Is it possible to make noise insulation of the car isolon. What materials are better to use for noise insulation of the car: standardplast (STP), isolon, liquid isolation, etc. Isolon laying in concrete floor

All types of production based on polyethylene foam and polyuolefins are produced under the ISOLON brand. The material is manufactured by special technology from recycled polymer raw materials by foaming. Due to unique characteristics, the isolon is universal insulation with a wide range of use. All products of the ISOLON brand are produced according to GOST.

The base of the isolon is made of elastic polyethylene foam with closed cells located at the same distance. It has high thermal insulation qualities. The thermal conductivity coefficient is 0.032-0.035 W / m · K, which is much higher than that of other insulation. The temperature of ISOLON is from -60 to + 100 ° C. It has a dense cellular surface, so weakly absorbs water - no more than 0.78%, and also protects well from steam and moisture.

Even with a small thickness, the isolon has excellent sound-proof properties, which is well suited for noise insulation. Differs high chemical stability, it does not dissolve when contact with petroleum products.

Compatible with various building materials: wooden, concrete, brick and others. It can be used in wet rooms, as it does not rot and does not overgrow mold. Isolon has a low weight, a soft and elastic structure, ease of use. All work with him can be held with your own hands, thereby saving on the installation.

Certification

Izolon produced OJSC Izhevsk Plastics Plant - a company that is the world leader in this area. Isolon is not only heat insulating material, but also hydro and vaporizolation. It produces according to the international standard ISO 9001: 2008. Isolon is an environmentally friendly material that can be operated for 80 years.

Types and scope

Used in various industrial sectors. Under the trading brand produced:

- Isolon 100 - gas-filled (notchy) polyethylene;

- Isolon 300 - chemically stitched;

- Isolon 500 - physically sewn;

- Isolontape - material covered with adhesive base from one or both sides;

- Ecoheat is a general designation of building materials based on isolon for premises repair.

Scope expands with increasing density and other insulation characteristics, also affects manufacturing method.

Calon brands 500 and 300 are used in the following cases:

- building;

- automotive;

- light and food industry;

- sports and recreation;

- domestic purpose;

- packing material;

- medicine.

Also used in maritime transport, oil and gas sector and in the manufacture of toys.

Brand 100 isol is used where it will not be exposed to loads and high temperatures. In the automotive industry, it is used as insulation and gaskets, as well as to protect against water and steam. Also often used for packaging.

Difference of the crosslied and dishetable isolon

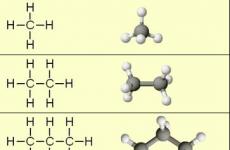

When using technologies and raw materials, various types of isolon are produced, due to which the characteristics change. ISOLON 300 and 500 are stitched, as a result, their physical, mechanical and other qualities are significantly improved. The stitching of the material changes the size of the pores when foaming. The stitched cell is 10 times less than that of standard polyethylene foam.

- The structure of Izolone 500 consists of very small cells, so it has the smallest thermal conductivity coefficient. In addition, it restores the form after deformations.

- ISOLON 300 cells are larger, therefore, according to the characteristics, the brand is inferior to the brand 500. It is less durable and not so smooth. Isolon 300 and 500 withstand the heating to + 100 ° C, and simple ISOLON 100 applies only to + 80 ° C.

- Polysto foam brand 100 does not have a stipulated structure, which is due to the technical parameters to other materials. Its cells have large sizes, so it keeps the heat worse. Even with a slight load, its structure is destroyed, it is not able to restore it. As a result, C Isolon 100 loses its heat-insulating and other characteristics. With a long load, it can completely turn into a normal film.

Stitched polyethylene foam significantly exceeds the characteristics of an unstituted material, including for service life.

Staying isolon to concrete floor

Isolon 500 is used for floor insulation, including for filling into a concrete tie. Works are carried out as follows:

- Concrete floor cleaned from old coatings, garbage and dirt.

- Climbing gaps, potholes, and also eliminate significant irregularities. The floor should not have sharp details, as they damage the insulating material.

- Cellon 500 is filling on the floor in one direction. Rolls are stacked with 10 cm. The joints are sampled so that the insulating layer turns out to be sealed. We necessarily make up the walls above the level of the fill of the concrete solution.

- The reinforced frame is stacked (metal grid).

- Pullen concrete solution.

If necessary, then by order of the client, the plant will produce polyethylene insulation, duplicated with a tissue metallized by PET films, foil, or painted in any color or make embossing. All this is possible to add antipyrin to reduce the flammability of the material.

Isolontape (Isolontile) is a self-adhesive polyethylene isolon (ISOLON). The adhesive layer serves as an ideal installation method and is a replacement for existing fastening tools to the surface. Anti-adhesive paper or film is used to protect the sticky layer during production and transport.

The compounds obtained using isolontape (isolontile) have noise insulating and damping properties, perfectly oppose vibration and shock loads. Application provides good sealing, the stability of the adhesive connection in a wide range of temperatures and good insulation qualities.

The use of self-adhesive material is recommended for the insulation of any metal surfaces: air ducts, pipelines, drying cabinets, car salons, and vans, for insulation of walls, floors, ceilings and other enclosing designs indoors for buildings of all types (residential, industrial, public) as under construction and during the reconstruction and repair of existing ones.

Advantages of adhesive tapes Isolontape (insulation):

is one of the most effective heat, hydro, vapor-and noiseolators existing today;

when installing, the integrity of the surface of the combined materials is preserved, since Do not require mounting holes;

the foamed base gives the tape the ability to take the surface shape, smoothing the defects (chips, cracks, roughness, etc.);

retains elasticity at temperatures from -80ºС to + 100ºС;

installation of parts less time-consuming and practically instant;

the line of connection of parts is invisible, which, accordingly, improves the appearance of the structure;

the adhesive tapes provide a large "shift resistance" with loads on the glued surface;

decreases the percentage of waste and marriage;

reduction of financial costs for the acquisition of hardware and tools;

racks to rotting and durable;

practically zero water absorption;

it has complete hygienic and environmental safety.

We have self-adhesive ISOLON (ISOLON) under the ISOLONTAPE brand (Izolyontip) in the following types: Isolontape 100. (ISOLON 100 Basis) Old NPE Isolontip Isolontape 500. (ISOLON 500 Basis) Old Name Isolontain PFE.

ISOLONTAPE 100 (notchy polyethylene with acrylic adhesive layer) We recommend when:

need cheap thermal insulation self-adhesive material operating without load or with minimal load;

uncritical surface quality, low mechanical strength, including compression;

requires increased heat resistance of the adhesive layer;

Not recommended to apply Isolontape 100. As a sealing and depreciation material due to the low physico-mechanical properties of Isolon 100!

Isolontape 500. (Physically crosslinked polyethylene with rubber adhesive layer) We recommend when:

needed accelerated gluing to the surface (high initial adhesion);

high mechanical strength of foam and its ability to restore shape after the load is removed (high-quality seals, shock absorbers);

high frost resistance, as well as high heat resistance of the foam base;

it requires the manufacture of functional elements from Isolontape (insulation) and high quality finishing finish.

The technological capabilities of the plant allow you to produce:

cutting on ribbons of various widths;

lamination of the base with tissues or polymer films, including metallized;

cutting on the sheets of the claimed length with 1M width;

processing by deforestation, cutting;

winding in Jamborlol with cropping or without trimming the edge.

Standard delivery is carried out in the logarls of 1m wide and the winding length from 10 to 50 meters, depending on the thickness of the base.

Packaging in a blue-colored polyethylene film. Fastening the material from spout is made by branded tape with the logo.

Isolon is a material used for insulation and noise insulation of rooms of various purposes. In use, this insulation appeared relatively recently, but for a short time, it became quite popular in construction and other fields of industry. The elastic structure of the material makes it in demand enough, so in this article we will try to consider it in more detail.

Ensure comfort and comfort in the house can be used with high-quality noise insulation. As you know, noises indoors can be two types: air and drums. In order to make sound insulation in the apartment it is necessary to choose a good insulation material that can absorb sounds and provide complete comfort. Today, the market of sound insulation materials is a huge selection of products that can be chosen in various parameters and criteria. Further comfort depends on the correctness of the choice of insulating material.

It is worth noting that all products made on the basis of polyethylene or polyhaulolafin is a product of the ISOLON brand. The production of insulation is conducted on modern equipment using a special technology. Thanks to its qualities and features, the product is considered universal insulating material, and has a large scope.

What is Coleon?

Isolon is a material with high elastic qualities and thermal insulating properties. Material made of polyethylene waste, as a result of recycling. The structure of the insulation is bubble, due to which high performance indicators are achieved. To date, this material is recognized as one of the most effective insulation. It is widely used in machine-building, automotive, and shoe industries. Also, the isolon is considered excellent heat and soundproofer for rooms of various purposes.

Production technology

Isolon Noise isolation is made with a foil base, which improves the insulating properties of the material. In addition, it can have a sticky base, which will allow without additional funds to fasten the insulation on various surfaces. The porous structure of the insulation can be used for any destination. With the use of isolon, we warm cars, houses and apartments.

Difference of the crosslied and dishetable isolon

There are two types of isolon: stitched and embroidered. The peculiarity of the second variant is that the material of the molecules structure is unrelated. In the polymer molecules there is no chemical bond, while the structure does not change in the stitched insole. When the stitching process occurs, an improved molecule is formed, cross-connected or mesh.

In simple language, the crosslinked isolon has a higher quality and respectively characteristics. The stitching process improves the thermal insulation properties of the material, as well as resistance to the effects of aggressive compositions of substances, ultraviolet radiation and precipitation.

Specifications

Isolon is made on the basis of polyethylene raw materials. The porous structure makes the product with one of the best types of heat and soundproof material. As for the coefficient of heat transfer, it is significantly higher than in other insulating materials. The operating temperature of the isolon is from -60 to +100 degrees Celsius. Due to the dense cellular surface, the insulation practically does not absorb water, which is especially good when insulating rooms with high humidity.

Interesting!It is worth noting that the isolon even if it has a small thickness, then its warmth and sound insulation qualities exceed some materials. When interacting with petroleum products does not destroy.

Isolon can be used for any type of surfaces:

- Wood slabs;

- Concrete;

- Brick;

- Metal.

Use the insulation can be in rooms with a high degree of humidity, which also adds material advantages. It is made of insulating material in rolls and plates, which allows you to choose the perfect solution. The small weight of the product and its elasticity make assembly work with simple and fast. The installed sound insulation isolon can not only protect the house or car from cold and noise, but also save money on a call to the wizard, because everything can be done independently without the involvement of specialists.

Types and scope

To date, the manufacturer provides such types of products:

- ISONOL 100 - notchy pennate;

- Iisonol 300 - chemically crosslinked;

- ISONOL 500 - sewn with physical way;

- Isolontape - the material has one or two adhesive side;

- Ecoheat - insulation personalized for works in the room.

Isolon of the brand 300 and 500 are used in most cases to work as an insulator. It is used in construction, automotive, light food industry, everyday life and medicine.

Interesting! Brand Izolone 100 can be used in cases where heavy loads and high temperature do not affect the insulation. It is perfect for noise insulation of the car.

One of the features of the material is that it can be operated at low temperatures and not lose its properties. Thanks to this quality, the isolon is often used in the automotive industry.

Due to the high resistance of moisture, it is used for metal surfaces, protecting them from corrosion formation. According to experts, C Isolon is a heater that is reliably and durablely exploited without loss of qualities. When using isolon, no care is not necessary. The material is not flammable, since when interacting with open fire decomposes into two components of water and carbon dioxide gas.

When the floors are insulated often before the fill of the liquid solution, the surface is covered with a small thickness insole. Such a substrate is not needed to protect the lower floors from the flow, but exclusively due to thermal insulation properties. The structure of the material does not absorb moisture, therefore, under bulk floor, a kind of airbag is formed, guaranteeing efficient heat and sound insulation.

Soundproofing

For the insulation of any surface, the material is necessary to decompose along the entire length and glue. If the isolan is used for internal isolation, it is important to remember that the walls should be breathed and ventilated so that the fungus and mold are not formed. Such a heater as an insulation can be used for outdoor insulation, as it is not subjected to ultraviolet exposure.

Installation work with olella is quite simple and does not require additional investment. For installation, you do not need several people and many different tools. The weight of the insulation is insignificant and it is quite possible to put himself. When installing, it is necessary to correctly calculate the parameters of the processed room to make isolation with the minimum amount of joints and seams. In addition to high thermal insulation qualities, Coleon also perfectly copes with air noise. Create perfect comfortable conditions in the house can be used by various sound and thermal insulation materials. Isolon is one of the few products, which since the appearance on the market has gained tremendous popularity.

Hello, dear car enthusiasts! When you decide that you are just necessary, the materials you go to choose in an auto shop. Naturally, specialized.

And, again, naturally, ask a question - how to choose the best material for noise insulation or what noise isolation better. I do not want to upset you, but, the best noise insulation is only in advertising. And our task is to choose correctly and the right materials for noise insulation.

After all, in essence, on the technology of manufacture, all materials for noise insulation of cars, have ± identical properties and qualities. If these are the materials for noise insulation factory, and not a frank fake.

What is needed to choose correctly and buy materials for noise insulation? Tonight! Know what happens and where certain materials for noise insulation of the car are used.

After all, the material that needs to be used for wheelproof arches does not have to be used for noise insulation of the car. So we will conduct a small excursion to the types and types of materials for the car noiseploy.

The best noise isolation of the car depends on the choice of material

SHOWISLATION STP for auto

Like everything that can be classified, the materials for car soundproofing are also divided into types that are responsible for this or that section of the work of the car. And designed to eliminate one or another type of noise.

The right choice and combination of materials for noise insulation of different types, allows you to get a practically silent car (ideally). What are these types of materials for noise insulation.

Noise absorber (noise insulation, sound absorber) - This is the type of materials that are designed to absorb the sound waves of the air. For noise insulation of the car, as a rule, the following noise absorbing materials are applied:

- Accent is one of the main materials in the line: car noise isolation materials STP (standardplast). In addition to noise insulating properties, it has such qualities as: sound expression and thermal insulation.

- Bitoplast is an excellent sealing and anti-graded material. And due to its structure, and high-quality noise absorber.

- Isolon is noise insulation with this material, in principle, does not differ from the accent. In the standardplast category, noise insulation by this material is estimated at solid "well".

Soundproofing (sound insulation) - this type of materials is fundamentally different from noise absorbs, due to its closure structure and impermeable facial film. These materials possess such qualities as: tightness and heat support. Especially effective in the presence of a foil surface.

Vibodmipfer (Vibration Isolation)- Materials designed to reduce the amplitude of the oscillations of plastic and metal surfaces of the car while driving. At the heart of all vibration insulation materials lies one principle - the viscoerocerace of the material (bitumen, foamed rubber).

The most common, are the materials:

- Bimastbom - material vibrating absorbing. The base is a fabric and bituminous composition. Foilized by aluminum film, perfectly processed with scissors.

- Bimastandard - from this series of vibration insulation materials, has the greatest elasticity. It does not require warm-up, perfectly falls on curve curvilinear surfaces. Foil coating is absent.

- Vibroplast M1 (M2) - the difference in thickness: 1.5 and 2.3 mm, respectively. Easy when installing, but has the lowest KMP (mechanical loss coefficient) for this line of materials. On the recommendations of specialists to metal surfaces it is better not to apply it.

- The visomat is a vibrating absorbing material on a bitumen basis. Self-adhesive. Positive properties: does not absorb moisture and does not decompose with time. For installation requires warming up to 50 degrees.

Pastener (anti-graded) materials - Designed to eliminate sounds that arise when contacting metal or plastic parts of the car.

Folk craftsmen as a plug-in material used to use: paralymp, carpet, even plasticine. Today there is no need for this: to select plasticine in a child. Let him learn, and you should go to the car and choose:

- Bitoplast - material based on polyurethane, with a sticky layer, 5-10mm thick. The impregnation of the material makes it: durable, waterproof, and increases sound-absorbing qualities.

- Madeline - tissue material with adhesive layer. Due to the decorative form, it can be used in an open form to process jacks between panels. Presented on the market in two colors: black and gray.

Liquid noise insulation for outdoor car treatment

Video - Materials for car noise insulation

You probably heard such names like: liquid shoes, anticorrosive, liquid noise insulation. As a rule, the materials of this group are used for the outer insulating and anti-corrosion car processing. , eg.

The outer surfaces of the car require special attention of the driver. Reasons are clear - the constant impact of the aggressive environment, especially in winter, simply burns the body of the car.

Here, in fact, in order to prevent premature wear and, at the same time, to conduct noise insulation of the car, and liquid noise insulation is used. According to the method of applying, materials are divided into: aerosol coating and "painting" (brush, spatula).

Mastic materials for noise insulation have such necessary qualities as: a wide range of use temperature, resistance to reagents, resistance to mechanical effects (it is about such quality as antigrave protection of the car).

In addition to the tasks of anti-corrosion and anti-agvine, liquid materials act as an additional noise insulation of the car.

Here, perhaps, that's all. For information and conscious choice of materials for noise insulation of the car, it is quite enough. And the properties and quality of each of the materials, you must study according to the instructions and descriptions in each case.

Comfort in the car's cabin is not only the optimal temperature and purity of the air. For many cars, the car is one of the conditions of comfort, the minimum amount of vibroshums is. Such noise may have different nature and origin and, as a rule, indicate the presence of faults in the nodes of the mechanisms.

However, even after technical inspection and eliminating all malfunctions, the car can vibrate while driving.

Most often it is caused by the low rigidity of the details of the case, because of which they begin to resonate while driving. The insulation isolon can significantly reduce the intensity of such a phenomenon and improve the conditions in the cabin for the driver and passengers.

What is isolon

This material is a foamed polyethylene, bubbles in which are filled with carbon dioxide or other gases. There are several types of this material that differ in the method of production, density, cell structure and "stitching", i.e. Ways of formation of molecular ties.

The main properties of isolon, allowing it to apply it for cars:

- Hydrophobicity and hygroscopicity. The material practically does not absorb and does not accumulate moisture, which provides additional protection for the internal surfaces of the body from corrosion.

- Hygienic and environmental purity. The material is not a source of substances harmful to health, when combustion decomposes into water and carbon dioxide.

- Durability. The service life is much higher than that of similar materials.

- Exceptional sound insulation and sound-absorbing properties.

How to find problem areas

It is possible to determine the need to perform noise insulation of the vehicle with a light tapping by body elements. The sound sound arising from this indicates that the "Problemy" place was found in need of protection.

Most often, there are some places:

- Roof;

- Doors;

- Trunk;

- Rear wings;

- Dashboard in the cabin.

The investment in the defense of these sites is the most effective in combating extra noise.

Execution of isolation

Performance starts from disassembling the cabin. It is necessary to remove all the elements of the trim to provide access to the inner surfaces of the body. At the same time, it is desirable to march the details so that it becomes everything in its place when assembling.

Especially relevant is for the dashboard to remove which, you need to turn off a large number of wires.

At the next step, a visual inspection of surfaces and their anti-corrosion treatment is carried out. Often, the inner surfaces are processed by the manufacturer of anti-corrosion composition on a fat or waxy-based basis, which can make it difficult to bone. It is also necessary to remove degreasing composition.

Next, you need to cut out and distribute the material, after which you can get to the salary. Most often, the body is curvilinear surfaces, which complicates cutting. The material has to be cut into small pieces and stick individually.

It is necessary to fit "at the place", especially when processing doors, since they are located in them the mechanisms of windows, and it is necessary to leave the workspace for them.

Before sticking, the insole should be heated with a hairdryer to improve elasticity and adjustment. The use of isolon for noise insulation of the car gives good results when combining it with a vibroplast, which is applied to open metal surfaces.

The "sandwich" resulting in this way will be excellent vibration defense due to the fact that the number of media is increasing, which make it difficult to pass the sound and the spread of vibration. After the end of processing the parts of the cabin are installed in place.