forest flooring, more than 3 people in one place;

Resetting forest elements when disassembly.

5.13. Forest flooring, located above 1.0 m from the ground level, should be fenced. The fence consists of a handrail located at an altitude of at least 1.0 m from the working flooring, one intermediate horizontal element and the onboard board with a height of at least 15 cm. The gap between the floorboards should be no more than 5 mm.

5.14. The gap between the wall of the existing building and the working flooring of the established forests should not exceed passport values.

5.15. After the installation of each tier of the forests, their correctness and quality of installation is checked with them by examining the entire design.

5.16. The act of acceptance of forests is approved by the chief engineer of the organization. Before confirming the act, working from the forest is not allowed.

5.17. Woods should be made posters with loads for the placement of loads and their permissible value.

5.18. Dismantling of forests can be started only after all work on the forests will be finished and all materials, inventory, tool and removed construction trash will be removed from the forests.

5.19. During the dismantling of the forests, all the doorways of the first floor and balconies must be closed.

5.20. The dismantling area of \u200b\u200bwork should be fenced and have warning signs and inscriptions.

5.21. During the operation of forests, it is necessary to be guided by the requirements of fire safety rules in the production of construction and installation work and the main department of fire protection.

5.22. The working flooring of forests must have the following primary means of fire extinguishing:

- for every 20 m workstock - 1 fire extinguisher.

- buckets - at least 4 pcs. On all flooring.

5.23. For fire safety, in addition to the staircase in the forests, spare outputs should be provided from the working flooring to the room through the openings.

5.24. In addition to the solutions listed in this section, the requirements and operation of forests must be respected by the requirements of SNiP 12-03-2001 "Labor Safety in Construction", part 1. General requirements; Snip 12-04-2002 "Labor safety in construction" Part 2. Construction production.

Sheet 1.

Plan of installation of forests

Leaf 2.

Forest installation plan at a mark +60, 300

Leaf 3.

Forest alignment on the facade "P - A"

| Legend |

|

| | |

| | |

| | |

| | Frame forest |

| | Stairs |

| | |

Sheet 4.

Forest alignment on the facade "Aa / 1"

| Legend |

|

| | Fastening anchor bracket with a clamp (see Leaf 9) |

| | Forest places for columns |

| | Forest places for floors |

| | Frame forest |

| | Stairs |

| | Connection of frame forests with elements of clamps |

Sheet 5.

Forest alignment on the facade "A / 1-P"

| Legend |

|

| | Fastening anchor bracket with a clamp (see Leaf 9) |

| | Forest places for columns |

| | Forest places for floors |

| | Frame forest |

| | Stairs |

| | Connection of frame forests with elements of clamps |

Sheet 6.

Grounding scheme

to the mark +60.300

Forest grounding circuit diagram

at + 60.300

Sheet 7.

Console mounting sequence

Sequence of remote consoles

| ||

| 5. M1 and M2 installers twist the anchor bolts until it stops and check the reliability of their fastening. The remaining cantilever beams are set in the same way. | 6. After mounting the console beams, the M1 and M2 installers are installed between them and the slab overlapping the telescopic racks and securely press console beams to the guns of the gun. | 7. After installing telescopic racks, the M1 and M2 installers are laid on console transverse beams. To lay a long-distance from overlapping a transverse beam, it is necessary to put on the cantilever beams flooring from the boards. 40 mm. |

Leaf 8.

Console device diagram

Console installation scheme

1-1

Sheet 9.

Scheme of frame frames with elements of clamps

Sheet 10.

Knots

Forest mounting diagram in inventory traffic jams

1 - crossing (met. Pipe); 2 - inventory cork; 3 - outer wall; 4 - swivel clamp (mount to the rack)

Ground-proof device

1 - lightning message; 2 - clamp; 3 - strip; 4 - grounding pipe; 5 - Forest rack

Leaf 11.

Specification

Specification

Facade A1-P (up to the 60.300)

| N. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 62 |

| 2 | Frame without stairs | pC. | 578 |

| 3 | Frame with end fence | pC. | 64 |

| 4 | Horizontal connections | pC. | 480 |

| 5 | Diagonal connections | pC. | 480 |

| 6 | Square Nastilov | m. | 1440 |

| 7 | Forest area | m. | 2880 |

| 8 | Rigel | pC. | 960 |

| 9 | Supported post. | pC. | 44 |

| 10 | Rotary clamp | pC. | 1536 |

| 11 | Classic screed | pC. | 768 |

Specification

Facade A1-P (above 60.300 marks)

| N. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 38 |

| 2 | Frame without stairs | pC. | 362 |

| 3 | Frame with end fence | pC. | 40 |

| 4 | Horizontal connections | pC. | 300 |

| 5 | Diagonal connections | pC. | 300 |

| 6 | Square Nastilov | m. | 900 |

| 7 | Forest area | m. | 1800 |

| 8 | Rigel | pC. | 600 |

| 9 | Supported post. | pC. | 44 |

| 10 | Rotary clamp | pC. | 960 |

| 11 | Classic screed | pC. | 480 |

Specification

Facade A-A1 (up to 60.300)

| N. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 58 |

| 2 | Frame without stairs | pC. | 542 |

| 3 | Frame with end fence | pC. | 60 |

| 4 | Horizontal connections | pC. | 450 |

| 5 | Diagonal connections | pC. | 450 |

| 6 | Square Nastilov | m. | 1350 |

| 7 | Forest area | m. | 2700 |

| 8 | Rigel | pC. | 900 |

| 9 | Supported post. | pC. | 44 |

| 10 | Rotary clamp | pC. | 1440 |

| 11 | Classic screed | pC. | 720 |

Specification

Facade A-A1 (above 60.300 marks)

| N. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 38 |

| 2 | Frame without stairs | pC. | 362 |

| 3 | Frame with end fence | pC. | 40 |

| 4 | Horizontal connections | pC. | 300 |

| 5 | Diagonal connections | pC. | 300 |

| 6 | Square Nastilov | m. | 900 |

| 7 | Forest area | m. | 1800 |

| 8 | Rigel | pC. | 600 |

| 9 | Supported post. | pC. | 44 |

| 10 | Rotary clamp | pC. | 960 |

| 11 | Classic screed | pC. | 480 |

Specification

Facade P-A (up to 60.300)

| N p.p. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 53 |

| 2 | Frame without stairs | pC. | 344 |

| 3 | Frame with end fence | pC. | 108 |

| 4 | Horizontal connections | pC. | 365 |

| 5 | Diagonal connections | pC. | 365 |

| 6 | Square Nastilov | m. | 1095 |

| 7 | Forest area | m. | 2190 |

| 8 | Rigel | pC. | 730 |

| 9 | Supported post. | pC. | 36 |

| 10 | Rotary clamp | pC. | 680 |

| 11 | Classic screed | pC. | 340 |

Specification

Facade P-A (above 60.300 marks)

| N. | Name | Units | number (For step 3 m) |

| 1 | Rama with a staircase | pC. | 38 |

| 2 | Frame without stairs | pC. | 242 |

| 3 | Frame with end fence | pC. | 80 |

| 4 | Horizontal connections | pC. | 260 |

| 5 | Diagonal connections | pC. | 260 |

| 6 | Square Nastilov | m. | 780 |

| 7 | Forest area | m. | 1560 |

| 8 | Rigel | pC. | 520 |

| 9 | Supported post. | pC. | 36 |

| 10 | Rotary clamp | pC. | 480 |

| 11 | Classic screed | pC. | 240 |

Methodical documentation in construction

Installation of scaffolding

On high-rise buildings.

PROJECT OF WORK PRODUCTION

MDS 12-57.2010

Moscow 2010.

The document is compiled in the development and addition of MDS 12-25.2006, MDS 12-40.2008, MDS 12-46.2008.

The document was developed by employees of RemstroServis-R LLC (E.V. Gnatyuk, B.A. Mordkovich)and CJSC Tsniyomtp (Yu.A. Korytov).

The document is intended for design organizations developing projects manufacturing projects, and for construction and installation organizations carrying out the installation of scaffolding to high-rise buildings.

Introduction

In Russia's megalopolis, there is an increase in the volume of the construction of high-altitude (from 30 floors and above) monolithic reinforced concrete residential and public buildings. On the facades of these buildings, various works are performed using construction forests: finishing, insulating and others.

Forests are applicable to buildings with a variety of architectural and planning and structural parameters, configuration, height and length.

Forests are indispensable in the cramped conditions of urban development, where they are used as a universal means of lifting, as well as for the placement of building materials and facade structures.

The laboriousness of the installation of forests does not exceed, as a rule, 0.6 people, which occur to 1 m 2 of the facade area.

Projects for the work of work on the installation of forests are included in the main organizational and technological documents for construction and are in demand by local state supervision authorities when making permits for construction work.

The document is applicable directly to the installation of the most widely used forests manufactured according to the technical conditions of GOST 27321-87. In this project, the work of the work used tubular, clamps, the racks of which are joined using nozzles.

The draft work project consists of textual and graphic parts. The graphic part is represented by the circuits of nodes, the installation sequence, fastening of forests to the wall, the supporting device of the forests at the floors of the building.

This methodical document is intended to assist project, design and technological and construction organizations in the development of a project for the installation of high-rise forests.

The basis of the methodological document is the results of the works of CJSC TsNIIMTP and other design and technological institutions, as well as the generalization of the practical experience of the installation of forests of Remstrocervis-R LLC and other Moscow construction organizations.

1 Characteristics of the building and scaffolding

The building residential monolithic reinforced concrete in the plan has a complex shape with rectangular and oval outlines of walls, dimensional dimensions: the length of the facade is at least 50 m, the width is 30 m, the height is up to 160 m. The thickness of the walls and inter overlap - at least 200 mm, window And other openings allow you to mount the reference devices to install forests at the height.

The project for the installation of forests is designed on the basis of a contract, technical specifications and the presented source data. As part of the technical task and baseline data: working documentation for construction work on the facade, passport and instructions for the installation of scaffolding, drawings on the building (in the amount required for the installation of forests).

This project manufacturing is developed under the following source data.

The design of the chomute forests is inventory, light, collapsible, reusable applications. Forest turnover is at least 60 times, and service life is at least 5 years.

Forests, for example: LSPH-200-60 Metacon firms, racking appropriate clamps according to GOST 27321. The pitch of the tier in height is 2 m, the step of the racks along the wall is 2.5 m, the width of the passage between the racks is 1.25 m. The flooring shields can fit on all tiers at the same time. Regulatory load no more than 200 kgf / m 2. Maximum forest height - 60 m.

The forests are mounted from tubular elements - racks and semi-resistance with a diameter of 60 mm, installed in support shoes with wooden lining, from longitudinal bonds with a diameter of 48 mm connected with racks using clamps, cross-fastened forests to the wall with metal or polymer plugs (dowels) . On the extreme sections of the forests with the help of rotary clamps, diagonal connections are established.

Racks and sequins are joined with nozzles.

Communications are connected with bolts.

The plugs are inserted into the holes drove in the wall. The plugs screw the hooks, while the plugs are made. On the hooks put on the eyes of the crossbar, after that, the crossbars are attached to the clamps to the racks.

The choms are unproofy connects at the right angle of the rack and seal with crossbars and railings. Rotary clamp joins a rack with diagonal connections under an acute or blunt angle.

The extreme rows of racks are fixed through one tier in height, the inner rows of racks are fixed in a checker manner through two tiers in height and through two horizontal racks.

When using forests according to GOST 27321, for example, the type of LSPX-200-60 Metacon firm, for the installation of high-altitude buildings, there are a number of informed settlements not provided for by the manufacturer.

To increase the bearing capacity of high-altitude forests, so-called double racks from a pipe with an outer diameter of 60 mm are used, which are the main element of high-altitude forests and the main condition for installing standard forests into high-altitude buildings. The carrier capacity of the rack must be verified by the calculation, the load on the rack should not exceed 3 TCs. The actual load on the most loaded racks should be selectively determined experimentally, using instruments, such as special scales, and recorded in the work log.

In addition, the following activities are also carried out.

Thus, the regulatory load on the forest is set not 200 kgf / m 2, but reduced, for example, not more than 100 kgf / m 2.

To reduce the load on the forest, it is reduced, according to the calculation, the number of workers and protective flooring. At the same time, the shields of the flooring can not be laid at all tiers at the same time, but in turn and sprinkle.

Depending on the local conditions, it may be necessary to change the pitch of the racks along the wall: for example, not 2.5 m, and 2.6 m or 2.4 m.

The width of the passage between the racks can be taken not 1.25 m, but, for example, 1.31 m.

A diagram of fastening forests to the wall, indicated in the manual for the manufacturer's manual.

Forests can be mounted not on the ground site (without or with asphalt concrete coating), and at the height - on the support devices from the console beams.

With simple architectural and construction solutions, one or two of the above events are carried out. Modern architectural and construction solutions of the building are distinguished by difficulties that requires the development of almost all or all the above measures and the corresponding reflection of them in the project work on the installation of forests.

All specified activities, as mentioned, should be justified by calculations and coordinated with the manufacturer.

The implementation of the above measures allows you to apply various installation schemes of high-altitude forests depending on the configuration of the walls, the height of the building and other local conditions.

The project presents the provisions on the organization and technology of forest installation, the requirements for the quality and acceptance of work, the need for mechanization, tools, inventory and adaptations has been determined, the requirements of safety and labor protection.

When developing a project, regulatory, methodological and reference documents specified in the list of documents used are used.

2 List of Used Documents

Instructing workers are made on the order, receptions and rules of assembly and fastening forests to the wall.

The plan of the forest installation zone leads in the project work on sheets, as a rule, A2 format (420 × 594) or A3 (297 × 420).

In fig. 1 is given as an example of a fragment of the forest mounting zone on the invigination corresponding to the factory settle of forests. The symbols for RD-11-06 show the forests, the border of the danger zone in the fall of the subject with the forest tier, the temporary fencing of the mounting zone.

The border of the danger zone is set by the calculation of the RD-11-06, depending on the height of the yarus of the forests.

Legend:

Bearing outdoor walls

Scaffolding

the border of the danger zone in the fall of the subject with the yarus of the forests

temporary fencing of forest mounting zone

Fig. one

3.1.2 Inspection, control and assessment of the technical condition of the components of the mounted forests are made.

Damaged components are subject to chosen.

Details sorted by details are laid along the walls.

3.1.3 Preparations for work, installation and launch of lifting mechanisms (roof crane, cantilever crane, winches) for lifting and descent of composite parts of forests.

These works are performed according to the instructions of manufacturers of lifting mechanisms.

3.1.4 Preparation of mechanization (manual drilling machines, perforators, traaming, etc.) and tools, their completeness and readiness for work are checked.

3.1.5 For forest support along the facade, a platform is prepared by a width of at least 3 m with asphalt concrete coating or a planned and a raven dirt area. The bearing capacity of the sites is checked by the calculation. From the site there should be a removal of water. If the soil is wet, the rubbing is produced with a slottle of rubble, broken brick, concrete.

If the height difference takes place, the platform under the forest along the facade is aligned horizontally in the longitudinal and transverse directions.

For altitude altitude, standard concrete slabs and boards with a thickness of at least 40-50 mm can be applied.

3.1.6 Marking of the points of installation of anchor stoppers on the wall of the building is carried out in accordance with the working drawing on the wall or "on the place".

At the initial stage, the wage marking points are determined with such a calculation so that the points do not coincide with the windows of windows. In the coincidence of the point of attachment with the opening in the forest wall, they are fixed to carrying structures (walls, columns, overlap) from the inside of the building with the help of fasteners and fixtures; It is not allowed to mount the forest to balconies, eaves, parapets.

The distance of the installation point of an anchor tube to the opening should be at least 150-200 mm. The horizontal of the extreme points is determined using the level, the points are noted by the indelible paint. For two extreme points, using a laser level and roulette, they define and mark the intermediate points of the installation of anchor plugs. Then, on the extreme points of the horizontal line, the vertical lines are determined. The indelible paint mark the installation points of the anchor plugs on the extreme vertical lines.

3.2 Main works

3.2.1 Mounting work with zero marks are made by the invigs, as a rule, use for the capture of one set of forests supplied by the manufacturer. The amount of capture is usually installed not more than 50 m along the facade of the building and high no higher than 60 m. When mounting the forests from a mark of 60 m and above, the height of the capture is not higher than 20 m.

To speed up the installation of forests (in the presence of multiple forest sets), work can be made by several parallel invigoys.

Independent parallel capture can be organized when mounting forests on a supporting device made of console beams, which is installed on the interlaced ceiling at height, as a rule, above 60 m.

3.2.2 When using dual racks up to a height of 80 m, and above - single forests are mounted to a height of up to 160 m. The distance between the dual racks is taken, as a rule, 300 mm (Fig. 2)

Fig. 2.

If the configuration of the wall does not allow to apply such a scheme, the forests are installed on the above support devices at the blocking of the building. The height of the capture is not higher than 20 m.

3.2.3 Forest installation is performed according to the manufacturer's instructions, on tiers on the length of the capture.

The technological process of installation consists of assembly of the first, second, third and other tiers, fastening forests to the building and installation of reference devices at the height.

3.2.4 Assembly of forest tiers are made as follows. On the prepared, smooth in the horizontal plane, the platform (see) set shoes with screw adjustment of height.

The height difference in the direction along the wall is aligned by laying concrete slabs and linings from the boards.

Under the shoes of each pair of racks are laid in the transverse direction from the board with a thickness of at least 40-50 mm. The installation of shoes is shown in Fig. 3, a.

The assembly of the main parts of the tiers is performed in the following sequence.

Install in the shoes dual racks of the internal and external rows of forests (Fig. 3 b).

We establish transverse and longitudinal connections on the internal and outer rows of racks for the supports of the first assembly tier (Fig. 3, B).

Each rack laid shields on longitudinal support-supports of the first mounting tier.

From the playgrounds of the first mounting tier, the longitudinal bonds of the first working tier are set and drilled in the wall of the hole for traffic jams (dowels) under the fastening of the transverse links of the first working tier.

Corks (dowels) are inserted into the holes and fasten the transverse connection to the wall.

From the playgrounds of the first mounting tier, the fences of the first working tier are installed, the angular racks are increasing, shields of the mounting tier in the flooring of the first tier. The flooring is equipped with an on-board fence with a height of 150 mm.

With flooring the first tier, the racks are increasing, the second mounting tier is installed from which the second working tier is collected.

Operations on the assembly of subsequent tiers are repeated.

Fig. 3.

3.2.5 Foresting of forests to the building is carried out to the reinforced concrete wall with a thickness of at least 200 mm using factory metal plugs or polymer dowels and through the openings (window, door, balcony).

Foresting forests with dowels is shown in Fig. four.

Fig. four

Dowels, such as typeMGD 14 × 100, MUNGO MGV bolt 12 × 350 The ring is strengthened in a wall four meters in a checker order according to the planned attachment points. The diameter and depth of the hole in the wall must comply with the values \u200b\u200bspecified in the factory instruction.

The strength of the attachment of the dowels in the wall is checked by calculating and must be tested by selectively using the device (fixture) to pull the tube from the wall. Extinguishing effort from concrete must be provided at least 300 kgf.

If the hole is turned erroneously in the wrong place and it is necessary to drill a new one, then the latter must be from an erroneous at least one depth of the drilled hole. This rule is not necessarily if the erroneous hole is pre-concreted or filled with a similar polymer composition.

Cleaning holes from drilling waste (dust) is made with compressed air.

The dowel is inserted into the prepared hole and burst with a mounting hammer.

Fastening forests to the wall through the window, the opening is shown in Fig. five.

Fig. five

The inventory of the attachment is made, as a rule, from the same tubular elements as forests.

The elongated transverse links of forests are set in the opening, then the longitudinal pipes are placed on them. The fastening of bonds and pipes is carried out using clamps or otherwise.

3.2.6 The supporting device at height is mounted from two cantilever beams and spacer racks. The beams are placed on the overlap through the sheet metal lining so that the length of their console part allows to install forests at a distance of 600 mm from the wall to the axis of the inner rack. Then the opposite ends of the beams are installed racks with screw mechanisms. The upper supports of the racks with wooden pads are summarized to overlapping. With the help of screw mechanisms with a torque of at least 5 kgf · m, the racks rest in the overlap and in the beams, pressing them to overlap and fixing the reference device in the opening.

To secure forests on the reference device, loops welded to beams are used.

The cantilever beams most often use a channel according to GOST 8240. The channel number (from number 12 and more) is selected by calculating depending on the load from the forests, which is determined by the direct summing of the weight of the forest details (not more than 20 m height) and the workload. The weight of the cantilever beam should not exceed 140-150 kgf from the condition that the assembly brigade performs manual mounting operations. Therefore, the chaserler number must correspond to the minimum allowable console beam strength.

For space-standing struts, mounting racks of the telescopic design with a screw mechanism for regulating the height of the supports are used. The main parameters of the racks: height up to 3100 mm, spacer effort from 3000 to 5000 kgf (see MDS 12-41).