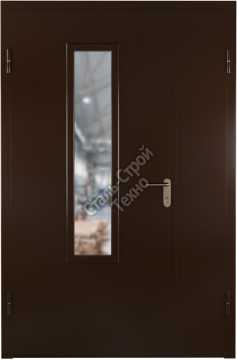

How many fire-fighting metal doors weigh. Metal door weight

Metal fire doors are the most common and most popular form of fire-resistant structures due to a number of reasons:

- Versatility - can be used as ordinary technical doorsand as ordinary entrance;

- Burglar resistance - perhaps the following basic quality, after fire resistance;

- Price in many cases lower than on or on doors with glazing, similar sizes and fire resistance limits;

- The relative simplicity of manufacturing - DPM is only a little different from the usual metal door, which means that manufacturers need to make only a number of changes (or additions) in the design to get a completely new model and thereby - expand product line;

- In options finish finish many manufacturers include painting or pasting with imitation under various materials, including under wood, aluminum and stainless steel - What allows you to successfully enter them into any interior.

Door box

There are the following types:

- The covering box - as it were, "covers" the surface of the wall with external and inner. It is usually applied to ensure that when installing the door it was easier to give her presentable appearancebecause On both sides, the cloth has platbands that allow you to hide some flaws of the installation (irregularities, mounting foam etc.);

- The inner box is the "end" is installed directly inside the doorway. Such a box does not have a platband, so mounted, as a rule, before finishing walls (for example, plasterboard or tile);

- The angular box is considered the most universal, because Allows you to install doors in almost any type of opening. It has a platband from the outside.

The box of the metal fire doors is made of an all-bent cold-rolled metal (more often than steel) sheet, or from galvanized steel, with a thickness of 1.2 mm. Also the box can be made of profile pipes Square or rectangular section.

Thickness steel sheet door box Depends on the type of fire resistance - the higher the limit of fire resistance, the greater the width of the canvas, which means the weight of the entire structure, and in order for the design to be reliably held in the wall, a reinforced door box is necessary, i.e. with thicker steel.

Therefore, there is a relationship between the fire resistance of the door, its weight and thickness of steel of which it is made.

On the perimeter of the door frame, a thermosetting sealing tape 10 mm width, 2 mm thick, is attached. If there is a possibility of fire from the external and inner side, two rows of thermosetting tape are glued. Also attached on the box rubber compressor, most often in one or two rows.

The finish finish of the box occurs most often by painting in the color of the door canvase in the color standard RAL or by the PVC film.

Construction of the web

It is usually made of steel sheets, most often a thickness of from 0.8 mm to 1.5 mm. Between the steel sheets is the mineral plate (mineral wool), this material has good thermal insulating, sound insulation and fire-resistant properties.

Mineral wool does not burn, but only melts. But for its melting, the temperature should be very high - about a thousand degrees Celsius and above.

For example, when conducting flap tests, the temperature in the furnace, after 60 minutes of exposure open flame, about 950 - 980 degrees Celsius.

The width of the door leaf - varies from 50 to 100 mm, depending on the degree of fire resistance and a particular manufacturer. In any case, the higher the degree of fire resistance, the greater the width of the door canvase and its weight.

Iron PDs can be both single-alone and double-alone, both equanka and diverse.

On the perimeter of the door leaf, there is a rubber seal from cold smoke, most often in one or two rows.

Glazing

Metal fire doors can be deaf and glazed.

Glazing is produced either up to 25% or more than 25 percent of the area of \u200b\u200bthe canvas.

Fire glass is used for glazing, in places of fastening the glass to the doorway additionally fasten the thermosetting sealing tape or another insulating fire-resistant material.

On the door canvase there are one or two anti-removal spikes, the canvas itself is separated in the following ways:

- Coloring powder paint on the RAL scale;

- Covered with PVC film on the RAL scale;

- It is painted or salary, imitating various textures - various wood, aluminum, stainless steel.

Weight

With a sheet thickness of 0.8 mm. And the thickness of the canvas is 55 mm, is about 25 - 27 kilograms per square meter. Accordingly, if the thickness of the canvas and the thickness of the steel sheet is higher - then the weight of the canvas will be higher.

The thickness of the door of the door increases in proportion to the limit of fire resistance - the higher the limit of fire resistance, the higher the thickness of the canvas, which means the weight of everything door Block.

Thus, a deaf single-section metallic fire door standard sizes The EI 30 fire resistance limit will weigh about 80 - 100 kilograms, depending on the thickness of the door leaf and the steel sheet.

Two-foil doors with an elevated fire resistance class (for example, EI 120), as well as the design of non-standard sizes can weigh up to 300 kilograms.

Furnitura

From the main constructive features Steel fire-resistant doors can be selected as follows:

- Mandatory presence of door closers - all refractory products must be closed during a fire, otherwise they will not fulfill their function, so DPM, like DPD in obligatory Tools door closers;

- Made of special fire-resistant steel. Their design eliminates the jamming of the mechanism during the fire. Even if on the handle and the lock for a long time to influence fire, they are obliged to maintain performance - to open and close to unhindered, in order to prevent the locking of the flaps during the evacuation. The performance of all mechanisms is tested during testing doors according to GOST for fire resistance;

- For bipoly metal fire doors, the presence of a closer on each of two canvases and the presence of a regulator (coordinator) of alternate closing of the sash;

- To achieve smokeproof - use the retractable (automatic) threshold seal;

- Additionally, DPM can be equipped with a ventilation grille, glazed or steel bump on the canvas.

Main types of fire resistance

Like other types of fire-prevention doors, the most popular classes of fire resistance among the Iron Fireproof door Systems are Ei 60 and Ei 30. Those. DPM of the 1st and 2nd type (class), respectively.

Also, the limits of fire resistance EI 45, EI 90, EI 120 are quite common.

Installation sites

Metal fire fighting doors are most often installed in places where their functionality, unpretentiousness and burglariness are valued much higher than their aesthetic qualities.

Basically, such products are installed as technical and conventional inlets of metal doors to numerous objects, a variety of purposes, including:

- Production buildings and structures - factories, factories, laboratories, scientific research centers, workshops, etc.;

- Technical premises - transformer, electrical, server, boiler rooms, warehouses (including for storing combustible materials, weapons, ammunition, etc.), garbage collectors, ventilation chambers, machine branches of elevators, gas stations etc.;

- Buildings and facilities for service large number people - shopping and office centers, libraries, hospitals, film centers, hotels, schools, kindergartens, sports centers, circus, clubs, train stations, hostels, concert halls, as well as in multi-unit residential buildings etc.

Approximate prices

On average, the price for metal refractory doors in retail varies in the range from:

- 10 thousand rubles - deaf single-section, fire resistance EI 30 standard sizes;

- up to 30 thousand rubles for double glazed up to 25% of the area of \u200b\u200bthe canvas, EI 60 fire resistance.

The order of the doors in bulk will cost an order of magnitude cheaper, depending on the number of pieces in the party, you can count on a discount from 500 rubles to 2500 thousand rubles or more, from each product.

Constructions with availability additional equipment And custom-made according to the specified sizes will be significantly more expensive than standard models.

What affects the price

The difference in price, as already noted earlier, depends on numerous factors, among them:

- Dimensions - what more sizes, the more expensive doors;

- Fire resistance limit - the higher, the higher the price;

- Glazing and its area - than more square glazing, the higher the price;

- Accessories - the more high-quality fittings are used, respectively, above the price;

- Availability of additional equipment - bunches, fraamug, RPZ, ventilation lattices - significantly wanders the entire design.

The weight of fire-prevention metal doors is mainly consisted of the weight of the metal and the weight of fire-fighting mineral wool, and naturally strongly depends on the size of the door.

Let's see how the weight of the fire doors for typical sizes is folded.

1. Fire fire EI60 2080 * 880, single-section. The manufacture of such a door leaves 2 sheet metal and 0.11 m cubic meters. Mineral wool.

Cold rolled metal 1250 * 2500 0.8 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 20 kg. * 2 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 40 kg. + 13.2 kg. \u003d. 53 kg. The weight of the fire door.

Metal thickness of 1.0 mm. and mineral wool.

Cold rolled metal 1250 * 2500 thickness of 1.0 mm. + Mineral wool density 120 kg. / m. cube \u003d 25 kg. * 2 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 50 kg. + 13.2 kg. \u003d. 63 kg. The weight of the fire door.

Cold rolled metal 1250 * 2500 with a thickness of 1.2 mm. + Mineral wool density 120 kg. / m. cube \u003d 30 kg. * 2 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 60 kg. + 13.2 kg. \u003d. 73 kg. The weight of the fire door.

Cold rolled metal 1250 * 2500 1.5 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 38 kg. * 2 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 76 kg. + 13.2 kg. \u003d. 89 kg. The weight of the fire door.

Cold rolled metal 1250 * 2500 2.0 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 50 kg. * 2 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 100 kg. + 13.2 kg. \u003d. 113 kg. The weight of the fire door.

2. Door fire fire EI60 2080 * 1280, double. The manufacture of such a door is 3 sheet metal and mineral wool.

We will make a simple calculation of the weight of the door for basic materials.

Metal thick 0.8 mm. and mineral wool.

Cold rolled metal 1250 * 2500 0.8 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 20 kg. * 3 sheets + 120 kg. / M. cube * 0.16 m. Cube. \u003d 60 kg. + 19.2 kg. \u003d. 79 kg. The weight of the fire door.

Metal thickness 1.0 mm. and mineral wool.

Cold rolled metal 1250 * 2500 thickness of 1.0 mm. + Mineral wool density 120 kg. / m. cube \u003d 25 kg. * 3 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 75 kg. + 19.2 kg. \u003d. 94 kg. The weight of the fire door.

Metal thickness of 1.2 mm. and mineral wool.

Cold rolled metal 1250 * 2500 with a thickness of 1.2 mm. + Mineral wool density 120 kg. / m. cube \u003d 30 kg. * 3 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 90 kg. + 19.2 kg. \u003d. 109 kg. The weight of the fire door.

Metal thickness 1.5 mm. and mineral wool.

Cold rolled metal 1250 * 2500 1.5 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 38 kg. * 3 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 114 kg. + 19.2 kg. \u003d. 133 kg. The weight of the fire door.

Metal thickness 2.0 mm. and mineral wool.

Cold rolled metal 1250 * 2500 2.0 mm thick. + Mineral wool density 120 kg. / m. cube \u003d 50 kg. * 3 sheets + 120 kg. / M. cube * 0.11 m. Cube. \u003d 150 kg. + 19.2 kg. \u003d. 169 kg. The weight of the fire door.

Now it is clear that the weight of the metal fire doors, practically directly depends on the thickness of the metal. There is an erroneous opinion that the fire prevention doors depend on the thickness of the metal - there is absolutely not dependent ones, and depend on the density and thickness of the mineral wool. The thickness of the metal affects hacking resistance and total durability of doors.

This video shows how to open chinese door With a metal thickness of 0.33 mm.

Each host planning to put fire doors is asked how much the design will weigh. This issue is particularly relevant during the calculation of the price of the transportation of the door for railway or automotive roadSince the cost of transportation directly depends on weight of cargo. So what does the mass of fire structures depend on?

Each host planning to put fire doors is asked how much the design will weigh. This issue is particularly relevant during the calculation of the price of the transportation of the door for railway or automotive roadSince the cost of transportation directly depends on weight of cargo. So what does the mass of fire structures depend on?

Factors affecting the mass of the fire doors:

- the material from which the canvas is made;

- view of the filler: natural filler weighs much severe synthetic, mineral wool, for example;

- type of web design;

- type of design box;

- provided by the manufacturer level of fire resistance;

- if the glass is glazed, its weight depends on the type of glass and glazing area.

Recently manufacturers fire structures Try to make their products lighter. If the average mass of the first generation model was approximately 50-55 kilograms per square meter, today this figure is approaching 40-45 kilograms per square meter. Such results managed to achieve thanks to the use of steel bent profile Instead of sheet steel.

Recently manufacturers fire structures Try to make their products lighter. If the average mass of the first generation model was approximately 50-55 kilograms per square meter, today this figure is approaching 40-45 kilograms per square meter. Such results managed to achieve thanks to the use of steel bent profile Instead of sheet steel.

Alone to calculate the weight of the fire door is easy. To do this, you only need to multiply the weight indicator of one square meter Balds on total area Block. There are standard weight indicators provided for the designs of the first and second generation. Thus, the mass of one square meter of the first generation model will be 55 kg, a single-generation single-generation model - 42 kg, a bivalve second-generation model - 45 kg. The standard error of weight indicators is 5 kg, which is a completely permissible error for calculating freight transportation. For example, the mass of the door with a height of 2 meters 100 cm and 900 mm width will be 85 kg, 2 meters high 250 cm and 1250 mm wide will be 127 kg.

As can be seen from the previous example, when calculating the weight of the door should also take into account the width of the door block. This width depends on the type of block and is 105 mm for the boxes of the face and angular type, for a box of a clamp type - about 200-300 mm.

The input steel door is presented to the requirements designed to secure housing from the penetration of foreign and provide it comfortable exploitation. Below are their list:

- The metal door should have a sufficient margin of safety. This is prerequisite To protect the design from hacking.

- In addition to the strength, the door design should also be "smart". Such a property can give it reliable systems of constipation.

- The metal door should provide the possibility of observation. This is achieved by the use of special video systems or, at least - ordinary door eyes.

- The front rail door must be insulated. Thermal insulators for filling its canvases can be various materials: foam, mineral wool and others.

- The weight of the door canvase must correspond to the quality and power of its canopies. Otherwise, the heavy door on the weak loops can easily knock out from the input opening.

Moorelines of the door

The main parameter determining the weight of the inlet door is the thickness of the metal sheets that are used in its manufacture. In addition to it, the weight of the metal door affects:

- mass of the door box;

- layer of thermal insulation;

- the number of rigidity ribs;

- outdoor sheathing;

- necessary fittings.

Sheet steel, which is used in the manufacture of doors, is hot and cold rolled products. Steel of the first type is cheap, but quickly rust. Steel second type is more expensive, it is more resistant to moisture and therefore suitable for the manufacture of outdoor doors of high-rise buildings or private sector homes.

The adopted thickness of thin steel sheets is 0.8 mm, and thick - 4mm. For apartment entrance doors, sheets of 2-3mm thickness are used, and to protect the inlets of cottages or cottages, thicker sheets are selected for doors - 4mm.

In order for the mass of the door structure less, and its stiffness is greater, special "ribs" is made of profile rental. The minimum number of rigid ribs that are installed in the metal canvas should be at least three: two of them are located vertically the doors, and one - by its horizontal.

The weight of the metal door also affects the material and the thickness of the insulation, which is placed in its canvas. Polystyrene plates are much easier than similar products from mineral wool.

To give the iron door of an attractive view, her sheets are trimmed various materials: MDF, laminated panels, slats, veneer and other. When using them, the mass of the door canvase also increases.

Door accessories, including locks, handles and loops also affect general weight Designs. Some shut-off mechanisms have a mass of more than 5kg. The high weight of the door canvase requires more loops. Standard entrance doors Usually have two loops, and special heavy cloths are hung on 3-4.

In general, the whole mass of the door block with a box should not weigh more than it is necessary according to its functional purpose.

Weight of entrance doors

The canvas of ordinary input iron doors have a small weight from 40 to 50kg. The easiest of them are Chinese products weighing about 40kg. They have powder sputtering and sheet thickness not more than 2mm. Such doors will not be able to securely protect the entrance to the apartment, although they have a good appearance.

The optimal weight of the apartment metal door should be 60-70kg. The canvas of such doors almost always have a decorative trim, which in addition to its main function plays the role of an additional thermal insulator.

In addition to ordinary apartment doors there are their special models having a much greater weight. For example, the mass of the fire-fighting metal door can be up to 130kg. It includes the weight of the metal of the door block and mineral fire wool. The size of such a door also affects its weight. The fire-resistant properties of the fire doors do not depend on the thickness of its sheets. The main criterion here are the thickness and density of the door insulating filler. The weight of superproof doors having a canvas consisting of two or three layers of steel may exceed 150kg.

To determine how much a metal door weighs, often use such a formula: the mass of 1m2 canvas is multiplied by the area of \u200b\u200bthe door design.

Choosing a metal door, should not be oriented only on the weight of the block. The name of the manufacturer also has great importance. Firms that protect their reputation will not use poor-quality raw materials to grow products over the norm, but will guide their activities to increase reliability door structures.

In the manufacture of metal fire doors, cold-rolled sheet metal and fire-resistant mineral Wat. The doors of the same size may have a different weight, this affects the mass of the used sheet metalcalculated by the formula

m \u003d V * ρ, where V is the volume of the sheet, ρ-determination of the metal.

Thus, the fire-fighting metal, the weight of which is always proportional to the mass of the sheet metal (P \u003d M * G), will depend on the mass of the sheet, from which it is made. For example, we calculate the weight of a typical fire door made of steel. For the manufacture of one single-bed fire fire door EI 60 2100x900, 2 steel sheets are needed and 0.11-0.12 cubic meters of thermal insulation plate, which is approximately 13-14 kg.

We define the mass of the steel sheet (thickness of 0.8 mm; 1 mm; 1.5 mm, 2 mm) size 1250 * 2500, the density of steel is 7.85 kg / m2:

m (0.8) \u003d V * ρ \u003d 1250 * 2500 * 0 .8 * 7.85 \u003d 19.625 kg;

m (1.0) \u003d V * ρ \u003d 1250 * 2500 * 1.0 * 7.85 \u003d 24.531 kg;

m (1.5) \u003d V * ρ \u003d 1250 * 2500 * 1.5 * 7.85 \u003d 36.796 kg;

m (2.0) \u003d V * ρ \u003d 1250 * 2500 * 2.0 * 7.85 \u003d 49.062 kg.

Those. With a sheet thickness of 0.8 mm fire fire steel steelit is 19,625 * 2 + 14 \u003d 53.25 kg, with a sheet thickness of 2 mm, the weight is equal to 49.062 * 2 + 14 \u003d 112 kg. As can be seen from the calculations, the thickness of the sheet, the correspondingly the weight of the steel fire door. It should be noted, the metal thickness of the door affects its reliability and does not affect fire resistance.

Other articles on the topic

Choosing Fire Door Material

The main material used in the production of fire doors is steel. There is quite obvious choice.

The use of fire doors

Fire fires steel doors It is designed to ensure safety from the spread of fire and inevitable concomitant factors, namely from smoke, toxic combustion products, high temperatures.

Quality fire doors

The most important indicator of the reliability of the door is the limit of fire resistance. Each manufacturer really high-quality door Must be obliged to present a fire safety certificate.

Act Check Fire Doors

Considering the fact that fire doors are intended for use in extreme conditions, their mandatory careful verification of GOST is produced.

Installing fire doors: Rules and requirements

The installed fire-fighting door should not have damage arising in the process of transportation and storage.

Fireman metal and its weight

As can be seen from the calculations, the thickness of the sheet, the correspondingly the weight of the steel fire door. It should be noted, the metal thickness of the door affects its reliability and does not affect fire resistance.

Fire fire door

One of the main types of special door structures that are used for installation in open, unfilled openness of fireproof barriers (partitions, walls, overlap) - fire fire doors.

Fire Doors NGO Pulse

Certified Products on russian market Offered by various manufacturers. Fire doors pulse,as well as models of other, no less well-known manufacturers installed in many institutions, buildings, on facilities of various purposes.

Fire door 30.

One of the main types of special door Townsthat are installed in fire barriers (carriers and non-relaxing walls, partitions) with the normalized limits of fire resistance - fire doors (EI 30).

Door fire-stop dp.

The fire fire (DP) door is designed to create an obstacle of fire and smoke when emergency situations. The installation of special doors is made in the openings of fire-preventive barriers (walls, partitions) that highlight the most fire-hazardous parts of the buildings.