Soundproofing interior partitions. Everything about interior partitions: materials, construction features, sound insulation. Additional sound insulation of tongue-and-groove and aerated concrete partitions

Protecting living space from extraneous sounds is a task that builders have been puzzling over since the first buildings were erected. One of the most effective methods One of the ways to protect rooms from excessive noise was the installation of plasterboard partitions with sound insulation.

Sound propagation and absorption

The concept of “sound,” as physicists define it, is mechanical vibrations propagated by some source in an elastic medium - air, wood, metal, etc. By emitting vibrations, the source creates pressure (low or high), which spreads in all directions. The sound wave generated in this case enters the human hearing organs and transmits vibrations to the eardrum, the vibration of which is perceived by the brain as sound.

The parameters of sound propagation largely depend on the density of the medium and can vary significantly. So, when encountering an obstacle, sound waves are reflected or refracted. If a porous substance gets in their way, it absorbs the wave, dissipating it inside itself. This physical property materials are widely used in construction, for example, for soundproofing ceilings and plasterboard partitions.

The greatest dissipation of sound energy is due to an increase in the number of pores and voids present in the substance. The materials themselves, made taking into account these features, are called sound-absorbing or sound-proofing.

Types of Soundproofing Materials

So, having studied a brief theoretical background, we can conclude: effective protection protecting your home from extraneous sounds is impossible without the use of additional materials. Modern market offers a huge number of solutions to achieve required level soundproofing of premises. Materials that are used to combat excessive household noise are divided into two main categories:

- Sound-absorbing (Figure 1). Capable of absorbing sound waves, preventing their reflection and further propagation. They have a granular, fibrous or porous structure and are most suitable for protecting residential premises from extraneous noise, thanks to easy installation, optimal characteristics and low cost. For example, they are widely used in soundproofing ceilings and plasterboard partitions.

- Soundproofing (Figure 2). They prevent the penetration of sound vibrations by reflecting them. Sound insulators are massive, since it is the thickness and mass that affects their sound permeability. The most common, reliable and high-quality sound insulating materials are concrete, brick and plasterboard.

Let us note that only the joint, combined use of these materials makes it possible to achieve the desired effect when equipping a home with sound insulation.

Materials for soundproofing partitions

The choice of sound insulator largely depends on the nature of the noise. To combat “airborne” noise (loud screaming, music or the barking of a neighbor’s dog), materials with a porous structure (soft or semi-hard) are used. “Impact” noise (the sound of falling objects, the clatter of footsteps, or the vibration of the drill bit of a working drill) is effectively eliminated only by dense cushioning (hard) materials.

Among the most common and most effective materials, used for sound insulation plasterboard partitions, it should be noted:

- Glass wool. Elastic, non-flammable, durable and vibration-resistant material. It is lightweight and elastic. Glass wool does not absorb moisture and has a high sound absorption coefficient. It is produced in the form of rolls or briquettes and is conveniently mounted.

- Mineral wool. The material made from silicate and metallurgical slag differs unique characteristics soundproofing. The advantages of mineral wool are absolute non-flammability, environmental friendliness and the ability to create multi-layer structures with its help. Soundproofing a plasterboard partition using this material will not be difficult, since it is very easy to install and relatively inexpensive.

- Pressed cork chips. These sheets have excellent insulating properties and are not susceptible to rotting or attack by insects or rodents. Cork is durable and environmentally friendly, but its use, compared to other sound insulators, is less common due to its rather high cost.

Soundproofing of interior partitions made of plasterboard

Building new house or changing the standard layout of an already finished home, we often think about installing interior frame partitions for more effective zoning and increasing the usable area of the premises.

We will not describe all the stages of construction of structures, since this will be the subject of a separate detailed article. We will only talk about the features and advantages of partitions, as well as the rules for their sound insulation:

- Since these structures are not load-bearing, it is not necessary to use heavy solid brick or concrete in their manufacture.

- IN wide range building materials intended for such work, the greatest preference is given to plasterboard. Its advantages are that it is universal, inexpensive, easy to install and has a perfectly flat surface.

However, along with installation, we should not forget about soundproofing plasterboard partitions between rooms.

- The effectiveness of the design depends on the combination of a soft inner layer that absorbs noise with hard, sound-reflective outer layers.

- The level of sound insulation in such structures depends on the thickness and rigidity of the facing layers, the width of the gap between them, as well as the sound absorption coefficient of the internal material.

- Narrow multilayer partitions are much more effective than thick monolithic ones. In addition, they can save a lot of money usable area housing.

When equipping a plasterboard partition with sound insulation, you must remember that the places where the frame is attached to rigid structures, the ceiling and floor, must be insulated with elastic gaskets.

Important! For safety reasons, all electrical wiring installed in the interior partition must be laid only in corrugated tubes!

Proper soundproofing of walls is the key to a comfortable pastime.

The partition is used to divide space into zones in private buildings, offices or public spaces. Soundproofing of interior partitions is important factor. Sound waves can travel through surfaces. To stop them, you need to reduce the sound pressure. For this purpose, various soundproofing materials are used. This article will look at how soundproofing of partitions is carried out and what is needed for this.

Sound propagation and absorption

Sound is the name given to mechanical vibrations propagated by a source in an elastic medium. By creating vibrations, the source generates pressure that spreads in different directions. The sound wave generated as a result of such processes penetrates the human hearing organs and transmits vibrations to the eardrum, which, when vibrating, is perceived by the brain as sound.

The characteristics of sound propagation directly depend on the density of the medium and can vary greatly. For example, if sound encounters any obstacle along its path, its waves are reflected or refracted.

If a porous material is placed in its path, it absorbs the wave by internal scattering. This characteristic of products is often used in construction for or other surfaces. The materials themselves, produced taking into account such features, are called sound-absorbing or sound-proofing. In the following table you can see a comparison of such materials.

Sound insulation of plasterboard structures

Products made from plasterboard sheets are becoming increasingly popular. When deciding to divide the space of a room into zones, sound insulation should be ensured in mandatory. At proper planning the costs will be small. The following video will help you become more familiar with this procedure.

She herself has high level soundproofing, but it can be increased by the following actions:

- use of soundproofing materials;

- sound insulation of walls using special technology;

- use of soundproofing fasteners when installing the frame;

- use of special profiles;

- increasing the interval between partitions;

- use of thick frames;

- increasing the thickness of the finish;

- the use of various fillers for the frame.

A plasterboard partition is constructed in two layers: the outer one is a shell made of a sheet of material, and the inner one involves the installation of a special filler.

Its cost is quite high, so fillers can be used. Porous slabs in soundproofing partitions are the main component providing sound insulation.

Soundproofing a partition is impossible without taking into account metal frame, which is a good conductor for sound.

Soundproofing a partition is impossible without taking into account metal frame, which is a good conductor for sound. You will need to lay a sealing tape under the initial horizontal profiles, and metal fastenings mounted with polymer gaskets.

Soundproofing of frame partitions is carried out as follows:

- One side of the frame is covered with a sheet of plasterboard.

- Communications are laid, sockets and switches are installed and connected.

- In inner part The partitions are filled with sound-absorbing material. There should be no empty areas between the sheets.

- The layer is covered with a membrane or porous tape.

- On the other side, a plasterboard sheet is mounted.

- Cracks and empty spaces are filled with sealant.

Comparison various partitions with sound insulation can be seen in the following table.

Use of new developments

Great competition in the building materials market forces manufacturers to invent new soundproof materials. Work is being carried out in the following directions:

- production of acoustic plasterboard;

- use of special fillers with noise absorption function for partitions;

- plastic gaskets that are mounted under the frame and have the function of reducing the sound of an impact;

- filling partitions and installing false walls;

- spraying fibers inside structures.

Acoustic drywall

Various brands have begun producing similar drywall, which significantly reduces the noise level when finishing interior partitions or processing other surfaces. Good sound absorption is ensured by a large number of holes that reflect sound waves directed at the coating. In addition to this, with reverse side A non-woven fabric with a sound absorption function is glued onto the material.

Sound-absorbing filler

Soundproofing of partitions is possible by laying sound-absorbing filler inside. For such purposes, polystyrene foam is often used. In addition to sound insulation, finishing can provide good level thermal insulation. By adding a fire retardant, the fire resistance of the filler significantly increases.

Mineral wool slabs also have good performance sound absorption. For sound insulation, acoustic slabs with a thickness of no more than 4 cm are usually used. Good sound insulation can only provide homogeneous slabs.

Fillers for partitions with improved sound insulation parameters have more high cost, but allow you to achieve complete sound insulation in your home. In addition, thinner filler can be used, which reduces the cost of work and loss of room space.

Membranes made of thin fabric coated with pile can provide high quality sound absorption. Their thickness can vary from 2.5 to 12 mm.

Panels made of polyester and polyurethane foam are used as internal fillers and when installing false walls. Some varieties can be a fire hazard because they contain flammable materials.

An inexpensive filler is. It reduces the noise level slightly, but has extremely low efficiency.

Spraying coatings

Spraying of products is often used due to the low cost and simplicity of the procedures. This method allows you to regulate acoustic parameters inside entertainment and public buildings. To implement it you will need the help of specialists.

Possibility of spraying foamed cellulose composition onto various surfaces allows you to avoid installing a frame, which is used to hold plasterboard partitions. The method is inexpensive and not highly labor intensive.

When using special tools, the sound insulation of partitions can be increased by applying cellulose from the inside.

Mistakes when creating sound insulation

Novice builders often make mistakes when trying to soundproof interior designs. The most common mistakes are:

- Cladding houses only with sound-absorbing components. In order to increase sound insulation, the material must be used together with special panels, and large fences with acoustic decoupling must be used in the junction areas.

- Placing noisy equipment in rooms with partitions. The effectiveness of noise reduction materials has limits. It is not always possible to create high-quality sound protection. Equipment publishing a large number of sounds, it is better to place them away from the partitions.

- Soundproof the partition using three layers of plasterboard with filler. For high efficiency you need to use special components and install gaskets between the frame and the partition, and also fill the joints with special sealants.

- Soundproofing buildings with thin soundproofing screens. A soundproofing partition can only be created using structures with a minimum thickness of 40 mm.

Soundproofing screens can be seen in the next photo.

As can be seen from the article, soundproofing partitions is possible different ways. You just need to carefully select the material, since the level of sound protection will depend on it. The work is not too complicated, so even a beginner in the construction craft can handle it. Thanks to the photos and videos used in the article, it will be possible to see in practice how such a procedure is performed.

In most apartments, interior walls are built from tongue-and-groove, foam concrete or cinder blocks - materials that are extremely poor in terms of sound insulation.

Why are these particular materials chosen for interior partitions? The thing is that it is convenient for builders to erect such walls, and they are erected quite quickly: in a couple of days you can erect all the walls, and then make good money by plastering them. The low noise insulation of such walls and their high ability to transmit noise from adjacent apartments are, as a rule, not of concern to workers, since they will not then live in the apartment being renovated. “Nothing personal - this is business!”

What is the best material to build interior partitions from for better sound insulation?

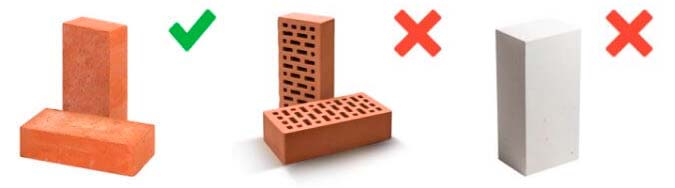

Partitions can be single-layer or multi-layer. Single-layer walls are walls made of blocks, and multilayer walls are frame-sheathing structures, for example, made of plasterboard. If we talk about partitions made of homogeneous materials, then high noise insulation will be provided only by materials with, such as: solid red brick, expanded clay concrete blocks.

Expanded clay concrete blocks covered with sand are used for interior walls in recording studios

Soundproofing a brick partition

Red partitions will have good sound insulation solid brick(hollow or sand-lime brick is not suitable). Red brick has high surface density and good internal losses.

The wall should be thick half a brick(and not in a quarter) and must be plastered on both sides (total thickness ~140 mm). It is important not to skimp on cement mortar.

Building regulations prohibit the construction brick walls in apartments

One might think that we have found suitable material, if not for one moment that makes it impossible to use solid bricks in apartments! Current building codes prohibit the construction of brick partitions in apartment buildings— the floors are simply not designed for such a load!

Soundproofing of interior walls made of other materials

Rest Construction Materials, passing by weight, have low sound insulation and do not provide standard values.

For example, the density of tongue-and-groove blocks (plaster) is 1100 kg/m 3 . The calculated noise insulation of a partition made of plastered tongue-and-groove timber with a standard thickness of 80 mm is ΔR w = 40 dB.

Sound insulation of walls made of foam concrete or aerated concrete blocks have even weaker sound insulation than walls made of tongue-and-groove walls. The density of foam concrete grade D400 is only 400 kg/m 3, i.e. even less than the tongue-and-groove! A 100 mm thick foam concrete wall has an insulation index of only ΔR w = 37 dB.

The low sound insulation of such walls is also caused by undesirable resonance phenomena in the range of 500–800 Hz (the middle of the speech frequency range), which significantly reduce the sound insulation of household noise.

Indirect noise transmission to block walls

Another unpleasant feature of walls made of tongue-and-groove or porous concrete is their strong re-emission of noise from lower and upper neighbors. Due to the low weight of such walls, sounds from massive floors are transmitted very well to them. In addition, plaster has very low internal losses (as a test, you can knock on the plaster wall and feel its “ringing”), which also enhances the re-emission of structural noise.

Subjectively, after dismantling all the internal walls, the noise level is reduced by about half!

Installation of interior walls made of blocks cannot be carried out without rigid connections with the existing structures of the house, so it will not be possible to completely eliminate the transmission of vibrations to them.

A noticeable reduction in noise can be achieved if the partitions are not raised to overlap the ceiling by 10-20 mm. The gap should be filled mineral wool or another damper and seal the joint. This measure will reduce the transmission of noise from above to the partitions.

An example of a vibration-isolated connection between a partition and a ceiling.

Under no circumstances should you use polyurethane foam, which is very light and has a closed cell structure, and therefore has neither reflective nor absorbent properties. At the same time, foam is an acoustically rigid material and perfectly transmits vibrations.

Sound insulation of interior walls made of tongue-and-groove (or aerated concrete) turns out to be insufficient. Such partitions often have to be additionally soundproofed.

An important stage in arranging a quiet, full-fledged room is soundproofing interior partitions. If you have kids at home and you want to create for them cozy corner, protected from loud sounds and neighbors, it is imperative to install a noise-absorbing structure.

If you don't know what better sound insulation interior partitions, contact Revecon. We manufacture structures of any complexity and install them to order. All work and products are guaranteed.

Catalog of our products - we work in Moscow and the Moscow region

Purpose of soundproofing systems

Interior partitions without appropriate fillers they will not be able to guarantee noise protection. Structural housings with noise-absorbing functions are designed to:

- Stop loud sounds;

- Reduce vibration from noise;

- Minimize sound from household appliances.

Sound insulation is a range of measures to reduce the intensity of noise in an apartment, private household or entertainment venue.

Types of structures that protect against extraneous sounds

Revecon offers various interior systems, capable of providing excellent protection from neighbors and unwanted vibrations.

Types of partitions for apartments and cottages:

| Types of systems | Characteristics |

| Frame soundproofing partitions and walls | Designs that reduce the level of noise pressure as waves pass through them. The main task of such partitions is to reflect sound, creating an obstacle when vibration does not pass through the system. |

| Noise-absorbing structures | When arranging them, materials are used that absorb sound and reflect the energy of the wave when it interacts with the interior wall. |

| Soundproof systems | Their goal is to completely eliminate the penetration of extraneous noise and not let it pass outside or inside the room. |

When installing sound-absorbing partitions, Revecon engineers use high-quality sound-absorbing and sound-insulating materials. This is the only way to ensure the appropriate level of protection from extraneous vibrations.

Selection of soundproofing materials

The use of plasterboard, which has special characteristics, will reduce the level of noise penetrating through interior structures.

What is better for soundproofing an interior partition:

- Membranes are thin sheets supplied in rolls;

- Sound-absorbing slabs.

The basis of the membrane is a polymer fabric protected by a layer of felt particles. The thickness of the material is 2.5-12 mm, which allows the use of certain types of raw materials when arranging thin structures. The plate acts as a sound barrier, blocking the passage of waves. Felt spraying enhances the effectiveness of protection.

As a complement or alternative to membranes, Revecon engineers use different materials with a porous structure that provides excellent sound absorption, thereby improving sound insulation performance.

Using the latest technology

Competition in the finishing and building materials market forces manufacturers to improve the quality of their products. For these purposes, work is carried out in the following directions:

- Installation of acoustic gypsum board;

- Use of special filler with sound-absorbing properties;

- Elastic materials under the frame, reducing sounds from mechanical impact;

- Filling structures and arranging false panels;

- Cellulose fillers inside the system.

Thanks to modern technologies, use quality materials Revecon company produces partitions of any complexity with varying degrees of noise absorption.

Soundproofing interior panels: instructions

Assemble a high-quality partition that provides reliable protection from noise, having experience, qualification can be done without difficulty. To do this, you will need wooden blocks or an aluminum profile, a mineral filler and a material that prevents the penetration of waves through the frame - gypsum plasterboard.

How to soundproof an interior partition:

- Apply markings of the future structure to the surface flooring, then the ceiling and walls.

- Fix the profiles with dowels (every 40 cm). Cover the guides with polyurethane tape. Install the skeleton stands.

- On the one hand, using self-tapping screws, fix the gypsum board in one or several layers. Cut noise-absorbing mats.

- Install the prepared membranes inside the system by surprise. Bring the edges into the U-shaped space aluminum profile on the one hand, on the other, focus.

- Place communications inside the partition - wires, sockets, cables. Fix the gypsum board on the other side.

At the final stage, Revecon engineers perform Finishing work taking into account the characteristics of the interior panel, the characteristics of the room and the wishes of the customer.

Possible mistakes when creating sound insulation

To ensure proper quality of sound absorption, Revecon experts do not recommend finishing the room exclusively with sound-absorbing boards, placing noisy equipment anywhere in the building, or constructing walls using 3-layer plasterboard with filler.

Sound insulation can only be created using the “mass-elasticity-mass” system, with a minimum thickness of 40-50 mm.

If you need to properly arrange soundproofing of interior partitions, contact Revecon. Our craftsmen will take measurements and prepare a design of any complexity, taking into account all your wishes.

The advantages of a wooden house over stone buildings attract more and more people to such buildings. Environmentally friendly, warm and cozy home, which retains heat for a long time, is an indicator of the refined taste and certain wealth of its owner. In addition, a wooden house is not electrified, and practically no dust collects in it. However, for a comfortable stay you always need soundproofing.

Why is sound insulation needed?

Along with a lot of advantages, wood is an excellent conductor of sound, and a structure made from it has many resonant frequencies, at which the sound is amplified several times. This property of wood products is used when creating musical instruments, production of special resonance panels for concert halls.

However, in the built wooden house a huge number of sounds amplified by resonance, and even those that are simply transmitted through walls without amplification, will cause a lot of trouble for owners who want to relax in silence. That is why during construction wooden houses Be sure to take into account the need for sound insulation using modern materials.

It should be taken into account that, according to the principle of implementation, there are two main types of sound insulation:

- sound insulation is the implementation of a number of measures to reduce the penetration of sounds from outside into a living space;

- sound absorption - taking measures to reduce the passage of sounds from the room to the outside.

When planning noise insulation measures, you should also take into account the permissible noise level requirements. In particular, for residential premises the maximum daily level is set at 40 dB, and during the day - 30 dB. This level can be measured using special devices– sound level meters. Increasing the level of sounds (noise) above these limits significantly reduces the comfort of staying in the room, and a level of 120 dB is already dangerous for the hearing organs.

When clarifying the factors influencing the noise level in the room, it should be taken into account that:

- a whisper creates a sound level of 20 dB;

- quiet speech – 40 dB;

- noise from a passing car - about 80 dB;

- music player - on average about 90-100 dB;

- fireworks and firecrackers – up to 130 dB.

Types of noise

Before planning noise insulation measures, you should take into account the main sources of noise and the types of noise from which you need to protect interior spaces wooden house. External noise can be divided into several types.

Acoustic

These are sounds traveling through the air and representing acoustic waves. The sources of such noise can be both conversations of neighbors, and operating audio equipment (players, tape recorders, amplifiers, radios, TV), sounds from the operation of car engines, and the voices of animals.

Drums

This type of sound is transmitted quite well and far directly solids, to which shock or vibration impact. Such sources include, for example, hammer drills, hammer blows, the stomping of people walking, the sound of objects falling on the floor, the sound of a train moving along the rails.

Combined noises

This is the presence of noise, both acoustic and percussive. For example, the same hammer drill creates two types of noise. When the nozzle impacts the surface, frequent impacts are created, and the operation of the hammer drill engine creates acoustic noise.

Thus, when carrying out noise insulation, it is necessary to take into account which noise sources are nearby, and from what type of noise it is necessary to isolate the room. In addition, the intensity of the sound (its volume) should also be taken into account.

Types of sound insulation and its installation

First of all, for effective sound insulation it is necessary to eliminate sound bridges in the room that arise at the connection points wooden parts and beams. Sounds are transmitted very effectively through these bridges; in addition, additional resonant frequencies arise in these places, at which the sound is amplified.

When carrying out soundproofing of premises, various materials and compositions are used, such as pierced mats, ready-made slabs different material, roll sound insulation, liquid formulations applied by spraying.

The use of one or another material depends on the type of construction of the walls, floors and ceilings of the room. So, with a frame design, it is necessary to fill the inside of the wall with special soundproofing materials, and in this case the wall consists of three parts (two external covered and internal soundproofing).

- In case of limited thickness between the outer parts of the wall, it is used as a sound and heat insulator. foamed polyethylene or polyurethane.

- To reduce sound transmission between the wooden parts of the house they use glass wool sound insulators and other materials. They are placed between beams and joists, eliminating direct contact wooden parts buildings. And also to reduce the level of sound transmission and vibration, the beams are wrapped with special construction felt, and polypropylene or cork backing. Such work is carried out during the construction of the house, since it will be difficult to perform it later.

- Very simple, but very It is effective to lay floors in places where they rest on sound insulators without rigidly attaching them to the base. This creates a “floating floor” that is not connected to the rest of the structure. At the same time, very high-quality sound insulation is ensured. And the option of fastening floors on damper support springs or brackets is also used, which requires the use of special springs (brackets) designed for heavy loads. In this case, the load is calculated based on total weight floor with furniture plus the weight of several people (depending on the area of the room).

- To obtain additional interfloor noise and thermal insulation Between the ceiling and the floor of the next floor, expanded clay chips are most often poured. It is lightweight, but at the same time performs its functions perfectly. Sometimes sand is also poured in, but in this case it is necessary to significantly increase the overall strength of the structure, taking into account that the total weight of the structure will increase, and use stronger materials for the ceiling. In order to reduce the total weight, leaves or dry sawdust are added to the sand.

You can start soundproofing with your own hands, gradually using one or another method.

In particular, you should start by carefully sealing all the cracks through which sound passes with special mastic or putty. The voids made for the installation of electrical switches are filled polyurethane foam. Seal the inlets of water supply and gas pipes into the house using elastic sealants.

When implementing interior soundproofing, soundproofing materials are placed in the voids of wall partitions. Often sound insulation is combined with thermal insulation through the use of heat-insulating materials lined with plasterboard.

In general, soundproofing walls in a wooden house requires an integrated approach with the elimination of all possible sound conductors in the room. At the same time, the location of the air ducts is also taken into account, which, especially those made of wood, are excellent conductors of sounds both indoors between rooms from neighbors, and outside into the room.

Cork sound insulation has been known for a long time, it was used in the construction of various houses and buildings. For example, on the Black Sea coast in Gagra (the former name of Gagra) specifically for the recreation of members royal family A small castle was built, in which cork slabs were laid in all walls and doors in order to increase the effectiveness of sound insulation. Thus, sounds from outside practically do not penetrate into the rooms of this building.

Currently, panels from balsa wood for interior decoration. Such panels, in addition to excellent appearance, successfully perform the function of sound insulation. Soundproofing membranes made of balsa wood are used not only for finishing houses, but also in the construction of professional recording studios, where high-quality sound insulation of the room where sound recording takes place has vital importance for high quality sound.

And also soundproofing wooden structure can be performed using modern special liquids adhesive compositions. At the same time, the quality of sound insulation is at a fairly high level.

Very often, foam, polyurethane and other materials are used for sound insulation, which quite successfully absorb sound wave, are not subject to corrosion and are very durable.