Why do you need to re-ground? How to make grounding of support structures Grounding 10 kV support

Grounding devices of supports of air lines with voltage

0.38; 6; 10; 20 kV.

this section is prepared according to a typical project series 3.407-150

Typical designs of this series are designed taking into account the requirements of the rules of the device of electrical installations (PUE) of the sixth edition both in constructive execution and in terms of taking into account the normalized resistances by spreading earthing machines for soils with equivalent resistivity up to 100.

The series includes the designs of earthing machines intended for grounding of supports, as well as supports with an equipment installed on them 0.38, 6, 10, 20 kV in accordance with the requirements of Chapter 1.7 and other PUE heads.

The following entries are provided: vertical, horizontal (radial), vertical in combination with horizontal, closed horizontal (contour), contour in combination with vertical and horizontal (radiation).

Constructive implementation of grounding and zero protective conductors laid on the BL supports are accepted in accordance with applicable typical projects and re-applying projects BL.

The designs of this series should be applied by designers, installers and operational plants for structures and reconstruction of VL 0.38, 6, 10 and 20 square meters.

In this series, grounders are not considered in the districts of the northern construction and climatic zone (Subaryons IA, IB, IG and ID according to SIIP 2.01.01-82) and in the areas of distribution of rock soils.

General situations for grounding

The initial data in the design of grounding devices WL are the parameters of the electrical structure of the Earth and the requirements for the values \u200b\u200bof ground resistance.

The specific resistances of the soil r and the thickness of the soil layers with various values R can be obtained directly during measurements on the highway of the designed VL or according to measurements of the resistivity of similar soils in the area of \u200b\u200bthe VL route, on the substation sites, etc.

In the absence of data direct measurements of the resistivity of the soil, designers should be used by the geological cutting of the soil on the highway and the generalized values \u200b\u200bof the specific resistivity different soilsshown in the table.

Generalized values \u200b\u200bof the resistivity of soils

Currently, sufficiently reliable engineering methods for determining the electrical structure of the Earth are developed, calculating the resistance of the entrancers in a homogeneous and two-layer Earth, as well as ways to bring the real multilayer electrical structures of the Earth to the calculated two-layer equivalent models. The developed methods make it possible to determine the expedient structures of artificial entrancers for the electrical structure of the soil ensuring the normalized value of the ground resistance.

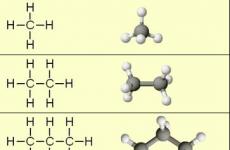

Choice of section Earth Elements

Based on the studies of the CIBNIIE conducted, it was found that the resistance to the spreading is practically independent of the size and configuration cross section Ground. At the same time, earthing elements having round cross section, much more durable is equivalent to the cross section of flat conductors, because with the same corrosion speed, the remaining cross section of the latter decreases much faster. In this regard, for earthingers, it is advisable to apply only round steel.

Constructive implementation of earthing and installation recommendations

Eggs are provided from round steel: a horizontal diameter of 10 mm, vertical - 12mm, which is quite enough for the estimated service life in conditions of weak and medium corrosion.

In case of enhanced corrosion, measures should be taken that increase the durability of earthing.

Corner steel and steel pipes can also be used as vertical earthing. At the same time, their dimensions must comply with the requirements of PUE.

Considering that the limiting depth of the immersion of vertical grounds (electrodes) with currently existing mechanisms in a sufficiently soft soil 20 m, in the present series they are provided for 3, 5, 10, 15 and 20m.

In soils with small specific resistances (with up to 10 omchm), it is planned to use only the bottom grounding release - the rod electrode of about 2 m long, supplied complete with a reinforced concrete rack.

When installing the entrancers, the requirements of the construction norms and Rules and GOST 12.1.030-81 should be followed.

To develop trenches when laying horizontal entrancers, it is possible to use an ETC -161 excavator on the basis of the tractor of Belarus MTZ-50. They can also fit with the assembly plow. With this one should take into account the need to dig meat with the size of 80x80x60 cm in the plugs of vertical ground and the subsequent attachment with the help of welding to the horizontal earthing.

Vertical earthingers are immersed by vibrating or deploying, as well as, by a bog or bookmark in finished wells.

The immersion of the vertical electrodes is performed with the calculation so that their top is 20cm above the trench bottom.

Then the horizontal earthing motors are paved. The ends of the vertical entries are used in places of adjustment to the horizontal earthing man in the direction of the axis of the trench.

The connection of the grounding between soda should be welded in the fleece. In this case, the length of the flush should be equal to six diameters of the grounding. Welding should be performed throughout the perimeter of the lash. Earth connection nodes are shown in the ES37 and ES38 sections.

To protect against corrosion, the precast joints should be covered with a bitumen varnish.

Tranche's frustration is made by a bulldozer on the basis of the tractor Belarus MTZ-50.

In the ES42 section, the volumes of earthworks are given in the case of riveting trenches with a mechanized and manual copper.

When implementing the draft VL in particular, the entrancers need to take into account the capabilities of Mecholonna, which will build this line in terms of EE mechanisms.

After the earthing device, the control measurements of their resistance are performed. In case the resistance exceeds the normalized value, vertical grounds are added to obtain the required resistance value.

Joining grounding to support

Attaching grounding to special grounding releases (details) of reinforced concrete supports of supports and the grounding descents of wooden supports can be COC welded and bolted. Contact compounds must comply with class 2 according to GOST 10434-82.

At the site of joining the grounding agents to grounding descents on wooden supports of 0.38 kV, additional segments made of round steel with a diameter of 10 mm are envisaged, and the grounding winds on wooden supports VL 6, 10 and 20 kV performed from round steel with a diameter of at least 10 mm are joined directly To the earthing.

The presence of a bolt connection of the grounding descent with the grounding makes it possible to monitor grounding devices of the BL supports without lifting on the support and disconnect the line.

In the presence of devices for earthing control, the grounding disk with the earthing can be performed in indefinite.

Control and measurements of earthing should be carried out in accordance with "Rules technical exploitation Electrical stations and networks. "

Due to the fact that engineering methods of ground calculation are designed for a two-layer soil structure, the estimated multilayer electrical structure of the soil is reduced to an equivalent two-layer structure. The method of bringing depends on the nature of the change in the resistivity of the layers of the calculated structure in the depth and depth of the entry of the ground.

In a homogeneous soil and in the ground with a resolishing resolution resistance (order at 3 or more times), vertical entries are most appropriate.

If the underlying soil layers have significantly higher resistivity values \u200b\u200bthan the upper, or when the immersion of vertical entries is difficult or impossible due to the density of soils, horizontal (radial) entries are recommended as artificial entrancers.

If the vertical entries do not provide normalized resistance values, then in addition to the vertical, horizontal are laid, i.e., combined grounding machines are applied.

According to the equivalent two-layer structure and the pre-selected earthing design, it is determined.

For found and for the normalized resistance of the grounding device, the corresponding type of ground of this series is selected.

Below is a table of selection of earthing drawings.

Earth calculations are made on the computer on the program developed by the West Siberian branch of the institute "CELENERGOPROEK".

Attention: according to PUE 7th ed. Grounding conductors for repeated grounding PEN conductor must have dimensions of not least given in Table. 1.7.4.

Table 1.7.4. The smallest dimensions of the entrancers and grounding conductors laid in the ground

Table selection of earthing drawings

In the modern world, the lighting surrounds us everywhere: both at home and on the street. Moreover, the role of the outdoor type of lighting is very important in cities and villages, because it eliminates many problems in the evening and night time.

When creating an outdoor type of lighting, one of the important stages of installation is the grounding of the supports.

During the grounding for supports of the outdoor type of lighting, it is necessary to understand and know the basic rules that are governed by the relevant documentation (for example, PUE). This procedure is especially important for air lines (WL) and network support networks of outdoor lighting. About everything related to this procedure, we will talk in this article.

For what is needed

Outdoor lighting supports

Grounding for a support network of the outer lighting or VL (0.4, 6-10, 20 and 35 kV) is of great importance, since it hinders the risk of obtaining electricians when contact with structural elements in a situation where the cable isolation occurred. If there is grounding on the metal support of the network of outdoor lighting or VL, the voltage is "bottled" on the ground, thereby becoming safe for people. This indicator depends on how the resistance has the soil in which the WL support is installed (0.4, 6-10, 20 and 35 kV). As a result, even if somewhere there was a violation of the insulation VL, the designs will remain safe.

Under the standard operating conditions, pin insulators mounted on supports will ensure reliable insulation of all wires from structural elements. But there are situations where the voltage is online

Significantly exceeds the voltage that was calculated (0.4, 6-10, 20 and 35 kV). In such a situation of overvoltage, it is possible to break the insulation WL and, as a result, the output of the network is out.

In order to limit the value of overvoltage and improve safety, it is necessary to lower the resistance for the "current spreading". For this purpose, they are installed on the VL (0.4, 6-10, 20 and 35 kV) and the suburb of the outdoor type of lighting the protective ground.

Features of the procedure

Grounding metal supports

The grounding circuit is formed on the basis of which the support was made. To date, three design options are used:

- reinforced concrete. Here, in the presence of a network, a grounded neutral, along with the design of structures, the protection is drawn up through the connection to the grounded wire (zero) of the special conductor. The latter must go with a diameter of 6 mm (no less);

- wooden. On wooden podorants, pins and hooks are not ground;

Note! Grounding on wooden supports put only when the power line or external lighting system passes through the settlements, where there are single and two-storey buildings. The settlement in such a situation should also not have excessive towering pipes (shielded), trees, etc. There is a need to protect the network from overvoltage of atmospheric order using grounding devices. Their resistance is up to 30 ohms (no more).

- metal supports. Here the defense is made by analogy with reinforced concrete structures. Such supports are most often found. They gradually displace wooden and even reinforced concrete supports.

When grounding VL (0.4, 6-10, 20 and 35 kV), it is necessary to take into account the distance between adjacent supports. Typically, the distance between them is 100 or 200 m. This parameter is determined by the average thunderstorm number characteristic of this locality.

It is necessary to land the supports (repeated or not), having a branch to the facilities where there are a large number of people.

For overvoltage protection, two types of groundwater are used:

- vertical pins that break into the ground vertically;

- horizontal plates. Such entries are usually used for stony soils.

The type of grounding is predetermined by the type of soil at the place of mounting the WL support (0.4, 6-10, 20 and 35 kV) or outdoor lighting.

How is the procedure itself

Setting earthing

Installation of grounding (repeated or not) for VL (0.4, 6-10, 20, and 35 kV), power networks, or outdoor lighting supports is as follows:

- rOOM trench (about 0.5 m). Trench depth up to 1 m is needed for arable land. I need to measure the depth from the beginning of the supports;

- the length of the trench, as well as the number of earthing carts must be specified in the project for the construction of WL (0.4, 6-10, 20 and 35 kV);

- then we carry out the immersion of earthing, forming the contour;

- next, the welding (or a rod or strip) occurs;

- after that, the protection of welding joints from possible corrosion is made.

After the ground loop, an installation of a grounding descent is carried out. It is performed from the steel rod or strip and has the same dimensions as the compound installed between the grounding agents. The protection circuit is connected to the descent below. The descent from above is supplied to the metal non-conductive parts of the support.

This procedure is clearly visible in the picture.

Grounding on the support (wooden):

a - common appearance, B - Emboding of hooks

To the wooden support after contour (earthing 1 and 2), the connecting strip (2) and the descent (3) are supplied. Here, the descent is mounted often (step - 300 mm), fastening the brackets. At the same time, the descent, and more precisely its upper part (4), will perform above the support, performing the role of a lightning conductor. The figure (b) presents a grounding for a metal support in the power supply network or outdoor lighting. The overvoltage protection circuit here will also connect with the descent (1). But in this situation, the descent will be connected with the welding of the jumper (2) or bolted clamps, which direct the zero potential of the Earth on the zero wire (3) and the hook (4).

Requirements Pue.

Pue is a regulatory documentation on which it should be relying when implementing protective grounding measures (repeated it or not) of the power supply network or outdoor lighting. The grounding circuit should always be installed on these rules to avoid problems in the future.

In PUU sets out such recommendations:

- in the presence of electrical installation with a deaf-winded neutral, first of all, the zero wires should be grounded;

Grounding on each support

Grounding on each support

Note! The grounding circuit in this situation does not need to be installed at the first support. This is determined by the fact that here the zero wire will be tightly connected to the zero point of the power supply.

Protective grounding:

1 - places for welding; 2 - the earthing itself; 3 - Explorer to the earthing man.

- in the presence of electrical installations with a deaf-free neutral, re-grounding as a overvoltage protection must be installed not very often (step - kilometer line);

- any subsequent re-grounding is required to have resistance up to 10 ohms (maximum). If there is an installation with a power of more than 100 kVA. If the installation power is lower, then the resistance must be up to 30 ohms (maximum);

- for the BL support, you need to perform grounding devices if you need to re-protect against overvoltage. It is allowed to use structures for protection against oversight of natural origin (lightning). In this situation, the resistance for the grounding device should be taken not higher than 30 ohms;

- any metal constructions must be connected to special renovicers;

- in the presence of reinforced concrete supports, special re-conductors must be connected to the plugs and supports rebels;

- When installing a SIP, having insulated bearing conductors, protection against overstrain of support (reinforced concrete and metal wooden, for VL) are not subject to. Here the re-ground is necessary for pins and hooks. This is done in order to form for overvoltage of atmospheric origin.

Features

When forming a grounding for BL up to 1 kV, followed by the following nuances:

- if there is a network with a grounded neutral, a jumper is made from an uninsulated conductor for reinforcing reinforcement (reinforced concrete / metallic). It is attached to the zero wire through bolted clamps (branch);

- contact connections of the jumpers before its installation, it is necessary to clean well and coat with vaseline;

- if there is a network with an isolated neutral for the same supports, the protection installation is carried out by connecting special grounding devices. In this case, the resistance of these structures should not be criticized by a bar in 50 ohms;

- grounding structures to create an external lighting system in the presence of cable power is carried out through a cable metal sheath. This happens if there is a grounded neutral.

In other situations, everything is determined by the types of systems, supports and other components.

Conclusion

When creating grounding on different types Supports included in the exterior lighting system or VL are necessary in obligatory Follow the established rules and recommendations given in Pue. This can only be achieved by high-quality and correct grounding, which will protect supports from damage to cable insulation and prevent risky situations when people can beat current when touched to supports.

Select box for LED tapes, correct installation

Select box for LED tapes, correct installation

Developed taking into account the requirements of state standards, construction norms and rules, recommendations of scientific and technical councils for the consideration of projects of chapters. Projects of chapters are considered by the working groups of the Coordination Council on the revision of PUE

Prepared by AOOT "RESEP", co-valve - JSC "Firm OrgRes"

Agreed in the prescribed manner with the state system of Russia, Gosgortkhnadzor of Russia, RAO "UES of Russia" (OJSC "VNIIE") and presented to the statenergoador statement of the Ministry of Energy of Russia

From October 1, 2003, chapter 2.4 "Rules of the Electric Installation Device" of the Sixth Edition

Requirements of the rules of electrical installations are required for all organizations regardless of the forms of ownership and organizational and legal forms, as well as for individuals employed business activities without the formation of a legal entity.

Application area. Definitions

2.4.1. This head of the rules extends to the AC power lines by a voltage to 1 kV, performed using isolated or uninsulated wires.

Additional requirements for VL to 1 kV are given in ch. 2.5, 6.3 and 7.7.

Cable inserts in line and cable branches from the line must be performed in accordance with the requirements of ch. 2.3.

2.4.2. Air line (VL) power supply voltage up to 1 kV - a device for transmitting and distributing electricity using an isolated or uninsulated wire located on open air and attached linear reinforcement to supports, insulators or brackets, to the walls of buildings and to engineering facilities.

The power line of power supply with a voltage up to 1 kV using self-supporting insulated wires (SIP) is denoted.

The self-supporting insulated wire - twisted in the harness insulated veins, and the carrier vein can be both isolated and uninsulated. The mechanical load can be perceived or carrier living, or all the guitance conductors.

2.4.3. Highway Vl is a line of line from the supply transformer substation to the end support.

Linear branches or branches to the input can be attached to the highway.

A linear branch from the lines of the line attached to the lines of the VL, which has more than two spans.

A branch from VL to enter - a plot from the support of the highway or linear branch to the clamp (input insulator).

A branch from the blast is allowed to be performed in the span.

2.4.4. The state of the BL in the calculations of the mechanical part:

- normal mode - mode with non-vocabulary;

- emergency mode - mode for torn wires;

- mounting mode - mode under the installation of supports and wires.

The mechanical calculation of VL to 1 kV in emergency mode is not performed.

General requirements

2.4.5. The mechanical calculation of the elements of the VL should be made according to the methods set forth in ch. 2.5.

2.4.6. The power lines of the transmission should be placed so that the supports do not block the entrances to buildings and entrances to the courtyards and did not make it difficult to move the movements and pedestrians. In places where there is a danger of transportation of transport (at the entrances to the courtyards, near the congresses from the roads, when crossing roads), supports must be protected from the departure (for example, jackhamped stands).

2.4.7. On the supports of the VL at a height of at least 2 m from the Earth, 250 m on the VL highway must be installed (applied): the sequence number of the support; The posters on which the distances are indicated from the BL support to the cable line (on the supports mounted at a distance less than 4 m to the communication cables), the width of the security zone and the owner's telephone owner.

2.4.8. Under the passage of lilt on forests and green planting, cutting off is not required. At the same time, the distance from the wires to the trees and bushes with the largest arrows of the SIP and the greatest deviation should be at least 0.3 m.

During the passage of VL with uninsulated wires on forests and green deforestation, the deforestation is not required. At the same time, the distance from the wires with the highest arrows of the provice or the greatest deviation to trees and bushes should be at least 1 m.

The distance from insulated wires to green plantings should be at least 0.5 m.

2.4.9. The structures of the WL support should be protected from corrosion based on requirements 2.5.25, 2.5.26 and construction standards and rules.

2.4.10. The protection of electric overloads should be performed in accordance with the requirements of ch. 3.1.

Climatic conditions

2.4.11. Climatic conditions for calculating VL to 1 kV in normal mode should be taken as for VL to 20 kV in accordance with 2.5.38 - 2.5.74. At the same time, for VL to 1 kV, it should be taken:

- when calculating 2.5.52: CX \u003d 1.1 - for SIP, free or holled-coated;

- when calculating 2.5.54 and 2.5.55:

- γnw \u003d γng \u003d 0.8 - for monotoned VL;

- γnw \u003d γng \u003d 0.9 - for monotoned VL with suspension on PV supports;

- γnw \u003d 1.0 and γng \u003d 1,2 - for two-charted and multi vessels, as well as on the suspension on the supports of the self-supporting non-metallic optical cable (OXN);

- γp \u003d 1.0 and k1 \u003d 1.0 - in all cases.

2.4.12. The calculation of the length of the span of branch from VL to entering 2.4.20 should be performed in ice-free mode for two cases:

- the direction of the wind at an angle of 90º to the axis of the VL, the WL wires are covered with ice BE, the thickness of the ice wall on the branch wires B0 \u003d 0.5 BE;

- the wind direction along the VL (angle 0º), the thickness of the ice wall on the branch wires b0 \u003d Bue.

At the same time, in both cases, it is necessary to take into account the reduction of branching wires with the deviation of the top of the support.

Wires. Linear fittings

2.4.13. On VL should, as a rule, apply self-supporting insulated wires (SIP).

The CIP should relate to the category of protected, have isolation from an employed light-stabilized synthetic material, resistant to ultraviolet radiation and ozone effects.

2.4.14. Under the conditions of mechanical strength on highways of the VL, on linear branch from VL and on branches, the wires with minimal sections specified in Table 2.4.1 and 2.4.2 should be applied to the inputs listed in Table 2.4.1 and 2.4.2.

Table 2.4.1 Minimum allowable sections of insulated wires

* In brackets, the cross-section of the veins of self-supporting insulated wires twisted in the harness, without a carrier wire.

Table 2.4.2 Minimum allowable sections of uninsulated and insulated wires

2.4.15. When working in places, there is a destruction of wires from corrosion (coast of seas, salt lakes, industrial areas and areas of saline sands), as well as in places where on the basis of the research data it is possible to apply self-supporting insulated wires with an isolated residential .

2.4.16. The truck should, as a rule, should be carried out by wireless cross-section.

2.4.17. The mechanical calculation of the wires should be carried out according to the method of allowable stresses for the conditions specified in 2.5.38 - 2.5.74. At the same time, the voltages in the wires should not exceed the allowable stresses given in Table. 2.4.3, and the distances from the wires to the surface of the Earth, intersected structures and grounded elements of the supports must meet the requirements of this chapter.

When calculating, the parameters of the wires shown in Table are used. 2.5.8.

Table 2.4.3 Permissible mechanical voltage in wires VL to 1 kV

2.4.18. All types of mechanical loads and impacts on SIP with a carrier residential should perceive this lived, and on a SIP without a carrier wire - all the veins of the twisted harness should be perceived.

2.4.19. The length of the span of branch from VL to the commissioning should be determined by the calculation depending on the strength of the support, on which the branch, the height of the suspension of the branch wires on the support and on the input, quantity and sections of the branch wires.

Upon distances from the highway, the vehicle exceeding the calculated values \u200b\u200bof the span of the branch, the required number of additional supports is set.

2.4.20. Selecting the secting of current-carrying conductors for a long time permissible current should be carried out taking into account the requirements of ch. 1.3.

The cross section of current-host conductor should be checked by the heating condition with short circuits (KZ) and thermal resistance.

2.4.21. Fastening, SIP connection and accession to SIP should be performed as follows:

- the fastening of the wire of the highway was carried out on intermediate and angular intermediate supports - using supporting clamps;

- the fastening of the wire of the highway was carried out on the supports of anchor type, as well as the terminal fastening of the wires of the branch on the support of the Blue and input - using tension clamps;

- the connection of the wire was in the span - with the help of special connecting clamps; In the hinges of the anchor type supports, it is allowed to connect a non-insulated carrier wire using a spot clamp. Connecting clamps intended for connecting the carrier wire in the span must have mechanical strength at least 90% of the explosive effort of the wire;

- the compound of the phase wires of the imaging is using connecting clamps having an insulating coating or a protective insulating shell;

- the connection of the wires in the span of the branch to the input is not allowed;

- connection of grounding conductors - with dyeing clamps;

- branch clamps should be applied in cases:

- branches from phase lived, with the exception of a SIP with all carriages of the harness;

- branch from the carrier vein.

2.4.22. The fastening of supporting and tensioning clamps to the supports of the lint, walls of buildings and structures should be performed using hooks and brackets.

2.4.23. Estimated efforts in supporting and tensioning clamps, attachment nodes and brackets in normal mode should not exceed 40% of their mechanical destructive load.

2.4.24. Connections of wires in the spans should be performed using connecting clamps that provide mechanical strength of at least 90% of the explosive wires.

In one span, no more than one connection on each wire is allowed.

In flights, the intersection of WL with engineering structures, the connection of wires of WL is not allowed.

Coupling wires in hinges anchor supports Must be done with clips or welding.

Wires of different marks or sections must be connected only in the hinges of the anchor supports.

2.4.25. Fastening of uninsulated wires to insulators and insulating traverses on the supports of the WL, with the exception of supports for intersections, it is recommended to perform single one.

Fastening of uninsulated wires to pin with insulators on intermediate supports should be performed, as a rule, on the neck of the insulator from its inner side with respect to the support rack.

2.4.26. Hooks and pins should be calculated in the normal mode of operation VL according to the method of destroying loads.

At the same time, efforts should not exceed the values \u200b\u200bgiven in 2.5.101.

Location of wires on supports

2.4.27. On supports allowed any location of isolated and uninsulated wire wires regardless of the area of \u200b\u200bclimatic conditions. Zero wire VL with uninsulated wires, as a rule, it is necessary to have below phase wires. The insulated wires of the outdoor lighting deployed on the supports of the blast can be placed above or below the SIP, as well as to be twisted in the SIP harness. Uninsulated and insulated wires of external lighting, laid on the supports of the VL, should be located, as a rule, over Pen (re) conductor VL.

2.4.28. The devices installed on the supports should be placed at a height of at least 1.6 m from the surface of the Earth.

The protective and partitioning devices installed on the supports must be placed below the WL wires.

2.4.29. The distances between the uninsulated wires on the support and in the flight on the conditions of their convergence in the span with the highest arrows of the provice to 1.2 m should be at least:

- with the vertical location of the wires and the location of the wires with a horizontal displacement of no more than 20 cm: 40 cm in I, II and III areas on ice, 60 cm in IV and special areas on ice;

- with other locations of the wires in all areas of ice at the wind speed with ice: up to 18 m / s - 40 cm, more than 18 m / s - 60 cm.

With the highest arrow of the provice more than 1.2 m, the distances should be enlarged in proportion to the ratio of the highest prime boom to the lilators of the wire equal to 1.2 m.

2.4.30. The vertical distance between isolated and uninsulated wires of various phases on a support during a branch from VL and with the intersection of different VLs on a common support should be at least 10 cm.

The distances from the wires of the VL to any elements of the support should be at least 5 cm.

2.4.31. With a joint suspension on common supports, VLI and VL up to 1 kV vertical distance between them on the support and in the span at ambient temperature plus 15 ºС without wind should be at least 0.4 m.

2.4.32. With a joint suspension on common supports of two or more, the distance between the SIP bundles should be at least 0.3 m.

2.4.33. With a joint suspension on the common supports of the wires of VL to 1 kV and wires of VL to 20 kV, the vertical distance between the nearest wires of various voltages on the overall support, as well as in the middle of the span at ambient temperature, plus 15 ºС without wind should be at least:

- 1.0 m - with a SIP suspension with insulated carrier and with all carriages;

- 1.75 m - with a SIP suspension with an uninsulated carrier wire;

- 2.0 m - when suspension of uninsulated and insulated wires of VL to 1 square.

2.4.34. When the suspension on the overall supports of the wires of VL to 1 kV and the protected wires of the VLZ 6-20 kV (see 2.5.1) vertical distance between the nearest wires of VL to 1 kV and VLZ 6-20 kV on the support and in the span at a temperature plus 15 ºС Without winds should be at least 0.3 m for SIP and 1.5 m for uninsulated and insulated wires of VL to 1 sq.

Insulation

2.4.35. The self-supporting insulated wire is attached to the supports without the use of insulators.

2.4.36. On WL with non-insulated and insulated wires, regardless of the material of the supports, the degree of contamination of the atmosphere and the intensity of the thunderstorm activity should be used insulators or traverse from insulating materials.

The choice and calculation of insulators and fittings are performed in accordance with 2.5.100.

2.4.37. On the supports of branches from WL with uninsulated and insulated wires, it should, as a rule, should be used by multi-track or additional insulators.

Ground. Protection against overvoltages

2.4.38. On the BL supports, grounding devices should be performed, intended for re-grounding, protection against thunderstorm overvoltages, grounding of electrical equipment installed on the supports of the VL. The resistance of the grounding device should be no more than 30 ohms.

2.4.39. Metal supports, Metal structures and reinforced concrete components of the supports must be attached to the re-conductor.

2.4.40. On reinforced concrete supports, the reinforcement should be attached to the reinforced concrete racks and support pods.

2.4.41. Hooks and pins of wooden supports WLs, as well as metal and reinforced concrete supports on the suspension on them, a sip with an isolated carrier conductor or with all carriages of harness, grounding is not subject to, with the exception of hooks and pins on the supports where repeated grounding and grounding for protection against atmospheric overvoltages.

2.4.42. Hooks, pins and armature of supports voltage up to 1 kV, limiting the span intersection, as well as supports on which a joint suspension is performed must be grounded.

2.4.43. On wooden supports, the grounding conductor should be connected to the cable conductor to the cable line to be connected to the conductor VL and the cable metal sheath.

2.4.44. Protective devices installed on WL supports to protect against thunderstorm overvoltages must be attached to the earthing in a separate descent.

2.4.45. The connection of grounding conductors among themselves, joining them to the upper grounding releases of reinforced concrete supports, to hooks and brackets, as well as to grounded metal structures and to grounded electrical equipment installed on BL supports, should be welding or bolted.

Attaching grounding conductors (descents) to the grounding in Earth should also be welding or have bolted connections.

2.4.46. In the populated area with single and two-storey buildings, the WL must have grounding devices intended for protection against atmospheric overvoltages. Resistance to these grounding devices should be no more than 30 ohms, and the distances between them should be no more than 200 m for areas with the number of thunderstorm clocks in a year to 40, 100 m - for areas with the number of thunder hours in a year more than 40.

In addition, grounding devices must be completed:

- on supports with branches to inputs in buildings in which a large number of people (schools, nursery, hospitals) may be focused or which represent a large material value (livestock and poultry houses, warehouses);

- on the terminal supports of lines having branches to inputs, at the same time the largest distance from the adjacent grounding of the same lines should be no more than 100 m for areas with the number of thunderstorm clocks in a year to 40 and 50 m - for areas with the number of thunder hours in the year more than 40 .

2.4.47. At the beginning and end of each highway, the Wires on the Wires are recommended to install clamps to attach the voltage and portable grounding devices.

Grounding protection devices from thunderstorm overvoltages are recommended to be combined with re-grounding re-conductor.

2.4.48. Requirements for grounding remedies and protective conductors are given in 1.7.102, 1.7.103, 1.7.126. As grounding conductors, round steel, having an anti-corrosion coating with a diameter with a diameter of at least 6 mm, is allowed.

2.4.49. The delay of the WL support must be attached to the grounding conductor.

Support

2.4.50. Supports from various materials can be used on the WL.

For VL, the following types of support should be applied:

- intermediate, installed on direct sections of the voltage vol. These supports in normal operating modes should not perceive the efforts directed along the VL;

- anchor, installed to limit the anchor span, as well as in places of change of the number, grades and sections of the wires of the VL. These supports should be perceived in the normal modes of efforts on the difference of wires, directed along the VL;

- corners installed in places to change the direction of the route VL. These supports at normal operation modes should perceive the resulting load from the removal of the wires of adjacent spans. Corner supports can be intermediate and anchor type;

- end, installed at the beginning and end of VL, as well as in places that limit cable inserts. They are supports of anchor type and should perceive in normal modes of operation of unilaterally all wires.

Supports on which branches are performed from VL are called branch; Supports on which the intersection of vl of different directions or the intersection of Wl with engineering structures is cross. These supports can be all specified types.

2.4.51. The designs of the supports must provide the ability to install:

- lamps street lighting all types;

- terminal cable couplings;

- protective devices;

- partitioning and switching devices;

- cabinets and panels for connecting electrical receivers.

2.4.52. Supports regardless of their type can be freestanding, with pins or dents.

Opporting supports can be attached to anchors installed in the ground, or to stone, brick, reinforced concrete and metal elements of buildings and structures. The delay cross section is determined by the calculation. They can be multi-breed or round steel. The single-run steel delay cross section should be at least 25 mm2.

2.4.53. Supports should be calculated on the first and second limit in the normal operation of the operation of the WL on the climatic conditions of 2.4.11 and 2.4.12.

Intermediate supports should be designed for the following combinations of loads:

- the simultaneous effect of the transverse wind load on the wires, free or holled-contained, and on the design of the support, as well as the load on the removal of branching wires to the inputs free from ice or partially covered with ice (by 2.4.12);

- on the load from the removal of branches of branches to the inputs coated with the holel, while taking into account the deviation of the support under the action of the load;

- on the conditional estimated load, equal to 1.5 kN, attached to the top of the support and directed along the axis of the VL.

Corner supports (intermediate and anchor) must be calculated on the resulting load from the drainage of wires and wind load on the wires and the design of the support.

Anchor supports must be calculated on the difference in the remittance of the wires of adjacent spans and the transverse load from the wind pressure during ice and without ice on the wires and the design of the support. For the smallest difference in the difference of the damage should be taken 50% the greatest value One-sided population of all wires.

End supports must be designed for unilateral waste of all wires.

Distributory supports are calculated on the resulting load from all wires.

2.4.54. When installing the supports on the sleeves of the track, where the soil or ice drifts are possible, the supports must be strengthened (security of the Earth, the mixing, the device of the banquet facilities, installation of icebreakers).

Dimensions, intersections and rapprochement

2.4.55. The distance vertically from the wires was carried to the surface of the Earth in the populated and unanished area to the Earth and the roadway of the streets should be at least 5 m. It can be reduced in a hard-to-reach area up to 2.5 m and in an inaccessible (slopes of mountains, rocks, rocks) - up to 1 m.

When crossing the non-coming part of the streets of branches from the vli to the inputs in the building of the distance from SIP to the sidewalks of the pedestrian tracks is allowed to reduce to 3.5 m.

The distance from SIP and insulated wires to the surface of the Earth on branches to enter should be at least 2.5 m.

The distance from uninsulated wires to the surface of the Earth on branches to the inputs should be at least 2.75 m.

2.4.56. The distance from the wires of the WL in the populated and unandlared area with the highest arrows of wires to the ground and the roadway of the streets should be at least 6 m. The distance from the wires to the Earth can be reduced in a hard-to-reach area to 3.5 m and in an inaccessible area (the slopes of the mountains , rocks, cliffs) - up to 1 m.

2.4.57. The distance horizontally from the SIP with their largest deviation to elements of buildings and structures should be at least:

- 1.0 m - to balconies, terraces and windows;

- 0.2 m - to deaf walls of buildings, structures.

It is allowed to pass through the roofs of buildings and structures (except for the roofs of buildings and structures (except for the roofs of GL.7.3 and 7.4), while the distance from them to the vertical wires should be at least 2.5 m.

2.4.58. The distance horizontally from the wires of the VL with the greatest deviation to buildings and structures should be at least:

- 1.5 m - to balconies, terraces and windows;

- 1.0 m to deaf walls.

The passage of VL with uninsulated wires over buildings and structures is not allowed.

2.4.59. The smallest distance from the SIP and wires to the surface of the Earth or water, as well as to various structures during the passage of VL above them is determined when highest temperature Air without taking into account the heating of wire conductions with electric shock.

2.4.60. When laying on the walls of buildings and structures, the minimum distance from the SIP should be:

- with horizontal strip

- above the window, the entrance door - 0.3 m;

- under the balcony, window, cornice - 0.5 m;

- to the ground - 2.5 m;

- with vertical strip

- to the window - 0.5 m;

- to balcony, entrance door - 1.0 m.

The distance in the light between the SIP and the building wall or the construction should be at least 0.06 m.

2.4.61. Horizontal distances from underground parts supports or heads of supports to underground cables, pipelines and ground columns various destination must be not less shown in Table 2.4.4.

Table 2.4.4 The smallest permissible distance horizontally from the underground parts of the supports or grounding devices of supports to underground cables, pipelines and ground columns

2.4.62. When crossing ll with various structures, as well as with streets and areas of settlements, the angle of intersection is not rationed.

2.4.63. The intersection of VL with shipping rivers and channels is not recommended. If it is necessary to perform such an intersection, the WL should be constructed in accordance with the requirements of 2.5.268 - 2.5.272. When crossing non-good rivers and channels, the smallest distances from the wires of the VL to the greatest water level should be at least 2 m, and to the level of ice - at least 6 m.

2.4.64. The intersections and rapprochement of a voltage voltage of up to 1 kV with a voltage of above 1 kV, as well as the joint suspension of their wires on common supports should be carried out in compliance with the requirements given in 2.5.220 - 2.5.230.

2.4.65. The intersection of VL (VLI) to 1 sq. Between itself, it is recommended to perform at cross supports; Also allowed their intersection in the span. The vertical distance between the wires of intersecting VL (VLI) must be at least: 0.1 m on the support, 1 m in the span.

2.4.66. In places of intersection of VL to 1 sV, intermediate supports and supports of anchor type can be used.

When intersection of an array of intersection, it is possible to choose the place of intersection, it is possible to choose a closer to the support of the upper crossing l.

2.4.67. With parallel passage and convergence of VL to 1 kV and VL above 1 kV, the distance between them horizontally should be at least listed at 2.5.230.

2.4.68. The joint suspension of the wires of VL to 1 kV and uninsulated wires of VL to 20 kV on common supports is allowed under compliance with the following conditions:

- vL wires up to 20 kV should be placed above the wires of VL to 1 kV;

- vL wires up to 20 kV, fixed on pin insulators, should have a double fastening.

2.4.69. During the suspension on the overall supports of the wires of VL to 1 kV and the protected wires of the VLZ 6-20 kV, the following requirements must be followed:

- VL to 1 kV must be carried out on the calculated climatic conditions of VL to 20 kV;

- vLZ 6-20 kV wires should be located, as a rule, above wires of VL to 1 kV;

- the fastening of wires of VLZ 6-20 kV on the pin insulators should be carried out reinforced.

2.4.70. When crossing the VL (VLI) with a voltage of above 1 kV, the distance from wires crossing VL to the intersected VL (VLI) must comply with the requirements given in 2.5.221 and 2.5.227.

The cross-section of the wiring of the intersected VL should be taken in accordance with 2.5.223.

Crossing, rapprochement, joint suspension Wl with communication lines, wired broadcasting and RK

2.4.71. The angle of intersection of VL with HP * and HPF should be close to 90º. For cramping conditions, the crossing angle is not normalized.

Air lines of communication in their purpose are divided into a long-distance telephone line (MTS), a lines of the rural telephone (STS), a lines of urban telephone (GTS), lines of wired broadcasting (LPV).

By importance, air lines and wired broadcasting are divided into classes:

- mTS and STS lines: MTS main lines connecting Moscow with republican, regional and regional centers and the last intermediaries, and the Ministries of the Ministry of Railways passing along railways and through the territory of railway stations (class I); MTS intrazone lines connecting republican, edge and regional centers with district centers and the last interconnects, and CTC connecting lines (Class II); CTC subscriber lines (Class III);

- the Lines of the GTS to classes are not divided;

- wired broadcast lines: feeder lines with a rated voltage above 360 \u200b\u200bV (Class I); Feeder lines with rated voltage up to 360 V and subscriber lines with voltage 15 and 30 V (Class II).

* Under drugs should be understood the links of the Ministry of Communications of the Russian Federation and other departments, as well as the alarm lines of the Ministry of Communications.

Under HDF should be understood the lines of wired broadcasting.

2.4.72. The distance vertically from the wires of VL to wires or suspended LS cables and hillium in the intersection flight with the highest arrows of the wire wire should be:

- from SIP and insulated wires - at least 1 m;

- from uninsulated wires - at least 1.25 m.

2.4.73. The distance vertically from the wires of VL to 1 kV to wires or suspended LS cables or LPVs when crossing the total support should be:

- between SIP and HP or LPV - not less than 0.5 m;

- there are no less than 1.5 m between the uninsulated wire of the VL and LPV.

2.4.74. The place of crossing the wires of the WL with wires or suspended LS cables and LPVs in the span should be closer to the WL support, but not less than 2 m from it.

2.4.75. The intersection of VL with drugs and HPP can be performed according to one of the following options:

- wires of VL and insulated LS and HPV wires;

- wires of VL and underground or suspension cable LS and LPV;

- wires of VL and non-insulated ls and holy lpv;

- underground cable insert in WL with insulated and uninsulated LS and HPD wires.

2.4.76. When crossing wires of WL with insulated wires, the LS and LPV must comply with the following requirements:

- the intersection of uninsulated wires of the WL with WHD wires, as well as with the wires of HPV voltage above 360 \u200b\u200bV should be performed only in the span. The intersection of uninsulated wires of the WL with wires of HPV voltage up to 360 V can be performed both in the span and on a common support;

- supports VL that limit the span of the intersection with the LS of the trunk and intra -one communication networks and the connecting lines of the CTC, as well as the HDF voltage above 360 \u200b\u200bV, should be anchor type. When crossing all the remaining LS and LPV, intermediate type supports are allowed, reinforced with an additional console or troop;

- vL wires should be located above the ls and hp wires. On the supports that limit the span intersection, uninsulated and insulated wire wires must have a double fastening, the SIP is fixed with anchor clips. LS and HPV wires on supports that limit the intersection of the intersection should have a double fastening. In cities and towns of urban-type, the newly under construction, LS and LPV are allowed to have a voltage of up to 1 sq.

2.4.77. When crossing the wires of the WL with an underground or suspended LS and LPV cable, the following requirements must be performed:

- the distance from the underground part of the metal or reinforced concrete support and the grounding of the wooden support to the Underground LS and LPV cable in the locality of the locality should, as a rule, at least 3 m. During the cramped conditions, it is allowed to reduce these distances to 1 m (provided that the allowability of interfering influences on LS and hp); In this case, the cable must be laid in steel pipe or covered with a chaserler or corner steel along the length in both sides of the support of at least 3 m;

- in non-heated area, the distance from the underground part or the earthing support of the VL to the Underground LS and HPD cable should be at least the values \u200b\u200bgiven in Table. 2.4.5;

- wires should be located, as a rule, above the LS and LPV suspended cable (see also 2.4.76, p.4);

- the connection of the wires of the VL in the intersection span with the suspension cable LS and HPF is not allowed. The cross section of the carrier vein SIP should be at least 35 mm2. VL wires must be a multi-breed section of at least: aluminum - 35 mm2, steel aluminum - 25 mm2; SIP conductor cross section with all carriers of harness - at least 25 mm2;

- the metal shell of the suspended cable and the cable on which the cable is suspended must be grounded on supports that limit the intersection span;

- the distance horizontally from the base of the LS cable support and HPF to the projection of the nearest wire for the horizontal plane should be at least the greatest height Opports span intersection.

Table 2.4.5 The smallest distance from the underground part and the grounding of the BL support to the Underground LS and LPV cable in non-heated area

2.4.78. When crossing angle with uninsulated LS and LPV wires, the following requirements must be respected:

- the intersection of VLI with drugs and hp can be performed in the span on the support;

- ruff supports that restrict the intersection of the LS of trunk and intra -one communication networks and with the connecting lines of the CTC should be anchor type. When crossing all the remaining drugs and HDPV, the use of intermediate supports, reinforced with an additional console or troop, is allowed;

- the carrier veins of a SIP or a harness with all carriers of conductors on the intersection area should have a tensile strength factor with the highest settlement loads of at least 2.5;

- wires should be located above the ls and hp. On supports that limit the intersection of the intersection, the carriers of the CIP wires should be fixed by tensioning clamps. Wires were allowed to be placed under the wires of the LDV. At the same time, the wires of the LPV on the supports that limit the intersection of the intersection should have a double fastening;

- the connection of the carrier core and carrier conductors of the SIP harness, as well as the LS and LPV wires in the intersection spans is not allowed.

2.4.79. When crossing isolated and uninsulated wires, the following requirements must be followed with uninsulated LS wires and LPVs:

- the intersection of wires of WL with Wires of drugs, as well as the wires of HPV voltage above 360 \u200b\u200bV should be performed only in the span.

The intersection of wires of the WL with subscriber and feeder lines of HPV voltage up to 360 V is allowed to be performed on BL supports; - supports VL, limiting the intersection of the intersection, should be anchor type;

- lS wires, both steel and non-ferrous metal, should have a tensile strength coefficient with the highest settlement loads of at least 2.2;

- vL wires should be located above the ls and hp wires. On supports that limit the span intersection, the WL wires must have a double fastening. The wires of the 380/220 Vl voltage and below are allowed to be located under the wires of the LPV and the LINDS of the GTS. At the same time, the wires of LPV and the LINDS of the GTS on the supports that limit the intersection of the intersection should have a double fastening;

- the connection of the wires of the VL, as well as the LS and LPV wires in the intersection spans is not allowed. Wires of VL must be multi-proper cross-sections: aluminum - 35 mm2, steel aluminum - 25 mm2.

2.4.80. When crossing the underground cable insert in WL with uninsulated and insulated wires, the LS and LPV must comply with the following requirements:

- the distance from the underground cable insert to VL to the LS and LPV supports and its earthing should be at least 1 m, and when laying the cable in an insulating pipe - not less than 0.5 m;

- the distance horizontally from the base of the cable support VL to the projection of the nearest LS wire and the HPV on the horizontal plane should be no less than the highest height of the intersection span.

2.4.81. The distance horizontally between the wires of the VLI and the LS wires and the HPV with parallel passage or convergence should be at least 1 m.

Under the rapprochement of air LS and LPV, the horizontal distance between insulated and uninsulated wires of the VL and the WHD wires and the LPV should be at least 2 m. In cramped conditions, this distance is allowed to decrease to 1.5 m. In all other cases, the distance between the lines should Being no less height of the highest support for VL, LS and LPV.

Under rapprochement of WL with underground or suspension cables, LS and LPV distances between them should be taken in accordance with 2.4.77 PP.1 and 5.

2.4.82. The rapprochement of VL with the antenna structures of transmitting radio centers, receiving radio centers, dedicated receiving points of wired broadcasting and local radio cores is not normalized.

2.4.83. The wires from the support of VL before entering the building should not be intersecting with wires of branches from the drugs and HDPs, and they should be placed at one level or above the LAN and LPV. The horizontal distance between the wires of the VL and the LS and LPV wires, television cables and the descents from the radiance on the inputs should be at least 0.5 m for SIP and 1.5 m for uninsulated VL wires.

2.4.84. The joint suspension of the suspended cable of the rural telephone and was allowed when performing the following requirements:

- zero veins SIP should be isolated;

- the distance from the SIP to the suspended cable of the STS in the span and on the support of VLI should be at least 0.5 m;

- each blast blast must have a grounding device, while the grounding resistance must be no more than 10 ohms;

- on each support, the PEN conductor must be re-ground;

- the carrying rope of the telephone cable together with the metal mesh outer cover of the cable must be attached to the earthinger of each support by a separate independent conductor (descent).

2.4.85. A joint suspension on common supports of uninsulated wires of VL, LS and LPV is not allowed.

On common supports, a joint suspension of uninsulated wires of VL and insulated wires of HPF is allowed. The following conditions must be respected:

- the rated voltage of the WL should be no more than 380 V;

- the distance from the lower wires of the LPV to the Earth, between the chains of LPV and their wires must comply with the requirements existing rules Ministry of Communications of Russia;

- uninsulated wires of the WL should be located above the wires of the LDF; At the same time, the distance vertically from the lower wire of the VL to the upper wire of the LDF should be on the support of at least 1.5 m, and in the span - at least 1.25 m; When the LPV wires are arranged on the brackets, this distance is taken from the lower wire of the VL located on the same side as the wires of the LPV.

2.4.86. On common supports, a joint suspension of SIP was allowed with non-insulated or insulated wires of LS and LPV. The following conditions must be respected:

- rated voltage of VLI should be no more than 380 V;

- the rated voltage of the PLV should be no more than 360 V;

- nominal voltage of drugs, the calculated mechanical voltage in the WHP wires, the distance from the lower wires of the LAN and HPF to the Earth, between the chains and their wires must comply with the requirements of the current Rules of the Ministry of Communications of Russia;

- the wires were carried out to 1 kV should be located above the LS and LPV wires; At the same time, the distance vertically from the SIP to the top wire of the LS and the LPV, regardless of their mutual location, should be at least 0.5 m on the support and in the span. Wires of VLI and LS and HPP are recommended to have different sides Supports.

2.4.87. A joint suspension on common supports of uninsulated wires of VL and LS cables is not allowed. The joint suspension on the common supports of the wires of the voltage of no more than 380 V and LPV cables are allowed under the observance of the conditions specified in 2.4.85.

Optical fibers Window must meet 2.5.192 and 2.5.193 requirements.

2.4.88. The joint suspension on the common supports of the wires of the voltage of no more than 380 V and telemechanic wires is allowed when complying with the requirements given in 2.4.85 and 2.4.86, as well as if the telemechanic chains are not used as wired telephone channels.

2.4.89. Suspension of fiber optic communication cables (OK) is allowed on the supports of VL (VLI) (OK):

- non-metallic self-supporting (OXN);

- non-metallic, piled on the phase wire or zhgut SIP (window).

Mechanical calculations of OPOR (VLI) with OCSN and the window should be made for the source conditions specified in 2.4.11 and 2.4.12.

Supports Vl, on which ok hang, and their fixing in the soil should be calculated taking into account additional loads arising from this.

The distance from the Oxn to the surface of the Earth in the populated and unanimous locations should be at least 5 m.

The distances between the wires of VL to 1 kV and the OCCN on the support and in the span should be at least 0.4 m.

Crossing and rapprochement of WL with engineering facilities

2.4.90. When crossing and parallel following the WL with iron and road road The requirements set forth in Ch. 2.5.

The intersections can also be performed using a cable insert in VL.

2.4.91. When rapprocked lines with roads, the distance from the wires of the VL to road signs and their carrier cables should be at least 1 m. Carriers must be grounded with a grounding device resistance of no more than 10 ohms.

2.4.92. When crossing and converging, the following requirements must be made with contact wires and carrier cables of tram and trolleybus lines:

- VL should, as a rule, are located outside the zone occupied by the facilities of contact networks, including supports.

In this zone, the BL support should be anchor type, and the uninsulated wires have a double fastening; - wires VL must be located above the carrier cables of contact wires. The WL wires must be multi-propelled with a cross section of at least: aluminum - 35 mm2, steel aluminum - 25 mm2, carrying SIP - 35 mm2, cross-section of SIP veins with all carriers of harness - at least 25 mm2. The connection of WL wires in the intersection flights is not allowed;

- the distance from the wires of VL with the highest arrows of the provice should be at least 8 m to the tram line rail and 10.5 m before the roadway of the street in the zone of the trolleybus line.

- At the same time, in all cases, the distance from the wires of the VL to the carrier cable or contact wire should be at least 1.5 m;

- the intersection of VL with contact wires in the location of the crossbar is prohibited;

- a joint suspension on the supports of the trolleybus lines of contact wires and wires of the voltage voltage no more than 380 V is allowed under the following conditions: the supports of trolleybus lines must have a mechanical strength sufficient for the wires of the WL wires, the distance between the wires of the VL and the bracket or the mounting cable of the contact wires must to be at least 1.5 m.

2.4.93. When crossing and converging, the following requirements must be performed with rope roads and overhead metal pipelines:

- Wl must pass under the cable car; The passage of WL over the cable car is not allowed;

- cable roads should have a bottom of the bedtime or grid for the fencing of the WL wires;

- under the passage of the VL under the cable car or under the pipeline, the WL wires must be from them at a distance: at least 1 m - with the smallest arrows of wires to the walkways or enclosing cable car meshes or to the pipeline; at least 1 m - with the highest arrows of the provice and the largest deviation of the wires to the elements of the cableway or to the pipeline;

- when crossing the VL with a pipeline, the distance from the wires of the VL with their largest arrows of the provice to the elements of the pipeline must be at least 1 m. Supports BL, which limit the span of intersection with the pipeline must be anchor type. The pipeline in the intersection span must be grounded, the earthing resistance is not more than 10 ohms;

- with a parallel tracking of the VL with a cable car or pipeline, the distance horizontally from the wires of the VL to the cable car or the pipeline must be at least the height of the support, and on the constrained parts of the track with the highest deviation of the wires - at least 1 m.

2.4.94. Under rapprochement of WL with fire and explosive installations and airfields should be guided by the requirements given in 2.5.278, 2.5.291 and 2.5.292.

2.4.95. The passage of VL to 1 kV with isolated and non-insulated wires is not allowed through the territories of sports facilities, schools (general education and boarding schools), technical schools, children's preschool institutions (children's homes, kindergartens, children's combines), orphanages, children's playgrounds, and also In the territories of children's health camps.

According to the above territories (except for sports and playgrounds), it is allowed to pass, provided that the zero veins of the SIP must be isolated, and its complete conductivity should be no less than the conductivity of the siep phase

Grounding of electric power lines

To improve the reliability of the power lines, to protect electrical equipment from atmospheric and internal overvoltages, as well as to ensure the safety of the maintenance personnel, the power lines support must be grounded.

The magnitude of the impedance of grounding devices is normalized by the "rules of electrical installation devices".

On the power lines of power lines on a voltage of 0.4 kV with reinforced concrete supports in networks with an isolated neutral, both fittings and hooks and pins of phase wires should be grounded. The resistance of the grounding device should not exceed 50 ohms.

In networks with grounded neutral hooks and pins of phase wires installed on reinforced concrete supports, and the reinforcement of these supports must be attached to the zero grounded wire. Grounding and zero conductors in all cases must have a diameter of at least 6 mm.

All metal and reinforced concrete supports, as well as wooden supports, on which are installed in lightning protection devices, power or measuring transformers, disconnectors, fuses, or other devices are mounted on the power supply lines of 6-10 kV.

Resistance to grounding devices supports are taken for locality not higher than those shown in Table. 18, and in non-heated area in soils with a specific soil resistance to 100 ohms · m - no more than 30 ohms, and in the soils with resistance above 100 ohms · m - not more than 0.3. When using 6-10 kV insulators on the power supply voltage of 6-10 kV, SEC 10-g, SEC 20-V and SC 10-g, the resistance of the grounding of the supports in non-heated area is not normalized.

Table 18.

Resistance to grounding devices LEP supports

6-10 kV voltage

|

# G0.Specific resistivity, Ohm · m |

Resistance grounding device, Ohm |

|

Up to 100. |

To 10 |

|

100-500 |

" 15 |

|

500-1000 |

" 20 |

|

1000-5000 |

" 30 |

|

More than 5000. |

6 · 10. |

When performing grounding devices, i.e. With the electrical connection of grounded parts from the ground, tend to ensure that the resistance of the grounding device is minimal and, of course, not higher than the values \u200b\u200brequired # M112293 0 1200003114 3645986701 3867774713 77 4092901925 584910322 1540216064 77 77Pue # s. A large proportion of grounding resistance falls on the transition from the ground to the soil. Therefore, in general, the resistance of the grounding device depends on the quality and state of the soil itself, the depth of the entrances, their type, quantity and mutual location.

Grounding devices consist of earthing and grounding descents connecting earthing meters with grounding elements. As grounding descents of reinforced concrete supports of the LAM to a voltage of 6-10 kV, all elements of the stress fittings of the racks are connected to the earthing. If the supports are installed on the delay, then the delicate of reinforced concrete supports must also be used as grounding conductors in addition to the reinforcement. Specially paved on the support grounding descents must have a cross section of at least 35 mm or a diameter of at least 10 mm.

On power lines with wooden supports, it is recommended to use bolt connection grounding descents; On metal and reinforced concrete supports, the connection of grounding descents can be performed both welded and bolted.

Grounders are metal conductors laid in the ground. Grounders can be made in the form of vertically clogged rods, pipes or corners, interconnected by horizontal conductors from round or strip steel into the ground ground. The length of the vertical entrancers is usually 2.5-3 m. Horizontal grounding conductors and top of the vertical entrancers must be at a depth of at least 0.5 m, and on arable land - at a depth of 1 m. Grounders are combined with a welding.

When installing supports on piles, a metal pile can be used as a ground, to which the grounding release of reinforced concrete supports can be connected.

To reduce the land area, occupied by the earthing, use deep grounding machines in the form of round steel rods, immersed vertically into the ground by 10-20 m and more. On the contrary, in dense or stony soils, where it is impossible to buery vertical grounding, surface horizontal earthingers are used, which are several beams from strip or round steel, laid in the ground at a small depth and connected to a grounding descent.

All types of grounds significantly reduce the magnitude of atmospheric and internal overvoltages on the LAP. However, all the same these protective grounds in some cases are not enough to protect the isolation of LPP and electrical appliances from overvoltages. Therefore, additional devices are installed on the lines to which the protective spark gaps include, tubular and valve arresters.

The protective property of the spark gap is based on the creation of a "weak" place in the line. Isolation of the spark gap, i.e. The distance over the air between its electrodes is that it is sufficiently sufficient to withstand the operating voltage of the LAP and prevent the operation of the operating current to the ground, and at the same time it is weaker than the line isolation. When the lightning strikes, the "weak" place (spark interval) breaks into the wires of the LEP (spark interval) and passes into the ground without breaking the insulation of the line. Protective spark gaps 1 (Fig. 22, A, b) consist of two metal electrodes 2 installed at a certain distance from each other. One electrode is connected to the 6 power supply wire and is isolated from the support with insulator 5, and the other is grounded (4). The second electrode is connected an additional protective gap 3. On the lines for a voltage of 6-10 kV with pin insulators, the shape of the electrodes is performed in the form of horns, which ensures the stretching of the arc during the discharge. In addition, on this LP, the protective gaps are arranged directly on the grounding descent, laid by support (Fig. 23).

Fig. 22. Protective spark gap for power supply voltage up to 10 sq. M:

a - electrical circuit; B - Installation Scheme

Fig. 23. Device protective interval on the support

Tubular and valve arresters set, as a rule, at approaches to substations, transitions of the power supply lines through lines and power supply lines, electrified railways, as well as to protect cable inserts on the LAP. The arresters are apparatuses that have spark gaps and arc devices. Set them in the same way as protective intervals - parallel protected isolation.

RV valve arresters are designed to protect against atmospheric overvoltages of electrical equipment insulation. They are produced on a voltage of 3.6 and 10 kV and can be installed both in the open air - on LPP and in closed rooms. The main electrical characteristic of the arresters is given in Table. 19. Constructive design, overall, installation and connections of arresters are shown in Fig. 24.

Table 19.

Characteristics of valve arresters

|

# G0.Indicators |

RVO-0,5 |

RVO-3. |

RVO-6. |

RVO-10. |

|

Rated voltage, kV |

||||

|

Punch voltage at a frequency of 50 Hz in a dry state and in the rain, sq .: |

||||

|

no less |

||||

|

no more |

30,5 |

|||

|

Length path of leakage of external insulation (at least), see |

||||

|

Mass, kg. |

Rice 24 Validated RVO type adjustment:

1 - bolt M8X20; 2 - Tire; 3 - spark gap; 4 - two M10X25 bolts for fastening

arrester; 5 - resistor; 6 - clamp; 7 - M8X20 bolt to attach ground wire

The arrester consists of a multiple spark gap 3 and a resistor 5, which are concluded in a hermetically closed porcelain tire 2. Porcelain tire is designed to protect the internal elements of the arrester from exposure external environment and ensuring stability characteristics. The resistor consists of woven discs made of silicon carbide, has a non-linear voltamper characteristic, that is, its resistance decreases under the influence of high voltage, and vice versa.

The multiple spark gap consists of several single intervals, which is formed by two shaped brass electrodes, separated by insulating gasket.

When the surveillance equipment is dangerous for insulation, the spark interval breaks, and the resistor is high voltage. The resistance of the resistor sharply decreases and the lightning current passes through it, without creating an increase in voltage dangerous for insulation. The following in the breakdown of the spark gap accompanying the industrial frequency current is interrupted when the voltage is first passed through the zero value.

The letter marking of the arresters means the type and design of the arrester, and the numbers are rated voltage.

The tubular arresters (Fig. 25) are an insulating tube 1 with an internal spark gap, which is formed by two metal electrodes 2 and 3. The pipe is made of gas-generating material and is closed one of its sides tightly. When the lightning strikes, the spark gap makes itself and there arises between the electrodes. Under the action of a large arc temperature of an insulating tube, gases are rapidly highlighted and the pressure rises in it. Under the influence of this pressure, the gases go through the open end of the tube, which create a longitudinal blowing, which stretches and cools the arc. When the accompanying current passes through the zero position, the stretched and cooled arc goes out and the current is broken. To protect the surface of the insulating tube from the destruction of leakage currents, the external spark gap is arranged in the discharge.

Figure 25. Tubular arrester

Tubular arresters are produced by RTF fibrobolet type or vinyl type type RTVs. The characteristic of tubular arresters is given in Table. twenty.

Table 20.

Characteristic of tubular arresters

|

# G0.Type of arrester |

Rated voltage, kV |

Length of the external spark gap, mm |

It is impossible to imagine modern civilization without electricity. A huge part of hydrocarbons is used to generate electricity.

However, electricity cannot be transported like oil or coal. For its transportation, power lines (LPP) are used, providing high-power electricity traffic at the required distances. Bringing the parameters transmitted over them to the standards inherent in its consumers implies the use of transformer substations that provide the required voltage in the network. Thus, it is powered by all electrical installations, ranging from the light bulb in the room and ending with industrial equipment.

To prevent injuries of service personnel and even more death, taking into account the high voltage, grounding devices of air lines and substations are applied. This publication sets itself the task of dealing with the reasons for their need, as well as the designs of these devices.

For what you need to ground LPP and substation

By big account, the air line (VL) is a series of columns (supports) exposed to natural factors, such as temperature differences, precipitation, direct exposure to solar ultraviolet and others. Due to their influence, the properties of dielectrics can change and directly touch the cable to the cable with support. Among other things, the short-term voltage jumps in line with a significant exceeding nominal (permissible) value, which can lead to a closure between cable and structural elements of the support.

When touched to such a pillar, a person can get injured and even die. Therefore, the installation of grounding on the airline does not apply to the category of recommendations or the prosperity of controls. This is dictated by the rules of the electrical installation devices (PUE) as the main regulatory document governing the requirements for the energy systems, including VL. According to this document, grounding devices of the air lines are required.

A description of the lightning protection of structures is a mansion. Supports can be made of wood, reinforced concrete or steel. For standing in the pure field of supports, sometimes having a very significant height, the lightning hit is not a rare phenomenon. If for steel or reinforced concrete, having good electrical conductivity and incapable of burning, it will not bring serious damage, then for wooden design It is fraught with destruction or ignition. Given the colossal voltage of the discharge of lightning, it is possible to destroy dielectrics enclosing construction elements From the conductive parts of VL, which, in turn, leads to an accident.

All this applies equally to substations. Until now, some of them are a large transformer in the middle of the field that feeds the farm, for example. Transformer installations are subject to all negative impactsas ll. Even if it is not so, they must comply with the requirements of PUE.

All this applies equally to substations. Until now, some of them are a large transformer in the middle of the field that feeds the farm, for example. Transformer installations are subject to all negative impactsas ll. Even if it is not so, they must comply with the requirements of PUE.