Courtyard cutting brick scheme. Brick stove laying schemes. Furnace drawing, where its overall dimensions are indicated

There are a large number of diverse furnaces that can serve both for heating and for heating at home and cooking. Some are quite voluminous and massive, others are compact, and for a particular room, the desired option is selected, which will be most effective for this area. In addition, any of the furnaces should be established with the obligatory accounting of the requirements developed by experts according to SNiP 41-01-2003.

In the contemporary information space, brick furnaces for the house drawings can always be found on the Internet. However, it is necessary to remember that it is quite difficult to build this structure, since each kinder has its own developments and professional secrets that are purchased only with experience.

Criteria for selecting a brick oven

If it is still decided to make such a job independently, then it is necessary to decide on the model - with knowledge of the case, turning attention not only to the appearance and design of the furnace, but also on its heating abilities in relation to the room that it will have to dump.

When choosing a furnace in size, it should be borne in mind that its lateral walls give more heat than the front and rear. This factor must be foreseen by planning the installation of the stove in one location.

The furnaces are divided not only by functionality, but in its form. They can be rectangular, T-shaped, with a protrusion in the form of a bed or kitchen stove and others.

The furnaces can only be used for heating residential rooms and installed, for example, between the living room and the bedroom, perform several functions and serve as a separation wall between the living rooms and the kitchen.

For premises with a small area, you should not choose too massive buildings. Although many of them are multifunctional, but it will take too much useful places that can be used for other needs.

Naturally, the location of the heated room in the house also plays a major role, as well as the degree of insulation of the entire building.

Furnace selection table depending on from the area of \u200b\u200bthe area and the location of the rooms:

| Room Square, m² | Furnace surface, m² | |||

|---|---|---|---|---|

| Not an angular room inside the house | Single angle room | Outdoor room | Parishion | |

| 8 | 1.25 | 1.95 | 2.1 | 3.4 |

| 10 | 1.5 | 2.4 | 2.6 | 4.5 |

| 15 | 2.3 | 3.4 | 3.9 | 6 |

| 20 | 3.2 | 4.2 | 4.6 | - |

| 25 | 4.6 | 6.9 | 7.8 | - |

All these criteria should be predetermined in advance, and, based on them, you should make a choice in favor of one or another model.

Types of brick furnaces

As mentioned above, the design of the furnaces can be different - and very difficult to build, and quite simple. The most famous of the models is the "Holland", "Swedie", "Russian". Modifications called the names of their designers are widely popular. So, the kukov, Podgorodnikova, Kuznetsova and other masters are very common.

- There are heating furnaces that do not have a hob and other elements, and consist only from the walls in which chimney channels, fireboxes, puff and cleaning chambers pass.

- Heating and cooking furnaces have a stove in their design for cooking, sometimes oven, water tank and drying chamber.

- Another type of heating is a furnace-fireplace, which has two fireboxes in its design - fireplace and furnace. This model can be used by flashing only one of the furnaces or both at the same time.

- There are also furnaces that include the entire complex necessary for human life in both the summer and in the winter. Often they are equipped with a heated bed, which can well serve as the basis for the bed.

You may be interested in information about what is

Prices for ready-made heating furnaces

heating furnaces

Choosing a place to install the furnace

It is important to envisage and the right place to install the furnace. The optimal place is to cross the walls of the house. If it does not have a large area, then such a stove can heat all the rooms at the same time. It is desirable that the structure is not far from the entrance to the building, since the heat coming from it will create an obstacle for cold air coming from the entrance door. In addition, if the firebox door goes to the hallway, it is easier to deliver fuel to it, without bringing it through the whole house.

When choosing a place, you need to take into account several other factors that are important for the operation of the furnace:

- The structure must be established in such a way that there is free access to any of its walls - it is necessary to take into account for unhindered monitoring of the integrity of the walls and for cleaning the cameras.

- When erecting the furnace, it is necessary to provide a separate foundation for it, not connected to the base of the house.

- The chimney tube should pass between the beams of the attic overlap and do not stumble upon them when it is raised - it is provided for the construction of the house, and if the furnace is built in the finished building, then before booking the foundation for it.

- For fire safety, on the floor, the heat-resistant flooring from a metal sheet or ceramic tile must be located on the floor before the furnace door.

Basic Brick Furnace Design

To know how each of the furnace elements works, and for which it is intended, it is necessary to consider the basic design of the heating structure:

- The fuel chamber is designed for laying and burning fuel. It is separated from the underdener chamber with a grate grid and is connected to the inner channels, which follows smoke and hot gases through the entire oven, redirecting to the chimney pipe.

- A configuration chamber provides an adjustable air supply to the furnace and is a collection of ash from burnt fuel, so it requires periodic cleaning.

- The oven, the cooktop and the water heating tank - these elements are embedded in the heating and cooking furnaces.

- Claimed cameras are needed, as they are assembled in them, which crepts from the walls of chimney channels passing inside the furnace. Using them, periodic furnace cleaning is performed to maintain normal traction.

- Smoking channels passing inside the furnace can have a different configuration in different models. Hot gaseous combustion products, passing along them, heats the walls of the furnace, which give heat into the room.

- Channels are sent smoke with combustion products into the chimney pipe located at the very top of the furnace and then the outward building.

One of the most important conditions for the effective work of the furnace is a good thrust, which is achieved by high-quality masonry in compliance with the scheme-order and periodic cleaning in the construction during operation. In addition, it is necessary to observe the necessary height of the chimney pipe and its proper location on the roof.

Perhaps you will be interested in information about why

Materials for building oven

An important issue for the durable functioning of the furnace is the choice of high-quality materials for its masonry, therefore it is not worth saving on them. For the construction of the structure, it will be necessary:

- Red refractory brick, the amount of which is determined by the selected model. It must be remembered that this material is quite fragile, so its transportation and unloading should be carried out extremely neat.

- Chamotte brick is used to masonry the heat chamber directly in contact with fire. It will be required from 40 to 200 pieces, but the exact amount can be found from the schema of the selected model. This kind of brick is able to withstand the temperature of 1450-1500 °, it holds heat for a long time, gradually giving it the walls of the furnace.

- Do not do in lifting the furnace and without a solution for masonry brick, which is made on the basis of clay. Pechskens advise to apply the Borovichevsky composition of the solution - it is enough plastic in the process of masonry and refractory during operation.

- Cast iron elements are the doors for firebox, pondered and sewage chambers, valves and grate. If the heating and cooking furnace rises, then it will be necessary one- or two-competophoic Plate, oven and water heating tank provided by construction.

- Steel wire for fastening cast iron elements in masonry.

- Asbestos cord or sheet - for laying between brick and metal details.

You may be interested in information about making a cast iron furnace

Now, having become acquainted with some nuances of the construction of the furnace, you can consider several models that should be available for masonry even beginners.

Heating furnace V. Bykov

This furnace is designed only for heating, as it does not provide for installing a plate or oven. However, despite this, it is quite popular for homes having a small area, as it is compact - takes little space, but at the same time there are even three rooms.

The structure of the structure is 510 × 1400 mm, when it is height without a pipe in 2150 mm. If you take a size in bricks, then it is 2 × 5½ bricks.

The furnace is quite simple in the masonry, as it does not have complex internal configurations. On the appearance, it generally resembles a thick wall, so the designer himself called it a "thick warm wall". The heat transfer from the entire structure is 2400 kcal / h, but at the same time the side walls account for 920 kcal / h, and on the front and rear part of only 280 kcal / h. The cross-section of the chimney channel is 130 × 260 mm.

Thanks to its small width, the furnace fits perfectly between two rooms, leaving the front part to the third, for example, to the hallway, and is not only a separator for two rooms, but also a heat source for them.

The entire design of this model is divided conditionally into two compartments - this is the upper gas feeding and the lower - heat. Two channels pass on the lower part - ascending and downward. They help heat the fuel part of the furnace and level the temperature throughout the structure, preventing overheating.

The upper part of the furnace is made in the form of a cap, divided, on five vertical, descending and upstream channels, which are overlapped with horizontally laid in the masonry bricks. They create a kind of sieve, a delayed heat outlet directly into the pipe. The walls of the channels not only direct the heated air in the desired direction, but also significantly increase the inner surface area of \u200b\u200bthe furnace. These factors increase the efficiency of the heating structure, which leads to greater heat transfer. It also contributes to the valve installed in the upper part, which regulates the output of warm air into the pipe.

For this model, the furnace will need the following materials:

- Red refractory brick - 407 pcs.

- White Chamotte Brick Sha -8 — 197 pcs.

- Machine door 210 × 250 mm - 1 pc.

- Doors of cleaning 140 × 140 mm - 2 pcs.

- Gearing grille 250 × 252 mm -1 pcs.

- Smoking gate 130 × 250 mm -1 pcs.

- Metal sheet for I flooring before furnace, 500 × 700 mm -1 pcs., Instead of a leaf, ceramic tile can be laid.

Prices for ready-made fireboxes for brick stoves

Brick stoves

Furnace coach Bykova

The furnace laying occurs on the foundation prepared for it, which must be the size of a greater base of the furnace 100 ÷ 120 mm in each direction. The foundation in height should be lower than the first floor for two rows of masonry. Before the start of the masonry, it will be supplied by a layer of waterproofing - rubberoid.

| Order | Description of work |

|---|---|

| According to this scheme, two zero rows are represented, which are below the level of the first floor. For each of the rows, 22 red bricks will be required. |

| Masonry located at one level with a clean floor, as well as a metal sheet mounted before furnace. The surface of the floor around the furnace is facing the heat-resistant ceramic tiles. |

| 1 row - a subdivile camera is formed. At the entrance to it, an armful brick is installed, which makes it easier to select the combustion waste. For the masonry of this row, 21 bricks need. |

| 2 row - when it is masonry, the door is installed attended and the camera itself continues to form. For the masonry of this row, 20 bricks will be required. |

| 3 row - a subdivile camera continues to form. The wire, fixed on the door of the door, is inserted into the laying seams. For a row, 19 whole bricks will need and 2 by ⅓ bricks, which are stacked near the installed door. |

| 4 row - bricks overlap the front of the subdivile chamber together with the door installed. In the rear of the design, the base of the swivel well begins to form. On this row will take 12 integers, 6 in ¾ and 2 in ½ bricks. |

| 5 row - the base of the fuel chamber is formed above the subdivinal chamber of chamotte brick. In the front and rear part of the base, crane bricks are stacked, for which burning waste will be slipped into an agolate-infideling chamber through a grate installed on the same row. Between it and bricks should necessarily be leaving a 5 mm gap. The fuel chamber door is mounted on the same row. 17 will need 17 and two bricks. |

| 6 row - the walls of the fuel chamber begin to form, the chimney of the well continues to be laid out. 11 pieces of chamotte brick are used. |

| 7 row - the chimney the well is divided into two bricks. Bricks over the wells must be stesany. As a result of the masonry, the base of two vertical channels is formed - ascending and downward. In this row, 11 integers are used, 2 in ½ and 4 cut sliced \u200b\u200bacross the entire width of chamotte bricks. |

| 8 row stacked according to the scheme, repeating the previous one, the difference is only the direction of the brick. 15 bricks will go to a row. |

| 9 row - two bricks overlap the fuel chamber door. This series will require 16 chamotte bricks. The back of the furnace is placed according to the scheme. |

| 10 row - bricks fit according to the scheme in compliance with their direction. On this series you need 16 bricks. |

| 11 A row - brick on the back wall of the furnace and at the entrance to the drop-down channel should be stanese from above, otherwise the work is carried out according to the scheme. The range will require 12 integers, 2 in ½ and 4 in ¾ chamotte bricks. |

| 12 row - there is a union of the falling chimney channel and the fuel chamber. For a number you need 13 integers and 2 in ½ chamotte bricks. |

| 13 row is placed, according to the presented scheme, and it uses 10 integers, 2 in ½ and 4 in ¾ chamotte bricks. |

| 14 row also stacked according to the scheme, 10 integers will be required and 6 in the brick. |

| 15 row - using prepared bricks, size ¾, the narrowing of the fuel chamber is arranged, combined with a downward channel. The total number of used bricks 7 and 14 pieces in ¾. |

| 16 row - bricks completely overlap the combined downstream channel and fuel chamber. This and the next row divide the structure into two parts - the gas-air top and fuel lower. For a number used 17 integers, 4 in ¾ and 2 in ½ bricks. |

| 17 A row is laid out of red bricks. It is left in the opening of the upward channel, the crashing bricks are mounted in its edges. 14 integers are used, 6 in ¾ and 2 in ½ bricks. |

| 18 row - a horizontal furnace channel is formed, it is the basis for mounting five channels that will go vertically. On the same row, the door of the clear chamber is installed. For a number, 8 integers are needed, 2 - ½, 2 - ¼ and 4 in the brick. |

| 19 row - there is a formation of the first vertical channel, the upper part of the structure. It will be a continuation of the rising channel of the lower furnace. Bricks forming this channel, you need to take a distance from the bottom. 11 and 4 in the brick are used. |

| 20 row - the second vertical channel begins to form in the same way as the first. Between the first and second channels, Polikirpich is mounted. This part in this row and in the following has a double purpose - is the basis for the next row and forms in the laying of the windows for heat exchange with walls and maintaining normal thrust. In the row used 7 integers, 3 in ½ and 8 in the brick. |

| 21 row - the third, fourth and fifth channels are formed in it. Bricks stacked in the base of separating wall channels, shut down, as in previous cases. For a number, you will need 11 integers, 5 in ½ and 4 in the brick. |

| 22 row is placed according to the scheme with compliance with the formation of channels. For a number you need 11 integers and 4 pieces of ½ and ¾ bricks, a total of 17 pieces. |

| 23 row is also placed according to the scheme and it is necessary to prepare 12 integers for it, 4 in ½ and 4 in the brick. |

| 24 row - the wall laying is completed on this row between the second and first vertical channels. The upper brick in the wall is shy away from the two top sides of the male. For a number it will take 9 integers, 3 in ½ and 8 in the brick. In total, it is necessary to use 18 bricks, some of which are divided in two. |

| 25 row - the wall laying between the second and third vertical channels is completed. The upper brick in the wall is shy on both sides. For masonry, 10 integers will be required, 4 in ¾ and 5 in ½ bricks. |

| 26 row - completion of the wall masonry between the third and fourth vertical channels. The top brick wall is also shuffling on both sides. It is necessary to prepare 10 integers, 4 in ¾ and 4 in ½ bricks. |

| 27 row - work follows according to the scheme, and it requires 9 integers, 4 in ¾ and 4 in ½ bricks. |

| 28 row - It uses bricks made in ¾ from whole bricks - they form a horizontal channel for flue gases, which is called the cap. For a number, 4 integers are used, 14 pieces - ¾, 4 crane spacing throughout the thickness. |

| 29 row - in it the channel formed in the previous row is completely overlap, except for the opening left for the chimney pipe. For its masonry, 17 integers will be required, 4 - ¾ and 2- ½ bricks. |

| 30 row is also laid out solid, according to the scheme, except for the discharge for the chimney. It uses 6 integers and 20 V ¾ bricks. |

| 31 row is laid out according to the scheme and for it is prepared by 17 integers, 4 in ¾ and 2 in ½ bricks. |

| 32 row - the first series of chimney pipe begins to be laid out, it will take 5 whole bricks for it. |

Furnace-fireplace "Swedie" A. Ryazankina

Positively popular, thanks to its effectiveness, the heating and cooking furnace of the Swedish type. Its design contributes to the rapid heating of the premises and allows not only to drop the house, but also prepare lunch.

Appearance "Swedish" Ryazankina

Such a furnace is usually installed between the kitchen and the residential area of \u200b\u200bthe house, having it in such a way that the cooking plate and oven are turned toward the kitchen. In some designs, "Swedish" from the side intended for heating the living room or bedroom, a fireplace is provided. It is this option that it is worth considering, as it is perfect for both spacious and small build, and, as you know, many owners of private houses dream of a fireplace in one of the living rooms.

This furnace model is heated with firewood, has a size of 1020 × 890 mm around the perimeter and 2170 mm in height without taking into account the pipe. It should also be envisaged that the portal of the fireplace will act beyond the structure of 130 mm. The foundation should be larger than the base of the furnace and be 1040 × 1020. The power of "Swedes" reaches 3000 kcal / hour.

For the construction of this model, the following materials will be required:

- Red Brick, excluding pipe masonry - 714 pcs.

- Standing door 140 × 140 mm - 1 pc.

- Door for the furnace chamber 210 × 250 mm - 1 pc.

- Door for clean cameras 140 × 140 mm - 8 pcs.

- Okrug cabinet 450 × 360 × 300 mm - 1 pc.

- Two-door cast iron stove 410 × 710 mm - 1 pc.

- Gear grate 200 × 300 mm - 1 pc.

- Shifting valve 130 × 250 mm - 3 pcs.

- Steel corner 50 × 50 × 5 × 1020 mm - 2 pcs.

- Steel strip 50 × 5 × 920 mm - 3 pcs.

- Steel strip 50 × 5 × 530 mm - 2 pcs.

- Steel strip 50 × 5 × 480 mm - 2 pcs.

- The lattice for the fireplace, it can be made independently from the reinforcement rods.

- Metal sheet dL I floor before the furnace 500 × 700 mm - 1 pc.

- Asbestoset or cord for laying between metal elements and cloth bricks.

Masonry furnace

On the presented schemes, the location of all cast-iron elements of the fireplace furnace is shown in detail, and the masonry description will help avoid mistakes on some, quite complex, stages of work.

Experienced Masteners are recommended to perform the masonry of the entire furnace to start dry, that is, without a solution, adhering to the scheme and disassembled in the configuration of each row. This process is especially important to conduct newcomers who are barely familiar with the work of the liver.

Another cunning of experienced masters is a preliminary fitting and laying of each of the rows without a solution in the process of work. Any row is first laid out, and if there is a need, separate bricks are cut off or peredalized, and then their masonry is already produced.

Such an approach will somewhat slow down, but it will make it much better, without errors that are able to negatively affect the creation of a normal traction.

Performing a masonry, at hand you need to keep not only the scheme of each of the rows, but also the drawing of the furnace in the context. It will also help - allow you to present all the channels passing inside and the design of the furnace.

So, the laying is made as follows:

Order - from 1 to 6 row

- The first, solid row of the furnace, stacked onsteered on ready Foundation Ruberoid. It is very important to lay out a number perfectly and right, since the quality of the masonry of the whole design will depend on it. Therefore, it first stands the belt Ruberoid to be placed using a ruler, square and chalk, drawing out the shape of the base of the furnace, observing the dimensions. Then, leaning on the scheme and observing the configuration of the styling of the brick, the first row is assembly, and then the masonry per solution.

- 2 row. It contains metal elements consisting of segments of reinforcement, which will be fixed in the future using welding the fireplace grille, or this decorative element of VM levels is completely. The rest of the masonry is carried out according to the scheme.

- 3 row. At this stage, the doors of the first cleaning and configuration chamber are mounted, pre-wrapped with asbestos rope or covered asbestos. To fix the door on the ground, the wire is used, which is fought in the special loop-ears of the cast-iron frame. Next, the wire is placed in the laying seams, where it is fixed with the solution and presses the upper round of bricks. Temporarily, before the final consolidation, the doors on both sides are mapped with bricks.

- 4 row. The work goes according to the scheme, but a number is notable for the fact that the doors from two sides are fixed with the masonry that you need to withdraw perfectly smoothly. The seams in this area can be two - three millimeters wider, due to the wires embedded in them.

- 5 row is recommended to lay out with the use of chamotte fire-resistant brick, as well as all the walls of the furnace chamber. In the same row, a grate grid and an oven box, which is wrapped or plated asbestos, in order to avoid its premature exercise.

- 6 row. A flue door is installed on this row, incorrosted by asbestos cord, and with wire segments recorded in it.

- 7 row. The masonry is made according to the scheme, a steel band is mounted above the wall walls, which will serve as a support for the next row of masonry. It is placed smoothly or in the form of a half mart, giving it a necessary form in advance.

- 8 and 9 ranks are laid out according to the scheme presented.

- 10 row. The front wall of the furnace is strengthened, as a cast-iron cooking plate will be mounted in this part of the structure. A steel corner is fixed on the wall using two wire hooks, then the segments of the asbestos sheet are put on the installation site, and the stove itself is installed. In the same row, the door is fixed by another sewage chamber.

- 11 and 12 rows are laid out according to the scheme without installing metal elements. On the twelfth row there is overlapping the door of the sewage chamber.

Order - from 13 to 24 row

- From 13 to 15 rows are put on the designed scheme, strictly adhering to the configuration of brick masonry.

- 16 row. The device of the chamber walls is completed, located above the cooking plate, which overlaps with metal stripes. They will serve as the basis for laying the bricks of the next row.

- 17 and 18 rows are stacked according to the scheme.

- 19 row. At this stage, two more two mines of sewage chambers, which are fixed as previous ones, are mounted.

- 20, as well as 21 row plays according to the scheme.

- 22 row. Mounting another two-door cleaning cameras is made.

- 23 row. Masonry goes according to the scheme.

- 24 row. The smoke valve is installed, the frame of which is mounted on the solution.

- 25 row. Next to the first, on the adjacent channel of the chimney, the second smoke valve is mounted.

- 26 row. Installation of the door of the sewage chamber is made.

- From 27 to 30 rows are laid out according to the scheme.

- 31 row. At this stage, the third, last chimney valve is established.

- 32-3rd rows. In this area of \u200b\u200bconstruction, the transition to the lays down the pipe, which rises to the ceiling.

When the pipe is wiring through the attic overlap, it is necessary to isolate combustible design materials from it. To do this, a metal box with sides of the height of the overlap 100 ÷ 120 mm is arranged around the chimney. This "difference" remains in the attic room.

If the walls of the furnace are not covered with decorative material, then when the brick masonry is still a wet solution in the seams are expanded by a special tool, that is, it gives a neat convex or concave shape.

The stove is "Swedie" can be supplemented with warm laying. This interesting project is edged into video.

Video: Brick "Swedie" with a layman

And at the end of the article - another good advice. Before you decide on an independent building of the furnace, without having sufficient experience in this work, it is recommended, to begin to practice in the usual masonry of bricks per solution. Believe me, this process is not as simple as it seems at first glance.

Evgeny Afanasyevchief Editor

Publication author27.08.2015

The furnace brings comfort and comfort, so it is rarely some private house without it. Professional cooking services are quite expensive and not everyone afford. We will tell you how to build a brick stove correctly.

Types of furnaces - classification depending on the parameters

Laying stoves is a difficult thing, but can be able to cope with it with knowledge and patience. Choosing a furnace, take into account the parameters for which they are classified. First of all pay attention to its purpose. The heating furnaces are intended only for heating, can accumulate heat and give it for a long time. For this, the external walls are laid out in the Polkirpich, or even a whole. They slowly warm and slowly cooled, they heat up slightly, massive, large brick consumption. Also satisfy the heating furnaces of fast warm-up, which are less massive, well give warmly, but quickly cool.

The most common appearance in Russia is the heating and cooking furnaces. They not only warm the room, but also prepare food. In addition to the cast-iron stove, almost always have a bra spot. In addition, they can be built in: water heating boiler, water heating container, niches for drying, laying. The Russian oven from this species has a chamber for baking bread, pies. They differ from the usual kitchen slabs a large efficiency, high heat capacity, long keep warm, stable thrust.

For greater heat transfer to ordinary kitchen stoves, the heating shield is connected. This is the cheapest construction of relatively material costs and labor: it will take up to 200 bricks, heats up a small room. Very good option for small cottages. The stove, except for the heating pad, can be equipped with an oven, water heating boiler, water heating container.

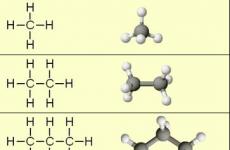

The fuel cell - heat transfer and fuel affect the device

The simplest device has a heating furnace, which has two parts: a fuel and smoke circuit. Other types of furnaces contain additional devices. The main part of any furnace is a fuel. It is imposed on certain requirements, in particular, there must be sufficient sizes: almost all fuel can accommodate for one bookmark. The air should flow in the required amount, a high temperature must be maintained.

With insufficient sizes of the fuel, there is a low heat transfer. The width depends on the required heat transfer: up to 1 thousand. Kcal - 12cm, up to 3 thousand - 27 cm, if more - up to 50 cm. For convenience, the dimensions of the fuel can be taken to multiple bricks. The length is made from 26 cm to 51 cm, the longest is intended for firewood. The fuel used affects the height: 6-15 rows (42-100 cm). The grinding is stacked on a number or two below the doors so that the coals did not fall out. Often make the tilt of the rear above the transfer for better burning.

Fullies: A - wood-haired; b - peat; B - coal.

For the fifume, a chamotte brick is used, which is laid out or fucked from the inside. The total thickness of the walls is at least 2 bricks. The topwear made in the form of an arch improvement improves combustion quality. The fuel fuel all types is well combined in the woody fuel. For coal, reinforced grasp of 4 cm thick is required and a good subdivination, for which the size of the grate is equal to the length of the ashtar under the fifth.

Flushing - advantages and disadvantages of different systems

The smoke-moving system increases the efficiency - gases when moving from the fifuer through the channels and cameras give heat walls. It is important to comply with the relationship between the volume of the fuel and the inner surface of the smoke-rotation. With an excess area of \u200b\u200bgas channels, the temperature decreases so much that condensate appears. Small interior area lowers efficiency - hot gases fly into the pipe.

The best way is absorbed with the ratio of the area of \u200b\u200bthe outer walls of the stoves, and the inner part of the smoke revolts 1: 3.

The cross section, the number and sizes are determined by their internal area. Channels are better folded in multiple bricks, they must provide a free passage of gases. The cross section should correspond to the thermal performance of the furnace: it smokes with an insufficient section and is well warmed up when excessive. The section 170-250 cm 2 is used in heat transfer of furnaces of 3 thousand kcal and less, from 3 to 5 thousand kcal - up to 300 cm 2.

The smoke rates can have channels (one or more) and be infantal.

Different types of smoke revolts: A - multi-turn vertical; b - multi-turn horizontal; in - single-turn vertical; r - multichannel single-turn; D - Babeless.

In the composition of the one-time system, one channel is lifting and as much or several parallel destructive. Parallel channels have low resistance to gases, the furnace array warms up more evenly. The one-time system has a drawback, which manifests itself in a significantly larger heating of the upper part than the lower one. In small furnaces, it is compensated by a significant heating of the fueling walls. For large furnaces, the scheme is used by which hot gases go through channels from below, thus, the normal heating of the room is ensured.

The multi-turn system consists of consistently located vertical or horizontal channels. The first disadvantage of such a system is that gases fall into numerous turns to experience considerable resistance. The second drawback in the highly unequal warming of the walls of the first and last channel, which often causes climbing masonry. Vertical channels provide good heat transfer, horizontal - craving, which helps with insufficient height tube.

Fire safety requires that the overlap of the oven was from the ceiling of combustible materials in 40 cm. The segment of the smoke tube from the furnace to the cutting in the ceiling is called the neck, its smallest height is three rows of bricks. The neck is a place to install valves or tops that close at the end of the burning. If you install such devices below, a lot of heat is lost. Gases are thrown out along the chimney, which will be discussed below.

Furnace selection - savings, heat transfer, simplicity and design

Determining with the design of the furnace, take into account its ability to satisfy certain requirements. An important role is played by economy when low fuel consumption provides an affordable room temperature. Few people want to turn the stove even twice a day, so preference is given to the designs that are evenly given warmly for 24 hours. These include ovens, well warmed in the lower part.

The maximum surface temperature should not exceed 95 °, otherwise the smell of Gary will be felt. Easy design, compliance with fire requirements also play an important role. And finally, the design of the furnace must correspond to the general aesthetic view of the room.

But the most important requirement for any furnace is the ability to warm all the premises. To do this, they define the heat loss, based on the volume, size of windows and doors, the characteristics of the material from which the house was built. Calculations show that each m 3 rooms with brick walls at the middle winter temperature -25 ° loses 60 kcal / h. One square meter of the furnace is able to give 500 kcal / h.

When calculating, we first determine the heat loss at home. Suppose you have an ordinary brick cottage 7 × 9 with a ceiling height of 2.5 m. There are only 4 separate rooms that planned to heat the same furnace installed in the middle of the room. First, we determine the cube: 7 × 9 × 2.5 \u003d 157.5. We multiply on the heat loss of one cube. Meter: 157.5 × 60 \u003d 9450. So, a furnace with heat transfer is 1000 kcal / h, some stock should always be done. A simpler calculation comes from the fact that one square meter of the floor area, which the stove occupies, heats 30-35 m 2 rooms.

Accommodation - how to determine the best place

The location of the furnace is selected by each at its discretion, but still, general recommendations should be taken into account. First of all, the stove in the house should give maximum heat. If one room is heated, the furnace is installed on a small distance from the wall, at least 15 cm, but can be placed close to the walls. Then the heat of heat will give two sides of four. In the schemes A, B are visible options for the location with the air gap in the wall, which is also called the retreat.

If the furnace design will heat two adjacent rooms, the most effective option when to build it in the partition (the same figure, B). Heating and three adjacent rooms are possible, as in Figure G. The furnace is also located in, common to all three rooms. In one room there is one side of the furnace, to the rest - two. In the drawings, D, E shows the options when the firebox is located on the veranda or in the back. This is a good option for small houses.

In the dwelling of the four rooms, the furnace is recommended to be installed at the junction of two internal partitions, so that one wall of the heating device in each of the rooms it comes out. This option provides the ability to coat from the kitchen, living room, veranda, without entering the garbage to the bedroom. Rude with a bed is great for giving with several rooms. Lenhing is removed into any room that the owner prefers.

Fundamental Foundation Device for Furnace

After determining the design and selection of the place, it is possible to start the embodiment of the project into life. We start with the foundation that is better to do simultaneously with the foundation of the building. In case of construction of the oven in the already erected house, we disassemble the floor and make the fill. To put, even the smallest and light furnace on the wooden floor, does not make sense. In just a few years, even the thick boards and lags begin to deteriorate, seize, the furnace will have to be rebuilt.

The size of the foundation makes more oven dimensions by 30 cm in all directions.

Make a foundation for a brick oven. It should not be contacted with the foundation of the walls, we provide a clearance between them at least 5 cm. The space between the two foundations fill in the heat insulating material. Separate foundations will provide an independent sedimentation of the walls of the building and the oven. If you connect both foundations, it often leads to a doss.

So that less heat from the furnace went to the ground, the heat insulation is placed on the concrete. It may be the following: first a plate of minvolokna or basalt insulation, then choosing a foil, tin. From above again insulation, on it - sheet metal. Felt is soaked in clay milk and weighed a layer of insulation. When he dries, we begin the laying. Such reliable thermal insulation will fight from heat loss even in the harsh conditions.

Clay Masonry Solution - Capture Secrets

The brick furnaces are laid out on the clay and sandy solution. The clay has unique properties, turning into a stone after the effects of fire, perfectly hits with a brick. To achieve maximum qualities from it, the solution should be prepared from pre-prepared ingredients with an optimal ratio.

Initially, we remove impurities from clay. Grind and put in an oblong capacity, concentrating only at one end. That part of the container where clay is located, slightly raise, we pour some water from below. We gradually take the shovel of clay and mix with water to the formation of a homogeneous pasta-like substance. It is shifted to another dishes until the required amount of solution is scored.

Bought dry clay soaked in a wide and deep dishes. I fall asleep 10-20 cm, covering completely water. After a day, we stirre, if necessary, add water and leave again for a day. When the pasta mixture is obtained, the chimney is considered ready. For strength to solution, add some salt: up to 250 g per bucket. Mass must crawl off a trowel without traces. Water should not appear on the surface of the solution if it happens, add washed sand into the solution.

By 50 pieces laid platering bricks need a bucket of the solution with a thickness of the seams 3-5 mm.

The solution should be necessary plasticity and fatty. To determine the quality of the solution, we take clay in five identical portions. Four add different amounts of sand: 0.25, 0.5, 1, 1.5, and leave the fifth without adding sand. We mix the solution from each part, make pancakes from them and dried. We define the quality to the touch and in appearance. If the pancake crumble, in it surplus sand, in the cracked it is not enough. If the sample does not crack and homogeneous, in it the optimal ratio of components of parts. It is in such a proportion that we prepare the solution.

In the masonry of brick ovens with their own hands there are many secrets that only experienced masters know, and unknown beginners. First of all, it concerns the choice of bricks. A ceramic brand brick is not below M-250, which is more expensive than usual M-100, M-150, but more homogeneous, can withstand constant heating and cooling. From it you can make decorative elements, the usual brick for this is unsuitable.

The inner walls of the fuel are laid out with refractory bricks, which withstands 1200 °. But behind it is a ceramic brick that can withstand only 650 °. With a strong heating of the fuel, the temperature is transmitted to it, reducing the service life. To extend the life of a red brick in the fuel cell, it is isolated from the refractory basalt cardboard 5 mm.

Much time occupies the control of the solution on the facing row. In order for the work faster, the brick is placed on the front of the brick, which is then removed. The facing row goes beautiful and neat. Experienced cooks are advised not to bother with the preparation of a clay and sandy solution, and buy a finished sandy mixture for furnaces. It refers to 5, 10 and 25 kg.

Any jumper, typical and other elements are more convenient to lay out if you use a metal corner. It is laid out from the inside, pressing the brick on both sides. The length of the corner should not exceed 0.8 m, otherwise it can be saved from heating. Avoid applying corners from the front side. In addition, it is ugly, there is a high probability of getting a burn with a random touch to it. Instead of corners from the front side, 16 mm studs are used with threads that fix the facial finish.

Extend the service life of the furnace, if you are stubbing all the accessories in the grooves with a depth of the thickness of the product.

Each Michael seeks to lay out a row with perfectly smooth suture, but not everyone is obtained. There is a simple reception: the metal rods of 8 mm are laid on each row, better rectangular. A solution is labeled between two rods, then bricks. When the last brick is laid, the rods are removed. Bricks can not be hesitated, otherwise the laying will go waves. The rods are lubricated with machine oil before use to make it easier to remove from the masonry. Their length should not exceed 1 m, otherwise the masonry will be damaged when they pull them out.

Chimney - how to ensure safety and good craving

On the furnace in the house, a housing tube is usually installed, which consists of a cervix, the rolling of the ceiling, a riser in the attic, the wipes at the roof and the headband. The roller protects the wooden ceiling and roofs from heating and possible sunbathing when furnace. In these places, the pipe makes a thickened, gradually naked bricks. You can use metal to support brick rows, but they should not overlap the inner chimney.

At the point of passing, the standing through the roof is made by the otter, which will not let the rain and the snow penetrate the attic through the slot. They are closed with roofing steel - a collar, whose ends run under the protrusions of the otter. Warld the smoke tube. Its height is determined by the location on the roof. In the middle of the skate and when the removal of it is not more than 1.5 m, it should protruding with a skate of 0.5 m. At a distance from the skate to 3 m, the top of the head and the skate. With a larger removal, height should be ensured at an angle of no more than 10 ° in relation to the skate.

The smoke trumpet is designed to provide good traction. It increases with an increase in the temperature of the exiting gases, but so it is economically inappropriate, therefore the pipe is expelled to the necessary height, which should be 5-6 m from the grate to the top of the head. Increases the traction also plastered inner surface, the lack of cracks in the brickwork. To eliminate the effect of wind that can interfere with a traction, a deflector is installed on the headpoint.

Swedie - optimal option of the heating and cooking furnace

The design is verified by centuries, small and economical. With dimensions of 880 × 1010 mm and a height of 2170 mm, it is capable of drying more than 30 m 2. Usually, the furnace with the stove is located in the kitchen, and the back wall of the furnace goes into the residential premises. It works perfectly on firewood, coal and briquettes. In the summer it is recommended to drown in small portions of large coal or pellets, firewood burns too fast in hot weather. Coal consumption in the heating season of 1.5 tons.

To build up:

- brick M-150 - 570 pieces;

- 200 kg of dry mortar;

- 1.7 m steel corner 40 × 40;

- 0.65 m steel strip 5 × 50;

- roofing iron forserting before furnace;

- flat slate to overlap the cooking chamber.

You will need standard furnace instruments: grate, a fuel door, a puff, a cast-iron stove with burners, valves - 2, cleaning - 3. The coach of the Swedish furnace with the cooking plate is presented below.

An important constructive element is an oven, which plays the role of an automatic switch between summer and winter move. It works as an aerodynamic barrier for gases from the fuel. Gas are delayed in it, completely burning under the cooking surface. The smoke-turn channels go hot, the oven warmly warm. For this reason, the wall removed from the furnace is sometimes made double and placed in it heat exchanger with a tank for hot water.

Excessive heating of the cooking surface is not observed, hot air from the niche goes into the room. In summer, the kitchen is not more cuisine with a proper firebox than from the gas stove. The fuel in small quantities in the summer is well warmed by a cooking surface, as the gases are delayed in the oven. The burner on the left heats up more, right - less, but enough for cooking.

Holland - a small-sized oven with high heat transfer

This is a unique simple building of tremendous efficiency. Compared to the classic Russian oven, it has more modest dimensions and a smaller wall thickness, which contributes to rapid warming. Even owners of stylish modern cottages it attracts their grace and efficiency. When laying a Dutch furnace, any variations are possible, which will not have a negative impact on its effectiveness.

This is a pure heating furnace, but, if desired, it can be equipped with a hob. The smallest design of 0.5 × 0.5 m, for the most massive need only 650 bricks, including 200 refractory. The main material is a brick of any quality, which is not reflected on its stability and functionality. But for the fuel, it is necessary to apply refractory brick. It warms up quickly, cools slowly, the fuel is consumed economically. Holland is able to heat up to 70 m 2.

As can be seen from the scheme, the oven Holland has no grate, the fuel is loaded into the furnace, the burning intensity is low. Efficiency is achieved at the expense of a special device of smoke revolts. The gas gases rise across the first channel and returned via the second channel. There they are heated again and go to the third canal. In the fourth and fifth channel, the same principle is repeated, and only on the sixth channel, the gases go into chimney.

Despite the modern abundance of heating and kitchen equipment, very many owners do not represent a private house without a furnace - and it is absolutely correct. Even if it is planned to create an autonomous heating system, the furnace will also be alike. For example, in order to save in the spring or autumn period, when the full heating is no longer needed, but also you do not want to breed in the house. Protoping the stove once a day or two days, in the premises you can maintain the optimal balance of adhesion and heat.

Folding the furnace with your own hands a step-by-step instruction of which has intricate configurations - for the beginner will be quite difficult. Therefore, if there is no experience in a cooking case, it is better to choose the available friend's friend in which it will simply figure out.

When choosing a model, it is necessary to take into account not only the simplicity of the scheme, but also heat transfer and the functionality of the furnace, since there are furnaces in which not all functions are provided. The heat transfer is chosen depending on the area, which should heat the heating structure.

There are quite a lot of furnace furnaces, as experienced cooks, working on one of them, make their own adjustments to its design, and due to this new and new variants of the heating device appear. And to stay on one of the types of furnaces, you need to know which they are on functionality.

Prices for chammatory brick for masonry furnaces

chamotte brick

Types of brick stoves

There are t.the rex basic species are heating and cooking, cooking and simply heating without additional embedded elements.

- The heating and cooking furnace can have not only a cooking plate, but the oven and a water heating tank, as well as a drying niche. In addition, such a structure can heat one or two rooms of a specific area.

Such furnaces are often embedded in the wall, turning the hob and the furnace in the direction of the kitchen, and the rear wall - in the living room. Thus, the furnace performs till function - it works as a partition, it prepares food on it, and it gives dry heat into the bedroom or living room.

- Operate only for heating, and most often have a compact size. This furnace is installed in order to maintain the balance of VL Agi and heat in the house in the autumn or in the spring, when it is too early to turn on autonomous heating or not yet included central.

This furnace is well installed, for example, in the country, in the event that there is a device where you can cook food. If the power supply in the country village is often disconnected, it is better to choose a building with a hob.

- The cooking version of the furnace can serve for heating, if you need to heat a small area. The device is perfect for a cottage house or for a small structure for permanent residence.

Having such a furnace and firewood, you can not worry about the fact that the house will be cold and raw, and the family will remain without dinner or hot tea when the electricity or gas is disconnected.

It should be noted that any of the types of furnace can be compact or massive. The choice of the size of the furnace structure depends on the area of \u200b\u200bthe house or room, as well as the place that is assigned to build.

Choosing a place to install the furnace

Choosing a place to build a furnace, you need to provide for nuances that are important not only to create comfortable operating conditions, but also for reasons of fire safety. Especially important to think about location Furnaces in the already built house, as the chimney pipe should not stumble upon it on the bays of the attic overlap or on the rafting legs of the roof.

The stove is installed at the inner bearing wall, in the middle of the room or embed it into the wall located inside the house.

- It is not recommended to build a furnace near the outer wall, as it will quickly get out, and the efficiency of its use will significantly decrease.

- In the middle of the big room, the furnace is set in the event that it is necessary to divide the room into two zones. Moreover, with a beautiful decorative trim, it will decorate the house and can become one of the elements to the interior that will emphasize a certain style.

- Embedding the oven to the partition between the rooms, it is necessary to provide for its insulation from the combustible wall materials using heat-resistant sheets of asbestos or special drywall.

- The place allocated for the furnace should be greater than its base at 120 ÷ 150 mm in each direction, since the foundation perimeter always slightly exceeds the size of the furnace.

- In order to easily determine the sizes, you need to choose the model to which the order scheme is attached.

When the model is selected and the installation location defines, you can proceed to the acquisition of materials and prepare all the necessary tools. The number and assortment of materials for each of the models is selected individually, but the tools used during the masonry are always the same.

Working Tools

For the construction process, the following devices and tools will be needed:

A) Kirk is used to dry and split the brick.

B) The oven hammer has the same functions as Kirk, but, in addition, it is convenient for them to remove the dried mortar.

C) The rule is used to align concrete on the surface of the foundation. It is often made independently of the perfectly smooth outdoor board.

D) Wooden blade is used for rubbing and stirring of the clay solution.

E) the level is the necessary tool, as it will help to withstand the evenness of the rows, both in the horizontal and vertical direction.

E) Bread from the urine is used to remove sand and hardened mortar from the inner surfaces.

G) Pliers are used to bite and fold steel wire when installing and fixing cast-iron elements of the structure.

H) The chimney lead is used for marking when finishing the furnace with tiles.

And) Stukolz - cut pipe used for fitting tiles.

K) Chettail rod for marking.

L) The rashpil is used to wipe the lumps and removing the influx on the finished masonry.

M) The building angle is necessary to remove internal and external angles by 90 degrees.

H) The plumb is used to check the vertical walls.

O) Rubber hammer is used to run into a row of bricks.

P) Chisel is needed to parse old masonry and brick splitting.

P) Trusks or Kelma are used to remove the surplus of the solution and impose it into the rows of bricks during masonry.

C) the extension will be needed if the furnace is not facing the finishing material, and the seams between the rows will neatly decorate.

In addition, two tanks for mortar and water will be needed, as well as sieve for sand, if the solution is made independently.

The masonry of the upper rows will be easier if there is a "goats"

For the convenience of working, it is necessary to have a frame that is different called "goats". It is convenient to stand on them, conducting a masonry at an altitude, especially since the work platform size provides for a place to install a container with a solution.

Forehead Foundation

- The foundation for the furnace is usually laid together with the overall basis for the entire structure, but they should not be interconnected, since during deformation or shrinkage, one of them can damage the other.

- If the furnace will be built in the foundation already built on the tape or biscuit, which has a wooden floor, then the coating will have to open and build the basis for the furnace from the soil.

- If a compact model of the furnace is chosen, and under the house there is a slab foundation, then the heating structure can be erected directly on it by making a waterproofing gasket.

If the foundation sune-Taki will have to be equipped with "from scratch", it must be remembered that it should have the same shape as the founding of the furnace, but to act beyond its limits by 120 ÷ 150 mm in each of the parties.

- On wooden the floor is placed The outline of the foundation is cut on the markup part of the board coating.

- Further, in the soil the underground rotates the damned size, a depth of 450 ÷ 500 mm.

- The ground at the bottom of the pit is good tamples, and the sandy befelling is made, which is wetted with water and also tamper to thickness in 80 ÷ 100 mm.

Potted under the chimney foundation with a sandy-gravel "pillow"

- After that, around the perimeter of the pit it is possible to lay a runneroid, which will perform the function of waterproofing and formwork, if it is temporarily strengthened by boards or bricks. After the concrete solution is frozen, the formwork with the foundation is removed.

Instead of runneroid, you can use formwork from boards, closed from the inside with a polyethylene web.

Immediately it should be noted that it is better if the concrete base under the furnace will rise above the floor at 70 ÷ 100 mm. In this way, you can save a brick and simplify the docking of the floor surface and the side walls of the foundation.

- From above sand is covered with a layer of crushed stone of the same thickness and is also well compacted.

- The next step on the bottom of the recovery is a reinforcement grid made of metal wire or finished grid. The elements of the lattice between themselves are connected by a twist from the wire.

Foundation reinforcement - option

- The first layer of solution is poured into the prepared kittle. It may consist of rubble, sand and cement - 1: 2: 1 or gravel and cement 3: 1. This layer should occupy approximately ⅓ the filled space.

- After filling the first layer, immediately knead and poured the second, consisting of sand and cement in proportions 3: 1.

The second layer is poured into such a height so that 50 mm remains to the top, which will be required for the upper aligning foundation SH OA.

If necessary, for the upper layer of concrete, the formwork can be expanded, and then on top of the flooded solution to lay a reinforcement grid having cells at 70 ÷ 80 mm.

- Then the last upper layer of the solution is poured and aligned with the rule.

The foundation is left to ripen concrete by 27 ÷ 30 days. It is advisable to make it daily with water and close with a plastic film, it will help make concrete more monolithic and durable.

On the finished foundation, after removal of the formwork, two or three layers of rubberoid, which will protect the brick masonry of the furnace from the capillary moisture coming from the soil or from the underground.

After that, you can move to the main work - masonry furnace.

Several recommendations for masonry work

- Before starting the brick laying on the solution, the entire structure rises from the brick dry, but each of the rows should be laid out strictly in accordance with the order scheme.

Pre-masonry Drying experienced cooks advise to spend all the masters who are first taken for the construction of the furnace. This event is necessary in order to understand the location of all internal channels and do not make rude mistakes when fitting bricks in each of the series.

To carry out the masonry, you need to be worse with wooden slats, which will determine the thickness of the seam between bricks. Usually their thickness is 5-7 mm. The same rail will be used in the main masonry, carried out with the solution. Such a "calibration" of the seam thickness is especially necessary if the masonry is done "under the extection", and must be flawless.

This process of PR is not inhaling, thoughtfully, as it is very important to understand how smoke will be discharged from the furnace, and how it will fall into the chimney pipe.

- Having lifted a dry design before starting the pipe laying, she carefully disassemble. If you simultaneously fit bricks in size, then each row can be folded into a separate stack, putting a row number on the bricks with a marker and a place in it.

- Performing basic masonry, each of the series also first lays out dry, and then, after thorough fitting of all parts, mounted on the solution.

- When the main laying is made, two dimensional rails are stacked on the edges of the previous row to withstand the exact seam thickness. The solution is then applied with a layer of 10 ÷ 12 mm. The brick is placed on top of the solution, pressed, and, if necessary, begged with a rubber hammer until the brick is stored in a measuring rack. The extra protested solution is selected by a trowel.

- Rakes are pulled out of the masonry after mounting the third ÷ fourth row above them, and then used again. Therefore, you need to prepare several pairs of these auxiliary elements.

- Capturing the rails, the seams are neatly filled with a solution and immediately "expand".

- Conducting the laying on the solution, each of the series is verified using a construction level to comply with horizontal and vertical planes.

Compliance with these nuances will help simplify the process of the construction of any furnace, avoid "fatal" errors that can lead to the need to rewar throughout the work.

Heating and cooking furnace with drying chamber of the structure of Yu. Proskurin

As mentioned above, there are a large number of different stove models. In this publication, one of the compact and functional options will be considered, which can be installed in a small house, as it does not take a lot of space, but it is capable of driving a room at 16 ÷ 17 m².

The design of the furnace Y. Proskurin is a two-speed heating and cooking option equipped with a single-mounted stove and a drying chamber designed for drying vegetables and fruits, healing herbs, mushrooms, and the like.

If desired, the drying cabinet can be installed in the niche of the oven chamber.

The furnace has dimensions (excluding the height of the chimney pipe) 750 × 630 × 2070 mm. Its heat transfer is 1700 kcal / h. The design provides for two modes of operation - summer and winter, which is very important for fuel economy, and to be able to heat the stove and cook food, do not touch all Designs in the summer.

List of essential materials

In order to build such a heating structure, the following materials will be needed:

| Name of materials and elements | Quantity (pcs.) | Sizes of elements (mm) |

|---|---|---|

| Red brick M-200 (excluding pipe masonry) | 281 ÷ 285. | - |

| Chamotte brick refractory brand sh-8 | 82 ÷ 85. | - |

| Opening door | 1 | 210 × 250. |

| Doors for cleaning channels | 2 | 140 × 140. |

| Door for confused | 1 | 140 × 250. |

| Summer stroke valve for chimney | 1 | 130 × 130. |

| Flashing | 1 | 130 × 130. |

| Hob | 1 | 130 × 130. |

| Colonnik | 1 | 200 × 300. |

| Single-mounted cooking panel | 1 | 410 × 340. |

| Steel band | 1 | 40 × 260 × 5 |

| 1 | 40 × 350 × 5 | |

| 1 | 40 × 360 × 5 | |

| Steel corner | 1 | 40 × 40 × 635 |

| 3 | 40 × 40 × 510 | |

| 4 | 40 × 40 × 350 | |

| Roofing iron | 1 | 380 × 310 |

| Foremost sheet metal | 1 | 500 × 700. |

In addition, it will take clay, sand, cement, crushed stone, gravel, mergel, and a bladder box, if it is decided, instead of a drying niche to install the oven.

Scheme-delegation of the construction of the furnace design of Y. Proskurin

| Illustration | BRIEF DESCRIPTION Valued operation |

|---|---|

| The first row is laid out with a solid plane with compliance with bricks. It is very important to put this series perfectly in all respects, since the quality of the masonry of the entire design will depend on it. |

| In the second row, a pensive (ash) camera and the base of two vertical channels is formed. On the same row, the doors of the pensive and the cleaner cameras are installed. |

| On metal doors there are special ears in which steel wire segments are tightened - they will then be mixed in the seams between bricks. Temporarily, to complete consolidation, the doors are supported by bricks from one or two sides. |

| The third row continues the formation of a pensive chamber and the lower part of the vertical channels. At the same time, fastening from two sides of the installed door. |

| On the fourth row, the doors of the pensive and clearance cameras are completely overlapped. The total camera of vertical channels is divided into two, so instead of a large hole, two, having a size of the length of the brick, and the width of the Pollipich are formed. |

| The fifth row is completely laid out with chamoten brick. Over the ash chamber, a hole with a landing place for a grate grid is formed. For this, part of the brick cuts out, from the side that it must be rotated to the hole above the subdivinal chamber. |

| On the same row is mounted and grate. It is planted on a clay solution or laid freely, without a solution. There should be a distance of 4-5 mm between it and brick. |

| On the sixth row, the formation of a flue chamber and vertical channels continues. |

| In addition, the flipper is installed on the same row, the frame of which, before installation, it is necessary to wind up or set asbestos, which, when heated metal, will give it an opportunity to expand without voltage and damage. |

| The seventh and eighth rows are laid out according to the coach, they continue to form the formation of fireboxes and vertical channels. |

| On the ninth row, the cooler door is overlapped by brick. Moreover, to remove the load from the ceiling from the door, the side and third of the edge of the bricks are stated on the one hand, and between them is installed with a brick, shy on both sides. |

| On the tenth row there is a combination of the fuel chamber and the first vertical channel - this is done in order for the hot smoke from the furnace to be sent to this generated hole. For smoothness of the course of smoke, protruding the angle of solid brick, which protects the second vertical channel, is cut. |

| On the eleventh row, the masonry goes according to the scheme, except that on the edges of bricks framing the flue chamber, cuts are made, which will form a deepening for mounting a single-mating hob. |

| Then, on the same row on sections made on bricks, asbestos stripes are stacked, and the plate panel is mounted. From the formation of a cooking niche is installed steel corner. |

| 12 A row is laid out of red bricks, and in the future all the laying goes out of it. Two vertical channels are drawn up again, and there is a niche around the hob. |

| 13 row is placed according to the scheme, but in the front of the first vertical channel, a place is formed to install a summer-winter stroke gauge. After that, a valve is mounted on the clay-sandy solution. |

| From 14 to 17 a row, the laying is performed according to one principle - the cooking niche and channels are formed. |

| On the 18th row of steel corners there is a floating niches. One of them is mounted on the edge of a niche, the second - at a brick distance from the first, and the third pressed to the second back side. This is done in order to conveniently carry out the laying of the next row. |

| A cooking niche is completely overlapped in 19, with the exception of the formation of the hole of the steam channel and the place to install the valve. To do this, the bricks make cutouts in which the valve is mounted. |

| 20 row is laid out according to the scheme. It continues the formation of two vertical channels and steaming. Moreover, if you carefully look at, you can see that one of the bricks forming the first vertical channel is shy. |

| On the 21st row there is a combination of the first vertical channel and steaming with the help of the left-handed space. In this row, almost all bricks are put only on the walls of the perimeter of the structure. Only the second vertical channel is protected. |

| In the same row, the resulting cavity is overlapped with metal stripes, which are stacked by the scheme shown in Figure. |

| Further, a roofing sheet is laid on steel strips, with which the chimney hole is organized, located in the opposite side of the steaming. |

| On the 22nd row, the masonry is made on top of the roofing sheet. The chimney hole is left and the two holes of vertical channels. In a place where the drying niche will be formed, the segment is stacked, which will protect the brick on the edge of the chamber from damage and make the edge of the niche more neat. |

| 23 row - a drying chamber is formed, and its rear wall is made of bricks installed on the side. He burns down the camera from the opening of the chimney channel. |

| The walls of the drying chamber, chimney and two vertical channels are formed on the 24 row. |

| 25 row - work continues according to the scheme. The second brick of the rear wall of the chamber is installed in the same way as the first. |

| On the 26th row, preparations for the combination of two vertical channels are preparing, so the internal bricks in both holes are raised at a low angle. |

| 27 A row - masonry combine the first and second channel. For them, a common worn door is installed. The rest of the work goes according to the scheme. |

| On the 28th row there is overlapping the drying chamber with three sections of the corners along the same principle, as the overlap of a cooking niche was made. Vertical channels are combined into one wide, and the cleft door is fixed by side bricks. |

| On 29, the drying chamber and vertical channels are completely overlapped. The opening of the chimney canal is left, which is placed with bricks with cut-out planting grooves for chimney valve. After laying a row, a frame with a valve is installed on the clay-sandy solution. |

| On the 30th row, the entire surface of the furnace is completely overlapped. Only a chimney hole is left, which must be sized in the Pollipich. |

| 31-32 row - the formation of a chimney begins. |

This figure shows an oven in the context. The scheme shows all the internal channels for which the heated air will circulate.

In the late autumn and early spring, there is not enough comfort in the country - in the house it becomes damp and cool. The problem can be solved by an electrical heater, but in a rustic home it is better to give preference to a traditional wood focus. Heat from the stove or fireplace warms not only the body, but also the soul, filling the room with a special aroma and comfort. To build a mini-oven with your own hands, you do not need much costs - the cost of the homemade unit will cost much cheaper than finished devices.

Heating and cooking summer oven: where to start and how to build

Small-sized furnaces, despite minor sizes, are installed on a reliable foundation. Only in some cases it is possible to do the enhancement of gender. Experienced masters work without diagrams and drawings, and beginners are encouraged to take the order of reputable liveshists as the basis.

Design and materials scheme

This square mini-furnace of the brick, ideally suitable for a small house, is distinguished by simplicity, compactness and good efficiency. The design includes a low chimney with a cross-section of a channel 13 * 13 cm. The stove has a glass cabinet that allows you to prepare and warm up dishes. The cabinet is made of steel sheet, but if desired, it can be replaced with the finished oven suitable sizes.

Appearance and furnace device

For masonry mini-furnace on firewood requires a refractory solution. You can cook it from clay yourself, but it will take longer, and the result will depend on the quality of clay and the correct determination of its fat content. It is much easier to trust manufacturers and acquire a ready-made heat-resistant mix in the store - in this case, the product will remain clean water into the proportions indicated on the package.

The size of the compact design: 51 * 51 cm, the height of the focus is 175 cm. To enhance the furnace, it is necessary to take chamotte brick - it is not afraid of direct contact with the flame and does not crack. The walls of the mini-oven for the country house are laying out with a red brick.

Consumption of materials:

- ceramic brick - 170 pieces;

- refractory masonry solution - 35-40 liters;

- door for firebox size 23 * 25 cm;

- standing door (13 * 14 cm);

- clear door (13 * 9 cm);

- grate grille (25 * 18 cm);

- catch (12 * 34 cm);

- steel sheet;

- steel wire - about 2.5 m;

- ruberoid for waterproofing.

Masonry scheme and oven drawing

The first row, as always, is laid out without a solution. On the second row, the confusion door is mounted using steel wire for fastening, and the ash bar is laid. On the fourth row, the grille is placed, providing for a gap and masonry of about 4 mm.

Styling of the fifth row starts from the installation of the furnace door. The door frame is wrapped with asbestos cord, and the door is immutted into the masonry using steel wire. Next follow according to the scheme: form a brass cabinet, chimney, pipe.

Stove-baby with kitchen stove and oven

Another mini oven for the cottage has dimensions at the base of just 51 * 64 cm, while the depth of the furnace is 50 cm. The model is perfect for the country's dacha or summer kitchen. You can use firewood, coal, peat, briquettes as fuel.

Features of construction and materials

Despite small dimensions, the compact stove is functional enough and is equipped with a hob and oven, which allows it to be used not only for heating the room, but also for master's needs. According to the reviews of those who have already built this assistant at their dacha, the kettle on the stove boils literally in minutes.

Compactness was maintained thanks to the vertical placement of all elements. Chimney has a cross section in one brick. The exhaust gases pass through the channels located behind the cooking chamber, then enter the horizontal chimney, bypass the oven on both sides and go into the pipe.

Mini furnace diagram for country house or summer kitchen

For construction, materials will be required:

- red brick - 220 pieces;

- a masonry solution of clay or ready - about 50 liters;

- grate;

- steel sheet (predominant) size 50 * 70 cm;

- steel strip 4 mm thick with parameters 350 * 25 cm;

- slate sheet 51 * 30 cm;

- gate - 2 pieces;

- fire door;

- 3 of the worn doors;

- paddle door;

- oven (32 * 38 * 42 cm);

- plate (38 * 35 cm) with one burner.

Order of masonry

The first row of a mini-furnace of bricks is laid without a solution. After the second row, the confusion door is installed, put the following row and begin to form the furnace. The grille is placed without a solution. On the order scheme clearly seen, where and how do the doors, stove, oven and valves should be installed.

To protect ceramic bricks from fire, a lining is carried out - a shamotless refractory brick is laid nearby. It is important to remember that different types of bricks can not be tied up with each other - they have different expansion temperatures. Neglecting this rule leads to cracks.

Option for beginner cooks: stove with cast iron furnace

Brick mini furnace can be built with their own hands based on ready-made cast iron furnaces. Cast iron fifumes are distinguished by durability - they do not crack and do not go. This option is more suitable for beginners, as all the main elements are already provided in the design. The combined oven is quickly warmed up and is cooling for a long time, due to which the focus efficiency is significantly increasing. If you wish, you can choose a focus of a fireplace type with a refractory glass door - such a model will not only enhance, but also decorate the room.

Before starting work, a durable and even base is preparing. To do this, you can pour a small concrete podium. The crying of cast iron furnaces are made in the Pollipich, leaving between the walls and facing the air cushion with a thickness of 1 to 10 cm. Additionally, it is necessary to provide small ventilation holes at the bottom of the building - they will provide the output of heated air and improve heat transfer.

Example of cast iron furnaces

You can start building a mini-oven with your own hands only with solid confidence in your knowledge and skills. Any doubts - a good reason to postpone an independent job and entrust the construction of a professional liver.

Video: Laying a small country furnace with their own hands

Despite the fact that in very many today are those or other heating systems, brick heating structures do not lose their popularity. On the contrary, engineers and folk crafts are being developed by all new furnace models, more compact, including various functions. Indeed, the furnace heating will never be superfluous for a private house, as it will be able to rescue the owners in different situations. For example, in the fall or in the spring, when the nights are cold, but it seems to include autonomous heating, the drowning oven will create a cozy atmosphere in the rooms and relieve them from excessive humidity. The oven will help maintain the optimally favorable atmosphere and the temperature balance, comfortable for a person.

Therefore, a search query about how to fold the oven with your own hands the drawings of which will tell in detail about the correct sequence of masonry work, does not come down from the pages of the Internet. Today, even those people who do not have the experience of the liver, show the desire to try their strength in this craft. If it is decided to install the furnace in the house with its own forces, then beginners it is recommended to choose a simple version of this facility with an understandable order.

In addition to the availability of the design, when choosing, you should pay attention to its heat capacity, that is, it is designed for heating. It is important to take into account the functionality of the structure and decide what I would like to get from it.

Varieties of brick stoves

There are several main types of furnaces - some of them perform only one main task - this is heated at home, others are used only for cooking, and the third includes several functions in their "set of features". Therefore, in order to decide on the desired model, you need to know what is each of the species.

- The construction is capable of not only to warm one or two rooms, but also help cook food and boil the water. If the model is equipped with a brass cabinet and drying niche, then the possibility of bake bread appears, and peel vegetables and fruits for the winter.

The heating and cooking furnace is often embedded in the wall or itself performs the role of the wall - for this it is rotated by a slab and a firebox in the direction of the kitchen, and the back wall in the residential area of \u200b\u200bthe house. You can solve two problems immediately - the heating of the premises and the possibility of cooking in a separate room.

If the design is additionally equipped with a fireplace, the furnace will work not only as a functional structure, but it will become a decorative decoration of the house.