Coating tracks: safety and durability. Design for sport games. Running track track track which standards should answer treadmills

Figure 6. Construction of a tagging athletics track: 1-waterproof primer base; 2-sand drainage layer; 3 Base of limestone rubble size up to 40mm; 4-intermediate layer of boiler slag (fraction 20-60 mm); 5-elastic-moisture interlayer of fibrous peat; 6 - coating of a special mixture; 7-filtering sprung; 8-tube drainage

The natural base of the track design serves bulk waterproof soils, so therefore it has been specially paid to the organization of drainage from the surface and from the strata of the structure. In the base of the track was laid a drainage layer of coarse-grained sand with a thickness of 20cm, and a tubular drainage with a solid filtering spray was arranged under the inner heating.

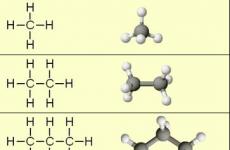

Base material - crushed the crystal limestone The size of up to 100 mm,intermediate layers - boiler slag and fibrous brown peat. The coating is made of a special mixture based on ground ceramics. Both browing treadmill Made of precast concrete elements of 25x6x 100 cm,installed on the preparation of skinny concrete.

If the drainage layer of sand, shells, slag, etc. is satisfied with the layer of thickness of more than 10 cm, the base power can be reduced to 5-8 cm due to the swelling of it from the rubble of soft stone rocks. It should be avoided by the redemption of the base during the Retail.

The elasticity of the design can be increased by the replacement of part of the slag layer by the sawing-pyrite mixture with a layer with a thickness of 10-12 cm.

The construction of the attachment of prefabricated elements of the browing should ensure the unhindered flow of surface water in the drain - drain, for which the width of the concrete base under the browing should not exceed 10-12 cm. It is also possible to mount the reinforced concrete block, like the structures of wooden rods on the "jacket", with the execution of supports-supports from concrete and an increase in the length of the prefab elements of the browch to 2-2.5 m.

Figure 7: Treadmill Design: 1 - Brick Crushed, fractions 40-70 mm: 2-range slag, fractions 20-30 mm (80%) + clay chamotone lump (20%); 3 fine-grained slag, fractions up to 12 mm (70% - loam (30%), 4-bauxite crushed, fractions 1-10 mm (75%) + threatened shaft 1-10 mm (25%); 5-bauxite crushed, fractions 0-3 mm (60%) + chamotte clay (20%) + tiled flour (20%); 6 - powder of finely divided chamotte clay with a puff.

Treadmill (Fig. 7). The base of the track is arranged from crushed brick (fractions 40-70 mm) laid on a planned and rolled ground base. The base thickness is from 12 cm in an outer brought to 20 cm in the inner, due to the lowering of the bottom of the trough of about 0.01. Two intermediate layers of a total thickness of 13.5 cm are laid on the base. The first intermediate layer is made with a thickness of 8 cm from the mixture of slag of 20-30 mm with clay, in the proportion of 4: 1. The second intermediate layer with a thickness of 5.5 cm is made of a mixture of fine-grained slag. The size of up to 12 mm and the Suglinka in proportion 7: 3 The coating is made up of three layers of a special mixture. A total thickness of 5 cm (including surface processing).

When creating a training facility, special attention is paid to sports coverage of treadmills. The safety of athletes depends on its quality and physical properties. Most often at open and closed stadiums, rubber coatings for treadmills are installed. They differ in a number of positive properties:

- good amortization;

- trauma safety;

- the optimal ratio of stiffness and elasticity;

- wear resistance;

- the possibility of fast repair.

Additional requirements are presented to sports coverages that are installed in open stadiums. The material should be well tolerating the temperature differences, atmospheric precipitations.

Popular types of cooping and stadiums

All modern sports coverage for stadiums are classified for a number of criteria:

- for its intended purpose - for open or closed sports grounds;

- by way of laying - bulk or modular coatings;

- in appearance - natural or artificial.

Often the owners of sports complexes prefer synthetic coatings for treadmills. They differ in durability and wear resistance. You can engage in a rubber treadmill in studded shoes - even frequent workouts will not affect the appearance of the coating. It is easy to care for the surface of the track, and the planned or unscheduled repair is not poured into a round sum.

Rubber Crumb Treadmill Design

CRUMB SP is one of the popular coating for athletics tracks.

It has a wide area of \u200b\u200bapplication - from small school stadiums to professional running complexes. Stalling tolerates various types of mechanical impacts, including frequent workouts in studded shoes.

The coating consists of two layers. The first layer is a mixture of two-component polyurethane and a black rubber crumb. The surface is extremely elastic and elastic, independently aligns after mechanical influences. The second layer is a sprayed mixture of two-component polyurethane and colored rubber crumbs. Applied by a special airless spraying apparatus.

Rubber coatings for running have a number of advantages, among whom it is worth noting:

- when creating a coating, only high-quality materials that are certified are used;

- the surface of the treadmill differs in uniformity, has the same thickness;

- even after a few years of operation, the material retains initial elasticity;

- the composition of the coatings includes materials safe to human health;

- material for treadmills is resistant to abrasion;

- the coating with the addition of rubber is suitable for open stadiums located in the regions with a harsh climate - severe precipitation, sharp temperature differences, etc.;

- rubber tracks for running quickly fit, and during the installation process you need a minimum set of tools and consumables;

- repair of the coating is carried out quickly - a patch is put on the sword surface, and the base is not affected.

Another important plus of rubber coating for running is the low value of the material. This factor is fundamental to the owners of large stadiums and sports complexes.

Disadvantages of rubber treadmills

As with any other material, rubber coatings have weaknesses. A tangible disadvantage is a loss of color. After 2-3 years, the treadmills in open stadiums become dull, and the markup in some places is erased.

The problem is solved simply - applying a new layer of special paint on the surface. After cosmetic repair, running tracks will be like new ones. One of the types of coating, a bulk professional coating for treadmills, repaired a little more complicated, it is necessary to apply a new layer of mastic and pour the coating with a rubber crumb, and then apply markup.

Do not forget about compliance with fire safety requirements. In addition, rubber coatings have no flaws.

When creating an athlete sports complex to train athletes, a number of requirements and recommendations must be taken into account. They can be learned from the list of standards of the International Association. In accordance with this document, the length of the treadmill should be 400 meters. The width of the working area on which the athlete runs is 1.22 m. The number of tracks varies depending on the type of object - they can be both 4-5 and all 8. The last figure is relevant for stadiums on which international competitions are held.

The inner part of the track is required to be equipped with an eyebrow, the dimensions of which are strictly regulated - 5x5 cm. Between the tracks there is a small markup - a white line of a width of 5 cm. A compulsory requirement is the presence of a slope directed into the inner side of the track.

Before laying a rubber coating for treadmills, it is necessary to build a drainage system. It consists of polymer concrete channels and plastic covers. The drainage system does not accumulate moisture at the training ground, which prevents the likelihood of injuries among athletes.

The International Association also places a number of requirements to the coverage. Surfaces must comply with IAAF standards - to be durable, low-spirited, non-slip and injuries. Such requirements correspond to modern coatings of rubber and polyurethane.

Covers for treadmills are rolled and seamless. In the first case, the specialists cut the material with slices of a certain length and widths, fixed on a concrete or asphalt base. A bulk laying method, which specializes in CP-SS, more technologically. After installation, a monolithic smooth surface is formed, on which there are no seams and height drops. The life of the seamless coating is at least 10 years.

Regardless of the selected type of coating, it is necessary to know about the requirements for the base. Synthetic materials are stacked on a flat surface of asphalt concrete. The base thickness is calculated depending on the type and structure of the upper coating.

Sizes of treadmills

A number of requirements are also for the sizes of treadmills. On the standard open athletics stadium make an oval track, the length of which does not exceed 400 meters. The track is divided into 8-10 sections for running, complemented by sectors for competitions in the jumps and throwing items. Sectors for jumping and throwing are usually located at the corners of the stadium. Shells should fall into the field area with a ground coating (to reduce the rebound). Often an athletic stadium is combined with a football field.

The circular treadmill is characterized by smooth the same turns, is a closed circuit. Straight tracks - segments on the field with limited length (about 130 meters).

In stadiums where international competitions are held, 8 circular and 10 straight cross tracks should be made. For other sports facilities, this amount decreases to 6. The width of each track must be at least 125 cm. Between the tracks, it is necessary to apply a white bounding line - 5 cm wide.

The surface of the treadmill must be perfectly smooth, without slopes. As a coating, such materials such as Tartan, regus, recorded can be used. The tracks are drawing on the tracks: the finish line and start line for all distances, the boundaries of the transmission zones in the relay run, the line of the pre-site construction, etc.

If competitions on running with obstacles are held on the athletics stadium, then portable barriers are installed at certain points. Their frame is made of light metal alloy, and the crossbar is made of wood. The barrier must be equipped with a crossbar height adjustment system.

Our company is engaged in styling professional coatings on sports facilities of different types - football fields, tennis courts, treadmills, basketball courts. At the request of the customer, we carry out a complete set of stadium - we put markings, install special equipment, fences and lighting devices. The object is crossed in the period specified in the contract, after which the athletes can begin to prepare for competitions.

The sequence of work on laying

Modern rubber coatings for sports facilities are characterized by high installation speed and impressive physical properties. Between the sheets of the material does not form seams, and the surface itself does not pass water, resistant to abrasion. During running, the slip effect is not created, which significantly reduces the risk of injury among athletes.

Sports coatings for treadmills are manufactured in several colors. The coating can be monophonic or multi-colored. The shade is selected taking into account the comfortable visual perception of athletes.

The process of laying rubber coatings on the sports belt can be divided into the following steps:

- Preparation of the foundation. Rubber coatings are mounted on a concrete or asphalt base. The service life of the coatings for running depends on its quality. Concrete thickness should be at least 8-10 cm; Asphalt - 5 cm. On open areas, it is necessary to make a small bias - 1% - so that water is not accumulated on the tracks after the rain or snow. On the perimeter of the object it is desirable to install borders.

- Surface primer. The special composition applied to the base of the sports ground will provide better fixation of the rubber coating.

- Zam and laying raw materials. In a large container installed on the object, a rubber crumb with a polyurethane binder composition and a resistant dye mixed. Mixer mass is brought to a homogeneous state. The billet is then applied to the base - the laying of the coating is carried out by hand with graters or using special equipment. To give strength, the surface is rumped with a rink. All equipment and tools are processed by a chipidar so that the rubber crumb will be peeled during the stacking.

- Application. When the surface of the treadmill is ready, the sports markup is applied to it.

Conduct training at the new sports ground can already after a few days after the rubber coating is mounted. During this time, the surface will have enough hardness to acquire. On the timing of the polymerization of the coating tracks, the temperature and humidity of the air affect.

For rubber coatings on open and closed sports equipment just to care for. From the surface, any contamination is easily removed, after which the treadmills become new. However, it is necessary to remember a number of requirements for rubber coating requirements.

- Rubber coating for running should be protected from paints, solvents, acids, machine oil.

- The surface of the treadmill does not withstand long-term heavy heating and open-fire contact.

- Finding or trash can not be removed from cross-country tracks with sharp and solid objects. Otherwise, you will have to carry out partial repair of the coating for running.

Dust and dirt accumulated on the surface of the rubber coating are rapidly removed by water from the hose. Use additionally means for cleaning is not needed.

Assessment of the state of the coating of the sports belt and determination of the feasibility of repairAt this stage, experts determine the type and scale of damage - the cracks measure, find the zones of bundle and scattering the coating, determine the area of \u200b\u200bswollen surfaces. All damage is applied on the paper scheme of the stadium. Specialists necessarily assess adhesion - the degree of clutch of two different surfaces - before restoration of the coating. For this purpose, a number of tests are made, the results of which allow you to calculate the exact amount of material necessary for the repair of the coating. It is also carried out and an assessment of the state of the foundation, because in some cases it also requires repair. The final decision on the repair or complete coating is received by the customer.

Repair of damageWhen repairing the coating, damaged places are cut and replaced with similar materials with the corresponding existing surface.

Restoration of color and repair of the entire surface of the treadmillThe coating of the stadium, which needs to be repaired, is cleaned of contamination, degreases with special compositions, under high pressure. Sometimes it is necessary to carry a grinding of the treadmill.

Damaged areas are removed, and their locations are installed on their place with the same physical properties. In addition, specialists can apply a new layer of material on an old surface. Before working with the customer, the type of material, the method of application, cost is consistent.

Application markupAt the renovated surface, experts apply sports markup. The procedure is carried out using special equipment.

Treadmill at the stadium - This is a mandatory attribute, without which it is difficult to imagine a modern sports facility. It is the tracks that have quite large loads in the process of operation, so it is important not just to cover them with gravel, but to make the most comfortable and safe surface. Do not forget that the treadmills can be laid in pedestrian zones, a forest park strip, in the courtyards of residential complexes.

What standards should the treadmill be answered?

Seamless rubber coating for treadmill

Cover Sport Economy - (analog Elastur) Waterproof, bottom layer - 10 mm (used black bus SBR fraction 2-4 mm fraction), and the top layer 2-3 mm (used black bus SBR fraction 1-2 mm fraction), stacked with using sprayer for rubber crumb

Cover Sport Base - The first layer is 10 mm (used black tire SBR and EPDM colored crumb of fraction 2-4 mm), and the second 2-3 mm (with a sprayer, polyurethane glue and pigment dye are applied)

Cover Sport Standard - 10 mm + 2-3 mm EPDM is done using a sprayer

Cover Sport Mix - 10 mm Black with EPDM + 2-3 mm EPDM, laid by sprayer

COVER SPORT PLUS (coating elastur treadmill) - 10 mm EPDM + 2-3 mm EPDM is applied using a sprayer

Repair of treadmills - Our company is engaged in the repair of seamless rubber coating as well, if necessary, the spoiled part is replaced by a new one. We will make high quality and on time.

Options for cross-country tracks: price and characteristics

| Name | units. change | Price for EDRUB. | Characteristic |

| Seamless rubber coating | m2. | 600 rubles. |

|

| Seamless rubber coating | m2. | 900 rub. |

|

| Seamless rubber coating | m2. | 1150 rub. |

|

| Rubber Coating Cover from EPDM crumb |

m2. | 1300 rub. |

|

| Sandwich two-layer coating | m2. | 1700 rub. |

|

| Sandwich coating | m2. | 2000 rubles. |

|

Different with high-tech equipment. At the device of stadiums, first of all pay attention to the correspondence of the size, markup and coating tracks standards from them directly depend on the results of athletes.

Treadmill

Constructions for sports under the open sky are usually universal. The center usually arrange a soccer field. It is surrounded by tribunes, treadmills. There are fields designed exclusively for athletic sports. Then in the center there are specially placed platforms for throwing a disc, hammer, spears, long jump, height, with a pole.

When erecting this kind of objects, the stadium treadmills is covered in the first place. In fact, the latter are a separate sports facility. It is intended for training and holding competitions on running (including barriers) and walking. The tracks are equipped on a flat horizontal surface, the edge is framed by side. They are rounded from above, their height does not exceed 3 cm.

The coating tracks should have high wear resistance, good depreciation properties, having a flat surface without joints, ensure efficient adhesion with the shoes of athletes, do not change its properties even after strong moisturizing (rain). The treadmill consists of 4-9 individual strips. Standard width - 122 cm, it also includes 5 cm markup. The minimum length is straight - 400 meters.

A bit of history

At the end of the XIX century, the surface of sports tracks at the Olympic Games was a mixture of sand and clay. In rainy weather, the stability of supports on them was unsatisfactory. In 1903, it was developed to have withstood adverse weather, but because of its hardness did not find widespread use.

A year later at the Olympics at the Stadium of the city of St. Louis (USA), a garment path was tested. The porous material made it possible to conduct competitions with small precipitation, quickly absorbing moisture. An explicit advantage was elasticity and good clutch with shoes of athletes. The garlase coating was used for many decades. About her there are lines in the song V. Vysotsky "Marathon": "I run, run, trash, gliding on the babes."

With a strong humidity, the garpa surface became unsuitable for use, in addition, considerable efforts and financial costs for care and repair were required. Other options for covering treadmills were developed. In 1912, a stone-wooden mixture appeared, waterproof, softer compared to asphalt, but short-lived. Later, the English company "Rubbub" suggested leaf rubber with water-conductive holes. It was a real breakthrough. One of the other began to appear more modern coatings based on latex or bitumen. They tied the cork, sand, rubber crumb and other materials.

Views

Surfaces can differ significantly. Conditionally, they are divided into the following groups:

- professional;

- semi-professional;

- for mass sports.

The first two groups of structures usually have rubber or synthetic treadmill. The main difference is as, the number of layers and their filling, the method of laying, the color scheme. Professional necessarily have a IAAF certificate and withstand the load when using studded shoes.

In publicly available places for fans of an active lifestyle for treadmills use:

- Gare or coke coatings. They are water permeable, require regular care.

- Asphalt or asphalteriesin - durable, rather rigid, do not let the water, do not require additional care.

Both options do not differ elasticity, with long-term classes can lead to injuries. Today, architects are laying modern, safer coating people in their projects.

Rubber cover

Rubber coating tracks are most in demand. The amount of glue, the size of the crumb, the proportion of mixing - characteristics, in accordance with which coatings are divided into two types:

- moisture-permeable;

- non-water.

They are classified by the number of layers:

- single-layer;

- multilayer.

Of the advantages you can select the following:

- convenience and comfort for athletes;

- excellent performance;

- selection of the desired color;

- trauma safety;

- environmental friendliness;

- excellent noise insulation;

- attractive appearance;

- simple care;

- the ability to restore the surface during damage;

- universality use.

Options for laying

Any coating is placed on the prepared platform. The soil must have a maximum smooth surface. The track itself is a peculiar design consisting of several layers:

- natural base;

- gravel layer;

- concrete or asphalt;

- glue;

- shock absorbing lining;

- finish layer.

The top layer is mounted in several ways:

- It can be bulk - all components are mixed directly at the place of installation.

- By laying mats, usually with a size of 120 x 100 cm;

- Rolls.

Leading world manufacturers of modern crossing tracks use environmentally friendly and high-quality materials. They must meet the following requirements:

- Have increased wear resistance, to withstand a long-term load under the studded shoes, adverse climatic conditions.

- Be safe to have the optimal coefficient of stiffness and elasticity.

- Be comfortable and reliable, to ensure good grip with the surface of the shoes of athletes even in rainy weather.

- Do not burn out in the sun, have an attractive appearance. Today manufacturers offer a variety of color solutions.

- Do not pass water.

- Do not require special care.

- Answer IAAF standards.

The arrangement of an open type sports facility is even today is one of the most complex construction tasks. Despite the fact that many modern materials are superbly opposed to environmental impacts, their properties are not enough to satisfy all the needs of the regulatory sports committee. In particular, we are talking about creating cross-country tracks, which always apply special requirements to the operational characteristics. Concrete or asphalt mixtures can not be used in this case, as their structure is too tough. At the same time, more pliable materials cannot provide the necessary wear resistance. Fortunately, the solution to the problem was the relatively affordable multilayer coating for treadmills based on the regulatory technology.

Coating tracks: features and advantages of a multi-layer structure

In essence, such a decision can be perceived as a single solid composite structure, each of which is performed by its special function. The regulatory material itself serves as a reliable basis for the impacts rendered to the upper layers. Next, the polyurethane layer is superimposed on it, which serves as a guarantee of the durability of the track. The upper part of the final structure is covered by the EPDM crumb of a large fraction in order to give the track the desired completion, as well as ensure the best grip of the treadmate with the athletes sole.

A distinctive feature of this integrated solution is that it is not necessary to implement much of the resources. And this is quite accessible to any construction company. It is also impossible not to note the environmental friendliness of each of the materials used. Neither separately, nor in aggregate, they do not pose a threat to life and human health. In addition, no harm to the environment is not applied.

Treadmills: Safety and Durability

The use of such an approach when organizing stadiums and individual treadmills is justified by the fact that on the one hand, the finish coating turns out to be sufficiently rigid. Thanks to this, it becomes possible to perform various athletic exercises. However, the presence of elastic components allows you to get quite good depreciation qualities, damping the strength of the blow when falling. Thus, the traumatic safety of the entire object is significantly reduced, which is the main requirement of controlling organizations.

Specialists of our company are ready to provide you with any informational support for the acquisition and use of materials used to organize treadmills of this type.