Types of fire extinguishing sprinklers. What is a sprinkler system and how does it work? Test Sprinkler Fire Extinguishing Installation

Like any creature on the planet, a person becomes defenseless in the face of the swelling element - fire. Therefore, people seeking to protect themselves from fire themselves and their property, install in houses of fire extinguishing system, work independently, even in cases of lack of person indoors.

Our article describes the installation of the sprinkler fire extinguishing system.

Warehouses with mobile shelves. Preferred racks are open upper or upper holes. Track with a width of mines. The specific requirements set out in the technical specifications for fire extinguishing equipment indicated for. Multi-storey buildings, elevators, people's protection. . With zoning zone, special requirements for monitoring the work of the main valve and its equipment are established. In addition, it must be equipped with a bypass pipeline with additional shut-off valvethat guarantees that zonal system It does not work when the control valve fails or is repaired.

Automatic called the settings of the sprinkler and. During exceeding the limits of the permissible temperature norm, both systems react instantly and independently, without outside intervention. Only sprinkler systems in any case are operational automatically, while the draincurrent can be started manually.

By type of components used to extinguish fire Fire extinguishing systems automatic triggering are:

To ensure maximum reliability, this equipment has significantly more rigid water supply. Depending on the situation, the duplication of valve stations is required, each of which must be equipped with a watering pipe. Finally, these are fire extinguishers designed to protect people.

Fire extinguishing systems must be divided into zones with no more than 200 sprinklers on the valve station, a wet system, high heat response sprinkles, the valve station must be loathe to ensure its performance under any conditions; In some cases, double bypass reinforcement, water supply system must be installed with increased reliability. In the event of protection of the theater, other special requirements apply.

- water;

- powder;

- gas;

- foam.

Automatic response device on water based Used most often due to relatively low cost. True, many are afraid that during a small ignition, sprinkler sprinkles will fill all the square and cause serious damage to property.

In fact, this is a myth. With the development of technologies, the systems of fine irrigation have been developed that form a peculiar water veil And localized directly on the fire site. This not only saves property in the rest of the room, but also reduces water consumption to eliminate fire.

Sprinkler fire extinguishers provide high efficiency Protection B. large quantities Applications that often exceed the limits used by the fire extinguishing agent. However, in all cases it is necessary to comply with the requirements of fire extinguishers and restrictions related to the relevant specifications.

Due to the long-time traditions of publishing these rules, it can be assumed that the search or such an application will be found in these documents. Continuing construction of commercial industrial zones and entertainment centers With a large representation of single-storey warehouses, supermarkets, multi-storey and new production technologies are also associated with the development of protection against sprinklers. Sprinkler protection lies in these and many other cases most effective fire prevention measuresthat adequately comply with the relevant standards fire safety Buildings, as well as insurance companies.

Automatic gas-based devices. Due to the supply of gas, the concentration of oxygen is reduced, and the fire goes out, without spoiling the property and without damaging the electrical appliance. Gas is used only non-flammable, for example, nitrogen or argon. That is, the fire extinguishing system with gas will be simply necessary in production and facilities with hardware operating equipment.

The use of sprinklers is limited only to insulated spaces.

Despite this positive development of the sprinkler industry, there are many misconceptions regarding sprinkler fire extinguishers. Let's see what is said and what is reality. In contrast to the wet system, this system is filled with air.

Why does the amount of water do not reduce the amount of sprinkler?

Therefore, its function does not freeze. It is true that the main cost of the spent on the sprinkler installation is water tanks. In the design regulations, the main parameters of fire extinguishing equipment, including the time of operation, the intensity of the fire supply and the area, from which the amount of water, calculates the volume of tanks is calculated. These sprinkler fire extinguishing parameters are based on the years of statistical monitoring and specific applications based on the results of fire resistance tests.

Principle of operation foamy systems It is similar to gas: pouring all items on the fire site, the foam has the ability to overlap completely oxygen access to fire.

Powder system Works automatically. The powder does not damage the property inside, withstands the large temperature difference from -50 ° C to + 50 ° C. But the powder is dangerous to the health of people, especially for the respiratory system.

Changes are possible, but only after a detailed explanation and after extensive professional discussion. Any inappropriate intervention in the design criteria for insurers and reinsurers in principle reject. You pay property damage and do not care about how effective sprinkler fire extinguishers are.

The most expensive are underground tanks. However, they should not be installed everywhere. Industrial zones gradually contribute to much cheaper overhead teams, welded or prefabricated tanks, the price of which is significantly lower. In particular, reservoirs with a reduced volume can be used.

Principle of operation of the sprinkler system

The principle of operation of this system is simple: when the flame occurs, it starts its work installed not the ceiling irrigation head with thermal lock - sprinkler. With an increase in the air temperature, the thermal lock sprinkled is displetened. Then, high pressure water sprinks through the special holes for spraying through the sprinkler socket.

The principle of operation of this system is simple: when the flame occurs, it starts its work installed not the ceiling irrigation head with thermal lock - sprinkler. With an increase in the air temperature, the thermal lock sprinkled is displetened. Then, high pressure water sprinks through the special holes for spraying through the sprinkler socket.

In addition to creating additions to technical conditions For the development of sprinkler fire extinguishers, other options for their decline are also required. In particular, this is, for example, design pipeline systems with a smaller diameter of the pipe, use preliminary assembly To install the pipeline or the use of plastic pipelines in exactly specific conditions.

In no case is this universal use system. It is applicable only to specific conditions with a number of significant restrictions. Among other things, conditions are strictly determined for the size and location of various barriers to splashing water. However, these conditions can not always be completed.

Control fire situation Specially installed smoke and temperature sensors. The appearance of smoke and the temperature norm is activated by the sensor operation, which gives a signal to the control unit. It is already activated by the work of the sprinkler.

Special check valves provide constant pressure at the desired level.

Therefore, we cannot talk about obsolescence and less efficiency of racks. However, it cannot be even missed due to lack of opportunity to lose the flexibility of warehouse space, which are required to investors. This is a cumbersome, in practice a common mistake.

Sprinkler fire extinguisher extinguishes fire without the help of firefighters

Especially for the rescue of people, which is a priority, but also for the complete destruction of fire and the subsequent stop of the equipment to extinguish the fire. In the standard fire extinguishing system, the fire extinguisher is declared under control. This means that it is assumed that the fire will not be fully repaid, and it will need to maneuver manually.

Requirements for the system. Types and standards

The main requirement that is presented to automated installations is flame extinguishing rate at the initial stageSo that the fire did not have time to gain momentum and spread to other territories.

Why are sprinkler fire extinguishers so highly appreciated by the insurer?

Because they are very reliable, efficient and safe! These consequences are the result of the long-term impact of insurers who from the very beginning recognized that they are highly efficient means Fire safety, which is confirmed by current statistical surveys. That is why more than 40 million sprinklers are mounted annually in the world. Since it does not change anything, protection against sprinkler can be considered promising and difficult to replace in subsequent years.

To do this in the installation phase fire installations It is necessary to ensure that the work and equipment meet the standards standards, the orders of the Ministry of Emergency Situations, GOST. All equipment must be accompanied by passports and quality certificates ..

According to existing standards, the permissible response time of the thermal lock of the sprinkler depends on the temperature necessary to start it. The higher the temperature of the launched fire, the faster the mechanism of its liquidation should work. According to GOST R 510043-2002, at t \u003d 79˚С and T \u003d 93˚С the maximum response time of the head of the head is 300 seconds.

Sprinklers are good to protect property, and not for people

In the case of protection from the sprinkler, it is necessary to remember that sprinklers are shooting in the first phase of burnout, that is, in optimal conditions. When well designed, there will be little spread of fire, which shows open statistics of the sprinkler. Under these conditions, there is also limited production of smoke and toxic combustion products, which is necessary for quick and safe evacuation of people.

When the sprinkler fire extinguishers work in the entire protected area, sprinklers unload water

Often often indicates the number of open sprinklers sufficient to extinguish the fire. In no case there were no more than two. In the end, these sprinklers spread to Europe and found their place in the design rules. In the case of the sprinkler fire extinguisher, only sprinklers are activated, which heat the fuse to the so-called opening temperature. Sprinklers that are not warm enough, i.e. Not in focus remain closed.

At the design stage, it is necessary to take into account the standp standards when calculating the distance between the irrigating heads in the room.

It is also necessary to take into account possible damage to the electrical nutrition or the failure of one of the elements of the node. To prevent such situations, add an additional electricity source, a spare pump and water tank.

Smoke and heat ventilation system does not affect the work of the sprinkler

If the sprayer opens more corresponds to the area from which it calculates the amount of water, this is a sign of a bad project or the result of an increased risk of fire in the protected area compared to the projection assumptions. This is a difficult question that should be found in accordance with paragraph 2 of Article 5. Among other things, it is necessary to solve the main functions and priorities, that is, the order and method of commissioning both of these devices. Coordination is provided by a fire safety solution processor.

There are norms in which the list of such buildings and structures in which automatic response is mandatory ("NPB 110-03", approved by the order of the Ministry of Emergency Situations of the Russian Federation). These include, for example, administrative premises, warehouses, shopping and entertainment centers, etc. And the installation of the OUTP in the residential premises is rather recommendatory.

This will lead to a rapid water supply, reduction of work time and possible disappearance of fire. Why can't you use cheaper spray nozzles, such as garden sprays, not sprinklers. Sprinkler is a self-acting valve that must perform dozens of complex tests before it is certified. In addition to leakage, the sprinkler checks the pressure and heat punch, the opening temperature, compressive strength, injection characteristics, consumption and corrosion resistance.

Sprinklers are not suitable for library protection.

For example, the particle size is determined on which the glass fuse is broken. Only certified sprinklers, specially designed, manufactured and proven for this purpose, meet the requirements. After carefully reviewing, dozens of world libraries are provided with sprinkler fire extinguishers. It should be remembered that when using a fire extinguisher for sprinkler coatings, the fire extinguishing fire is always less than that of water arising during manual intervention, always on the phase of developed fire.

To ensure efficient and uninterrupted operation of the AUPT sprinkler type it is necessary to regularly conduct control and maintenance of all components of the system.: Control of the health of sensors, check irriments, shut-off reinforcement, pumps, pipes and other components on the absence of leaks, mechanical damage, corrosion.

Sprinkler fire extinguishers must stop manually

In addition, the restaurant technology with dust books is satisfactorily solved. An unintentional launch of the sprinkler fire extinguisher can be minimized by selecting the type of water system. This is basically a system with pre-launch. This is a common way not only in us, but also throughout Europe. The reason is to make sure that the fire was successfully repaid. There are also systems with autonomous water supply. In Europe, these fire extinguishers are not common.

Sprinklers with a thin thermal fuse more modern than standard sprinklers

Both types have their excuse and accurate purpose defined by the design rule. Sprinklers with highly sensitive thermal fuse are primarily intended to protect people. In the case of property protection, the intentionally selected sprinkler is slower, so that the fire can be seen by extinguishing the fire extinguisher or hose system without using sprinkler fire extinguishers.

When malfunction of any system elements is detected, their urgent replacement or repair is needed. You can also not forget that even when the system is uninterrupted, the deadline for using the AUPT Sprinkler type - 10 years. After this time, the installation needs to be changed.

Advantages over other systems

As with any other system, the Sprinkler type apet has its advantages and disadvantages. Consider them in more detail.

As with any other system, the Sprinkler type apet has its advantages and disadvantages. Consider them in more detail.

Certificate issued, respectively. The conformity declaration proves that the product, that is, sprinkler fire extinguishers, is safe in the building. However, it is assumed that this will take place for each installation. This assumption is based on verifying the correct functioning of the manufacturer's quality system. To assess the compliance of sprinkler fire extinguishers, only the relevant requirements specified in the technical specifications are taken into account, as relevant to the state of scientific and technical information known at the time of the assessment of compliance.

Benefits:

- automatic triggering of the device;

- safety for the human body;

- relatively low costs;

- long term use - 10 years;

- works autonomously.

Disadvantages:

- in rare cases, the inertia works;

- ineffective when extinguishing fire from electrical appliances;

- can spoil some items located within the range of sprinkler.

Yet listed disadvantages are not sufficient argument to refuse to install the system under discussion.

Modern versions

Depending on the air temperature of the room, the following embodiments of the Sprinkler type performances are used:

- water-filled;

- air.

Already out of the name it becomes clear that water sprinkler installations - pipelines, where the working environment is water under pressure. Water-based sprinkular type systems are used only in heated rooms to avoid water freezing in pipes during the cold season.

Alternative to water installations for premises without heating will be air cooled or aerial systems . The principle of operation of air-compared systems is the following: in standby mode in the pipeline is constantly not water, but compressed air. If the sensor is triggered, the special valve displays the air, the water begins to enter the water under pressure and falls into the fire zone using the rod.

Outpanisters Outpanged are mounted in a vertical position outlets up, or down, or horizontally. In the aircraft systems, the installation of the rods is possible only in the vertical position of the sockets down or horizontally.

Air-based sprinkler system

This installation also received the definition of "dry". Air AUP will provide effective protection In conditions of a huge temperature drop from -50 ° C to + 50 ° C.

This installation also received the definition of "dry". Air AUP will provide effective protection In conditions of a huge temperature drop from -50 ° C to + 50 ° C.

The principle of operation of the air AUPT is the following: When damaged the thermal lock of the sprinkler through a special valve, compressed air comes out. Due to this, a slight increase in pressure occurs in the pipe. This, in turn, makes the water valves for water, which are already launching water through the pipeline.

Thus, choosing a sprinkler system, you can not worry about the safety of people and property. Its versatility, long service life, availability and safety of extinguishing (water), the reaction of only one rod at a specific point of fire is made out on a sprinkler type indispensable In rooms where there are constantly many people.

Do not forget that installations automatic fire extinguishing Should be complemented by manual means. Most often, these funds are compiled on the fire shield. GOST to shields are considered in. In all the options for configuring the shield. Your task is to control their health and.

To ensure a long and uninterrupted service before installing the system, you must make sure that all equipment and process mounting work Complied with established rules and regulations.

We think that you will be interested to watch the video, where the test of the sprinkler fire extinguishing system is shown in action.

The water-based sprinkler system is an automatic water fire extinguishing system completely filled with water or aqueous solution, designed to protect heated objects. Such systems are used on most objects requiring protection with a sprinkler fire extinguishing system.

Each section of the sprinkler installation must have an independent control node. When protecting several rooms or floors of the building with one sprinkler section to issue a signal specifying the address of the outbuilding, as well as the inclusion of alert and smoke system systems is allowed to be installed on the supply pipelines, excluding ring, fluid flow signaling devices.

Sprinkle rods of water-filled AUP are installed vertically sockets up or down or horizontally, in air AUP - vertically sockets up either horizontally.

The feed pipelines of water-filled sprinkler AUP with a diameter of 65 mm and is more allowed to attach the fire cranes internal fireproof water pipes. The duration of the operation of internal fire cranes, equipped with manual water fire trunks and connected to the feed pipelines of the sprinkler installation, should be taken equal to the operation of the sprinkler installation.

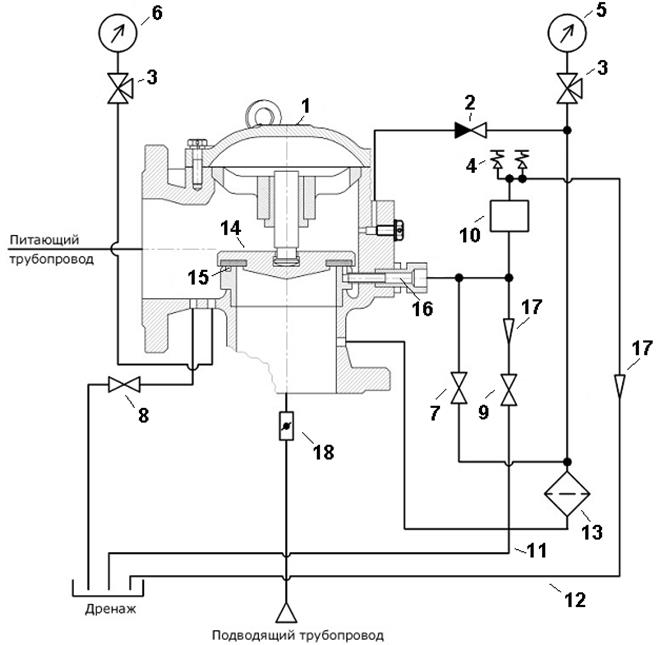

Control assembly sprinkler water-filled (UU) (Fig.3.11) Designed to work in sprinkler installations of water and foaming, carries out the flow of a fire extinguishing fluid, gives a signal to form a command pulse to control the elements fire automation (pumps, alert system, shutting down fans and technological equipment, etc.), as well as controls the state and checks the performance of these installations during operation.

Fig.3.11. Appearance Sprinkler water-filled node

The hydraulic diagram of the sprinkler water-compounded node is presented in Fig. 3.12. Valve (1) The signal sprinkler is the main element of the UU sprinkler water-based system. Valve - Normally closed locking device designed to start fire extinguishing substance When the sprinkler irrigator is triggered and the issuance of the control hydraulic pulse. The reverse valve (2) prevents the pressure discharge in the feed pipe with its decrease in the supply pipeline.

Fig.3.12. Hydraulic scheme of sprinkler water-compounded node

Two three-way cranes (3) are designed to disable manometers when maintenance and verification. Two pressure alarms (4) are designed to be issuing a signal when the UU is triggered. Pressure gauge (5) is designed to control the pressure in the supply pipeline. Pressure gauge (6) is designed to control the pressure in the feed pipeline. Crane (7) is designed to control (check) pressure alarms for maintenance. The crane (8) is designed to drain the liquid into the drainage from the valve and the distribution pipe (in the standby mode is closed). The crane (9) is designed to close and open the signaling hole when installing the UU in the standby mode. The delay chamber (10) is installed on the pressure alarm lines and is intended to minimize the probability of issuing false signals caused by sharp fluctuations in the water supply source pressure. The drain tube (11) is intended to drain the liquid into the drainage from the signaling hole, has a narrowing (17) with a diameter of 3mm. The drain tube (12) is designed to reset the air from the delay chamber, has a narrowing (17) with a diameter of 3mm. The filter (13) is designed to protect the valve working bodies and clogging from clogging by unauthorized items in the standby mode.

When the sprinkler rod is triggered, the pressure in the supply pipeline and in the cavity above the shutter (14) decreases, the liquid under excess pressure In the inlet cavity of the valve opens the shutter, the fluid movement begins on the distribution pipe to the rope, and the bedding groove (15) of the saddle, the liquid enters the signal hole (16) and flows into the drainage in the pipeline. On the path of the flow of fluid in the pipeline, there is a narrowing (17) (3mm diameter), which creates an additional fluid resistance and providing required pressure To trigger pressure alarms (4). Pressure alarms give signals to control the pump and on the console of the central observation, the UU goes into the operating mode.

Installing UU to duty mode Perform in the following sequence:

Close all controls (cranes);

Open a valve (18) to fill the system with fire extinguishing liquid and creating pressure in the valve and distribution pipeline;

Open a crane (9) (after filling the system with liquid and creating pressure in the valve), give a track of accumulated water from the signal line and from the delay chamber. Permanent leakage of fluid in standby mode should not be.

Conduct a test manual start:

Open a crane (8), when the pressure drops, the valve shutter must open, and the pressure signaling devices (4) should give a signal to trigger the valve. I will install in the standby mode.

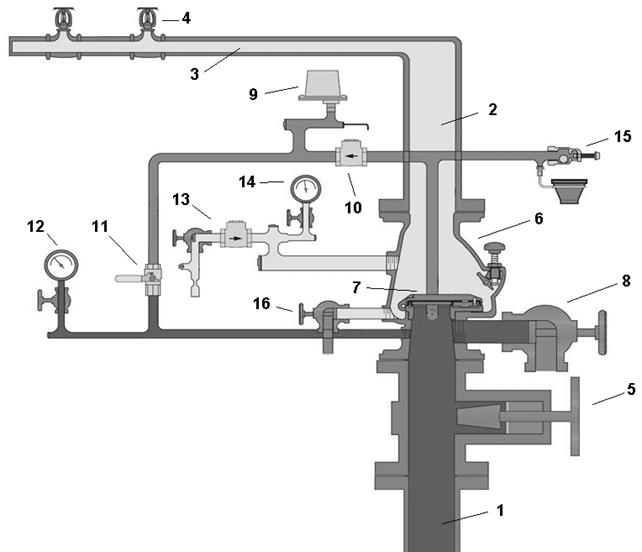

Aerial sprinkler system It is a water-airing automatic water extinguishing system (Fig. 3.13) intended for unheated premises (protected objects on which low temperatures are possible).

The system is based on the following:

The supply pipe (1) is filled with water or aqueous solution, powered (2) and distribution (3) are filled with compressed air or nitrogen.

Sprinkler rods (4) are installed only up the outlet.

The pumping station must be in a heated room.

Elements pumping station In addition to standard elements are:

Compressor;

Equipment for control and maintenance of air pressure.

Air sprinkler systems, as a rule, are protected by unheated warehouses, hangars, car parks, individual premises of enterprises, etc.

Fig. 3.13. Sprinkler Air Control Node

Sprinkler air control unit includes air sprinkler valve (6) with damper (7), valve (5), main drainage valve (8), universal pressure signaling (9), check valve (10), the testing valve (11) is designed to be measured, the pressure gauge (12) is designed to control the pressure in the supply pipe, the system for connecting air supply (13), automatic drainage valve (15), pressure gauge (14) is designed to control pressure air, lower drain valve (16).

The air valve is a differential type device, which requires significantly lower air pressure (nitrogen) in the system to maintain the valve in the original state than water pressure on entering.

The essence of the valve differential is based on the inequalities of the pressure of the pressure on the air side and from the water side in combination with the difference between the distances from the damper axis to the water seal center and from the damper axis to the air seal center. In this case, air pressure 1 psi (0.07 bar) balances the water pressure of 5.5 psi (0.38 bar).

The value of the minimum required air pressure (nitrogen) in the system is given in Table 3.3.

Table 3.3.

Functional dependence of the required air pressure

in the water pressure system

From the data submitted, it follows that the air pressure is about 18% of the static water pressure on the introduction plus the required supply for 1.4 bar, which is necessary to prevent false positives caused by fluctuations in the input pressure of water.

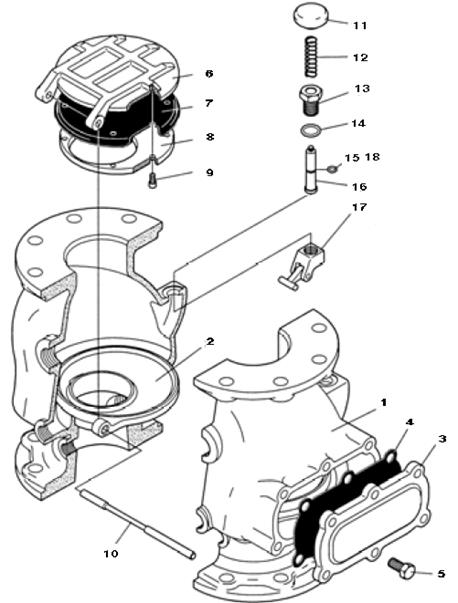

Fig. 3.14 Composer air valve composition: 1 - valve body; 2 - Latch Saddle; 3 - side cover; 4 strokes lateral lid; 5- Bolt with a 6-face head; 6 places; 7 - gasket of dampers; 8 - damper pads; 9 - Fastening bolt of dampers; 10 - valve valve axis; 11 - the reset button to its original state; 12 - Dump Spring; 13 - reset sleeve; 14 - Ring of the reset sleeve; 15 - Ring Plunger Reset; 16 - Dump plunger; 17 - Relief latch.

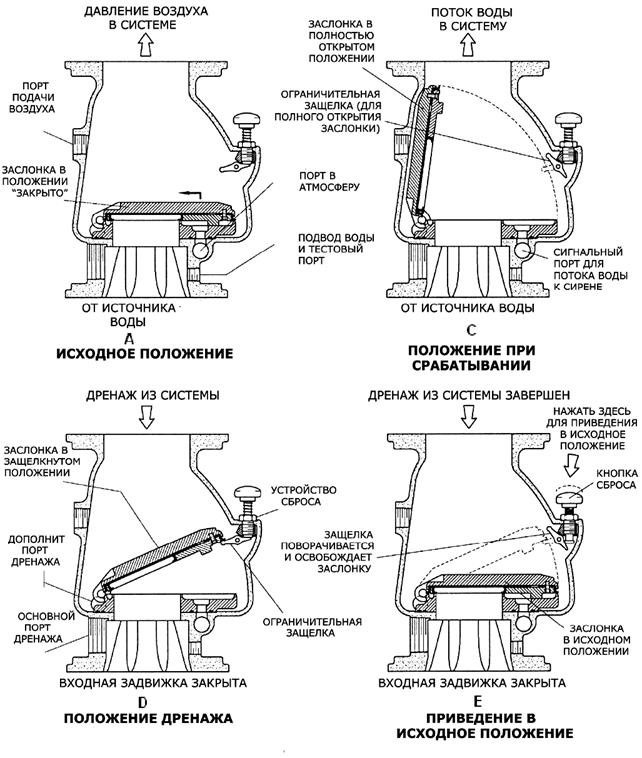

The composition of the flap of the spinClerous air is presented in Fig. 3.14. The state of the valve in various modes is represented in Fig.3.15 The valve intermediate camera located between air and water seals is under atmospheric pressure Through the connection of the signal port and the strapping of a normally open automatic drainage valve. The connection of the intermediate camera with the atmosphere is an important aspect valve operation. Otherwise, air pressure in the system attached to the top of the damper would not have enough to hold the valve in the closed state. For example, if the air pressure in the system is 2.7 bar, and the residual pressure in the intermediate chamber is 1.7 bar, then the resulting pressure on the flap is only 1.0 bar. This pressure is not enough to keep the damper in the closed state against the pressure from the water source of 6.9 bar on the flap below. That is why the rod of the automatic drainage valve must be pressed several times during the valve installation procedure into the original state or during test starts, which guarantees its open state.

When opening one or more sprinklers, the air pressure in the system drops due to its leakage through open rods. With a sufficient reduction in air pressure, the water pressure will exceed the differential that holds the damper in the closed state, and opens the flap, as shown in Fig.3.15 (s). The flow of water enters the distribution pipeline and sprinkles through open rods. In addition, when the damper is open, the intermediate camera is under pressure and the flow of water is heading through the valve signal port, activates the alarm system. On the other hand, the magnitude of the flow of water through the signal port is enough to close the normally open automatic drainage valve.

After the valve is triggered and the subsequent closing of the valve at the system input to stop the water flow, the valve valve will be fixed in the open state, as shown in Fig.3.15 (D). Locking in the open state will allow complete drainage system through the main drainage port.

Fig. 3.15. Sprinkler valve

in various modes

Upon completion of the drainage of the system during the installation of the system to the original state, the external reset button can be easily pressed and the valve will be removed from the latch, as shown in Fig.3.15 (E). Thus, the air sprinkler system will be installed in its original state without removing the side cover.