Rules for the placement and use of fire tanks

Any fire water tanks are part of the overall fire system at the facility. Their purpose is to store a given volume of water in the absence of the possibility of connecting fire extinguishing equipment to the central water main, or to provide fire brigades with additional volumes of water.

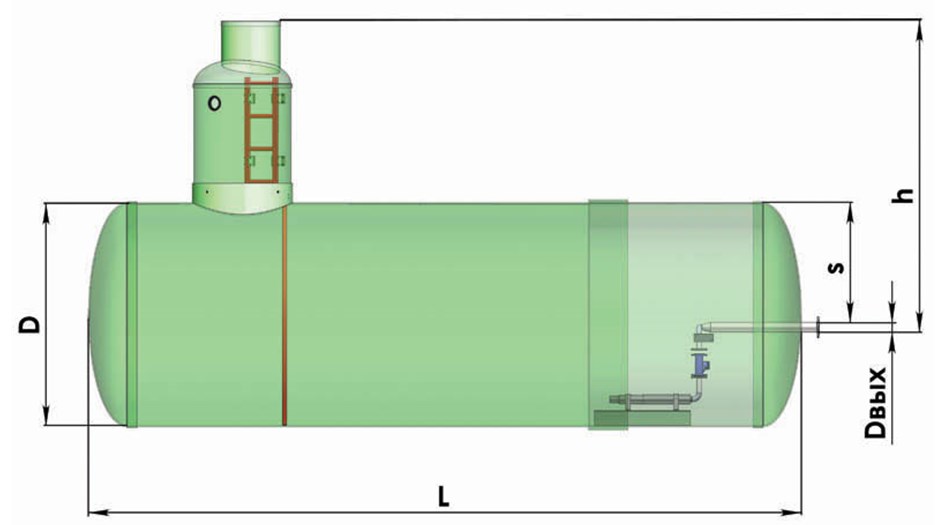

By their design, ground fire tanks are represented by single-walled vertical or horizontal tanks. They can be either diamond-shaped or cylindrical. The bottom is usually cone-shaped.

At the same time, vertical tanks can have a capacity of 100 to 5,000 cubic meters of water. Horizontal ones are less capacious - from 5 to 100 cubic meters.

There are fire tanks made of fiberglass or sheet steel. Inside they can be equipped with a special anti-corrosion coating. The material is selected based on the specific requirements at the facility, as well as the climatic features in the area. Inside the case there are special strong rings (ribs), which are designed to provide additional structural strength.

Tank placement

Fire tanks design and placement standards are very strict. They are determined by the rules of SNiP 2.04.01-85, as well as SNiP 2.07.01-89, SNiP II-89-80 and SNiP II-97-76 - depending on which facilities the tanks are installed on. According to these standards:

- tanks equipped with pumps are installed within a radius of 100 to 150 meters from buildings;

- in the presence of a pump - up to 200 meters;

- no closer than 10 meters from buildings of 1 and 2 categories of fire resistance;

- no closer than 30 meters from buildings of 3 - 5 fire resistance categories, as well as fuel and lubricants warehouses.

When designing the location of tanks, one should be guided by their availability at any time of the day for quick fire extinguishing.

When calculating the volume of tanks, it must be borne in mind that there are at least two tanks on one node. One of them should be in a filled state not less than half and should be instantly included in the work at the moment the other is empty.

The working volume of the tanks must provide at least 10 minutes of continuous extinguishing of both internal and external fires. It is allowed to use fire tanks for other needs, but at the same time, the tanks must be constantly filled with no less than 70 percent of their volume.

The installation of the tank itself is carried out on a specially prepared base. For its organization, concrete blocks, concrete pillows, as well as special supports made of durable metal can be used. It should also be borne in mind that above ground tanks may need additional insulation measures - especially in harsh climates. It is assumed that there is:

- a special coil with a coolant supply from boiler rooms, or from heating mains;

- heating electrical installation for the pipeline and tanks directly;

- devices for providing artificial circulation of liquids inside the system in order to prevent its freezing.

Tanks must necessarily be equipped with a pipeline for supply, a pipeline discharge system, overflow devices, a ventilation system, pipeline systems for complete drainage of water, it is necessary to provide water level indicators.

Tank operation

First of all, the filling of fire tanks should be carried out through special supply lines. It is allowed to carry out from natural or artificial reservoirs. In the case of an artificial reservoir, a special protective grid should be equipped on the connecting pipeline from its side.

In the case of additional use of tanks for domestic and other needs, the complete renewal of water in them must occur no later than 48 hours. Sometimes this period can be extended up to 72 hours. Otherwise, the water in the tank becomes unsuitable for domestic use.

The maintenance team should regularly inspect the entire system. If any malfunction is found, it must be corrected immediately.

Once a year, a complete cleaning of the system should be carried out with the emptying of the tanks into special reservoirs or into the sewage system. Reuse of water in this case is not allowed.

The maintenance team must also strictly monitor the water level inside the system.

Water intake from the reservoir for fire extinguishing purposes is carried out using a fire hose line and injection units provided for by the design. You can connect the hose line either through special connectors, or by simply immersing them in the tank.

Pressure tanks and water towers of fire-fighting high-pressure water pipes must be equipped with an automatic device to ensure their instantaneous shutdown in the event that fire pumps are started.

If all Codes and Rules are observed, then fire tanks are extremely effective means to ensure successful fire suppression.