Gas block-modular boiler rooms: equipment, construction, installation. Block-modular boiler systems and installations

Heating is one of the most important engineering systemswithout any industrial, residential or domestic structure can do without any industrial. Without it, you just freeze in the winter. To provide the population with heat, whole boilers are built, which can work on various types of fuel. However, their construction requires a large amount of time and is quite expensive. Gas make it possible to avoid specified problems. In this article, you will have the opportunity to consider all the features of the presented structure.

What is a design

Gas block-modular boiler rooms are specific engineering facilities, the main function which is heating the heat carrier to provide heat and hot water supply in residential one-storey or multi-storey houses, on the industrial enterprises, household buildings.

This design can be connected to central or individual heating parts. Transportation of the structure can be made using rail or road transport. In order to prevent the embezzlement of the components of the nodes of such a boiler room, during the transportation of it is sewn with a folding metal.

For the design of structures, various fuel can be used. Most often their work can be based on gas bolery quite high power.

Product device

Gas block-modular boiler rooms in their composition have such components:

1. Boilers. Their quantity depends on the power of the station.

2. Technological equipment.

3. The main fuel supply system.

4. Electrical equipment.

5. Pumps.

6. System of elimination of combustion products.

7. Device accounting system.

8. Water preparatory installation.

9. Automatic system Control, security and alerts.

Such knots have a standard boiler room. Naturally, different manufacturers Provide different equipment of the presented equipment. Other systems may be present in the design.

Product advantages

Gas block-modular boiler rooms possess such advantages:

They allow you to significantly reduce the heating fee, as the operation and installation of such structures are relatively inexpensive.

Features of manufacturing and transportation design

Block-modular gas boiler houses, photos you can carefully consider in the article, along with all equipment are fully manufactured at the factory. That is, you no longer have to worry about buying and installing individual nodes.

The module frame itself is made from steel pipeswho have rectangular cross section. They are connected by welding. The base is a platform, the floor of which is assembled by the type of sandwich panel.

Next in the block is installed all necessary equipment. It is necessary to consider that the roof and walls are attached to the base with the help of bolts or screws. Doors and windows in the module are usually aluminum and they open out.

Technical characteristics of the product

To date, block-modular construction is very common. However, before buying the presented structure, it is necessary to consider its technical features:

1. Power of equipment: 0.4-28 MW.

2. Fuel type: Natural or liquefied gasCoal.

3. Temperature to which the coolant can be heated: 60-95 degrees.

4. Number of boilers: 1-3 pcs.

5. Scheme of boiler room: single or dual circuit.

6. Warranty from the manufacturer: more than 25 years of impeccable service.

7. KPD: about 98%.

9. Temperature hot water: 60-80 degrees.

If you want to install block-modular gas boilers, specifications are the main parameter of the selection. After all, the performance and efficacy of the structure depends on them.

Features of the choice and rules of operation of the structure

Production of block-modular boiler rooms provides a large number of different models. In fair man to figure it out quite difficult. Therefore, when buying, try to guide such selection criteria:

Power and thermal production of installation. It all depends on the area of \u200b\u200bheated premises.

Number of boilers. Standard design provides only 2 units, although it may be more.

Number of blocks. It depends on how large will be heated building.

Type of fuel. It all depends on your opportunities.

Availability additional parameters. There may be a chart of temperature, voltage control in the network, the coolant consumption per day or a week and others.

The cost of the module. Its price varies from 900,000 rubles.

Reputation of the manufacturer and user reviews. These parameters will help you really do not make a mistake and choose quality equipment. Naturally, it is better to give preference to proven brands.

Regarding use special requirements not. It is only necessary to periodically clean equipment from scale and contaminants. To fulfill this work, you may need from a few days before the week. The cleaning is better to exercise in the summer when the equipment does not work, but is on preventive maintenance.

Mounted module features

Construction of block-modular boiler houses consists of several stages:

1. Design. It is necessary to observe everything here. necessary rules security, since the object represents a potential explosive and fire danger. The project is consistent with the SES, architecture, Mrs.inadvor, Technudzor and other bodies.

2. Production of blocks.

3. Transportation of the product to the installation site.

5. Connect all necessary communication systems, smoky arrangement.

6. Adjustment of the module, correction of shortcomings, trial start.

Installation of a block-modular boiler room has some features. To start construction site It will be necessary to prepare: Clear from garbage, pour the foundation, bring engineering communications. Next, the installation of blocks on the solidified base is performed. If you need several modules, they are connected using bolted screeds.

The next installation step is to summarize and connect pipelines, connecting them between blocks. After that, the roof and walls of the structure are installed. Next step - fastening additional elements and chimney. Last queue, the module is connected to networks. After that, you need to check the reliability of all fasteners and perform idle start. If everything is in order, setting is ready for use.

What nuances of the construction of the boiler house exist

It should be noted that the units presented are increased danger. This means that for their installation requires special permission and other documents. So, you will need to assemble such papers:

The list of those devices and equipment that are located in the module.

List of all regulatory work on the installation and connection of the unit.

Instructions and documents in which scheduled work and maintenance of equipment are recorded.

Technical passport for all the equipment that will be installed in the boiler room.

Instructions for the operation of the unit as a whole and its individual nodes.

Passport BMK.

A copy of the permission of Rostechnadzor for the operation of the boiler room.

Certificate of conformity for installed equipment.

In principle, half of these papers provide you with a manufacturer, since it makes a holistic installation.

That's all the features of block plants for the heating of buildings. Despite all safety guarantees from the manufacturer, it is impossible to neglect the rules of operation of the boiler room. Good luck!

The Group of Companies "Integrated Heating Systems" offers to buy modern automated block-modular boiler plants at competitive prices. Favorable terms of implementation and an individual approach to each project allow you to meet the needs of the most demanding customers.

Manufactured automated block-modular installations are designed to arrange heating and hot water supply both in industrial facilities and at social and domestic facilities. The main feature These boiler rooms are the technological layout of the entire equipment, made in a special building (module) of the factory production.

The choice of customers presents modern sets with a nominal capacity from 0.2 to 50 MW. Completion of block-modular boiler rooms are made by both import and modern domestic equipment, which allows you to raise the efficiency to 92%.

1.0 MW boiler room - in stock in stock

Boilers: "Viessmann" (Germany) "Vitoplex 300" - 2 pcs., With a capacity of 500 kW each. Burners: "ELCO S.A.S" (Switzerland). Water treatment: "Hydrakhinzhiniring" (Russia). Heat exchangers: Alfa Laval Flow "(Russia). Pumps: "Wilo SE" (Germany). Automation: "Elex-M" (Russia) with a remote dispatch system using GSM.

Features of production and construction of automated modular boiler systems

The benefits of these settings include compact dimensions that allow you to install them:

- like roofs;

- built into the building;

- addured or separately worth it.

Thanks to the block principle, the BMK layout is not only quickly mounted on the customer's site, but also promptly dismantled when they are transported to a new place of operation. Advantages of automated block boiler installations:

- deliveries from the factory in full readiness for work;

- modular execution allows you to deliver to the customer's place by automotive or rail transport;

- reducing construction and installation time;

- attractive appearance and a small amount of harmful emissions.

The use of modern block-modular installations (BMK) allows you to automate the operation process, reducing the number of serving staff of boiler rooms. If there is a non-standard situation, the system independently overlaps the fuel supply, feeding the signal to the remote dispatch remote control.

In the manufacture and construction of these installations are used modern boilers such manufacturers like:

- VIESSMANN WERKE GMBH & CO.KG (Germany);

- Entropros (RF, St. Petersburg);

- Bosch Thermotechnik GmbH (Germany);

- Unical (Italy).

This is exactly what allows you to optimize the process of heating water or steam, increasing the efficiency of block boiler houses and reducing energy consumption. Depending on the needs of the customer, modern block-modular boiler plants operating on gas, liquid or solid fuel (or combined) are supplied.

![]()

Block-modular water-heating boiler room 20.0 MW.

kimra, Tver region.

Why is it profitable to buy automated block boilers from ITS GK?

In HC "ITS", the delivery time and construction, which vary from 2 weeks to several months, depending on the stated capacity and the desired configuration of BMK are reduced. Completion of block boilers is carried out only with certified equipment, which covers the manufacturer's warranty.

If necessary, customers are provided with related services:

- design;

- delivery of modules to the construction site;

- construction of an object;

- installation, connection to communications, commissioning;

- subject to the object by controlling authorities.

Ordering the construction of a modular boiler room in ITS GC, the client receives the following benefits:

- two-year warranty on all work performed;

- competitive prices for the manufacture and installation of a modular boiler room;

- operational execution of the order;

- warranty service of the erected objects.

Would you like to buy an automated block-modular boiler installation (BMK) at an optimal cost? Contact GC "Integrated Heating Systems", our phone in Moscow 8-800-555-13-11.

The cost of each product and the timing of its supply is calculated individually and largely depend on the required power and complete technical characteristics object, as well as from the configuration and manufacturer of selected equipment.

The final price also affects the terms of delivery and the volume of design and installation work. The cost of 1 MW is from 4 million rubles.

LLC "Security Technologies"

As a customer, we are fully satisfied with the quality of products and services. During production, the customer's wishes were as follows. The company TPK "Stella" delivered shipping exactly on time in accordance with the Treaty. Products meet all declared requirements.

All technical issues arising in the process of work are solved by qualified and promptly. We also want to mention professionalism and undoubted competence of employees of the company.

We believe that it was not mistaken in the choice of the supplier and we will be happy to continue our cooperation, we wish you successful development and achieving new vertices in business! "

D. V. Natirov

CEO Director of Safety Technologies

LLC "IRBIS"

On behalf of the company "Irbis" express you sincere thanks!

LLC TPK "Stella" has repeatedly performed work under the contract for the supply of goods of a different range.

During ours collaboration Company employees showed their high professionalism. We want to note that TPK "Stella" has highly qualified personnel and modern engineering equipment. It is important that the company not only monitors the quality of work performed, but also take into account all the wishes of the customer.

LLC TPK "Stella" performed its work according to the term specified in the contract.

Upon completion of the production, employees of the company promptly prepared accompanying documents.

We are confident in the taste and responsibility of the company of the Challet Chamber of Commerce and Industry, which demonstrates our many years of cooperation.

Director of IBIS LLC

T. V. Domanovskaya

AT GROUP LLC

"This letter is expressing sincere thanks to the company TPK Stella LLC for professionally performed work.

At all stages of cooperation, the company has proven itself - as a reliable partner.

Delivery times were observed, despite the large amount of procurement.

We want to celebrate the professionalism of the staff of the Design Bureau of the TPK "Stella". Our problem was solved as efficiently as possible in extremely short time.

Sincerely wish your company prosperity and further success in the implementation of new projects! "

P. N. Sheglekhanov

General Director of InzhstroyProekt LLC

LLC "Yugorskneftegazstroy"

"During working with us, LLC TPK" Stella "has established itself as a conscientious and reliable supplier. We bring your gratitude to you and hope for a long and fruitful mutually beneficial cooperation. "

M. Yu. Bespalov

Head of OMTS LLC Yugorskneftegazstroy

LLC "Lungy metal constructions"

I confirm here that the company TPK STELLA has successfully delivered the capacity for the SUG (Gazagolder) in the address "Light Matallic Constructions"

The equipment received meets high quality standards. Supply was carried out exactly on time in accordance with the contract of delivery.

During our cooperation, we made sure that the company TPK "Stella" is a reliable partner, timely and quality fulfilling its obligations. Separately, we want to note the qualitative information support that Stella's company provides our enterprise throughout the equipment of the equipment manufactured.

TPK "Stella" is a reliable provider that manifests competence, attention and efficiency at all stages of the project.

We highly appreciate the strengths of strong partnerships between our organizations and wish you prosperity, production success, economic and financial well-being.

We hope for further cooperation and strengthening relationships for the benefit of our enterprises.

G.nonral Director MA Khalatov

Blocked modular boiler rooms, (BMK modular boiler rooms) are boiler installations of complete factory readiness, designed for heating and hot water supply of industrial, housing and social facilities. Block-modular boiler houses work on natural Gas, liquefied gas and liquid fuel. All technological equipment is placed in the factory manufacture. The housing of the boiler installation must be all-metal, insulated and fireproof.

Modern trends in energy dictate care from centralized sources of heat supply. Due to the large maintenance costs of networks, the price of heat released is increasing, and expensive connection to these networks declares the consumer to acquire its own autonomous sources of heat supply. Modern heating equipment Allows you to ensure any object with an autonomous source of heat, such as a block-modular boiler room, and at the same time the price of heat generated thermal energy as a result is significantly lower than the price of heat released by centralized sources of heat supply.

Block-modular boiler this is modern approach to the organization of the autonomous source of heat supply, which does not depend on the seasonal disconnection of heating, reduce the costs of consumed thermal energy, eliminate the risk of heat supply surveys due to accidents on networks, improve the quality of the parameters of the heat consumed and hot water.

Boilers in block-modular design can be used to generate a saturated pair under the technological needs of the production branches such as: production building materials, Food Industry, Textile Industry, Tobacco Industry, chemical industry, refinery and many other industries.

Modular boiler room, does not require constant presence of the operator. The equipment of the modular boiler room works in automatic mode: the sensors in the boiler room are constantly monitored.

The dimensions and design of modular boiler rooms provide for the possibility of simple movement and transportation of rail and by car.

The main advantage, blocking modular boiler rooms is the efficiency of their commissioning, low cost and cost-effective content.

|

|

|

|

|

|

|

|

|

|

|

|

|

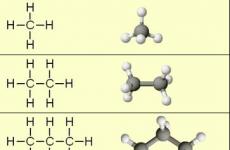

Blocking modular boiler rooms can be divided by a method for heat released (water heating, steam, overheated water, Thermalized), in purpose (heating, technological), according to the type of fuel used (gas, diesel, gas-dial, fuel oil, gas-fuel, solid fuel), according to embodiments (block-modular, roof, stationary, attached, built-in). The goal of boiler rooms is always alone - this is heat generation for its further use.

Blocked modular boiler rooms are a design that represents a set of modules that, when delivered to the customer and further assembly, form a production capacity ready for operation. This design includes all necessary elements To connect to communication networks and is collected by the brigade of the artist's installers on the territory of the customer.

Block-modular boiler rooms can be used both separately, as well as attached. Execution of a separate boiler room is determined only by technical calculations, since the norms allow various options constructions. Conditions at a particular enterprise are determined - to offer a separate boiler room or attached.

Block-modular boiler room according to the method of discharged heat and purpose can be water heating (the temperature of the coolant (water) to 115 ° C and above 115 ° C (overheated water)), steam ( saturated steam, superheated pairs), thermal oil (diathermy oil). There is also a division of the type of fuel: gas boiler rooms, modular boiler rooms on diesel fuel, on fuel oil. Gas boilers use natural and liquefied gas. Also, boiler rooms may have two types of fuel - primary and reserve, or emergency (gas-separable, gas-fledged). By options for execution, block-modular boiler rooms can be both separate and attached, depending on the customer's desire and on the conditions of a particular enterprise.

Block-modular boiler room on which boilers are standing using liquid fuel (fuel oil, diesel fuel, oil of various types, exhaust oil, etc.), must have appropriate fuel warehouses and the preparation of this fuel to burn in the boiler. Mostly it comes down to heating liquid fuel so that it can be sprayed in the burners for full combustion in the boiler firebox.

The compactness of the installation of blocking modular boiler rooms minimizes assembly and commissioning. Optimization of all operating modes and selection of equipment Exactly under the needs of the customer allow to reduce the cost of the boiler room, which, in combination with the possibilities of modern automation, it allows you to significantly increase the PDVs present block-modular boiler rooms with modern, high-quality and highly reliable equipment providing long-lasting and safe operation, speed and convenience of service. In their boilers, our company carries out the installation of steam boilers, water-heating fireproof boilers of leading European producers, such as: "Ici Caldaie" Italy, "Unical" Italy, "Loos" Germany, "Viessmann" Germany, Biasi, ITALY, "ERENSAN" Turkey , "HOVAL" AUSTRIA, ENTROROS Russia. Modern burner devices of various European manufacturers: "F.B.R." Italy, Cuenod France, Ecoflam ITALY, "Weishaupt" Germany, "Saacke" Germany, "Dreizler" Germany, "CIB Unigas" Italy.

Automation and Security Systems

All presented equipment fully satisfies the standards operating in the territory Russian Federation, and has necessary permissions and certificates of conformity. The block-modular boiler houses produced by our company, according to the desire of the Customer, are presented in various designs. This can be fully automatic mode of operation, which disappears the need for a constant presence of service personnel. Control over the functioning of the boiler room is fully carried out offline (information is displayed on the central control panel, which is installed directly in the boiler room). Also, in the event of an emergency, the alarm will be immediately transferred to the dispatcher through cellular, Internet, or telephone.

Transportation of block-modular boiler rooms can be carried out both rail and road transport to any area of \u200b\u200bour country. The design of the boiler room makes it possible in as soon as possible produce mounting work By docking block modules on the customer's site and prepare a boiler room for commissioning and adjusting work.

Energazinezhiniring offers a wide range of services, from the supply of heating and steam boilers of UNICAL (Italy) directly from the manufacturer's factory to the full implementation of the projects of heating and steam boilers in block-modular and inpatient execution followed by warranty and post-warranty service.