How to make a Stanley cabinet with your own hands. How to make a wardrobe with your own hands: drawings, assembly, examples of successful solutions. How to do it yourself: step-by-step instructions

Currently, many residents rural areas can't afford to buy new furniture for your home. And city apartments don’t always have large area where it would be possible to place household items. But, despite this, people still learned to cope with these problems on their own. To do this you can do wooden cabinet with your own hands, without the services of specialists. Carrying out such a design at home is not particularly difficult, but in order for the furniture to have a long service life, it is necessary to become familiar with the sequence and nuances of the work in advance.

Today the consumer market provides various wooden materials for the manufacture of household items. Therefore, before you begin to consider the question of how to make a cabinet yourself, you first need to decide what material it will be made from. According to experts, the best products for these works the following are considered:

- plywood - this multilayer material has high wear resistance and strength. In addition, due to its environmental friendliness, it is absolutely harmless to human health. Plywood is produced in solid slabs, which simplifies the process of assembling household items;

- particle boards - chipboard sheets are considered the most popular products for creating home furniture. This is due to the fact that they combine good quality affordable price. These products are resistant to changes in temperature and moisture, do not deform under the influence of an aggressive environment and are characterized by increased strength;

- solid wooden boards- the material from the boards is cut from different types of wood. They are produced different sizes, certain types processing and quality of carpentry work. For the construction of furniture, boards from pine, birch and oak are mainly selected. These rocks are endowed with high strength and resistance to changes in temperature and humidity.

Installing household items from pine with your own hands is a labor-intensive process, since the rock is not hard enough. But if you choose this material, you can create an extravagant design in any room.

Wooden boards

So, having considered the options for materials that will be needed to make furniture, it is also worth familiarizing yourself with the tools for performing the work. The manufacture of cabinets is carried out using the following equipment:

- hand saw for sawing wood;

- grinding machine for polishing the surface of wood;

- protractor, for measuring the angle of inclination;

- ruler or meter tape for measuring dimensions;

- wooden dowels, for fastening the product and filling;

- metal corners for fastening furniture structures;

- wood slab for making shelving;

- mastic for sealing the structure.

In addition, in order to enliven a household item with the desired shade, you will need to purchase acrylic paint water based.

Nuances of work taking into account the type of structure

There are several ways to build a wooden cabinet with your own hands.

Corpus

As you can see from the photo, cabinet furniture consists of several component elements, which is why it is also commonly called modular. The peculiarity of such a cabinet is that the owners can, at will, supplement it with various internal and external elements. Initially, the design of the product is developed so that all parts are combined with each other and the body. To build a building, you will need elements such as a roof, bottom, back and side walls. All these elements can be made in the form of removable straight shelves on which things will be placed. It will also be possible to additionally build a pull-out shoe cabinet.

Preparing grooves for fastening shelves

It is better to assemble the structure in a horizontal position

Vertical faceplates

Built-in

A distinctive feature of the built-in wardrobe is that it can be made from scrap materials. The fact is that it is mainly installed in niches of the room or in places where it is not possible to place standard furniture. A solid frame is not required to build the cabinet. It may be missing one or more walls, which are replaced by the floor, ceiling or walls of the building. Filling elements, as a rule, can be made in the same way as for cabinet furniture. But having constructed such a cabinet with his own hands from scrap materials, the consumer must be prepared for the fact that, unlike a cabinet product, this furniture cannot be moved to another place.

The design of each cabinet requires not only the presence of a body and internal filling, but also the front part. The main element of the façade is the door.

When making a built-in wardrobe, it is important to correctly mark the space for future shelves

Shelves must be securely attached

Special logs are required to secure doors

Door fastening

Today the consumer market offers various systems for fastening furniture doors. Each element has its own specific purpose, which depends on how the cabinet is opened.

Swing

Hinged doors are the most common type of furniture design. It consists of wooden canvas and fastening equipment. The number of panels for a cabinet depends on the number of internal sections. As a rule, if the cabinet has one common section, two doors will be required. If the furniture consists of one narrow and one wide section, three doors will be required. The production of door fastenings is carried out at side walls

- cabinet using the following hinges: detachable - such a mount is installed with inside

- cabinet walls;

universal - these products can be installed regardless of the sides of the cabinet. The hinges are attached simultaneously to the body and doors of the furniture.

After the hinges are attached to the product box, the doors are hung on them.

Hole preparation

Alignment and installation of hinges

Coupe Compartment doors are a sliding system where, when the closet is opened, one door overlaps another. Installation of such a structure requires certain knowledge and skills, so before installing sliding wardrobe

from plywood with your own hands, first you need to familiarize yourself with the names of the components and their location.

- The accessories set includes:

- special wheels for moving doors, installed in their upper and lower parts; upper suspended structure

- , for guiding the canvases;

- a lower guide structure along which the door wheels will move in the grooves;

- cassettes for installing wooden panels;

locks and closers for easy door opening.

This design is intended for cabinet furniture with a threshold. If a built-in wardrobe is being installed, it will be possible not to install lower guide elements on the floor.

Markings and drawings

In the cabinet layout diagrams, it is necessary to take into account its width and height. To do this, first use a tape measure to measure the intended installation location. When carrying out measuring work, it is important to consider the distance from baseboards, window sills, pipelines and connectors for connecting electrical appliances. If you lose sight of these points, the wooden cabinet may not fit into the allotted space, or in the future there may be obstacles when opening doors or accessing the power source.

For a DIY cabinet, the drawings can be created using an automated CAD program or by hand. In the first case, the cabinet diagram is drawn up by a special computer system; in the second option, cabinet drawings are made with your own hands. As practice has shown, the second option is simpler, so it is chosen more often. To create a drawing by hand, you will need a sheet of paper and a pencil. Next, sketches of the cabinet are drawn on the sheet.

Description of drawing up a drawing of a wooden product:

- front view of the cabinet - this sketch includes the width and height of the furniture, the height of the base, the size of the sections, the distance of the shelves from each other. When drawing up a drawing, it is important to take into account the thickness of the furniture walls and its contents. You also need to indicate the attachment points for shelves and doors;

- top and side view - in this case, the depth of furniture and shelves is marked on a sheet of paper. When applying filling depth values, it is important to take into account the fastening of the doors. To ensure that the shelves do not interfere with the installation of fastening equipment, they should be located at a distance of 10 cm from the edge façade wall furniture. Also in this sketch you need to indicate the rounding of the shelves with a radius of R.

In addition to the indicated values of the furniture body, you need to draw the dimensions of the filling elements on a sheet of paper. Shelves can be made in different configurations and thicknesses, but they must be of the appropriate size.

Manufacturing of parts

Having made a drawing of the cabinet design with your own hands and prepared the appropriate equipment, you can begin to manufacture its parts. To do this, transfer the dimensions of the furniture elements onto a sheet of chipboard using a meter and pencil:

- upper part of the cabinet in quantity – 1 piece;

- side walls in quantity - 2 pcs;

- bottom in quantity - 1 piece;

- back wall in quantity – 1 piece;

- furniture shelves in the amount of individual consumer preference.

Next, using a saw along the marked lines, they begin to cut out the parts step by step. When performing these works, it is necessary to take into account the thickness of the saw itself, otherwise the furniture elements will be smaller after sawing.

Having understood our drawings and understanding which part belongs to what, we begin the assembly.

Having selected the diameter of the drill for the holes for the comformats, take the drill in your hands and begin drilling the holes. Drill holes symmetrically to avoid damaging appearance closet

- Using a screwdriver, assemble the cabinet frame onto the comformats.

- Next, you need to strengthen the doors with canopies (if the door system is ordinary) or screw in guides (if you have sliding doors).

- Then, in the places where there will be shelves and drawers, make markings for shelf supports and drawer guides. The markings must be precise so that the shelves and drawers are not awry, but run parallel.

- After marking, drill the corresponding holes and screw the shelf supports and drawer guides.

- After assembling the cabinet, bring its appearance to the ideal. As you can see, there is a missing edge at the chipboard seams. Take an iron and a towel. Carefully place the edge on the chipboard and iron it through the towel.

- After gluing the edge, pick it up sharp knife and carefully, slowly, begin trimming the excess edge.

- Finally, put the plugs on the comformats.

Now we can congratulate you! You have become the owner of a beautiful handmade wardrobe.

Using these instructions and your imagination, you can make your own wardrobe with lighting inside, with built-in lamps, or with a regular mirror on the doors. Once you have the courage, you can create a cabinet of any design and complexity. As you can see, there is nothing difficult about this!

Comments12

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

- anonymous anonymous

More on the topic

- February 27, 2009 at 4:05 pm

- February 10, 2017 at 06:00

- April 19, 2010 at 08:59

Increasingly, people are trying to replace conventional ones with sliding wardrobes in their apartments, houses and even offices. But what is the reason for the popularity of this type of furniture, what are its pros and cons, what is it made of and is it possible to make it yourself? Our review today will help you sort out these questions and learn how to make a sliding wardrobe with your own hands (the drawings attached at the end will make the task much easier).

Materials used

Sliding wardrobes are already good because they can be made from almost any material. In particular, for the manufacture of such structures the following is used:

- natural wood;

- laminated chipboard and MDF;

- furniture panels;

- glass and s;

- metal profile for compartment doors.

Tree

Sliding wardrobes from natural wood- the most expensive option. Sliding doors are mainly made from now, and the base and shelves are made from cheaper ones, but also durable materials. Sliding wardrobes made of natural wood look very beautiful, expensive and presentable. However, furniture made from other materials is no worse.

Drywall

If you hear the expression “plasterboard sliding wardrobes,” then know that this is just a niche in which the walls, top and shelves are made of plasterboard. In fact it's Walk-in closet, in which all the “insides” are hidden behind sliding doors.

MDF, chipboard and fiberboard

Cabinets can be a free-standing structure made entirely of, and. They can also be made in the form of a niche with sliding doors made of these materials or mirrors framed with a special metal profile with a roller mechanism. You can buy such sliding wardrobes in furniture stores or make them yourself.

In addition to the straight-line design, you can also do it yourself corner cupboard With sliding system doors. True, its design has its own nuances.

Cutting material and selecting accessories

After all the details have been calculated, you need to draw up a cutting map, which will reduce costs. In order not to bother, you can provide a list of parts with sizes and quantities to the company where you plan to buy the material. Most companies selling laminated chipboard, MDF and provide cutting and cutting services for the material.

Concerning furniture fittings, then the main share of expenses falls on the purchase metal profile, rollers and guides for wardrobes, mesh baskets, tie holders, rods, etc. You also need to purchase drawer guides and handles.

Cabinet filling

The filling of the closet largely depends on the needs and financial capabilities of the owner, since installation, for example, of pantographs and shoes, tie holders, etc., will cost a decent amount. We must think through functionality at the design stage. The closet must have a section for outerwear, a compartment with shelves for light items and bedding, drawers for small items and underwear, as well as a place for shoes and a mezzanine for rarely used and bulky items.

To place clothes on hangers, both longitudinal and transverse retractable rods can be used. You can also make stationary inclined shelves for shoes or install special movable lattice baskets. The same applies to shelves for linen. In general, manufacturers annually, if not monthly, offer more and more new and improved devices for storing clothes.

Everything related to doors and sliding systems

Doors for a sliding wardrobe can be the simplest (frameless), representing a piece of laminated chipboard required size equipped with plastic wheels. This is the simplest and most cheap option, which is now practically not used.

There are also more complex and expensive sliding door systems for sliding wardrobes. They consist of upper and lower metal guides, a frame made of steel or aluminum profile, rollers and filler made of chipboard, MDF, glass or mirror. Such systems are more reliable, durable and quite presentable. The most popular systems are Komondor and Braun.

This video will help you choose the right sliding door system:

Assembling a wardrobe

So, there is a drawing, the material has been ordered, sawn and even delivered, just like necessary fittings, all that remains is to assemble our built-in wardrobe. Yes, we completely forgot about the tools. We will need the following:

- tape measure, metal ruler and square;

- electric drill and;

- confirmations;

- screws 3.5×16 mm, 3.5×25 mm;

- screwdriver;

- confirmation drill with a diameter of 5 mm;

- Phillips and hexagonal screwdriver bits;

- hammer;

- furniture nails 20÷25 mm.

Assembling the box and drawers

First of all, you need to inspect and mark all the parts of the wardrobe. First mark the sides, placing them with their back sides facing each other. When marking, be careful and take into account all the nuances. So, for example, the sidewall has a width of 600 mm, and the shelves are 500 mm, and during marking, some “parking” make the same indentation of 70÷80 mm on both sides of both the barrel and the shelves. As a result, we get mismatched holes and extra holes. To prevent this from happening, when different widths Marking of parts should begin from the rear edge, that is, with a barrel width of 600 mm and a shelf width of 500 mm, the holes should be at a distance of 70 and 430 mm.

If you have no experience in assembling “live”, then it is better to drill the holes right away.

The boxes are best assembled as shown in the bottom picture. In our case, it is better to make two sidewalls 450 mm long. The height of the sidewalls of two drawers can be 140 mm, and one drawer can be made twice as deep. The guides must match the length of the barrels or be shorter. In order to correctly install the guides, you can use the template, which, in principle, is in the instructions for the product or search on the Internet.

The assembly is carried out using confirmations, and the façade is first attached to double-sided tape and then additionally secured with 3.5×25 mm screws. After the boxes are assembled, you need to check the diagonals, nail the fiberboard bottom and install the guides.

When calculating boxes, follow the following formula. Let's say we use 16 mm laminated chipboard, and the width of the upper shelves is 450 mm. This means we subtract 24 mm from 450 mm. on the guides and 32 mm on the sides of the drawers. As a result, the length of the middle sides of the drawer will be 394 mm. Very important when calculating openings, shelves, etc. take into account the thickness of the materials. Beginners often make these mistakes, which leads to damage to the material.

Important! Be sure to check the diagonals before filling the bottom of the drawers or the back wall of the cabinet. If this is not done, then the drawers may fit in with friction or not completely, and the doors will be skewed and will not fit properly with the sides of the cabinet.

If the upper or lower shelves are divided into several separate sections, but must be on the same line, then they need to be secured according to the helicopter principle. In the lower figure, red dots mark the places where such shelves are attached.

After the box with shelves and drawers has been assembled and the back wall has been filled, you can lift and install the cabinet in the planned location. If there are gaps, you can close them with false panels made of the same material as the entire structure. Decorative strips are attached to the structure frame. After this, you can proceed to the manufacture of sliding doors.

The video “How to assemble a wardrobe with your own hands” will help you better understand all the processes of making furniture at home:

DIY sliding doors

In order not to make a mistake and not spoil an expensive profile, you can use the special Aristo program for calculating sliding doors. Before making facades, you need to decide on their filling, that is, whether they will be glass, mirror, laminated chipboard or a combination.

After making the calculations, you can begin assembly. First you need to mark and make holes in the side profiles for fastening. If the filling is glass or mirror, then we put a silicone gasket on the material and put a long piece of profile on it. Next, we attach the upper and lower blanks, and finally “dress” the last element of the frame. After this, you can begin to tighten the parts together using the screws that come with the kit, but you need to do this carefully so as not to pinch or strip the threads.

We install guides for the wardrobe on the bottom and lid and fix them with screws. Now you can install the doors. If you find a loose fit between the facade and the side frame, you will need to adjust the wardrobe doors.

Rollers for wardrobes

The roller system for sliding wardrobe doors plays a very important role. The choice of system depends on the comfort of use of the facades, as well as the weight that they can withstand without compromising operation.

For example, a roller system for a frameless door can withstand a weight of about 15 kg, while more serious and expensive mechanisms can support facades weighing 60÷100 kg. It is better, of course, to choose expensive systems from a trusted manufacturer, especially if the doors are made of mirror or glass with a sandblasted pattern.

After the doors are installed on the rollers in the guides, you need to install the schlagel on their long sides. Essentially, it is a bumper and softens the impact of the facades on the sidewalls, and also prevents dust from entering the cabinet.

In principle, the installation and adjustment of sliding doors completes the manufacture of a wardrobe. All you have to do is wipe the marker or pencil, brush away the sawdust and wipe it with furniture care product and you can enjoy the creation of your hands.

The presented video shows how to assemble wardrobe doors yourself:

Photo gallery of interesting wardrobe options

We looked at what a wardrobe is, what it consists of and is made of. We also found out that you can make such furniture yourself. However, most people still prefer to contact specialized companies that make kitchens, living rooms, children's rooms and wardrobes to order. Let's see what cabinet furniture manufacturers delight people with.

Sandblasting images on mirror facades

Just mirrored wardrobe doors look beautiful, but applying a pattern to them using sandblasting technology makes the facades more attractive and original. The drawing is created using a previously developed stencil. The design can also be applied to glass surfaces.

Sandblasting can be done by itself, pasted on mirror surface, in this case the background remains clean and untouched. There is also the exact opposite processing option. There is a third way, when processing is performed with reverse side mirrors

Decorative PVC film stickers

The simplest option for decorating facades for sliding wardrobes is to use vinyl stickers. The film can be easily pasted and, if necessary, replaced with a new one. Vinyl films are available in various patterns and different shapes. This decor is affordable for anyone.

What to consider when choosing a wardrobe

Before you buy or order a wardrobe, you need to consider several important points, on which the durability of the product, comfort of use and aesthetic pleasure of this piece of furniture will depend in the future.

- Materials and accessories. It is clear that they must be of high quality, durable and have all quality and safety standards. It is best, of course, if they are from well-known, trusted manufacturers, since furniture is not a household item that is bought for 1–3 years.

- Shape and dimensions. When buying a sliding wardrobe, of course, it is best to find out in advance the dimensions of the place where you plan to install it and focus on them accordingly. It is also necessary to take into account the shape of the cabinet. If it will simply stand against a wall or in a niche, then you should choose a straight design, but if you intend to install it in a corner, then purchase a corner model, and if available large room You can order a combined model – corner + straight.

- Content or functionality. Of course, this largely depends on your needs and wallet. There is hardly any need for a pantograph, mesh laundry baskets or tie holders in a small closet. A longitudinal rod for outerwear, shelves for linen and drawers for small items is quite enough.

- Quality systems for sliding doors. Since sliding facades in a wardrobe account for almost the lion's share of the cost, it is natural that their quality should be taken seriously. The comfort of their use depends on the quality and reliability of sliding systems. It’s worth saying right away that the most simple system, the so-called “Polish” one is not a very good option - it “crashes” literally after a year of use.

Where can you buy or order sliding wardrobes and how much does this pleasure cost?

A sliding wardrobe can be purchased in a store or from a specialized furniture company. It’s worth saying right away that the price of a custom-made wardrobe differs significantly from the finished product. But what else affects the cost besides individuality?

Baikal-Titan-2-15 Cardinal-2 Corner wardrobe Alliance Corner wardrobe Versailles-1

Baikal-Titan-2-15 Cardinal-2 Corner wardrobe Alliance Corner wardrobe Versailles-1 The cost of the cabinet also depends on the manufacturer. The model that famous manufacturer costs, for example, 50,000÷70,000 rubles. You can buy copies from manufacturers at half the price.

Article

Having decided to update the interior of your home, you should think about changing furniture pieces.

Every home should have roomy clothing.

It can be purchased at finished form, order individual production or do it yourself.

The distinctive features of such an item will be that it perfectly matches the style of your home and expresses your taste.

The variety of available materials on the market opens up opportunities for consumers limitless possibilities. You can assemble furniture with your own hands from:

The variety of available materials on the market opens up opportunities for consumers limitless possibilities. You can assemble furniture with your own hands from:

- natural wood;

- linings;

- drywall;

- laminate;

- MDF or chipboard;

- Chipboard.

The appearance of the product and its durability will depend on the material chosen.

Wood or lining are the most popular materials. They differ:

- naturalness;

- aesthetics;

- ease of use;

- long service life;

- reliability.

Important. In wet areas, furniture pieces made from wood may peel or warp. Therefore, they must be impregnated with a water-polymer emulsion or hot drying oil.

Drywall lightweight and easy to use. It is easy to cut, saw and process with various available tools. But plasterboard structures are not very durable.

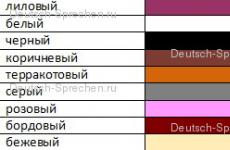

Laminate, chipboard, MDF– resistant to sudden temperature changes. They cut perfectly, do not crack and have an impeccable appearance. Color palette These materials are striking in a variety of shades. Thanks to this, the furniture fits into different stylistic directions.

Width and depth

Before you begin, you must carefully calculate the dimensions of the product. Based on these calculations, a drawing is created. Standard sizes are:

- optimal depth The length of the product is 60 cm. This closet will accommodate clothes hangers, drawers, and laundry baskets. For sliding wardrobes with sliding doors, the depth should be increased by 10 cm;

- minimum width products are calculated individually. Most often it is 40 cm. Here it is worth starting from the size of the room and personal preferences;

- height wardrobe should be 240 cm. But if desired, it can be increased or decreased.

Drawing

The main feature of any piece of furniture should be its ergonomics and good spaciousness. To make it much easier to assemble the cabinet and calculate the required amount of consumables, you need to draw a preliminary sketch and diagram.

For cabinet furniture it is necessary to build the back, side and top walls. And for built-in– side walls and top cover are not needed. The cabinet is mounted directly into a niche, and shelves and other elements are attached directly to the walls in the room.

A drawing of a wardrobe for outerwear is drawn up using a ruler, pencil and a sheet of paper. If you draw it by hand, it will take a decent amount of time.

Advice. To create a drawing it is easier to use special programs on the computer.

Tools and materials

To make a cabinet you need to prepare the following tools:

To make a cabinet you need to prepare the following tools:

- jigsaw and drill with hammer drill;

- screwdriver;

- miter saw;

- building level;

- hammer, tape measure, square;

- hacksaw for metal;

- construction knife.

As for materials, you can cut it yourself or order it from a furniture company. The second option is more convenient.

Advice. By ordering LSDP cutting, you get the design and quality of material you need in one place, and receive sawn and trimmed parts completely ready for assembly.

All that remains for you is to mark the locations for the holes, for attaching fittings and fasteners.

How to do it at home?

After all preparatory work, you can begin manufacturing and assembling the frame. If we are talking about built-in furniture, then its assembly begins on one side and proceeds in order:

- First, the shelves are attached to the side and rear walls using corners.

- Next, a stand is mounted, which is attached to the wall and to the installed elements.

- After this, the remaining shelves are mounted to the walls and the counter.

Important. When assembling the cabinet frame, you must strictly follow the drawing to avoid inconsistencies. Make sure there are no distortions during the assembly process.

To assemble a built-in wardrobe you will need confirmations and dowels. With the help of confirmations they are attached to each other individual elements. And dowels are used to give the structure special strength and reliability.

To assemble a built-in wardrobe you will need confirmations and dowels. With the help of confirmations they are attached to each other individual elements. And dowels are used to give the structure special strength and reliability.

To drill holes for confirmations, a drill with a diameter of 5 mm is used. The back wall can be attached with small nails or a construction stapler.

Internal shelves and walls can be fixed furniture corners. The corners are fastened with self-tapping screws. To give the structure increased strength, confirmats are used.

Advice. It is better to assemble the cabinet at the place of its installation.

The final stage after assembling the frame is the internal arrangement of shelves, drawers, and clothes rails. It is also worth taking care of proper interior lighting.

Finishing

The final finishing of hand-made furniture directly depends on the selected materials.

The final finishing of hand-made furniture directly depends on the selected materials.

A product made of MDF, laminated chipboard or natural solid wood, in additional finishing does not need. But plasterboard products should be decorated to add aesthetics.

Cabinet interior surfaces painted to match the walls. This visually enlarges the room. And to make a piece of furniture a bright spot, you can use a rich paint color. Plasterboard shelves are pre-primed and glued vinyl wallpaper or self-adhesive tape.

As for doors, they are most often ordered ready-made from laminated chipboard sheets or mirrors and do not require additional finishing. And the side walls can be primed, puttied, covered with film, wallpaper or painted with permanent paint.

Photo

After finishing the work, you may end up with something like the following photos:

Useful video

The main stages of manufacturing can be seen in the following video:

Conclusion

In conclusion, it is worth noting that building and assembling a wardrobe with your own hands is quite easy. The main thing is to choose the right one Consumables, create competent diagrams and drawings, and stock up on free time.

In contact with

Are there many things and pieces of furniture in your home that you can easily discard? Surely enough. However, they do not include such a piece of furniture as a wardrobe.

After all, this is where you store most of your clothes, towels and bed linen. And therefore it is almost impossible to do without it.

Of course, it is possible to replace it with cabinets and chests of drawers. But their number will be so large that the space of the room will be completely cluttered. Not everyone can afford this.

Many people live in quite small apartments, in which every centimeter of free space should be rationally used, so do not forget that you can order modern wardrobes with delivery and assembly from our partners.

But often the cost of such important products is unreasonably high. And therefore, some people are forced to refuse to buy cabinets.

But experts are confident that a way out of this situation can be found. For example, make this product yourself.

If you are wondering how to make a cabinet with your own hands, then we recommend that you read this article. In it we will look in detail at the simplest example of assembly, which even a novice carpenter without experience can handle.

Cabinet detailing

To make the cabinet we will use a material such as chipboard. The thickness of one of its boards is 18 mm. In addition to the main material, a self-adhesive melamine edge with a thickness of about 0.5 mm will also be used. The product will be equipped with a standard sliding system for facades.

You can purchase the edge at furniture store. It is worth noting that to construct a built-in wardrobe with your own hands, you may need a special sliding mechanism.

Most often, it is not easy to find something similar in a regular store. Then you will need to order it. However, even in this case, facade system will cost you much less than if you purchased a finished product.

The cabinet that will be considered as an example has a height of 2288 mm and its width is 1166 mm.

Required tools and materials

Before you begin building your cabinet, you should make sure you have everything on hand. necessary materials and tools. You can find out the number of boards and parts if you carefully examine the cabinet drawing, which is presented to your attention below.

A standard set of tools required for cabinet carpentry includes: drill, level, hammer drill, measuring tape, hammer, glue, hacksaw and fasteners.

Self-tapping screws and dowels act as connecting elements. Please note that you should select a hacksaw that is suitable for both wood and metal.

The rods that will be used for hangers must be sawn off from a single structure. Their diameter should not exceed 22 mm for the declared dimensions of the product.

If you are not confident that you can make them correctly yourself, then the best option will become purchase. You can buy them in a store that specializes in selling furniture fittings.

You can also buy pens in the store. When purchasing them, pay attention to the design. It must correspond not only to the product being manufactured, but also to the overall interior design.

Note!

Manufacturing stages

At the first stage, you need to prepare all the details. Pay attention to the photo of a do-it-yourself cabinet, which is presented below. To create it we used a circular saw, since it made it possible to cut the boards most accurately and accurately.

The second step is to prepare the edges. To glue them, you need to use a regular iron and follow the instructions.

At the third stage, grinding is performed. With its help, you will get rid of any roughness that exists after cutting. To do this, you can use regular sandpaper with fine grains.

At the fourth stage, you should begin collecting boxes. An example of assembly is shown in the figure.

At the fifth stage, the entire structure is assembled.

Note!

It is worth noting that assembling the cabinet itself is no different from assembling the drawers. After all, the cabinet itself differs from the drawers only in its size.

In order to make a confirmatory tie, you will need to use a hex bit. If you don’t have one on hand, you can use an ordinary hand key. However, this will require more time to work.

Fastening the guides under the doors should be done using self-tapping screws, which have a size of 4 by 16 mm. The distance between the front edge of the bottom and the sides of the product should also be measured locally.

Be sure to ensure that the product is equipped quality system, which will eliminate the possibility of cracks. This is extremely important if you plan to make a corner cabinet with your own hands, since any cracks will be noticeable.

Photo of a do-it-yourself cabinet

Note!