Placement of heat detectors. Arrangement of fire detectors - theory and practice

Today automatic installations fire alarm are a mandatory engineering system of any building. Not only the safety of property depends on their faultless work, but also, most importantly, the health and life of people. Timely and reliable fire detection gives people the opportunity to evacuate to a safe area, and fire brigades - to quickly start extinguishing the fire, preventing its spread.

Types of detectors

Fire detectors in the composition are designed to detect fire. Depending on the principle of action, they are divided into types. This:

- smoke detector - reacts to the appearance of smoke in the room;

- thermal sensor - triggered when the set temperature is exceeded;

- flame detector - captures the visible or infrared radiation of the flame;

- gas analyzer - registers combustion products such as carbon monoxide.

The correct choice of the detector allows you to timely detect the source of the fire.

Fire load and detector type

Premises for various purposes have their own specifics in the development of a fire and the manifestation of its factors. Of decisive importance is the fire load - all objects and materials in the room. For example, the fire of paints or fuel is accompanied by a bright flame, which can be detected by a flame detector. But the same will not be effective in rooms with the storage of materials prone to smoldering; a smoke detector will react to smoke from smoldering materials.

Smoke detectors

The most common and effective tool fire detection is an automatic smoke detector. After all, the release of smoke is characteristic of the combustion process of many substances, such as paper, wood, textiles, cable products, electronic equipment, etc. These sensors are designed to detect fires accompanied by the release of smoke in the early stages of a fire. Detectors of this type are effective when installed in residential buildings, public buildings, production and warehouses with the circulation of materials prone to the release of smoke during combustion.

How smoke detectors work

The operation of smoke sensors is based on the scattering of light on microparticles of smoke. The emitter of a sensor, usually an LED, operating in the light or infrared range. It irradiates the air in the smoke chamber, when smoked, part of the light flux is reflected from the smoke particles and scattered. This scattered radiation is recorded on a photodetector. The microprocessor, based on the analysis of the photodetector signal, puts the detector into an alarm state. Depending on the concentration of the emitter and receiver, the detectors can be point and linear. The names of devices of this type begin with "IP 212", followed by the digital designation of the model. In the designation, the letters stand for “fire detector”, the first number 2 is “smoke”, the number 12 is “optical”. Thus, the entire marking "IP 212" means: "Optical smoke detector".

Point smoke detectors

In devices of this type, the emitter and receiver are installed in the same housing on opposite sides of the smoke chamber. The perforation of the sensor body ensures unhindered penetration of smoke into the smoke chamber. Thus, the optical-electronic smoke detector controls the degree of smoke in the room only at one point. This type of sensor is compact, easy to install and efficient. Their main drawback is the limited controlled area, not exceeding 80 sq.m. In most cases, point detectors are installed on the ceiling, in increments depending on the height of the room. But it is possible to install them on the walls, under the ceiling.

Linear smoke detectors

In these sensors, the emitter and receiver are made in the form of separate devices installed on different sides premises. Thus, the emitter beam passes through the entire room and controls its smoke. As a rule, the range of this type of detectors does not exceed 150 m. There are variants of devices in which the emitter and receiver are installed in the same housing, and their optical axes are directed in the same direction. For the operation of such a detector, an additional reflector (reflector) is used, which is installed on the opposite wall and returns the transmitter beam to the receiver. The linear smoke detector is mainly used to protect long and high spaces, such as halls, indoor arenas, galleries. They are installed on the walls under the ceiling, the emitter on one wall, the receiver on the opposite. IN high rooms, such as atriums, sensors are installed in several tiers.

Sensor sensitivity

The most important parameter of smoke detectors is their sensitivity. It characterizes the ability of the sensor to capture the minimum concentration of smoke particles in the analyzed air. This value is measured in dB and is in the range of 0.05-0.2 dB. The difference between high-quality sensors is the ability to maintain their sensitivity when changing orientation, supply voltage, illumination, temperature, and others. external factors. To check the photodetector, special laser pointers or aerosols are used, which allow remote control of the detector's performance.

Analog and address systems

The detectors are connected by a loop to the control panel, which analyzes their condition and, if triggered, issues an alarm signal. Depending on the method of transmitting their state, the detectors are either analog or addressable.

The analog fire smoke detector is connected in parallel to the loop and, when triggered, sharply reduces its resistance, in other words, short-circuits the loop. This change in the resistance of the loop is fixed by the control panel. Typically, the connection analog detectors is carried out by a two-wire loop, through which power is also supplied. But there are options for connecting in a four-wire scheme. The disadvantage of such a system is the inability to continuously monitor the performance of the detector, in addition, sometimes a loop is triggered without indicating the triggered sensor.

The optoelectronic addressable smoke detector is equipped with a microprocessor that monitors the state of the sensor and, if necessary, corrects its settings. Such sensors are connected to a digital loop, in which each detector is assigned its own number. In such a system, the control panel receives not only data on the detector's operation and its number, but also service information on performance, dust content, etc.

The housings of most modern detectors have built-in LEDs that determine their status by blinking.

Autonomous fire detectors

Often there is no need to install automatic, it is enough just to notify people in the same room about the occurrence of a fire. For these purposes, an autonomous smoke detector is intended. These devices combine a smoke sensor and (siren). When the room is filled with smoke, the detector detects the presence of smoke and sound signal alerts people to the presence of a dangerous concentration of smoke. Such sensors are self-powered - built-in batteries, the capacity of which is sufficient to operate for three years.

These detectors are ideal for installation in an apartment or small house. Some models allow you to combine sensors into a small network, for example, within an apartment. On the body of such a sensor there is an LED indicator, the color and frequency of flashing of which indicate its condition.

Good day, a regular Reader of my Blog, as well as those who accidentally looked at my page. Today we will discuss the need and how to install fire detector on the wall.

It would seem, you say, why install fire detector on the wall, if its “native” place is on the floor or on the false ceiling? Why be so perverted? ……. Do not rush to jump to conclusions! We will, as always, look into the issue. Of course, if possible, it is necessary to install fire detector on the floor, as actually prescribed by existing regulatory documents, and subject to all standard distances. Well, now let's analyze the possibilities together. To do this, recall the NPB -88 -2001 (standards fire safety), which actually do not work in many ways now and have been successfully replaced by the Technical Regulations with a numerous set of rules attached to this Regulation. So, according to NPB-88-2001, when installing a fire detector on the ceiling, it was necessary, among other things, to observe distances of 0.5 meters from spotlights, which are a source of thermal radiation and from ventilation openings (retreat 1 meter). I hope everyone remembers this. Now let's see what we get with the standard distances, according to SP5.13130.2009, and now in latest edition with all changes. However, before diving into the points of our already beloved SP5, let me make a small digression. It must be said that not only fire safety requirements are constantly changing and getting tougher. Also, over time, sanitary standards, as well as Rostekhnadzor standards, as well as various departmental requirements and various other documents are changing towards tightening. For example, in medical institutions the degree of required illumination in hospital wards and doctors' offices has increased significantly. Also, the approach to general ventilation has become much stricter and, accordingly, the required degree of necessary air exchange in public buildings has increased significantly. Considering what has already been said above, it is not surprising that there is a significant increase in lamps and air intake openings for general ventilation in offices, corridors, etc. It goes without saying that the specified tightening of standards in each of the industrial areas does not take into account the circumstances affecting others. engineering systems. Now that we have clarified the fact that the entire ceiling is practically plastered with lamps and ventilation holes, we will finally turn to SP5 and read what it says on the issue of how to install a fire detector on the ceiling in compliance with all standard distances.

SP5, paragraph 13.3.6 Placement of point heat and smoke fire detectors should be carried out taking into account the air flows in the protected room caused by the supply or exhaust ventilation, while the distance from the detector to the ventilation hole must be at least 1 m. fire detector the distance from the air intake pipe with holes to the ventilation hole is regulated by the value of the allowable air flow for of this type detector.

The horizontal and vertical distance from the detectors to nearby objects and devices in any place must be at least 0.5 m. fire detectors should be carried out in such a way that nearby objects (pipes, ducts, openings, etc.) do not interfere with the effects of fire factors on the detectors, and sources of light radiation, electromagnetic interference do not affect the performance fire detector.

Now let's analyze. With ventilation, everything remained as before (we retreat 1 meter), apart from the fact that the ventilation holes themselves have become much larger. But at what distance should be placed fire detector to the lamp - this is more difficult. Concepts added “sources of light radiation, electromagnetic interference”. Try to prove to the inspector that an ordinary fluorescent lamp, which was not previously considered a source of thermal radiation and at this distance it was not considered necessary to retreat 0.5 meters from it to the fire detector, is not a source of light radiation or electromagnetic interference! Will not work. So, you will have to install a fire detector, taking into account the standard distance of 0.5 meters to each lamp.

So, we come to the room, look at the ceiling and understand that there is nowhere to install a fire detector, subject to all the required standard distances, since the entire ceiling is already occupied by ventilation and lighting systems. And what to do?

Answer - if you do not want to break the rules and then babble some childish excuses about the impossibility and so on ... ... ... in front of the inspector, feel free to put a fire detector on the wall! Let us turn again to SP5 and read what distances from the fire detector we must observe in this case.

13.3.4 Spot fire detectors should be installed under the ceiling.

If unable to install fire detectors directly on the ceiling, they can be installed on cables, as well as walls, columns and other load-bearing building structures.

When installing dot fire detectors on the walls they should be placed at a distance of at least 0.5 m from the corner and at a distance from the ceiling in accordance with Appendix P.

Well, fine - we retreat from the corner of 0.5 meters - this is understandable. Now we look at what is written in Appendix P

Appendix P

Distances from the upper overlap point to the measuring element of the fire detector.

Room height, m |

Distance from the upper point of overlap to the measuring zone of fire detectors located under the roof ridge, mm |

|||||

The angle of inclination of the overlap, arc. deg. |

||||||

Up to 15 |

Over 15 to 30 |

Over 30 |

||||

min |

max |

min |

max |

min |

max |

|

Until 6 |

30 |

200 |

200 |

300 |

300 |

500 |

Over 6 to 8 |

70 |

250 |

250 |

400 |

400 |

600 |

Over 8 to 10 |

100 |

300 |

300 |

500 |

500 |

700 |

Over 10 to 12 |

150 |

350 |

350 |

600 |

600 |

800 |

Now everything is transparent and clear - in an ordinary room up to 6 meters high, with a simple horizontal overlap without any slopes, that is, if you follow the table with an overlap angle of up to 15 degrees, you should maintain distances from the fire detector to the level of overlap from 3 to 20 centimeters. If the heights are different, we read the plate below and act according to the instructions written in it.

Well, that's actually all that I wanted to state in my article."Fire detector on the wall." I recommend that designers in their projects write a phrase about the possibility of installing a fire detector on a wall or column, if it is impossible to install it on the floor in compliance with all standard distances. Next, bring paragraph SP5 13.3.4, the plate from Appendix “P” and that’s it. Not much work, is it? But the installers will thank you, because you thought for them and wrote already turnkey solution, which the installers simply follow and that's it. Therefore, I wish you success in achieving the perfection of regulatory knowledge, read my Blog further, comment, ask questions and rate.

– fire protection of cable products

– job description specialist in P.B.

– fines for violations in the field of fire safety

– calculation of sound pressure at the object

Technical report - what is it for?

Fire protection behind false ceiling

Addressable fire detector - how much per room?

If you copy this article fire detector on the wall for placement on the pages of another site, please copy along with links to my page, since the article was written by me personally, it is unique and is my intellectual property. Good luck.

Our group Vkontakte -

We continue the series of articles about installing the system security and fire alarm in stock building materials. We have already talked about the installation of motion sensors (volumizers), today we will talk about the installation of smoke and heat detectors.

Installation of fire smoke detectors

The calculation of the number of smoke detectors must be carried out based on the following table:

We install sensors at a height of about 3 meters, the area served by one sensor is about 25 square meters. m. It would be possible to install only one sensor, but then the distance to the walls would be too large. We select the necessary places in accordance with the table. In our case, the distance between devices is much less than 9 meters.

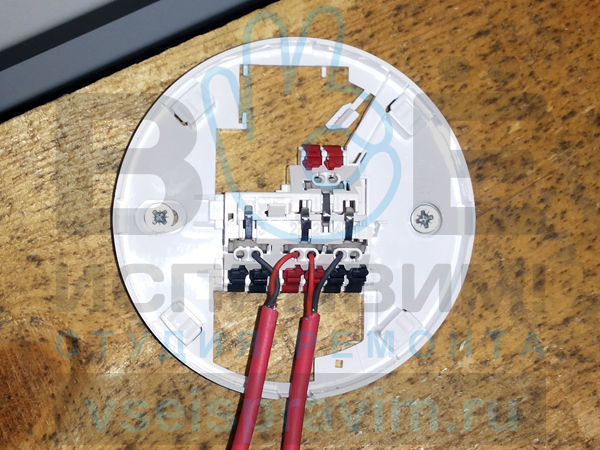

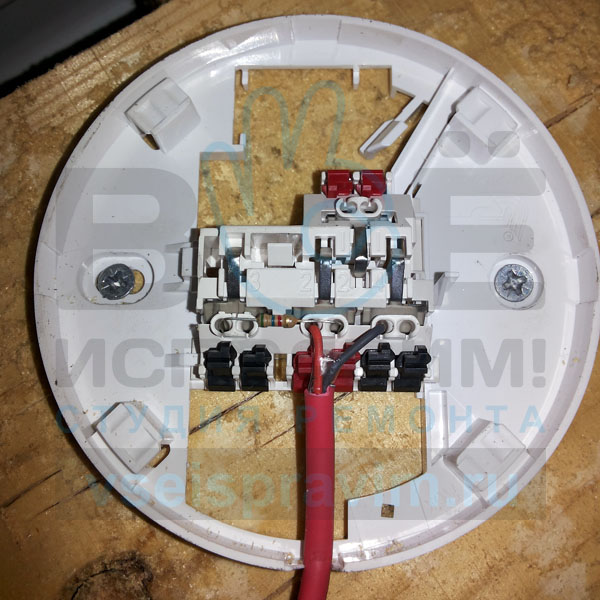

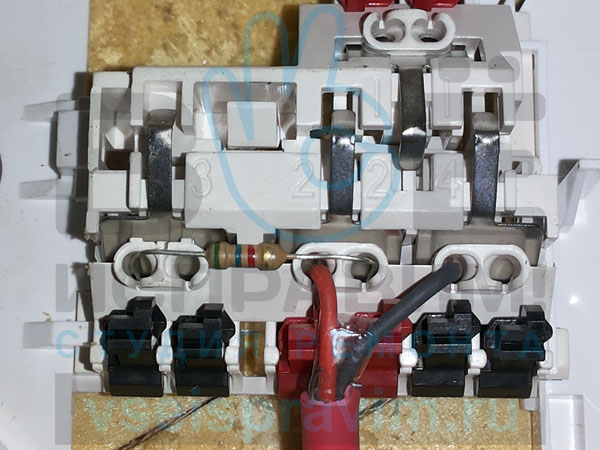

We fasten the device on self-tapping screws to wooden beam. Both smoke detectors are combined into one line and connected to one loop of the fire alarm controller, so we have two wires: one brings the signal and power, and the other leads them to the second sensor.

When installing, it is important not to get tangled in the wires! They have different colour(black and red). We connect them to the contacts of the corresponding color.

Now we connect the second sensor. Please note, here we install not only the wires, but also the shunt resistor. We will not go into complex physical terms, but simply consider the principle of operation of this resistor in the sensor.

The shunt resistor is connected to the same pins as the wires. It processes the current signal in the cable within a certain range. And when smoke appears, it is he who sends a signal to the controller - sends back less current.

This is what the assembled sensor looks like.

Installation of a fire heat detector

Heat detectors react to sudden changes in ambient temperature. Usually they are set to a temperature of about 75 degrees Celsius. In our case, disposable sensors are used (after they have been triggered, they must be replaced with new ones). The calculation is carried out according to the following table:

We also hook two heat detectors to one controller loop, so we install them in a chain. Power and signal are supplied to the first one, and wiring to the next sensor is diverted from it.

To the latter, we simply hook the wires, and that's it. No additional resistors are required.

Testing a smoke detector for a fire and security alarm

We placed smoke and heat sensors at some distance from each other. They react to different signs of a fire (smoke and temperature increase), so it is not advisable to carry them to different angles.

You can test it with a regular cigarette. To do this, we bring a lit cigarette to the sensor and direct the smoke directly into it. If the system is properly installed and configured, an alarm will be generated.

It is not only not recommended to install alarm systems on your own, but it is also strictly PROHIBITED, since any mistake can cost several human lives. Therefore, if you need, contact the studio "We'll fix everything!"

Each of us is concerned about the safety of both our own and those around us. Also about the protection and safety of your home, office, store or production building. That's why everything in great demand use fire alarms. Modern market offers a fairly wide variety of such systems. We will consider the norms and installation requirements in this article “Rules and norms for the installation of fire detectors”.

For example, they may be equipped various types sensors (detectors) or different type management. But in general, the principle of operation of such systems is almost the same. It lies in the fact that the detector reacts to the occurrence of smoke and fire. As a result, it sends a certain signal to the control panel, which instantly analyzes the information received and starts the fire extinguishing, smoke protection, warning, and so on algorithm. But in order for the system to be as efficient as possible, it is necessary to know the basic rules for installing fire detectors. After all, no matter how perfect and reliable system, if it is mounted incorrectly, and most importantly, the sensors are not correctly positioned. Based on this, the system will not be able to clearly and quickly respond to the appearance of fires.

Installation standards for fire detectors of various types

Fundamentally importance has the number of installed detectors. According to the regulations, there should be at least two sensors in each room, and ideally there should be a distance of no more than nine meters between them. But the installation of one signaling device is also allowed. If the area of the room is not large, and the system itself constantly monitors the operation of the fire alarm and informs the control panel about the slightest malfunction.

Depending on the type of sensors, there are a number of nuances in the rules for their placement. The installation standards for smoke fire detectors prescribe the need to take into account air flows that are caused by exhaust or supply systems ventilation. The distance from the ventilation openings to the sensor must be at least one meter. If the ceiling of the room has protruding structures - beams, ribs of plates, and so on, then signaling devices must be installed in each compartment with a width of 75 centimeters or more.

The basic norms for the installation of manual fire call points are that they must be located at a height of one and a half meters from the floor level and at a distance of no more than 50 meters from each other, and with outer side buildings, this distance should not exceed 150 meters. It is very important that the hand sensor is not placed near magnetic or electromagnetic devices, the action of which can trigger the alarm. The norms for the installation of autonomous fire detectors are that their performance must be maintained under artificial or natural lighting up to 12 thousand lux. Air humidity is about 95% and temperatures -10 - +55 degrees Celsius. Also, it must necessarily have a device that constantly checks its performance, and the distance from the walls to its optical axes must be more than half a meter.

Installation standards for thermal fire detectors - the distance between them should be from 4 to 5 meters, and from the sensors to the walls - at least 2 and not more than 2.5 meters. In addition, they should be located away from the lamps (at least 0.5 centimeters). Particular attention should be paid to compliance with the standards of overhead fire detectors, because it is in this space that various cables and wires, the short circuit in which often leads to fires. The number of sensors depends on the area of the room. The same applies to the installation of fire detectors under a suspended ceiling. But in this case, if the architectural and artistic features of the ceiling do not allow placing sensors, then the standards allow their installation on columns, walls or on special strings (cables). In this case, the deflection of the string should be no more than three millimeters.

If we talk about the installation standards for autonomous fire detectors in apartments, then it is important to consider that there must be at least one sensor for every 30 meters. It is also imperative to mount signaling devices in each ceiling compartment if there are ribs of plates, beams and other structures protruding from the ceiling surface by more than 0.4 meters. In addition, sensors are recommended to be installed above front door. In other places, if the air flow rate does not exceed one meter per second, do not mount them in direct sunlight and near ventilation openings.

Special requirements and standards for the installation of fire detectors at industrial and agricultural facilities

Naturally, it is necessary to take care of the fire safety of any object, both residential and industrial. But special attention should be paid to this issue by the heads of enterprises that produce or use flammable or flammable substances. And this applies not only to industry, but also to agriculture, for example, to elevators. This seemingly safe complex, in fact, is very fire hazardous. Grain dust, accumulating on elevators, when high temperatures air can lead to an explosion and, as a result, to very serious fires, carrying severe consequences. According to the statistics of previous years, only in the period from 1970 to 1990, more than two hundred explosions of grain dust and fires of extremely destructive power occurred on the territory of Russia.

Modern farmers began to pay more attention and comply with the rules for installing fire detectors in elevators. One of them is the laying of special thermal cables that can detect overheating sources anywhere in the facility. They have steel conductors and heat-sensitive polymers, allowing timely identification of the source of ignition and taking appropriate measures to extinguish it.

Question:

Installed a fire alarm system at the facility. Smoke detectors were installed, incl. on an Armstrong suspended ceiling, in the center of the tiles. The fire inspector claims that this is unacceptable, contrary to SP 5.13130.2009.

Does the inspector really have grounds for such a remark, and are we obliged to fulfill his requirement to move the detectors to the intersection of the tiles?

Answer:

Requirements for automatic fire alarm installations (AUPS) are currently established:

- Federal Law No. 123-FZ of July 22, 2008 "Technical Regulations on Fire Safety Requirements" (as amended on July 13, 2015);

- GOST R 53325-2012 "Fire fighting equipment. Technical means fire automatics. Are common technical requirements and test methods" (rev. 06.11.2014);

- SP 5.13130.2009 "Systems fire protection. Fire alarm and fire extinguishing installations are automatic. Design norms and rules" (as amended on 06/01/2011).

In accordance with clause 13.3.4 of SP 5.13130.2009, point fire detectors should be installed under the ceiling.

If it is not possible to install detectors directly on the ceiling, they can be installed on cables, as well as walls, columns and other supporting building structures.

In accordance with paragraph 13.3.16 of SP 5.13130.2009, floor-mounted detectors can be used to protect the space below the perforated false ceiling, if the following conditions are simultaneously met:

- perforation has a periodic structure and its area exceeds 40% of the surface;

- minimum size each perforation in any section is at least 10 mm;

- the thickness of the false ceiling is no more than three times the minimum size of the perforation cell.

If at least one of these requirements is not met, the detectors must be installed on the false ceiling in the main room, and if it is necessary to protect the space behind the false ceiling, additional detectors must be installed on the main ceiling.

Accordingly, in clause 13.3.4 of SP 5.13130.2009, under "other carriers building structures"means precisely the building structures that relate to load-bearing elements buildings.

In accordance with clause 5.4.2 of SP 2.13130.2012 "Fire protection systems. Ensuring the fire resistance of protected objects" (as amended on 10/23/2013), load-bearing elements of buildings include bearing walls, columns, ties, stiffening diaphragms, trusses, elements of floors and bare roofs (beams, crossbars, slabs, floorings), if they participate in ensuring the overall stability and geometric stability of the building in case of fire.

Structures (including frames) false ceiling"Armstrong" type, as well as filling elements (including tiles) of the "Armstrong" false ceiling, do not belong to the load-bearing building structures of the building.

In accordance with paragraph 13.3.16 of SP 5.13130.2009, detectors can be installed on a false ceiling, but the procedure for their placement on suspended ceiling structures is not regulated.

In accordance with clause 13.3.18 of SP 5.13130.2009, the placement and use of fire detectors, the application procedure for which is not defined in this set of rules, must be carried out in accordance with the recommendations agreed upon in the prescribed manner.

In accordance with clause 13.1.11 of SP 5.13130.2009, fire detectors should be used in accordance with the requirements of this set of rules, other normative documents on fire safety, as well as technical documentation for detectors of specific types.

In accordance with clause 4.2.7.2 of GOST R 53325-2012, the operational documentation of the IP must contain the required amount of technical data and information on installation and operation, indicating the scope and recommended frequency of maintenance.

In accordance with clause 4.2.7.3 of GOST R 53325-2012, the delivery set of the IP should ensure their installation without the use of non-standard equipment and non-standard tools. If it is necessary to use non-standard tools, they must be included in the scope of delivery.

Accordingly, the installation of fire detectors on an Armstrong false ceiling is possible both on the frame of the false ceiling and on the tiles of the suspended ceiling, provided that the technical documentation for specific fire detectors determines the procedure for installing fire detectors in the filling elements (tiles) of the false ceiling.