How much do fireproof metal doors weigh? Fireproof metal door weight

Every owner planning to install fire doors asks how much such a structure will weigh. This issue becomes especially relevant when calculating the price of door transportation by rail or road, since the cost of transportation directly depends on the weight of the cargo. So what does the mass of a fire-prevention structure depend on?

Every owner planning to install fire doors asks how much such a structure will weigh. This issue becomes especially relevant when calculating the price of door transportation by rail or road, since the cost of transportation directly depends on the weight of the cargo. So what does the mass of a fire-prevention structure depend on?

Factors affecting mass fire door:

- the material from which the canvas is made;

- type of filler: natural filler weighs much heavier than synthetic, mineral wool, For example;

- type of construction of the canvas;

- type of box construction;

- the level of fire resistance provided by the manufacturer;

- if the door is glazed, then its weight depends on the type of glass units and the area of the glazing.

Recently, manufacturers fire protection structures trying to make their products lighter. If the average mass of the first generation model was approximately 50-55 kilograms per square meter, then today this figure is approaching 40-45 kilograms per square meter. These results were achieved thanks to the use of steel curved profile instead of sheet steel.

Recently, manufacturers fire protection structures trying to make their products lighter. If the average mass of the first generation model was approximately 50-55 kilograms per square meter, then today this figure is approaching 40-45 kilograms per square meter. These results were achieved thanks to the use of steel curved profile instead of sheet steel.

It is not difficult to calculate the weight of a fire door on your own. To do this, you only need to multiply the indicator of the weight of one square meter of the canvas by total area block. There are standard weights available for the first and second generation designs. Thus, the mass of one square meter of the first generation model will be 55 kg, the single-leaf model of the second generation - 42 kg, and the double-leaf model of the second generation - 45 kg. The standard error of weight indicators is 5 kg, which is a perfectly acceptable error for calculating cargo transportation. For example, the mass of a door 2 meters 100 cm high and 900 mm wide will be 85 kg, 2 meters 250 cm high and 1250 mm wide will be 127 kg.

As you can see from the previous example, when calculating the weight of the door, you should also take into account the width door block... This width depends on the type of block and is 105 mm for end-type and corner-type boxes, and about 200-300 mm for wrap-around boxes.

Metal fire doors are the most common and most popular type of fire resistant structures for a number of reasons:

- Versatility - can be used as usual technical doors, and as usual input;

- Burglary resistance is perhaps the next main quality, after fire resistance;

- The price in many cases is lower than for or for doors with glazing of similar standard sizes and fire resistance limits;

- Relative ease of manufacture - PDM is only slightly different from the usual metal door, which means that manufacturers only need to make a number of changes (or additions) to the design in order to get a completely new model and thereby expand the range of products;

- In options finishing many manufacturers, includes painting or pasting with imitation for various materials, including wood, aluminum and stainless steel- which allows you to successfully fit them into any interior.

Door frame

There are the following types:

- Wrap-around box - as it were, "covers" the surface of the wall from the outside and inside... It is used, as a rule, to make it easier when installing the door to give it a presentable appearance since on both sides, the canvas has platbands, which allow you to hide some installation flaws (irregularities, polyurethane foam etc.);

- Inner frame - it is also "end" is installed directly inside the doorway. Such a box does not have platbands, therefore, it is usually mounted before fine finishing walls (for example, plasterboard or tiles);

- Corner box - is considered the most versatile, because allows you to install doors in almost any type of openings. Has a casing on the outside.

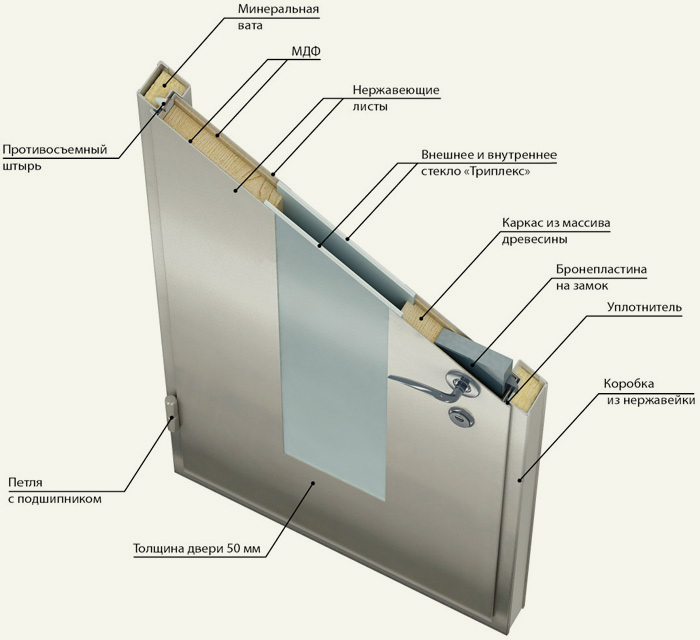

The frame of a metal fire door is made of solid-bent cold-rolled metal (usually steel) sheet, or galvanized steel, with a thickness of 1.2 mm. Also the box can be made of shaped pipes square or rectangular.

Steel sheet thickness door frame depends on the type of fire resistance - the higher the fire resistance limit, the greater the width of the web, and therefore the weight of the entire structure, and in order for the structure to be securely held in the wall, a reinforced door frame is required, i.e. with thicker steel.

Therefore, there is a relationship between the fire resistance of the door, its weight and the thickness of the steel from which it is made.

A thermosetting sealing tape 10 mm wide and 2 mm thick is attached to the perimeter of the door frame. If there is a possibility of fire from the outside and inside, two rows of thermosetting tape are glued. Also attached to the box rubber compressor, most often in one or two rows.

Finishing the box is most often done by painting in color door leaf according to the RAL color standard or by pasting with PVC foil.

Canvas construction

Usually made from steel sheets, most often from 0.8 mm to 1.5 mm thick. A mineral board (mineral wool) is placed between the steel sheets, this material has good thermal insulation, sound insulation and fire resistance properties.

Mineral wool does not burn, but only melts. But for it to melt, the temperature must be very high - on the order of a thousand degrees Celsius and above.

For example, when conducting fire tests, the temperature in the oven, after 60 minutes of exposure open flame, about 950 - 980 degrees Celsius.

Door leaf width - varies from 50 to 100 mm, depending on the degree of fire resistance and a specific manufacturer. In any case, the higher the degree of fire resistance, the greater the width of the door leaf and its weight.

Iron PDs can be either single-field or bipartite, both equal-field and different-field.

A rubber seal against cold smoke is placed around the perimeter of the door leaf, most often in one or two rows.

Glazing

Metal fire doors can be deaf and glazed.

Glazing is made either up to 25% or more than 25 percent of the area of the canvas.

For glazing, fireproof glass is used, in the places where the glass is attached to the door leaf, a thermosetting sealing tape or other insulating fire-resistant material is additionally attached.

One or two anti-removable spikes are located on the door leaf; the leaf itself is finished in the following ways:

- Colored powder paint according to the RAL scale;

- Covered with PVC foil according to the RAL scale;

- It is painted or pasted over, imitating various textures - various types of wood, aluminum, stainless steel.

Weight

With a sheet thickness of 0.8 mm. and a web thickness of 55 mm, is about 25 - 27 kilograms per square meter. Accordingly, if the thickness of the sheet and the thickness of the steel sheet are higher, then the weight of the sheet will be higher.

The thickness of the door leaf increases in proportion to the fire resistance limit - the higher the fire resistance limit, the higher the leaf thickness, and hence the weight of the entire door block.

Thus, a blind single-floor metal fire door standard sizes with a fire resistance limit of EI 30 will weigh about 80 - 100 kilograms, depending on the thickness of the door leaf and steel sheet.

Double doors with a higher fire resistance class (for example, EI 120), as well as structures of non-standard dimensions, can weigh up to 300 kilograms.

Fittings

Of the main design features steel fire-rated doors are the following:

- The presence of door closers is mandatory - all refractory products must be closed during a fire, otherwise they will not fulfill their function, therefore DPM, like DPD in mandatory equipped door closers;

- made of special fire-resistant steel. Their design eliminates jamming of the mechanism during a fire. Even if the handle and the lock are exposed to fire for a long time, they are obliged to remain operational - to open and close without hindrance in order to prevent the doors from blocking during evacuation. The performance of all mechanisms is checked during the fire resistance tests of doors in accordance with GOST;

- For double-leaf metal fire doors, it is necessary to have a door closer on each of the two canvases and the presence of a regulator (coordinator) for alternately closing the leaves;

- To achieve smoke tightness, a retractable (automatic) threshold seal is used;

- Additionally, the PDM can be equipped with a ventilation grill, glazing or a steel bumper on the canvas.

The main types of fire resistance

As with other types of fire doors, the most popular fire resistance classes among iron fire doors door systems are EI 60 and EI 30. That is, PDA of the 1st and 2nd type (class), respectively.

The limits of fire resistance EI 45, EI 90, EI 120 are also quite common.

Installation locations

Metal fire doors are most often installed in places where their functionality, unpretentiousness and burglary resistance are valued much higher than their aesthetic qualities.

Basically, such products are installed as technical and ordinary entrance metal doors to numerous objects, for various purposes, including:

- Industrial buildings and structures - factories, factories, laboratories, research centers, workshops, etc .;

- Technical premises - transformer, switchboard, server rooms, boiler rooms, warehouses(including storage of combustible materials, weapons, ammunition, etc.), waste collection chambers, ventilation chambers, elevator engine rooms, gas stations etc.;

- Buildings and structures for service a large number people - shopping and office centers, libraries, hospitals, cinema centers, hotels, schools, kindergartens, sports centers, circuses, clubs, train stations, hostels, concert halls, as well as in multi-apartment residential buildings etc.

Approximate prices

On average, the retail price for metal fireproof doors ranges from:

- 10 thousand rubles - deaf single-floor, fire resistance EI 30 standard sizes;

- up to 30 thousand rubles for double glazed up to 25% of the area of the canvas, fire resistance EI 60.

Wholesale ordering of doors will cost an order of magnitude cheaper, depending on the number of pieces in the batch, you can count on a discount from 500 rubles to 2500 thousand rubles or more from each product.

Designs with additional equipment and made to order according to the specified dimensions will be significantly more expensive than standard models.

What affects the price

The difference in price, as noted earlier, depends on numerous factors, among them:

- Dimensions - what more sizes, the more expensive the door is;

- Fire resistance limit - the higher, the higher the price;

- Glazing and its area - what larger area glazing, the higher the price;

- Fittings - the more high-quality fittings are used, the correspondingly higher the price;

- Availability of additional equipment - bumpers, transoms, RPZ, ventilation grilles- will significantly increase the cost of the entire structure.

To the entrance steel door there are requirements designed to protect housing from the penetration of strangers and ensure it convenient operation... Below is a list of them:

- The metal door must have a sufficient safety margin. This is necessary condition to protect the structure from burglary.

- In addition to strength, the door structure must also be "smart". Such a property can be given to it by reliable constipation systems.

- The metal door must be able to be observed. This is achieved by using special video systems or, at least, ordinary door peepholes.

- The entrance iron door must be insulated. Various materials can act as heat insulators for filling its canvas: foam plastic, mineral wool and others.

- The weight of the door leaf must correspond to the quality and power of its awnings. Otherwise, a heavy door with weak hinges can easily be knocked out of the entrance opening.

Door weight components

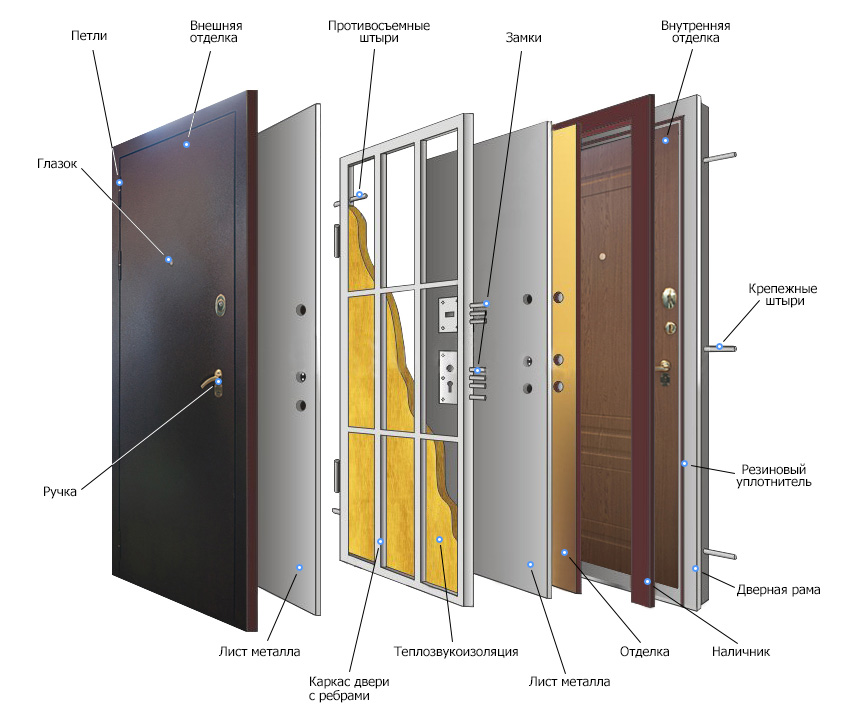

The main parameter that determines the weight of the front door is the thickness of the metal sheets that are used in its manufacture. In addition to it, the weight of a metal door is affected by:

- weight of the door frame;

- thermal insulation layer;

- number of stiffeners;

- outer cladding;

- the necessary accessories.

Sheet steel, which is used in the manufacture of doors, is hot and cold rolled. Steel of the first type is cheap, but rusts quickly. Steel of the second type is more expensive, it is more resistant to moisture and therefore it is suitable for the manufacture of external doors of entrances to high-rise buildings or private houses.

The accepted thickness of thin steel sheets is 0.8mm, and thick ones - 4mm. For apartment entrance doors, sheets with a thickness of 2-3 mm are used, and for the protection of the entrances of cottages or summer cottages, thicker sheets of 4 mm are chosen for doors.

To mass door structure was less, and its stiffness is greater, special "ribs" are made from profile rolled products. The minimum number of stiffeners that are installed in the metal sheet must be at least three: two of them are located along the vertical of the door, and one along its horizontal.

The weight of a metal door is also influenced by the material and thickness of the insulation that fits into its door leaf. Polystyrene boards are much lighter than similar mineral wool products.

To give the iron door an attractive look, its sheets are sheathed various materials: MDF, laminated panels, slats, veneer and others. When using them, the mass of the door leaf also increases.

Door hardware, which includes locks, handles and hinges, also affects total weight constructions. Some locking mechanisms weigh more than 5kg. The large weight of the door leaf requires more hinges. Standard entrance doors usually have two loops, and special heavy canvases are hung on 3-4.

In general, the entire mass of the door block with the frame should not weigh more than is necessary for its functional purpose.

Entrance door weight

The curtains of ordinary entrance iron doors are lightweight from 40 to 50 kg. The lightest of them are Chinese products weighing about 40 kg. They are powder coated and have a sheet thickness of no more than 2mm. Such doors will not be able to reliably protect the entrance to the apartment, although they have a good appearance.

The optimum weight of an apartment metal door should be 60-70kg. The curtains of such doors almost always have decorative cladding, which, in addition to its main function, plays the role of an additional heat insulator.

In addition to ordinary apartment doors, there are special models of them with a significantly greater weight. For example, the weight of a fireproof metal door can be up to 130kg. It includes the weight of the metal of the door block and the mineral fire-fighting wool. The size of such a door also affects its weight. The fire-resistant properties of a fire door are completely independent of the thickness of its sheets. The main criterion here is the thickness and density of the door insulation filler. The weight of heavy-duty doors with leafs consisting of two or three layers of steel can exceed 150 kg.

To determine how much a metal door weighs, the following formula is often used: the mass of 1m2 of the canvas is multiplied by the area of the door structure.

When choosing a metal door, you should not rely only on the weight of the unit. The manufacturer's name also has great importance... Firms that cherish their reputation will not use low-quality raw materials to make products heavier in excess of the norm, but will focus their activities on increasing the reliability of door structures.

The weight of fireproof metal doors is mainly made up of the weight of the metal and the weight of the fireproof mineral wool, and naturally strongly depends on the size of the door.

Let's see how the weight of a fire door is added for typical sizes.

1. Fire door Ei60 2080 * 880, single-floor... The manufacture of such a door takes 2 sheets of metal and 0.11 cubic meters. mineral wool.

Cold rolled metal 1250 * 2500 0.8 mm thick. + mineral wool density 120 kg / m cub. = 20 Kg. * 2 sheets + 120 kg. / M2. cbm * 0.11 cbm = 40 kg. + 13.2 Kg. = 53 kg. fire door weight.

Metal 1.0 mm thick. and mineral wool.

Cold rolled metal 1250 * 2500 with a thickness of 1.0 mm. + mineral wool density 120 kg / m cub. = 25 Kg. * 2 sheets + 120 kg. / M2. cbm * 0.11 cbm = 50 kg. + 13.2 Kg. = 63 kg. fire door weight.

Cold rolled metal 1250 * 2500 with a thickness of 1.2 mm. + mineral wool density 120 kg / m cub. = 30 Kg. * 2 sheets + 120 kg. / M2. cbm * 0.11 cbm = 60 kg. + 13.2 Kg. = 73 kg. fire door weight.

Cold-rolled metal 1250 * 2500 with a thickness of 1.5 mm. + mineral wool density 120 kg / m cub. = 38 Kg. * 2 sheets + 120 kg. / M2. cbm * 0.11 cbm = 76 kg. + 13.2 Kg. = 89 kg. fire door weight.

Cold-rolled metal 1250 * 2500 with a thickness of 2.0 mm. + mineral wool density 120 kg / m cub. = 50 Kg. * 2 sheets + 120 kg. / M2. cbm * 0.11 cbm = 100 kg. + 13.2 Kg. = 113 kg. fire door weight.

2. Fire door Ei60 2080 * 1280, double-leafed. It takes 3 sheets of metal and mineral wool to make such a door.

Let's make a simple calculation of the door weight based on the basic materials.

Metal 0.8 mm thick. and mineral wool.

Cold rolled metal 1250 * 2500 0.8 mm thick. + mineral wool density 120 kg / m cub. = 20 Kg. * 3 sheets + 120 kg. / M2. cbm * 0.16 cbm = 60 kg. + 19.2 Kg. = 79 kg. fire door weight.

Metal 1.0 mm thick. and mineral wool.

Cold rolled metal 1250 * 2500 with a thickness of 1.0 mm. + mineral wool density 120 kg / m cub. = 25 Kg. * 3 sheets + 120 kg. / M2. cbm * 0.11 cbm = 75 kg. + 19.2 Kg. = 94 kg. fire door weight.

Metal 1.2 mm thick. and mineral wool.

Cold-rolled metal 1250 * 2500 with a thickness of 1.2 mm. + mineral wool density 120 kg / m cub. = 30 Kg. * 3 sheets + 120 kg. / M2. cbm * 0.11 cbm = 90 kg. + 19.2 Kg. = 109 kg. fire door weight.

Metal 1.5 mm thick. and mineral wool.

Cold-rolled metal 1250 * 2500 with a thickness of 1.5 mm. + mineral wool density 120 kg / m cub. = 38 Kg. * 3 sheets + 120 kg. / M2. cbm * 0.11 cbm = 114 kg. + 19.2 Kg. = 133 kg. fire door weight.

Metal 2.0 mm thick. and mineral wool.

Cold-rolled metal 1250 * 2500 with a thickness of 2.0 mm. + mineral wool density 120 kg / m cub. = 50 Kg. * 3 sheets + 120 kg. / M2. cbm * 0.11 cbm = 150 kg. + 19.2 Kg. = 169 kg. fire door weight.

Now it is clear that the weight of a metal fire door is almost directly dependent on the thickness of the metal. There is a misconception that the fire-fighting properties of the door depend on the thickness of the metal - no, they do not depend at all, but depend on the density and thickness of the mineral wool. The thickness of the metal affects the burglary resistance and overall strength of the doors.

This video shows how they open chinese door with a metal thickness of 0.33 mm.

Attention! This door is made and is in our warehouse! Delivery is possible TODAY.

Delivery 1-3 days!

- Fire resistance 60 minutes!

- The size: 900 x 2100 mm.

Doors EI 60 are possible.

Price: 8 700 rub.

* the price is indicated without VAT

Specifications

- Fire resistance 60 minutes!

- Size: 900 x 2100 mm.

- Color to choose from. Powder coating according to the RAL scale. RAL 7035 coated as standard

900 x 2100 mm. Fire door metal EI 60

| Standard complete set | |

| Box type | Corner box with pre-drilled mounting holes. |

| Threshold type | Thrust 40 mm high. |

| Lock | Mortise cylinder lock with latch, DL firm according to DIN 18250. |

| Locking | Euro cylinder with a set of keys. |

| Fittings | Lever handles made of polypropylene with a short black cover plate from DL. |

| Hinges | Welded, 2 pcs, with thrust bearing. |

| Fasteners | Through the frame into the prepared holes with plugs. Or on anchor plates. |

| Coating | Powder coating according to RAL 7035 (shagreen gray). |

| Execution of the canvas | The inside of the canvas is filled with a special refractory material. Reinforcement under the door closer. |

| Seals | Expanding heat seal against hot smoke, rubber seal against cold smoke and drafts. |