Garage from foam blocks with their own hands - practical experience that opens access to new goals. Garage of foam blocks with their own hands - from A to Z, Building a garage from foam blocks

Possessing the best features for one-story building, foam blocks are often used to build a garage. In this case, their advantages (light weight, simplicity of processing and installation) are visible in the best possible way, and the garage from foam blocks will reliably protect your car.

All construction work can be carried out independently, and the technology itself is budget. To build a garage from foam blocks, you can fully do with your own drawing, but if the construction of a two-story building is conceived, it is desirable to refer to the specialists and order a project from them.

Foam block garage with sectional lifting gates

Any construction begins with a plan. It should display key data:

- Type of construction (separately or in the total array of garages);

- Purpose (number of transport units, household room);

- Dimensions of the building (length, width, height);

- Foundation type (tape, columnar or monolithic);

- Material for walls - foam blocks.

- Roof parameters (view, slope, one or bone roof);

- Looking pit. If the garage provides an observation channel, then it is much more convenient to dig up the pita in advance with the help of special equipment.

Alone to build a garage from foam blocks with their own hands you need to start with a whole complex of preparatory processes.

Learn more about the phased construction of the garage from foam blocks can be viewed on video:

House with a garage of foam blocks with their own hands

Garage Material Calculation

For the construction of the garage walls, foam blocks with dimensions of 600 × 300 × 200 mm are used. Before calculating the number of foam concrete blocks, you need to decide on the garage dimensions. As a rule, its dimensions are 6 × 5 × 3 meters. To calculate correctly, you need:

- Calculate the length of the walls (6 + 5) × 2 \u003d 22 meters.

- The result obtained is divided into the length of one block, which is 0.6 meters 22: 0.6 \u003d 36.6, is rounded up to an increase of up to 37 pieces.

- The number of rows is calculated (the standard height of the garage in three meters is taken into account). The height of the wall is divided into the height of the block 3: 0.3 \u003d 10 rows.

- To fully calculate the number of foam blocks on the parties, you need the number of blocks of one row multiply to the ranks: 10 × 37 \u003d 370 pieces.

- From this number, we take the number of blocks that are replaced by the gate and windows. When erecting walls with a thickness of 200 mm, the number of foam blocks on 1 m 2 will be 6 pieces. About 50 pieces are obtained on the garage openings. It turns out that for the construction of walls with dimensions 6 × 5 × 3

you need: 370 - 50 \u003d 320 pieces.

On a note. This calculation is taken averaged, excluding the thickness of the seams and the likely marriage during transportation. It is recommended to add 5% to the calculated result so that it does not have to purchase foam blocks from another batch that may differ in size and properties.

Calculation of the number of foam blocks

Choosing a place

After the project development, the acquisition of the material, the plan must be transferred to the area. First, determine and choose a place to build a garage. The best option is when the building is located next to the house, within walking distance.

If there is no such possibility, then you need to take into account the distance to the outbound road so that it is minimal. It is not desirable to build a garage of foam blocks with your own hands in lowland, as it threatens with flooding in the case of flood spring water. It is necessary to make sure that there are no future construction:

- Power line;

- Gas pipeline;

- Sewage mains;

- Water pipes.

In emergency cases, the repair of communications data is significantly difficult if the structure will be built on this territory.

Placement site for the construction of the garage

After you have chosen the place, you need to mark up the foundation. To do this, you will need a small set of tools:

- A hammer;

- Cord;

- Rods;

- Roulette.

First, determine the placement of one of the corners of the future structure, drive a small peg. Then alternately, we calculate the location of other similar points, drive the rods and then to control you need to check the distance to the diagonals of the received rectangle.

A durable cord is stretched along the knobs, and you can begin to the next stage - the preparation and device of the foundation.

Project Development on Terrain

Choosing foundation

When installing the foundation for the garage, it is necessary first of all to know the type of soil, the height of the groundwater in the place of the future buildings.

Depending on the soil, choose a specific type of foundation:

- Ribbon foundation. Such a base is the most traditional for garages on solid soil. It can be a blurred foundation reinforced by reinforcement to the freezing layer.

- Slab foundation. Such a base is placed up to 50 cm and is floating, it is used mainly on clay soils.

- Stamp method of foundation. Used on swamp places. At the same time, the floor will be raised above the ground, and the disadvantage of such a structure is that it will not be able to make a look.

What the foundation would not have chosen, the main thing is that it is durable and reliable, so it is necessary to take a very serious way to the process of the device of this basic basis.

More details about the construction of a monolithic belt foundation can be viewed on video:

Device of tape fundament

Bookmark Fundament

When the basis of the basis, regardless of the soil composition, you need to adhere to the main rule - the foundation must be based on a durable soil, which is below the layer of freezing.

The exception is peat and clay soils: in this case, a slab foundation can be applied. Let us consider in more detail the construction of a belt foundation, which is most often used when the foam block garages are erected.

On a note. Such a foundation is more favorable for the garage, if it provides for an observation pit or a basement.

Calculation of a solution for a ribbon foundation

Initially, you need to dig a ditch around the perimeter of the garage and then measure the width and depth of the Rib. To determine the volume of the belt base, the cross-sectional area is shortened to the length of the ditch. Suppose, the width and depth of the trench turned out to be 40 × 40 cm in size.

To calculate, it is necessary to take the formula: V \u003d S × L, where S is the ground cross section, L is the length of the entire basis. Substituting the source data, we purchase the following result: V \u003d 24 × 0.16 \u003d 3.84 m³.

As a result, the volume of concrete solution was obtained for a ribbon foundation 24 meters long. Such calculations are suitable for the basis of the correct form if the section is different, then the calculations will be others.

Calculation of material for a belt foundation

Construction of a ribbon base

To mount the foundation, you need to pre-produce preparatory work, for which:

- At the bottom of the trench, fall asleep layer of rubble with a thickness of 10-15 cm and upstairs to build a metal frame from rods and wire with a diameter of at least 6 mm and with a distance of the cell side 15-30 cm. This design will give the rigidity to the belt base;

- Then you need to make a formwork from the girlfriend (boards, plywood, chipboard or flat slate). From the surface of the Earth, as a rule, it is made of 30 cm high. For the creation of rigidity, struts, wedges and other fit pictures are used;

- After the device of the formwork and reinforcement, the prepared trench is poured with a solution of concrete, which is obtained in the concrete mixer. The mixture for the base is prepared in proportion: one part of cement (MA 400 mark) and three parts of sand, gravel or extinguishes;

- Pulling concrete Belt foundation is needed at a time, in order to avoid uneven drying and cracking of concrete.

After the fill with the concrete mixture in the formwork, it must be covered with a rubberoid, thereby protecting against direct sunlight and give out 3-4 weeks.

Construction of belt foundation

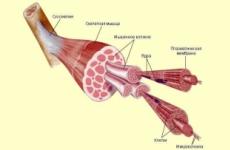

Features when the walls are erected from foam block

After the final grazing of the cement mortar, it is projected by the walls of the walls, but it is necessary to install stationary gates.

If the cloths are lifting, then you need to insert the guide profiles strictly vertically and at a certain distance from each other.

When erecting a garage from foam block, some conditions are required:

- Walls are recommended to do a thickness of 200 mm, which is the most economical option;

- To eliminate the contact of the foam block with water, the lower row rises by 300 mm (if the foundation is not raised) due to the slag block or concrete slabs.

- As a rule, the walls of the garage are erected from the blocks of the brand D 700-D 600 with a thermal conductivity from 12 to 0.16 m² · k / w, which is 4 times less than that of brickwork.

- It is necessary to observe from the first row vertical and horizontal position of the wall using a plumb and level. And at the same time, if you withstand the seams of a certain thickness, you can easily independently make a laying and build fairly smooth walls.

- Foam block has a relatively light weight, about 700 kg / m³, which significantly reduces the load on the foundation. And the strength of foam blocks allows you to build a building up to 3 meters high.

- The large sizes of foam block in combination with simple material processing make the laying process more quickly.

- Foam concrete is not lit.

The disadvantages of such blocks include an enlarged condensate inside the garage. That this does not happen, it is recommended to improve ventilation by installing forced electrical exhaust.

The walls made of foam blocks do not withstand conventional fasteners, so special dowels are applied with a PVC nozzle.

Attention. The laying of walls of foam blocks is made on glue or cement solution, while withstanding the seams when glued it is 3-5 mm, and on cement composition - 1 mm. Through two blocks in the horizontal slot, it is recommended to lay the reinforcing grid.

Reinforced masonry of walls of foam blocks

Roofing device

After the construction of the walls, it remains to install a stable design from the beams for the rafting roof. Pre-under the beams do not forget to put rubberoid as a waterproofing layer.

The final coating can be from any material (profile sheet, metal tile, rubberoid), but it is desirable that the roof is combined with the roofs of existing buildings.

Garage roof

Installation of lifting gates

The last step in the construction of the garage remains the installation of the gate. Each type of gate has its advantages and disadvantages. Consider in more detail how to install the lifting gate.

Such a gate is a convenient and reliable device to protect the garage from the penetration of unauthorized persons. When opening, they occupy a horizontal position, moving forward, forming a small canopy over the entrance.

The inner space of the gate is filled with polyurethane, which is an excellent insulating material. In such designs, all parts (rollers, brackets, couplings) are made of metal or plastic.

The drive for opening the gate is made by the electric motor through a gearbox, a mechanical, chain method or a universal method. The last option is used if there are interruptions in the region.

Council. Before installing the lifting gate, you need to purchase a set of component parts ready for assembly, and the installation itself produce yourself.

Garage lifting gates in open state

Installation of sectional lifting gates:

If the garage is not built on its site, and on the territory of the municipality, then its construction must be carried out in compliance with all the requirements of regulations, technical conditions and fire safety regulations.

This is due to the fact that in the future it was possible to arrange documents for a garage without alteration of individual elements of the newly created building.

As materials for building a garage, traditional slagoblock or brick are usually choosing, there were no alternatives before. Now there are more modern materials to which cellular concrete can be attributed. Of these, foam concrete has the most attractive cost and simplicity of laying. It is fully suitable for such a construction, and the time of work will be minimized. In this article we will look at how to build a garage from foam blocks with your own hands.

Why profitable foam block?

The garage from foam block has the following advantages:

- The material has a small cost, so almost everyone can afford it. Now offers for the sale of foam concrete more than enough.

- The structure from cellular concrete will be warm, unlike slag block or brick buildings.

- The small weight of the blocks allows you to build a garage from foam blocks with your own hands, not leaseing a special construction technique.

- The small weight of foam blocks reduces the burden on the foundation, which leads to cash savings.

- The laying of large-sized blocks is performed quickly and easily.

- Installation of blocks is very economical. For masonry, a lot of solution will not need.

Foam concrete, possessing a closed structure, does not pass air, therefore, to prevent the formation of condensate inside the structure, it is necessary to equip supply-exhaust ventilation.

Garage layout

Even before the start of construction, it is necessary to determine the size of the building and the functions of the garage. For example, whether we need an observation pit and a basement for storing conservation will be equipped with a tool racks, a table or workbench will be installed. The dimensions of the building should be such that he subsequently did not have to regret the lack of free space. Therefore, it is necessary to correctly calculate the size of the construction.

Standard garage dimensions are considered:

- Height - about 3 m.

- Length - 5-6 m.

- Width - 5 m.

Usually garages make one-storey, but you can make a two-story garage from foam blocks. In this case, the prerequisite is the presence of Armopean between the floors, to which the slabs of the overlapping will be relying.

Foam blocks garage foundation

Building the garage begins with the fill of the foundation. What is the foundation to prefer? In this capacity, it is better to choose a ribbon finely brewed concrete fill. Foam concrete has a slight weight, so this design will be enough. Many people build a slab base, but it deprives them of the possibility of creating observation pit and basement. Therefore, the ribbon foundation for the garage of foam blocks is preferable on ordinary soil. However, on bunched soils, the monolithic plate will be better to perform its function.

Work on the fill of the foundation under the garage from foam blocks starts with marking. With the help of a cord and pegs, there are places of future trench. Special attention is paid to the location of the gate. The opening flaps of the future gate should not meet any obstacles in their path. In particular, you should remove interfering bushes, fences, columns, etc.

The depth of the foundation for the construction of a garage from foam blocks is selected depending on the peculiarities of the soil on the site. In particular, if the groundwater lies on the site at a depth of more than 2 meters, and the soil is relatively dense, then you can proceed with a trench with a depth of 50-80 cm. But this is taking into account that the fertile layer will end at this depth.

The foundation for the garage from foam blocks is manufactured in the following sequence:

- A trench of a given depth is digging. Its width should be 15 cm exceeded the width of the foam block.

- The bottom of the trench is trambed.

- The trench is covered with a sand pillow with a layer of at least 10 cm.

- On top of the sand, a layer of rubble with a thickness of about 10 cm is falling asleep.

- A thorough traam is performed.

- Installing formwork.

- The trench is placed an armature frame associated with knitting wire.

- The trench is poured concrete. In the concrete you can add large gravel, placing butt stones.

Construction of observation yama

When we build a garage of foam blocks for storing a car in it, it is very desirable to equip the observation pit. Then it will be much more convenient to ensure the care of the vehicle. If it is decided to equip the observation pit in the garage, calculate the pre-sized dimensions. Typically, the depth of the pit is 180-200 cm, the width is about 1 m.

Procedure for manufacturing observation pit:

- A hole is digging on the depth and width exceeding the calculated 20-40 cm.

- The bottom of the pit is covered with rubble and concreted.

- Walls are restored with brick or concrete. In the second case, the formwork is installed.

- From above, the layer of brick or concrete is installed metal frame from the corners with a width of the wall 6 cm. It must be covered with concrete.

- When the solution freezes, the plaques of at least 4 cm thick are stacked inside the corner frame. They are insurance preventing a random drop in the car into the pit.

If, in addition to the observation pit, it is necessary to build and basement, then the observation pit is equipped with steps, which can be descended to the basement. In this case, in the center of the pit there is a flat platform designed to serve the car.

Calculation of the required number of foam blocks

First you need to decide on the number of necessary material. Consider how to calculate the number of foam blocks on the garage. Standard foam block sizes: length - 60 cm, height - 30 cm, width - 20 cm. For example, you need to build a garage with a size of 6 x 5 x 3 m. The calculation is performed in this order:

- The length of the perimeter of the walls is calculated: (6 + 5) x 2 \u003d 22 m.

- Number of blocks in a row: 22 / 0.6 m \u003d 37 pcs.

- Determine the number of rows: 300 cm / 30 cm \u003d 10 rows.

- Calculate how much the entire blocks you need: 10 rows x 37 pieces \u003d 370 pieces.

In the calculation of foam blocks on the garage, it is necessary to make an edress that takes into account the size of the gate and possible windows, if any. This number of foam blocks for the garage should be deducted from the total. And it is also necessary to make a correction to marriage and cutting materials by adding another 5% blocks to the final quantity.

Mounting the gate

Before starting the walls of the walls, you must install the garage doors. They are installed strictly by level on the layer of waterproofing, which is covered by the foundation. On the stems of the flaps, supports holding the gate are fixed. A little later, when the construction of the walls is started, to the side supports of the gate will need to fight pieces of armature about 40 cm long, which will be recessed in foam concrete. Such pieces will be 4 pieces on each side of the gate. In order for the fittings to fall between rows of blocks, it is recommended to welcome it at the place, after the masonry of the next series of blocks.

When a row of foam blocks approaches the gate up, you need to make a jumper over them. It can be finished or filled with a concrete beam. To do this, you can make a metal frame and welcome it up the gate. After that, the frame is filled with concrete solution with the formation of a monolithic jumper. But you can install over the gate and the finished beam. Subsequently, the next series of foam concrete blocks will be laid on the jumper.

Laying wall

When we build a garage of foam blocks with your own hands, it is important to build the wall correctly. For the walls there will be enough thickness of the block 20 cm. Before laying the first row, it should be paved on the foundation layer of waterproofing, which will prevent the material of the walls from moisture.

Laying walls starts from any angle. Initially, the angular blocks are laid out, and then the cord is stretched between them. For this cord, the remaining blocks are carried out. As a binder solution, you can use:

- Special adhesive for styling foam concrete. It is sold in a dry form, and before use is divorced by water in the specified proportion. This is the most economical option, since it is required relatively a bit. Cold bridges between blocks in winter will not be.

- Normal cement-sandy solution. It will be needed more, since the seams will be thicker. Such a solution is allowed to be used, although without the bridges of the cold, in this case, can not do.

In the process of masonry, it is impossible to forget to reinforce each 4th row of blocks. As a reinforcement, you can use a metal grid, reinforcement or steel rods. When using fittings or rods, it is necessary to cut 2 grooves in a row of blocks. They are stacked by rods. When docking blocks with gates, the relationship is provided to the gates of fittings. They should be inserted into the masonry between the rows of foam blocks.

Typically, the ranks are not complete, demanding the insertion of foam block pieces. Such emptiness is filled with in good blocks or pieces of blocks, cut off with a hacksaw.

The adhesive solution is applied specifically designed to be a celma having a teeth. This turns out a uniform layer of solution. Each beddown blocks are polished with a special grater to provide an ideally smooth surface.

Each subsequent number of blocks is placed with a displacement relative to the first row by 30-50% of the block length.

If the roof is mounted a single-table, the most common, then the side walls must have a slope to the rear wall. The angle of the slope is just calculated. On each meter of length, the bias should be about 5 cm. This will be quite enough to ensure the normal water drain from the roof.

If the roof is double, then you can immediately lay out frontones from foam concrete or other material.

In the event of the construction of the second floor, the concrete armoomas is poured over the last row of foam blocks.

Roof Device

The construction of a garage from foam blocks is accompanied by the construction of the roof. Consider, in what order a single roof is made:

- In the direction of the roof slope, 2-way beams are installed with a protrusion of the back and rear walls of at least 25 cm. You can use ordinary beams, but it will have to be touched longer. The step of beams - 80 cm. The beams must be mixed into the walls.

- On the lower shelves of foreign beams, boards are stacked with a thickness of 3-4 cm. If ordinary beams are used, the boards are nourished to their lower ends.

- Ruberoid is laid on top of the boards and bend on the edges up 10 cm.

- The insulation is stacked on top of the runneroid. It can be a foam of 5 cm thick, mineral wool, clamzit.

- If the insulation is bulk, it is advisable to make a concrete tie a thickness of about 3 cm. In all other cases, it is recommended to cover the roof of OSB sheets, and to lay rubberoid or slate sheets on top.

Pole concreting

A good concrete floor will provide cleanliness and order in the garage of foam blocks. Some garage owners are placed on the floor ceramic tiles, but this is not necessarily. It is necessary to concrete the floor in the following order:

- 10-15 cm rubble flooded on the leveled surface, then 5-10 cm of sand, and then 5-10 cm gravel.

- Such a pillow is thoroughly trambed.

- Concrete is pouring a layer of at least 20 cm.

- After the complete pouring of the concrete floor is ready to use.

Finish finish garage

Outdoor and interior decoration will make your garage more attractive, as well as protect foam blocks from moisture. Close Foam concrete from the outer side can be several types of finishing materials:

- Plastering solution. You can not use the usual sandy cement mixture, which will be badly kept on foam concrete. For foam concrete, special plaster containing special additives.

- Finishing sheets of foam with subsequent application of decorative plaster.

- Finishing siding.

To finish the inner walls of the garage, you can apply:

- Special plaster.

- Moisture-resistant plasterboard sheets with subsequent shpocking and painting.

The garage built of foam concrete blocks will not only be warm, but also cost-effective. If all the conditions and technology of construction are met, then the construction built by its own hands will simply simply and will not require repair.

Construction of garage

- Brick garage - from 16 000 rub / m2

- Feno-gas-concrete garage - from 11 000 rub / m2

- Frame garage - from 8000 rubles / m2

- Garage of profiled timber - from 12 000 rub / m2

- Garage of glued timber - from 16 000 rub / m2

- Garage of the rounded log - from 13 000 rub / m2

- Garage from R / B Plate - from 24 000 rub / m2

- Metal garage (LSTK / Professional flooring) - from 5 500 rubles / m2

Construction of a canopa

- Canopy for a car from polycarbonate on iron pillars - from 3300 rubles / m2

- Console canopy for car - from 4700 rubles / m2

- Worn canopy for a car - from 5100 rubles / m2

- Canopy for a car from a professional flooring - from 4000 rubles / m2

- Canopy for a car from metal tile - from 4100 rubles / m2

- Canopy for a car from wood - individually

Roofing

| Slinge system | from 300.00 rubles. | m2. |

| Okeekhet | from 150.00 rubles. | m2. |

| Cross-cutting board | from 150.00 rubles. | m2. |

| Fronteon sewing siding, block house, clapboard, etc. | from 300.00 rubles. | m2. |

| Laying under the undercoal hydraulic isolation | from 100.00 rubles. | m2. |

| Laying Ruberoid | from 100.00 rubles. | m2. |

| Laying ondulina | from 250.00 rubles. | m2. |

| Laying metal tile | from 300.00 rubles. | m2. |

| Laying flexible tile | from 400.00 rubles. | m2. |

| Laying OSB - Plywood | from 200.00 rubles. | m2. |

| Warming of roofing rods | from 150.00 rubles. | m2. |

| Installation of the drain system | from 250.00 rubles. | p.M. |

Prices for the foundation for the garage

- Ribbon foundation (height 60cm - thickness 30cm) - from 3000 rubles / mp

- Ribbon foundation (height 80cm - thickness 40cm) - from 4350 rubles / mp

- Monolithic plate (height 20cm) - from 3500 rubles / m2

- Monolithic plate (height 30cm) - from 4360 rubles / m2

Cost of one screw pile with screwing and concreting

- pile thickness 89 mm. + Height 1.5m - 3 000 rub.

- pile thickness 89 mm. + height 2.5m - 3,200 rubles.

- pile thickness 89 mm. + height 3m - 3 300 rubles.

- pile thickness 108 mm. + height 1.5m - 3 100 rubles.

- pile thickness 108 mm. + Height 2.5m - 3,400 rubles.

- pile thickness 108 mm. + height 3m - 3 500 rubles.

Electric installation work

| Assembly, installation and installation of electrical panels | Units. change | Cost |

| Installation of outdoor electric shield | pC. | from 800 rubles. |

| Installing a hidden electric shield | pC. | from 1500 rubles. |

| Installation of an electric shield without electric power meter | pC. | from 2000 rubles. |

| Installation of an electric shield with an electric power meter | pC. | from 2500 rubles. |

| Installation and disconnection of spread boxes 3 | Units. change | Cost |

| Up to 4 cables for open electrical wiring for soft material (wood) | pC. | 350 rub. |

| Up to 4 cables for open electrical wiring for solid material (brick / foam concrete / concrete) | pC. | 400/450/500 rub. |

| Up to 4 cables for electrical wiring under GPSO2 | pC. | 350 rub. |

| Up to 4 cables for hidden electrical wiring in foam concrete / brick / concrete | pC. | 500/550/600 rub. |

| From 5 cables for open electrical wiring for soft material (wood) | pC. | 450 rub. |

| From 5 cables for open electrical wiring for solid material (brick / foam concrete / concrete) | pC. | 500/550/600 rub. |

| From 5 cables for electrical wiring under GPSO2 | pC. | 450 rub. |

| From 5 cables for hidden wiring in foam concrete / brick / concrete | pC. | 600/650/700 rub. |

| Installation (gasket) of power cable up to 4 mm2: 2 | Units. change | Cost |

| Opened directly on the wall using the bracket | m / p. | 50 rubles. |

| Open in a corrugated tube on soft material (tree) | m / p. | 100 rubles. |

| Open in a corrugated pipe for solid material (brick / foam concrete / concrete) | m / p. | 150/150/150 rub. |

| Opened in the Cable Channel for Soft Material (Tree) | m / p. | 100 rubles. |

| Opened in Cable Channel for solid material (Brick / Foam concrete / concrete) | m / p. | 200/200/200 rub. |

| Hidden in foam concrete | m / p. | 300 rub. |

| Hidden in brick | m / p. | 350 rub. |

| Hidden in concrete | m / p. | 400 rubles. |

| Installation of a new electric motor (socket / switch) 1 | Units. change | Cost |

| Open electrical wiring for soft material (tree) | pC. | 200 rubles. |

| Open wiring for solid material (Brick / Foam concrete / concrete) | pC. | 250/250/250 rub. |

| Wiring under GPSoukarton | pC. | 250 rubles. |

| Hidden wiring in foam concrete | pC. | 300 rub. |

| Hidden wiring in brick | pC. | 350 rub. |

| Hidden wiring in concrete | pC. | 400 rubles. |

Finishing work

- Installation of a set of electricians inside the garage - from 10 000 rubles.

- Production of garage concrete floors - from 25,000 rubles.

- Replacement. Production of wooden floors - from 20,000 rubles.

- Internal decoration of the garage dry eurryagon - 800 rubles. for m2.

- Making a metal gate with a gate, painting - from 30,000 rubles.

- Set of lifting-section gates + installation - from 45 000 rubles.

- Cosmetic repair inside the garage - from 1500 rubles. for m2.

Construction of a garage from foam blocks with their own hands

The choice of material for the construction of the garage is the responsible task. It is important to ensure reliable protection of the car, the stability of the structure and the long-term resource of operation. Along with gasoblocks, brick and wood, foam concrete is widely used, allowing you to quickly and inexpensively build a garage from foam blocks with your own hands. Consider the features of technology, the specifics of design and algorithm for determining the need for material.

How to build a garage from foam blocks with your own hands

For use foam blocks, thanks to the following advantages:

- low price level. The lowest estimate of the construction costs allows construction with the use of blocks of foamed concrete to developers with limited financial capabilities;

It is impossible to approach the residual principle: "I blind from what was"

- a minor mass of blocks with increased dimensions. The low weight of the product allows to reduce the load on the base and use a ribbon foundation for the construction of a two-storey garage with an attic;

- increased strength characteristics. The increased margin of strength allows us to ensure the stability of the buildings, including increased dimensions (6 to 6), intended for 2 machines;

- reduced thermal conductivity. When using foam concrete, there will be no problems with maintaining a comfortable temperature, as the blocks are well maintained;

- easy masonry. To build a garage yourself or attach a car storage room to an existing building is easy, given that when we build, a special lifting technique is required.

Attention! Having preferred foam concrete for the construction of a garage structure, do not forget that the structure of the material and the thickness of the walls do not allow the blocks to "breathe". To remove the resulting condensate and reduce the humidity level, it is necessary to equip the supply-exhaust ventilation, equipped with an electric fan.

After examining the features of foam blocks, it is necessary to correctly perform a complex of preparatory work:

- carry out engineering and geodesic surveys, allowing to determine the level of groundwater location, the depth of freezing and the characteristics of the soil;

In recent years, the construction of a garage from foam blocks has become extremely popular among car owners

- make a decision to choose a design option - a two-story with an attic, for 2 cars in size 7 by 6 or one car with increased dimensions (6x4);

- develop a project, taking into account the characteristics of the structure, connecting electrical energy and water supply systems;

- determine how it is better to put foam blocks, calculate the need for construction material, to familiarize yourself with the construction technology;

- calculate the amount of estimates for the construction of the construction, taking into account the design features of the garage and transport costs for the delivery of building materials in a garage cooperative or to the country.

Important! The official document, allowing to start the construction of the construction, is a construction permit, which must be issued in advance.

Consider in detail the technology of construction with their own hands of the garage structure from foam blocks. It is important to figure out how to fold the walls ensuring their stability. Construction measures, following the sequence of operations:

- Marking the construction site, using the twine and wooden pegs. Check the presence of direct angles by performing measurements of diagonals, the difference in the size of which should not exceed 1 cm. Follow the dimensions specified in the project. Pay special attention to the absence of interference difficult to open the gate of the future structure.

Building a garage from foam block with their own hands begins with the foundation bookmark

- Prepare the foundation of the garage room, depending on the characteristics of the soil. As the basis of the structure located on the grunted ground, a slab foundation opened below the freezing level can be used. In this case, the arrangement of the observation pit or basement is excluded. On dense soil, the stability of the construction will provide the foundation of the ribbon type.

- Waterproof the basis of the structure. Protection of walls from moisture is carried out using a runneroid, which is stacked on the surface of the foundation. Reliable fastening of the waterproofing layer is ensured by misses the surface of the base and rubberoid with bitumen mastic.

- Install the exit gate, the reliable fixation of which will be ensured when the walls are erected. Secure the mortgage elements on the perimeter of the gate frame, which will ensure the design of the design in foam block. Cover the gate with a soil protecting metal from corrosion.

- Build walls. Start the laying from the corners of the building, providing the displacement of the foam blocks by 30-50% of the length. Thoroughly scroll with special glue or cement mortar. Control the horizontal of masonry using a construction level. Enhance the masonry by reinforcement every three rows. Provide holes for laying ventilation highways.

- Construct around the perimeter of the walls of Armopoyas, intended for a uniform allocation of effort. The fill of the amplification circuit with a concrete solution is made to the installed formwork height of 30 cm, in which the frame of steel reinforcement is placed.

- Build a viewing pit, concrete the floor, and fill with concrete inclined break on the external perimeter of the structure. Pay attention to the need to build a drainage system with closely arranged groundwater. Pour the floor with the M150 brand concrete.

Newbirds most often used for masonry ordinary cement-sandy solution

Attention! At the stage of acquiring material, pay attention to the absence of cracks, chipping and flatness of the product surface. The minimum thickness of the junctions is achieved by using a special glue that reduces heat loss by reducing the thickness of the "cold jumpers".

Having finished the construction of the Garage Room Box, proceed to the final stage of building events - the arrangement of the rafter design and the installation of the roof.

The construction of the roof of the garage - the final stage of the work

Different design options for the roof of the garage room are possible:

- single roof. Is the most common option. It is performed by concreting transverse beams or the installation of a reinforced concrete plate with the subsequent surface coating with waterproofing material;

- two-tight design of the tent type. It is formed by laying wooden bars overlap, which is fixed with a rafter design. The farm cord installed on the cord is bonded and covered with metal tile or ordinary slate;

Putting on the walls of wooden beams of overlapping, the rafter feet of the attic structure are fixed to them

- mansard roof. Allows rational to use the existing area and is widely used in garage cooperatives, where the standard area of \u200b\u200bthe room is clearly not enough. Additionally, the room is insulated, which can be operated year-round.

Consider the construction technology of a common single-piece roof:

- Cut the duct billets, the length of which exceeds the width of the structure by 40-50 cm.

- Install and fix across the garage walls with an interval of 0.8 m beams from a steel heap.

- Secure inside the garage room at the bottom of the board beams, the thickness of which is 4 cm.

- Place the rolled rolling ruler, drunk at the edges of the future overlap by 10-15 cm.

- Pour on the rubberoid clamzite or other insulation material.

- Reconfigure the insulation of the caption from a concrete solution from above, providing a thickness of 4-6 cm.

- After hardening concrete, treat the surface with bitumen mastics and thoroughly induce the rubberoid.

Attention! Ensure uniform speech of the beam design for the outline of garage walls by 20-25 cm. This will ensure the protection of walls from the negative impact of precipitation.

Development of a draft garage from foam blocks

Building measures are based on design results. The project provides complete information about the structure of the structure and the form of the foundation used, taking into account the characteristics of the soil and the level of groundwater.

When preparing for construction, it is determined with the appointment of the building: a garage for one or two cars, with a specially equipped place for things or without it

Even who has at least initial knowledge in the construction of buildings, under the power of building a garage of foam blocks with their own hands. Foam blocks are an excellent option for solving such a task. With a minimum of material costs as a result, you will get a solid and reliable asylum for your car.

In the garage of foam blocks, it will be reliably protected from negative environmental impacts, and you will get the opportunity to carry out a technical inspection and repair in a comfortable environment. In this article we will look at the features of the construction of a garage from foam blocks with their own hands.

One of the cheapest ways to build a garage is the foam blocks with your own hands. Foam blocks are distinguished by such properties as:

- Economy. As we have already said, the cost of foam blocks is one of the lowest among materials suitable for the construction of the garage;

- Ease. This material has a relatively small weight, which makes the construction of it simple, comfortable and low-cost. For facilities from foam blocks no powerful foundation is required;

- High strength. Despite the low weight, foam blocks have sufficient strength so that the garage, built of them, perfectly coped with its functions;

- Low thermal conductivity. The garage of foam blocks built by their own hands will create good conditions for both the car and for its owner. After all, it will keep warmly well. Often, such buildings do not even be insulated additionally;

- Easy mounting. A small weight greatly facilitates the construction process. This does not require heavy machinery and many working hands.

The excellent properties of foam blocks are due to the composition and technology of production of this material. Its structure is porous, but air bubbles inside the material do not interact with each other. This provides a very low level of absorption that the aerated concrete has. Due to this, the indicators of thermal insulation, frost resistance and sound insulation in foam blocks are higher than that of aerated concrete. Therefore, it is possible to apply it even in places where the humidity level is high enough.

There is one more advantage, because of which it is worth the construction of a garage from foam blocks with their own hands: foam blocks do not need outdoor decoration. Aerated concrete, on the contrary, cannot be left open, as it is not resistant to moisture and as a result of its penetration can crack. Foam blocks such trouble does not threaten.

As you can see, foam blocks are an excellent choice for such a building like a garage.

For the construction of the garage, blocks are usually used, dimensions of 600x300x200 mm. This allows you to choose the desired wall thickness - 200 or 300 mm. If you build a unheated garage, then 200 mm for walls is quite enough. If the construction will be heated, the wall thickness is determined by the climate.

- Determine the length of the perimeter: (5 + 6) * 2 \u003d 22;

- Determine the number of blocks: 22/06 \u003d 36.6;

- Thip the required number of rows. We divide the height of the garage to the height of the unit: 3 / 0.3 \u003d 10 rows;

- Now you can easily calculate how many blocks are needed for the entire garage: 37 * 10 \u003d 370 pieces.

When counting, do not forget to consider the gate and windows, if they mean. If the wall thickness is 200 mm, then about 6 blocks take place on 1 m². Based on the total area of \u200b\u200bopenings, you can calculate how many blocks will be superfluous. The standard gate and windows need to subtract 40-50 blocks. Total, about 300-320 blocks need to be needed on the garage of such sizes. This scheme makes it possible to easily calculate the required amount of material for the garage of any sizes.

Important! Please note that foam blocks differ fragility, so when transporting and performing work is possible a fight. It is also worth taking into account the seams. Therefore, it is better to acquire a material with a margin of about 5%.

After you have decided on exactly what kind of garage from foam blocks you want to build with your own hands, you can proceed directly to the implementation of your idea. The basis of any successful construction lies a competently developed project.

Project

Future construction requires careful planning. The project is the basis of the right settlements and financial savings.

The garage project can be developed using programs on a computer or contacting the professionals of project organizations. But this type of work can be performed independently. This will allow you to take into account all your wishes and implement the project exactly as you want.

Before design, it is necessary to solve such important issues as:

- Do you need an observation pit?

- Do you need a basement?

- Will there be in the garage inventory, equipment, etc.?

- Is the work zone in the garage foreseen?

Answers to these questions will help you create a project that fully meets your needs. Also, on the basis of the project, you can choose the optimal type of foundation, determine the necessary settings for the construction. Standard, the most popular garages from foam blocks usually have 3x3x6 sizes. You can always find ready-made options for typical projects on the Internet on specialized sites.

Foundation

An important element during construction is the foundation for a garage of foam blocks with your own hands. Foam blocks, as mentioned above, have a relatively small weight. Therefore, they do not require a powerful foundation. But his creation still needs to pay attention to maximum attention, because the strength, reliability and durability of the future building depends on its quality.

Work on the foundation begins with marking. It takes pegs that need to be driven into those places where the corners of the future garage from foam blocks will be located. Then the pegs must be connected by the twine. The angle between the ropes should be strictly 90º. And the markup must fully comply with the size defined project.

After you post a plot, appreciate the opportunity to open the future gate. Where the gate will open, there should be no obstacles.

If the markup succeeds, you can move directly to the foundation device.

It is important to correctly choose the type of this element correctly. It is determined, in addition to the weight of the materials, also the properties of the soil. If it is sufficiently dense, and underground waters lie at a depth of more than 2 meters, it is enough to build, a depth of 0.5 m. If the soil is bupied, then it is worth making a monolithic foundation.

Important! If you plan to build a garage from foam blocks with your own hands with a weak yam, then the monolithic foundation disappears. In this case, you need to make a deep ribbon or tape.

Consider the technology of creating a ribbon foundation by 0.8 m:

- On the markup it is necessary to dig a trench, a depth of 800 mm and a width of 350 mm;

- To align the bottom and tamper;

- Build a pillow of gravel and sand. Tamper

- Install formwork and frame of fittings;

- After that, you can pour a solution.

The foundation must gain sufficient strength. Usually it takes about a month. If the garage is provided in your future garage, then this time can be spent on its creation.

The next stage of construction is the walls. It is necessary to erect them only after the foundation becomes durable. Works are carried out in the following order:

- The first blocks are put in the corners;

- Rope is tensioning between them;

- Next, the masonry is carried out in the rope. The seams are laid by a special reinforcing grid. Each next row is laid out in such a way that the middle of the block falls on the seam between the two lower blocks. Blocks are installed with a long side along the wall;

- At the required height in the seams, the upper beam of the gate is mixed;

- At the level of the overlap bar, the masonry is carried out without blocking blocks.

Important! If the roof of your future garage from foam blocks is a single one, then during the construction of the walls it is necessary to perform a slope to the rear wall with a calculation of 5 cm of the slope by 1 mongor meter.

The slope is performed by trimming foam blocks. If planned, you need to think in advance how the fronttones will be closed. It may be masonry from foam blocks or lining.

Most often, a simple garage is covered with a concrete wall. But when we talk about the garage of foam blocks with your own hands, this option disappears, as foam blocks may not withstand the severity of such a design. A single-piece roof is chosen more often when they are going to build a garage from foam blocks with their own hands. Foam block projects can be with a double roof.

Consider the technology of the suburban roof:

- Beams exceeding the length of the wall for 200-250 mm are set across the roof every 800 mm and fit into the walls;

- Bottoms are tightly unfolded boards of 40 mm;

- On the board, the rubberoid with a bending along the edge of 10 cm is stacked;

- The heat insulation is stacked on the runner. It can be slag or clay;

- There is a cement-sand screed with a thin layer of up to 3 m;

- After the screed is dry, it must be treated with liquid bitumen mastic;

- Then across the construction method of the catch, it is necessary to spread the runner from the lower point upwards. The canvases are put on a mustache.

Thus, you will have a reliable and strong roof. Will just make a visor. It can be done from the corner or buy it already ready.

Goal

About the gate device you need to think before the construction of the walls. Reliable gates must be inserted into the laying. You can use different designs of the gate, when we build a garage from foam blocks with your own hands. The video about foam blocks most often offers the option of installing the usual swing gates. This option is optimal if you want to build an inexpensive and reliable garage. We bring to your attention instructions for installing such a gate:

- Place the waterproofing layer on the foundation before installing the gate. For this purpose, the rubberoid is well suited;

- Make a gate frame and brew to it on each side of 4 pieces of reinforcement with a diameter of 12 mm and 40 cm long. Stop segments Place on the frame in such a way that they coincide with the seams of foam blocks;

- Before installing the gate frame, paint it and boil it;

- Set the gate, check with the level and plumb. In the installation process, you can fix the gate using wooden bars.

Reliable goal is needed a reliable basis. Therefore, it is necessary to make a beam above the gate. It should be 200 mm on each side longer than the gate.

Important! If your project assumes the second floor, then around the perimeter of the building you need to build Armopoyas to hold the ceiling plates.

Insulation

The insulation of the garage must be carried out with the mind. The difference in temperatures inside and outside should not ideally exceed 5ºС so that the car is not covered with condensate. Therefore, it is very important to consider ventilation, and warming up the outside. The most popular materials for insulation of the garage are:

- Styrofoam;

- Mineral wool;

- Glasswater.

They are light, cheap, comfortable to use. The best option is the basalt mineral wool, which provides excellent sound and thermal insulation characteristics of the construction. But the most simple and affordable insulation option is insulation of foam. It is performed as follows:

- On the bottom on the dowel, the wooden plank is attached to which the first row of plates is stacked;

- The glue is applied throughout the perimeter of the slab toothed spatula. Accommodation is performed in a checker order;

- Plates need to tightly press. After the glue dries, the insulation will additionally be fixed with plastic dowels.

- Polyfoam must be protected from water. Therefore, it is covered by a layer of plaster with a reinforced layer. For this, the plates are covered with a thick layer of glue, into which the reinforced mesh is smeared with bands;

- After drying the glue, plaster and facade paint are applied to the surface.

Now you know how to build a garage from foam blocks with your own hands. Focoblocks can be purchased at a low price, but their cost will be about 30% of the cost of all construction. About the price will cost an independent construction of a garage from foam blocks, we will also tell me further.

If you want to save, then you should build a garage from foam blocks with your own hands. The price of foam blocks is one of the most accessible among materials suitable for such a task. In addition, due to the low weight of foam blocks, a significant savings on the foundation are formed. And its cost is usually a third of all construction costs. Also do not have to hire specialists and heavy equipment. In order to answer the question "How much does it cost to build a garage from foam blocks with your own hands?" It is necessary to know all the conditions of construction, namely:

- The territory of the construction, which determines the required type of foundation;

- Project features;

- Availability of observation pit;

- The need for insulation, etc.

Each project may have a lot of such nuances, and they all directly affect the prices of building a garage from foam blocks with their own hands. Video and instructions will not give you an accurate answer to the question of the cost of such construction. But exemplary benchmarks can still be called.

So you will need:

- Foam blocks. The price of wall foam blocks - approximately 2400-2900 rubles per m³. If you are planning partitions and compartments inside the garage, then the partition blocks are also needed, the price of which is 2750-2850 per m³. It is also worth considering the cost of delivery if necessary, as well as the battle of the material during transportation and work.

- The remaining materials: Cement - about 200 rubles for 50 kg, sand - about 180 rubles per m³, gravel, crushed stone - about 1150, 1190 rubles per m³, timber - from 14 rubles for the temporon meter.

"Garage of foam blocks with their own hands" - video of this character often look at those who want to save, we bring to your attention a few points that will help solve this task:

- Purchase materials in the season of reduced prices. On the whole building materials in winter make solid discounts;

- Refuse concrete floor. In the garage it is quite possible to do without a concrete base. The rammed soil filled with clay is quite enough for such a building;

- Make an economical cladding. The garage from foam blocks is quite enough to be placed in order to protect the moisture;

- Discard the observation pit. In modern conditions, it needs units of car owners who are really professionally engaged in the repair of cars.

- Save on the foundation as much as the primer allows. If possible, choose the foundation on piles or pillars.

We hope that the above-mentioned garage tips from the foam blocks will help you to build a quality, reliable and convenient garage personally for you with minimal cost!