Standard instructions for the use and maintenance of fire extinguishers at energy enterprises. Standard instructions for the use and maintenance of fire extinguishers

Instructions for using fire extinguishers

Content

1. General information

2. Actions of an employee of the organization in the event of a fire or signs of combustion (smoke, burning smell, increase in temperature, etc.)

6. Disadvantages of fire extinguishers.

7. General Features using a fire extinguisher

OTV - fire extinguishing agent

OP - powder fire extinguisher

OU – carbon dioxide fire extinguisher

1. General information.

1.1. Depending on the type of charged fire extinguisher, fire extinguishers are used to extinguish one or more fire classes, the symbols of which are indicated on the fire extinguisher labels:

1.2. Portable fire extinguishers used in the organization, depending on the fire extinguishing agent used, are divided into the following types:

- powder (OP):

- gas, including: carbon dioxide (CO).

2. Actions of an employee of the organization in the event of a fire or signs of combustion (smoke, burning smell, increase in temperature, etc.):

2.1. Stop working;

2.2. Disconnect electrical equipment;

2.3. Report the incident by phone 01 or mobile phone 112v fire department, in this case it is necessary to give the address of the facility, the location of the fire, and your last name;

2.4. Take, if possible, measures to evacuate people and extinguish the fire primary means fire extinguishing, safety of inventory items.

3. Comparative characteristics OP and OU

4. Features of extinguishing fires and fires.

4.1. Powder fire extinguisher

4.1.1. The powder ejection time ranges from 6 to 15 seconds.

4.1.2. When extinguishing fires with powder fire extinguishers, the fire is eliminated as soon as the combustion zone is surrounded by a cloud of powder of the required concentration; in addition, the cloud of powder has a shielding property, which makes it possible to approach the burning object at a close distance.

4.1.3. At the very beginning of extinguishing, you should not get too close to the fire, since due to the high speed of the powder jet, strong air suction (ejection) occurs, which only fans the flame above the fire. In addition, when extinguishing from a short distance, scattering or spraying of burning materials with a powerful jet of powder may occur, which will not lead to extinguishing, but to an increase in the area of the fire.

4.1.4. Powder fire extinguishers are not allowed to extinguish electrical equipment energized above 1000 V.

4.1.5. Powder fire extinguishers should not be used to protect equipment that can be damaged by powder (certain types of electronic equipment, manifold-type electrical machines, etc.).

4.1.6. Powder fire extinguishers, due to the high dust content during their operation and, as a consequence, sharply deteriorating visibility of the fire source and escape routes, as well as the irritating effect of the powder on the respiratory system, are not recommended for use in small rooms (less than 40 cubic meters).

4.2. Carbon dioxide fire extinguisher

4.2.1. Carbon dioxide fire extinguishers must not be used to extinguish fires of electrical equipment energized above 10 kV.

4.2.2. A carbon dioxide fire extinguisher equipped with a metal socket should not be used to extinguish fires from live electrical equipment.

4.2.3. When operating carbon dioxide fire extinguishers of all types, it is prohibited to hold the nozzle with an unprotected hand, since when carbon dioxide escapes, a snow-like mass with a temperature of minus 60-70°C is formed.

4.2.4. Carbon dioxide fire extinguishers should be used in cases where effective fire extinguishing requires fire retardant substances that do not damage equipment and objects (computer centers, electronic equipment, etc.).

4.2.5. When using carbon dioxide fire extinguishers, it is necessary to keep in mind that carbon dioxide in large concentrations relative to the volume of the room can cause poisoning of personnel, therefore, after using carbon dioxide fire extinguishers, small rooms should be ventilated.

4.2.6. Before using mobile carbon dioxide fire extinguishers, you should limit the number of personnel present in the room.

5. Activation of the fire extinguisher.

5.1. Powder fire extinguisher.

5.1.1. To operate manual powder fire extinguishers it is necessary to bring the fire extinguisher to the source of the fire, shake it, then pull out the wedge or pin, sharply press the punch (button with a needle) with your hand all the way and release it. The holding time of the fire extinguisher from the moment the punch is pressed until the start of supply of fire extinguishing powder must be at least 3-5 seconds. Then press the start lever and direct a stream of powder into the fire, taking into account the direction of the wind. To stop the flow of powder, simply release the lever.

5.1.2. Repeated use and intermittent action are allowed.

5.1.3. Direct the jet of fire extinguishing powder at an angle of 20-30 °C to the burning surface.

5.2. Carbon dioxide fire extinguisher

5.2.1. To activate manual carbon dioxide fire extinguishers, it is necessary to bring the fire extinguisher to the fire, break the seal and pull out the pin, move the bell to a position convenient for the operator, approach the fire at safe distance indicated on the fire extinguisher label and press the lever.

5.2.2. The lever allows you to interrupt the supply of carbon dioxide.

6. Disadvantages of fire extinguishers.

6.1. Powder fire extinguisher:

? absence of a cooling effect during extinguishing, which can lead to re-ignition of already extinguished fuel from heated surfaces;

? the difficulty of extinguishing a fire due to a sharp deterioration in the visibility of the source and emergency exits(especially in small rooms;

? danger to human health due to the formation of a powder cloud during the extinguishing process;

? damage to equipment and materials due to significant contamination of surfaces with powder;

? the possibility of operational failures due to the formation of plugs due to the ability of powders to clump and caking during storage;

? the possibility of static electricity discharges occurring when operating powder fire extinguishers with a nozzle made of polymer materials, which narrows the scope of their application.

6.2. Carbon dioxide fire extinguisher

? in high concentrations, carbon dioxide is dangerous to human health;

? the possibility of significant thermal stresses appearing in structures when they are exposed to a fire extinguishing agent with a relatively low sub-zero temperature and as a result their loss bearing capacity;

? the possibility of static electricity discharges appearing on the socket when the fire extinguishing agent exits the fire extinguisher;

? danger of frostbite when coming into contact with metal parts of a fire extinguisher or a jet;

? strong dependence of the intensity of the fire extinguishing agent on temperature environment.

7. General features of using fire extinguishers

7.1. Not allowed:

7.1.1. Operate the fire extinguisher if dents, swellings or cracks appear on the fire extinguisher body, on the shut-off head or on the union nut, as well as if the tightness of the connections of the fire extinguisher components is broken or if the pressure indicator is faulty.

7.1.2. Place fire extinguishers nearby heating devices, allow direct sunlight to hit the cylinders.

7.1.3. Strike the fire extinguisher or source of propellant gas.

7.1.4. When working, direct the fire spray towards nearby people.

7.2. General rules fire extinguishing:

7.2.1. Before extinguishing a fire, determine the class of fire and use the most suitable fire extinguisher for extinguishing it (in accordance with the fire extinguisher label).

7.2.2. Extinguish the fire from the windward side, starting from its leading edge gradually moving deeper

7.2.3. Start extinguishing spilled flammable and combustible liquids from the leading edge, directing a stream of powder at the burning surface, and not at the flame;

7.2.4. Extinguish burning liquid pouring from a height from top to bottom.

7.2.5. burning vertical surface simmer from top to bottom.

7.2.6. If there are several fire extinguishers, they must be used simultaneously.

7.2.7. Do not bring a fire extinguisher capable of extinguishing Class E fires closer to a burning electrical installation than the distance specified on the fire extinguisher label.

7.2.8. Make sure that an extinguished fire does not flare up again (never turn your back to it).

7.2.9. After use, the fire extinguisher must be sent for recharging.

STANDARD INSTRUCTIONS

on application and maintenance fire extinguishers

on energy enterprises

DEVELOPED BY: Department of Technical Audit and General Inspection of the Corporate Center of OJSC RAO UES of Russia.

PERFORMERS: Kamyshev V.N., Lvov M.Yu., Ababkov A.V., Medvedev Yu.I., Zamyslov D.A., Ivanov A.N., Nikonov D.S. (“Mosenergoproekt”).

APPROVED BY: Member of the Management Board, Technical Director of OAO RAO UES of Russia B.F. Vainzikher 10/23/2007.

Introduction

The Standard Instructions provide the classification, selection, basic parameters, placement requirements, operating temperature restrictions for portable and mobile fire extinguishers, the procedure for putting fire extinguishers into action, basic tactical techniques for working with fire extinguishers when extinguishing a possible fire at a protected facility, actions of personnel after extinguishing a fire, volume and frequency of maintenance of fire extinguishers, safety measures when using and maintaining fire extinguishers.

Standard instructions intended for use by energy enterprises.

1. General Provisions

1.1. These instructions establish requirements for the selection, placement and maintenance of portable and mobile fire extinguishers at energy enterprises.

1.2. In addition to the requirements of these instructions, you must be guided by the current normative and technical documentation, technical specifications(passports) for this equipment.

1.3. Production, administrative, auxiliary and warehouse buildings, structures and premises, as well as open production sites or areas, must be provided with portable and mobile fire extinguishers in accordance with the requirements of the current normative and technical documentation.

1.4. Fire extinguishers located in buildings, premises, laboratories, workshops, warehouses and other structures and installations are transferred for safekeeping to the heads of the relevant structural units.

1.5. Purchased fire extinguishers must meet the requirements set out in GOST R 51057-2001 and GOST R 51017-97.

2. Accepted abbreviations

OTV - fire extinguishing agent.

OV - water fire extinguisher.

OV(K) - water fire extinguisher with a compact jet.

OV(M) - water fire extinguisher with a fine spray jet.

ORP - air-foam fire extinguisher.

ORP(N) - air-foam fire extinguisher with low expansion foam.

ORP(S) - air-foam fire extinguisher with medium expansion foam.

OP - powder fire extinguisher.

OU - carbon dioxide fire extinguisher.

OX - freon fire extinguisher.

3. Classification of fire extinguishers and fire extinguishing agent (FMA)

3.1. Fire extinguishers are divided in accordance with GOST R 51057-2001 into portable (weighing up to 20 kg) and GOST R 51017-97 mobile (weighing at least 20, but not more than 400 kg). Mobile fire extinguishers may have one or more containers for charging fire extinguishers mounted on a trolley.

3.2. According to the type of fire extinguishing agent used, in accordance with NPB 166-97, fire extinguishers are divided into:

3.2.1. Aquatic (AW).

3.2.2. Air foam (AFP).

3.2.3. Powder (OP).

3.2.4. Gas, which are divided into:

- carbon dioxide (CO);

- refrigerant (CH).

3.2.5. Combined.

3.3. Water fire extinguishers are divided into:

3.3.1. Compact jet fire extinguishers - OV(K).

3.3.2. Fire extinguishers with a spray jet (average droplet diameter more than 100 microns) - OV(R).

3.3.3. Fire extinguishers with a fine spray jet (average droplet diameter less than 100 microns) - OV(M).

3.4. Air-foam fire extinguishers, according to the parameters of the foam flow they generate, are divided into:

3.4.1. Low expansion, foam expansion from 5 to 20 inclusive - ORP(N).

3.4.2. Medium expansion, foam expansion over 20 to 200 inclusive - ORP(C).

3.5. Based on the principle of displacement of the fire extinguishing agent, fire extinguishers are divided into:

3.5.1. Uploaders.

3.5.2. With a cylinder of compressed or liquefied gas.

3.5.3. With gas generating element.

3.5.4. With thermal element.

3.5.5. With ejector.

3.6. Based on the operating pressure, fire extinguishers are divided into low-pressure fire extinguishers (working pressure less than or equal to 2.5 MPa at an ambient temperature of (20±2) °C and fire extinguishers high pressure(working pressure above 2.5 MPa at ambient temperature (20 ± 2) °C).

3.7. According to the possibility and method of restoring the technical resource, fire extinguishers are divided into:

3.7.1. Rechargeable and repairable.

3.7.2. Non-rechargeable.

3.8. According to their intended purpose, depending on the type of charged fire extinguisher, fire extinguishers are divided in accordance with the requirements of GOST 27331-87 (Appendix 1):

3.8.1. For extinguishing fires of solid flammable substances (fire class A).

3.8.2. For extinguishing fires of liquid flammable substances (fire class B).

3.8.3. For extinguishing fires of gaseous flammable substances (fire class C).

3.8.4. For extinguishing fires of metals and metal-containing substances (fire class D).

3.8.5. For extinguishing fires in electrical installations under voltage (fire class E).

Fire extinguishers can be designed to extinguish several classes of fire.

3.9. Fire extinguishers are ranked depending on their ability to extinguish model fires of varying power. The rank of a fire extinguisher is indicated on its marking.

3.10. Fire extinguishing powders, depending on the classes of fire that can be extinguished with them, are divided into:

3.10.1. ABCE type powders - the main active component is phosphorus-ammonium salts.

3.10.2. VSE type powders - the main component of these powders can be sodium or potassium bicarbonate.

3.10.3. Type D powders - the main component is potassium chloride; graphite, etc.

Depending on the purpose, powder compositions are divided into powders general purpose(such as ABSE, VSE) and special-purpose powders (which, as a rule, extinguish not only class D fires, but also fires of other classes).

3.11. Foaming agents for general or special purposes are used as a surface-active base for the charge of an air-foam fire extinguisher. Additionally, the fire extinguisher charge may contain stabilizing additives (to increase the fire extinguishing ability, increase the service life, and reduce the corrosiveness of the charge).

3.12. By chemical composition foaming agents are divided into synthetic (hydrocarbon and fluorine-containing) and protein (fluoroprotein).

4. Selection of fire extinguishers

4.1. The number, type and rank of fire extinguishers required to protect a particular facility are established based on the magnitude of the fire load, the physical, chemical and fire hazard properties of the circulating combustible materials (category of the protected premises, determined in accordance with the industry list and according to NPB 105-03), the nature of the possible their interaction with fire protection equipment and the size of the protected object.

4.2. Depending on the charge, powder fire extinguishers are used to extinguish fires of classes ABCE, ALL or class D.

4.3. To extinguish class D fires, fire extinguishers must be charged with a special powder, which is recommended for extinguishing a given flammable substance, and equipped with a special damper to reduce the speed and kinetic energy of the powder jet. The parameters and number of fire extinguishers are determined based on the specifics of those applying fire hazardous materials, particle dispersion and possible fire area.

4.4. Powder fire extinguishers should not be used to protect equipment that can be damaged by powder (electronic computers, electronic equipment, collector-type electrical machines).

4.5. It is necessary to strictly observe the recommended storage conditions and periodically check the operational parameters of the powder charge (humidity, fluidity, dispersion).

4.6. It is prohibited to use carbon dioxide fire extinguishers to extinguish fires of electrical equipment under voltage above 1 (10) kV, and powder fire extinguishers under voltage above 1 kV.

4.7. Carbon dioxide fire extinguishers with a diffuser that creates a jet of extinguishing agent in the form of snow flakes are usually used to extinguish class A fires.

4.8. Carbon dioxide fire extinguishers with a diffuser that creates a flow of extinguishing agent in the form of a gas jet should be used to extinguish class E fires.

4.9. Halon fire extinguishers should be used in cases where it is necessary to effectively extinguish a fire. fire extinguishing compounds, not damaging the protected equipment and objects (computer centers, radio-electronic equipment, museum exhibits, archives, collector-type electrical machines, etc.).

4.10. Air-foam fire extinguishers are used to extinguish class A fires (usually with a low expansion foam barrel) and class B fires.

4.11. Air-foam fire extinguishers should not be used to extinguish fires of equipment under electrical voltage, to extinguish highly heated or molten substances, as well as substances that come into contact with water. chemical reaction, which is accompanied by intense heat generation and splashing.

4.12. Water extinguishers should be used to extinguish Class A fires.

4.13. It is prohibited to use water fire extinguishers to extinguish fires of equipment under electrical voltage, to extinguish highly heated or molten substances, as well as substances that enter into a chemical reaction with water, which is accompanied by intense heat release and splashing.

4.14. If there is a possibility of a significant fire occurring at the protected object (anticipated spill flammable liquid can occur over an area of more than 1 m2), mobile fire extinguishers must be used.

4.15. Premises equipped with automatic installations fire extinguishing, provide 50% of fire extinguishers based on their calculated quantity.

4.16. When choosing a fire extinguisher, it is necessary to take into account the compliance of its temperature range with possible climatic conditions operation at the protected facility.

4.17. Regarding the selection and placement of fire extinguishers on cars vehicles should be guided by Appendix 4 NPB 166-97.

4.18. Fire extinguishers must be put into operation in a fully charged and operational condition, with the shut-off and starting control unit sealed. They must remain in their designated places during the entire period of their operation.

4.19. The selection of the required number of fire extinguishers should be carried out for each room and object separately.

4.20. A person responsible for purchasing, storing and monitoring the condition of fire extinguishers must be identified at the facility.

4.21. A passport is issued for each fire extinguisher installed at the facility.

The fire extinguisher is assigned a serial number, which is applied to the fire extinguisher, recorded in the fire extinguisher passport and in the fire extinguisher logbook at the facility in accordance with Appendix 5 and clause 12.4 of NPB 166-97.

It is prohibited to use paper labels without protection from possible exposure to hazardous chemicals or environmental factors.

4.22. The placement of fire extinguishers, as well as their quantity, is determined by the design organization, specified and approved by the management of the relevant department of the facility, based on equipment standards and fire danger flammable substances and materials.

RUSSIAN OPEN JOINT STOCK COMPANY

ENERGY AND ELECTRIFICATION "UES OF RUSSIA"

STANDARD INSTRUCTIONS

on application and maintenance

fire extinguishers at energy enterprises

CJSC "ENERGY TECHNOLOGIES"

MOSCOW 2008

Developed by: Department of Technical Audit and General Inspection of the Corporate Center of RAO UES of Russia.

Performers: Kamyshev V.N., Lvov M.Yu., Ababkov A.V., Medvedev Yu.I., Zamyslov D.A., Ivanov A.N., Nikonov D.S. (“Mosenergoproekt”).

Approved by: Member of the Management Board, Technical Director of OAO RAO UES of Russia B.F. Vainzikher 10/23/2007.

Introduction

The Standard Instructions provide the classification, selection, basic parameters, placement requirements, operating temperature restrictions for portable and mobile fire extinguishers, the procedure for putting fire extinguishers into action, basic tactical techniques for working with fire extinguishers when extinguishing a possible fire at a protected facility, actions of personnel after extinguishing a fire, volume and frequency of maintenance of fire extinguishers, safety measures when using and maintaining fire extinguishers.

The standard instructions are intended for use by energy enterprises.

1. General Provisions.

1.1. These instructions establish requirements for the selection, placement and maintenance of portable and mobile fire extinguishers at energy enterprises.

1.2. In addition to the requirements of these instructions, it is necessary to be guided by the current normative and technical documentation, technical specifications (passports) for this equipment.

1.3. Production, administrative, auxiliary and warehouse buildings, structures and premises, as well as open production sites or areas, must be provided with portable and mobile fire extinguishers in accordance with the requirements of the current normative and technical documentation.

1.4. Fire extinguishers located in buildings, premises, laboratories, workshops, warehouses and other structures and installations are transferred for safekeeping to the heads of the relevant structural units.

1.5. Purchased fire extinguishers must meet the requirements set out in GOST R 51057-2001 and GOST R 51017-97.

2. Accepted abbreviations.

OTV - fire extinguishing agent.

OV - water fire extinguisher.

OV(K) - water fire extinguisher with a compact jet.

OV(M) - water fire extinguisher with a fine spray jet.

ORP - air-foam fire extinguisher.

ORP(N) - air-foam fire extinguisher with low expansion foam.

ORP(S) - air-foam fire extinguisher with medium expansion foam.

OP - powder fire extinguisher.

OU - carbon dioxide fire extinguisher.

OX - freon fire extinguisher.

3. Classification of fire extinguishers and fire extinguishing agent (FMA).

3.1. Fire extinguishers are divided in accordance with GOST R 51057-2001 into portable (weighing up to 20 kg) and GOST R 51017-97 mobile (weighing at least 20, but not more than 400 kg). Mobile fire extinguishers may have one or more containers for charging fire extinguishers mounted on a trolley.

3.2. According to the type of fire extinguishing agent used, in accordance with NPB 166-97, fire extinguishers are divided into:

3.2.1. Aquatic (AW).

3.2.2. Air foam (AFP).

3.2.3. Powder (OP).

3.2.4. Gas, which are divided into:

Carbon dioxide (CO);

Freon gases (CH).

3.2.5. Combined.

3.3. Water fire extinguishers are divided into:

3.3.1. Compact jet fire extinguishers - OV(K).

3.3.2. Fire extinguishers with a spray jet (average droplet diameter more than 100 microns) - OV(R).

3.3.3. Fire extinguishers with a fine spray jet (average droplet diameter less than 100 microns) - OV(M).

3.4. Air-foam fire extinguishers, according to the parameters of the foam flow they generate, are divided into:

3.4.1. Low expansion, foam expansion from 5 to 20 inclusive - ORP(N).

3.4.2. Medium expansion, foam expansion over 20 to 200 inclusive - ORP(C).

3.5. Based on the principle of displacement of the fire extinguishing agent, fire extinguishers are divided into:

3.5.1. Uploaders.

3.5.2. With a cylinder of compressed or liquefied gas.

3.5.3. With gas generating element.

3.5.4. With thermal element.

3.5.5. With ejector.

3.6. According to the operating pressure, fire extinguishers are divided into low pressure fire extinguishers (working pressure less than or equal to 2.5 MPa at ambient temperature (20 ± 2 °C) and high pressure fire extinguishers (working pressure above 2.5 MPa at ambient temperature (20 ± 2 °C) 2) °C).

3.7. According to the possibility and method of restoring the technical resource, fire extinguishers are divided into:

3.7.1. Rechargeable and repairable.

3.7.2. Non-rechargeable.

3.8. According to their intended purpose, depending on the type of charged fire extinguisher, fire extinguishers are divided in accordance with the requirements of GOST 27331-87 (Appendix):

3.8.1. For extinguishing fires of solid flammable substances (fire class A).

3.8.2. For extinguishing fires of liquid flammable substances (fire class B).

3.8.3. For extinguishing fires of gaseous flammable substances (fire class C).

3.8.4. For extinguishing fires of metals and metal-containing substances (fire class D).

3.8.5. For extinguishing fires in electrical installations under voltage (fire class E).

Fire extinguishers can be designed to extinguish several classes of fire.

3.9. Fire extinguishers are ranked depending on their ability to extinguish model fires of varying power. The rank of a fire extinguisher is indicated on its marking.

3.10. Fire extinguishing powders, depending on the classes of fire that can be extinguished with them, are divided into:

3.10.1. ABCE type powders - the main active component is phosphorus-ammonium salts.

3.10.2. VSE type powders - the main component of these powders can be sodium or potassium bicarbonate.

3.10.3. Type D powders - the main component is potassium chloride; graphite, etc.

Depending on the purpose, powder compositions are divided into general-purpose powders (such as ABSE, VSE) and special-purpose powders (which, as a rule, extinguish not only class D fires, but also fires of other classes).

3.11. Foaming agents for general or special purposes are used as a surface-active base for the charge of an air-foam fire extinguisher. Additionally, the fire extinguisher charge may contain stabilizing additives (to increase the fire extinguishing ability, increase the service life, and reduce the corrosiveness of the charge).

3.12. Based on their chemical composition, foaming agents are divided into synthetic (hydrocarbon and fluorine-containing) and protein (fluoroprotein).

4. Selection of fire extinguishers

4.1. The number, type and rank of fire extinguishers required to protect a particular facility are established based on the magnitude of the fire load, the physical, chemical and fire hazard properties of the circulating combustible materials (category of the protected premises, determined in accordance with the industry list and according to NPB 105-03), the nature of the possible their interaction with fire protection equipment and the size of the protected object.

4.2. Depending on the charge, powder fire extinguishers are used to extinguish fires of classes ABCE, ALL or class D.

4.3. To extinguish class D fires, fire extinguishers must be charged with a special powder, which is recommended for extinguishing a given flammable substance, and equipped with a special damper to reduce the speed and kinetic energy of the powder jet. The parameters and number of fire extinguishers are determined based on the specifics of the flammable materials in circulation, the dispersion of particles and the possible area of the fire.

4.4. Powder fire extinguishers should not be used to protect equipment that can be damaged by powder (electronic computers, electronic equipment, collector-type electrical machines).

4.6. It is prohibited to use carbon dioxide fire extinguishers to extinguish fires of electrical equipment under voltage above 1 (10) kV, and powder fire extinguishers under voltage above 1 kV.

4.7. Carbon dioxide fire extinguishers with a diffuser that creates a jet of extinguishing agent in the form of snow flakes are usually used to extinguish class A fires.

4.8. Carbon dioxide fire extinguishers with a diffuser that creates a flow of extinguishing agent in the form of a gas jet should be used to extinguish class E fires.

4.9. Halon fire extinguishers should be used in cases where effective fire extinguishing requires fire extinguishing compounds that do not damage the protected equipment and objects (computer centers, electronic equipment, museum exhibits, archives, collector-type electrical machines, etc.).

4.10. Air-foam fire extinguishers are used to extinguish class A fires (usually with a low expansion foam barrel) and class B fires.

4.11. Air-foam fire extinguishers should not be used to extinguish fires of equipment under electrical voltage, to extinguish highly heated or molten substances, as well as substances that enter into a chemical reaction with water, which is accompanied by intense heat generation and splashing.

4.12. Water extinguishers should be used to extinguish Class A fires.

4.13. It is prohibited to use water fire extinguishers to extinguish fires of equipment under electrical voltage, to extinguish highly heated or molten substances, as well as substances that enter into a chemical reaction with water, which is accompanied by intense heat release and splashing.

4.14. If there is a possibility of a significant fire occurring at the protected object (the expected spill of flammable liquid may occur over an area of more than 1 m2), it is necessary to use mobile fire extinguishers.

4.15. It is allowed to provide premises equipped with automatic fire extinguishing systems with 50% of fire extinguishers based on their calculated quantity.

4.16. When choosing a fire extinguisher, it is necessary to take into account the compliance of its temperature range of use with the possible climatic operating conditions at the protected object.

4.17. In matters of selection and placement of fire extinguishers on vehicles, you should be guided by Appendix 4 NPB 166-97.

4.18. Fire extinguishers must be put into operation in a fully charged and operational condition, with the shut-off and starting control unit sealed. They must remain in their designated places during the entire period of their operation.

4.19. The selection of the required number of fire extinguishers should be carried out for each room and object separately.

4.20. A person responsible for purchasing, storing and monitoring the condition of fire extinguishers must be identified at the facility.

4.21. A passport is issued for each fire extinguisher installed at the facility.

The fire extinguisher is assigned a serial number, which is applied to the fire extinguisher, recorded in the fire extinguisher passport and in the fire extinguisher logbook at the facility in accordance with Appendix 5 and clause 12.4 of NPB 166-97.

It is prohibited to use paper labels without protection from possible exposure to hazardous chemicals or environmental factors.

4.22. The placement of fire extinguishers, as well as their quantity, is determined by the design organization, specified and approved by the management of the relevant department of the facility, based on equipment standards and the fire hazard of flammable substances and materials.

5. Basic parameters of fire extinguishers and restrictions on the operating temperature of fire extinguishers.

5.1. Carbon dioxide fire extinguishers.

Designed to extinguish fires of various flammable substances, the combustion of which cannot occur without air access.

Carbon dioxide portable fire extinguishers with a capacity of 2, 3, 5, 8 and mobile with a capacity of 10, 20, 40, 80 liters can be used to extinguish electrical installations up to 10,000 V (the voltage is indicated in the fire extinguisher’s passport).

The extinguishing agent is carbon dioxide.

Technical characteristics of carbon dioxide fire extinguishers

|

Fire extinguisher brand |

Capacity, l |

Charge weight, kg |

Charge release time, s |

Fire extinguishing ability |

Dimensions, mm |

total weight, kg |

|

440´ 220 |

||||||

|

500´ 220 |

||||||

|

570´ 270 |

||||||

|

1000´ 570 |

||||||

|

1200´ 370 |

||||||

|

1250´ 415´ 280 |

||||||

|

700´ 1650´ 400 |

||||||

|

800´ 1700´ 760 |

* Ranks of model fire source:

10B - combustion of 10 liters of gasoline with a layer of 3 cm, located in a baking tray shaped like a circle (13B - 13 liters, respectively, 34B - 34 liters, etc.).

5.2. Powder fire extinguishers.

5.2.1. Uploaders.

Charged with fire extinguishing powder and pumped with gas (air, nitrogen, carbon dioxide) at a pressure of up to 16 atm. Designed to extinguish class A, B, C or BC fires, depending on the type of powder used, as well as electrical installations energized up to 1000 V (E).

Equipped with locking devices that ensure free opening and closing with a simple hand movement. The pressure gauge installed as an indicator on the head of the fire extinguisher shows the degree of efficiency of the fire extinguisher, which is a big advantage over fire extinguishers with a built-in pressure source.

Operate at temperatures -40 - +50 °C.

|

Fire extinguisher brand |

Charge weight, kg |

Release length, m |

Charge release time, s |

Fire extinguishing ability |

Dimensions, mm |

Total weight, kg |

|

285´ 110´ 110 |

||||||

|

350´ 170´ 130 |

||||||

|

435´ 170´ 130 |

||||||

|

530´ 420´ 440 |

||||||

|

590´ 225´ 400 |

||||||

|

1020´ 460´ 480 |

||||||

|

1090´ 640´ 630 |

________________

Ranks of model fire source:

* 10V - combustion of 10 liters of gasoline with a layer of 3 cm, located in a baking tray shaped like a circle (13V - 13 liters, respectively, 34V - 34 liters, etc.).

** 1A - combustion of a model hearth in the form of wooden blocks placed in a cube with a volume of 1/8 m 3; 2A the volume of the cube is 2 times larger (1/4 m3), 4A - 4 times larger (1/2 m3), etc.

Fire extinguishers with a built-in pressure source (gas generator, gas cylinder) in standby mode there is no pressure in the fire extinguisher body. To activate them, it is necessary to initiate a pressure source and only after 3 seconds begin extinguishing.

Operate at temperatures -40 - +50 °C.

Technical characteristics of powder fire extinguishers

|

Fire extinguisher brand |

Charge weight, kg |

Charge release time, s |

Release length, m |

Dimensions, mm |

Total weight, kg |

||||||||||||||||||||||||||

|

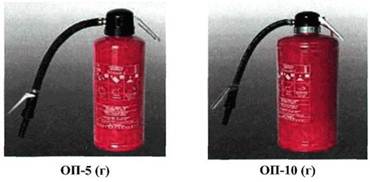

OP-5 (G), (B) |

550´ 300´ 320 |

||||||||||||||||||||||||||||||

|

OP-10 (G), (B) |

650´ 350´ 355 |

6.3. In rooms filled with production or other equipment that obscure fire extinguishers, indicators of their location must be installed. Signs must be made and located in prominent places at a height of 2.0 - 2.5 m from the floor level, taking into account the conditions of their visibility and comply with the requirements of the normative and technical documentation. 6.4. The distance from a possible source of fire to the nearest fire extinguisher is determined by the requirements of the rules; it should not exceed: 6.4.1. 20 m - for public buildings and structures. 6.4.2. 30 m - for premises of categories A, B and C. 6.4.3. 40 m - for premises of categories B and D. 6.4.4. 70 m - for premises of category D. 6.5. It is recommended that portable fire extinguishers be installed on hanging brackets or in special cabinets. Fire extinguishers must be located so that the main inscriptions and pictograms indicating the order of their activation are clearly visible and face outward or towards the most likely approach to them. 6.6. The locking and starting device of fire extinguishers and cabinet doors (if they are located in a cabinet) must be sealed. 6.7. Fire extinguishers with a total weight of less than 15 kg must be installed so that their top is located at a height of no more than 1.5 m from the floor; portable fire extinguishers with a total weight of 15 kg or more must be installed so that the top of the fire extinguisher is located at a height of no more than 1.0 m. They can be installed on the floor, with mandatory fixation from possible fall due to accidental impact. 6.8. The distance from the door to the fire extinguisher should be such as not to interfere with its full opening. 6.9. Fire extinguishers should not be installed in locations where temperatures exceed the temperature range indicated on the fire extinguisher. 6.10. Water and foam fire extinguishers installed outdoors or in unheated rooms and not intended for operation at subzero temperatures must be removed during the cold season (air temperature below +1 °C). In this case, information about the location of fire extinguishers during the specified period and the location of the nearest fire extinguisher must be placed in their place. 7. Procedure for activating fire extinguishers.7.1. To activate portable carbon dioxide fire extinguishers OU-2, OU-5 and OU-8 it is necessary: 7.1.1. Using the transport handle, remove and bring the fire extinguisher to the burning area. 7.1.2. Direct the bell towards the combustion source and open the shut-off device (valve or lever). The shut-off and start device allows you to interrupt the supply of carbon dioxide.

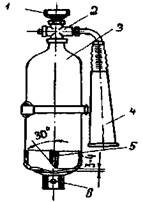

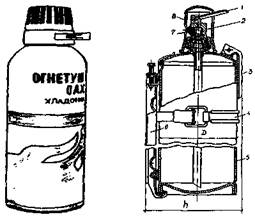

The portable carbon dioxide fire extinguisher OU-2 consists of:

Portable carbon dioxide fire extinguisher OU-5 (OU-8) consists of: 7.2. To activate mobile fire extinguishers of the OU-25 and OU-80 types, you must: 7.2.1. Roll the fire extinguisher to the fire site and install it in the working position (vertically for OU-25 and inclined for OU-80). 7.2.2. Unwind the hose and open the shut-off device. 7.2.3. Holding the bell by the special insulated handle, direct snow mass to the source of the fire.

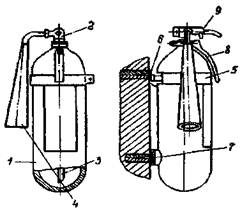

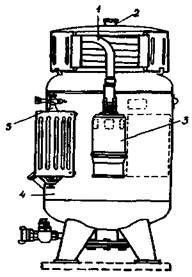

The mobile carbon dioxide fire extinguisher OU-25 and OU-80 consists of:

Mobile carbon dioxide fire extinguisher OU-80 7.3. To activate portable powder fire extinguishers OP-2, OP-5 and OP-10, you must: 7.3.1. Bring a fire extinguisher to the fire. 7.3.2. Pull out the wedge or pin 9. 7.3.3. Press lever 2 and direct a stream of powder into the fire. To stop the flow of powder, simply lower the lever. Repeated use and intermittent action are allowed. In the working position, the fire extinguisher should be held strictly vertically, without turning it over.

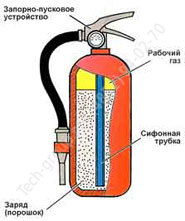

Portable powder fire extinguisher OP-5 consists of: 7.4. Mobile fire extinguishers OP-50 and OP-100 have a transport trolley, working and starting cylinders, as well as a hose for supplying powder to the fire zone. To activate the fire extinguisher, do the following: 7.4.1. Roll the fire extinguisher without sharply tipping over to a distance of 5 - 10 m from the fire source and install it strictly in a vertical position. 7.4.2. Remove and route the powder supply hose without kinking or twisting. 7.4.3. Break the seal and turn the locking head lever all the way. 7.4.4. Having opened the exhaust valve, direct the powder stream into the fire zone in a zigzag motion to achieve greater flame coverage by the powder cloud. It is permissible to open and close the exhaust valve multiple times when extinguishing a fire. After the end of extinguishing, the pressure in the fire extinguisher must be reduced by opening the release valve. Do not disassemble a pressurized fire extinguisher to reduce the pressure.

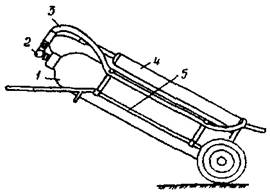

Mobile powder fire extinguisher OP-100 consists of: 7.5. To activate portable halon fire extinguishers or their varieties, you should: 7.5.1. Bring them by the handle to the source of the fire. 7.5.2. By pressing the button or lever of the shut-off device, open the safety membrane. 7.5.3. Direct the jet towards the flame.

The portable hadon fire extinguisher OUB-ZA (OUB-7A) consists of: 7.6. To activate the portable air-foam fire extinguisher OVP-10 you must: 7.6.1. Remove the fire extinguisher using the transport handle 6 and bring it to the burning area. 7.6.2. Break the seal and press the lever of the locking and starting device 8, while the needle opens the cartridge with the working gas, under the influence of which the pressure in the housing increases and the foaming agent solution is supplied through a siphon tube and hose to the spray barrel 5, where, mixing with the sucked in air, air-mechanical foam of medium expansion is formed. 7.6.3. Direct the foam towards the combustion area. During operation, the fire extinguisher must be kept in a vertical position.

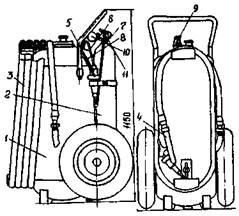

The portable air-foam fire extinguisher OVP-10 consists of: 7.7. To activate the mobile fire extinguisher OVP-100 you must: 7.7.1. Install the fire extinguisher in a vertical position 5 - 6 m from the source of combustion and unwind the hose, avoiding kinks and twists. 7.7.2. Break the seal and open the locking device (valve or lever) of the starting cylinder all the way. 7.7.3. Direct a stream of foam at the combustion site.

Mobile air-foam fire extinguisher OVP-100 consists of: 7.8. To activate the stationary fire extinguisher OVPU-250 (UVP-250), you must: 7.8.1. Unwind hose 1 with foam generator 3 and direct it to the fire. 7.8.2. Break the seal and open the locking device (valve or lever) of the starting cylinder until it stops 5.

Stationary air-foam fire extinguisher OVPU-250 (UVP-250) consists of: 8. Scope and frequency of maintenance of fire extinguishers.8.1. Fire extinguishers put into operation must undergo maintenance, which ensures that the fire extinguishers are constantly ready for use and the reliable operation of all components of the fire extinguisher throughout its entire service life. Maintenance includes periodic inspections, inspections, repairs, testing and recharging of fire extinguishers. 8.2. Periodic checks are necessary to monitor the condition of the fire extinguisher, control the installation location of the fire extinguisher and the reliability of its fastening, the possibility of free access to it, the presence, location and readability of instructions for working with the fire extinguisher. 8.3. Maintenance and repair of fire extinguishers must be carried out in accordance with the operating instructions and use necessary tools, materials by a person appointed by order for the enterprise and who has passed, in the prescribed manner, a test of knowledge of regulatory and technical documents on the design and operation of fire extinguishers and fire extinguisher parameters, capable of independently carrying out the required amount of work on servicing fire extinguishers (if there is a license for this type of activity). 8.4. Fire extinguishers taken out of service during repair, testing or recharging must be replaced with backup fire extinguishers with similar parameters. 8.5.1. Presence of dents, chips, deep scratches on the body, control units, nuts and head of the fire extinguisher. 8.5.2. The state of protective and paint coatings. 8.5.3. Availability of clear and clear instructions. 8.5.4. Availability of sealed safety device. 8.5.5. The serviceability of the pressure gauge or pressure indicator (if it is provided for in the design of the fire extinguisher), the presence of the necessary mark and the amount of pressure in the pump-type fire extinguisher or in the gas cylinder. 8.5.6. Condition of the flexible hose (if any) and the fire extinguishing agent sprayer (presence of mechanical damage, traces of corrosion, casting flash or other objects that prevent the free exit of the fire extinguisher from the fire extinguisher). 8.5.7. The condition of the chassis and the reliability of fastening the fire extinguisher body on the cart (for a mobile fire extinguisher), on the wall or in the fire cabinet (for a portable fire extinguisher). Based on the results of the inspection, the necessary notes are made in the fire extinguisher’s passport, it is assigned a serial number, which is applied to the fire extinguisher and recorded in the fire extinguisher logbook. 8.6. The quarterly inspection includes an inspection of the fire extinguisher installation site and approaches to it, as well as an external inspection of the fire extinguisher (clause 9.5). 8.7. An annual inspection of a fire extinguisher includes an external inspection of the fire extinguisher (p.), inspection of its installation site and approaches to it. During the annual inspection, the amount of leakage of the expelling gas from the gas cylinder or the exhaust gas from the gas cylinder is monitored. gas fire extinguisher. They carry out a selective opening of powder fire extinguishers, assess the condition of the filters, check the parameters of the fire extinguishing agent and, if they do not meet the requirements of the relevant regulatory documents, recharging fire extinguishers. 8.8. If during the inspection it is discovered that any fire extinguisher parameter does not comply with the requirements of current regulatory documents, it is necessary to eliminate the causes of the identified deviations in parameters and recharge the fire extinguishers. 8.9. In the event that the amount of leakage per year of expellant gas or fire extinguisher from a gas fire extinguisher exceeds the limit values defined by current regulatory documents, such fire extinguishers must be taken out of service and sent for repair and recharging. 8.10. At least once every 5 (10) years (indicated in the fire extinguisher data sheet), each carbon dioxide or powder fire extinguisher and propellant gas cylinder must be recharged. Air-foam and water fire extinguishers are recharged annually. 8.11. A note about the inspections and tests carried out is made on the fire extinguisher and in the operational certificate. 9. Documentation for fire extinguishers.9.1. A passport is issued for each fire extinguisher installed at the facility. The fire extinguisher is assigned a serial number, which is applied to the fire extinguisher, recorded in the fire extinguisher passport and in the fire extinguisher logbook at the facility. 9.2. The fire extinguisher log book at the facility must contain the following information: 9.2.1. The brand of the fire extinguisher, the number assigned to it, the date it was put into operation, the location of its installation. 9.2.2. Parameters of the fire extinguisher during the initial inspection (weight, pressure, brand of charged fire extinguisher, notes on the technical condition of the fire extinguisher). 9.2.3. Date of inspection, comments on the condition of the fire extinguisher. 9.2.4. Date of maintenance with opening of the fire extinguisher. 9.2.5. Date of inspection or replacement of the OTV charge, brand of the charged OTV (its concentration for water and foam fire extinguishers), the name of the organization that carried out the recharging. 9.2.6. Date of verification of the pressure indicator and fuse, by whom they were checked. 9.2.7. The date of the strength test of the fire extinguisher and its components, the name of the organization that conducted the test; date of the next scheduled test. 9.2.8. Condition of the mobile fire extinguisher chassis, date of its inspection, identified deficiencies, planned measures. 9.2.9. Position, surname, name, patronymic and signature of the responsible person. 9.3. The operational certificate for a fire extinguisher must contain the following information: 9.3.1. The number assigned to the fire extinguisher. 9.3.2. Date the fire extinguisher was put into operation. 9.3.3. Fire extinguisher installation location. 9.3.4. Type and brand of fire extinguisher. 9.3.5. Fire extinguisher manufacturer. 9.3.6. Factory number. 9.3.7. Date of manufacture of the fire extinguisher. 9.3.8. Brand (concentration) of charged fire extinguishing agent:

Notes: * Pressure in the body of the injection fire extinguisher or in the gas cylinder (if it is located outside and equipped with a pressure gauge or pressure indicator). ** Cylinder weight with liquefied gas to displace fire extinguishing agent from the fire extinguisher. If the canister is located inside the fire extinguisher body, then its mass is determined once a year (selectively for powder fire extinguishers) and compared with the value indicated in the fire extinguisher passport. 10. Safety precautions when using and maintaining fire extinguishers.10.1. When maintaining fire extinguishers, it is necessary to comply with the safety requirements set out in the regulatory and technical documentation for this type fire extinguisher. 10.2. The fire extinguishing agent charged into the fire extinguisher and the gas-generating device installed in it must have a hygienic certificate (conclusion) Russian Federation. 10.3. Prohibited: 10.3.1. Operate fire extinguishers if dents, swellings or cracks appear on the fire extinguisher body, on the shut-off head or on the union nut, as well as if the tightness of the connections of the fire extinguisher components is broken or if the pressure indicator is faulty. 10.3.2. Carry out any work if the fire extinguisher body is under pressure of expelling gas or fire extinguishing vapors. 10.3.3. Fill the body of the injection fire extinguisher with displacing gas outside the protective enclosure and from a source that does not have safety valve, pressure regulator and pressure gauge. 10.3.4. Strike the fire extinguisher or source of propellant gas. 10.3.5. Carry out hydraulic (pneumatic) tests of the fire extinguisher and its components outside protective device, preventing the scattering of fragments and injury to operating personnel in the event of destruction of the fire extinguisher. 10.3.6. Use open fire or other ignition sources when handling concentrated solutions of individual foaming agents (PO-3AI, PO-3NP, SAMPO, GTO-6NP and Morskoy), since they can form explosive mixtures with air. 10.3.7. Work with fire extinguishing agents without appropriate respiratory, skin and vision protection. 10.3.8. Discharge refrigerants into the atmosphere or discharge foaming agents without proper processing. 10.3.9. When working, direct the hose towards nearby people. 10.4. Persons working with fire extinguishers during their maintenance and charging must comply with the safety and personal hygiene requirements set out in the regulatory and technical documentation for the relevant fire extinguishers, fire extinguishing agents and sources of propellant gas. 10.5. When extinguishing a fire indoors using gas mobile fire extinguishers (carbon dioxide or freon), it is necessary to take into account the possibility of reducing the oxygen content in the indoor air below the limit value and use insulating respiratory protection. 10.6. When extinguishing a fire with powder fire extinguishers, it is necessary to take into account the possibility of high dust formation and reduced visibility of the fire (especially in a small room) as a result of the formation of a powder cloud. 10.7. When extinguishing electrical equipment using gas or powder fire extinguishers, it is necessary to maintain a safe distance (at least 1 m) from the spray nozzle and the fire extinguisher body to live parts. 10.8. When extinguishing a fire using a foam or water extinguisher, it is necessary to de-energize the premises and equipment. 10.9. The fire extinguisher activation mechanism must be equipped with a locking device to prevent unauthorized activation. Removing the interlock device must involve operations that are different from operating the fire extinguisher. The blocking device must be sealed and have a simple design so that it cannot be deformed or broken in case of arbitrary impact. 10.10. The fire extinguisher and its individual components must not have sharp edges, corners or protruding elements that could cause injury to operating personnel. 10.11. The socket of a carbon dioxide fire extinguisher with a flexible hose must have a handle to protect the operator’s hand from hypothermia. 10.12. A mobile fire extinguisher must be equipped with a safety device to prevent pressure from exceeding the permissible value (GOST 12.2.085). 10.13. In terms of the degree of impact on the human body, the charges should not exceed the 3rd hazard class according to GOST 12.1.007. 10.14. Charges for air-foam fire extinguishers should not have carcinogenic or mutagenic effects on the human body. 10.15. Formulations containing fluorinated surfactants may have weak cumulative and skin-resorptive effects. 10.16. When working with air-foam fire extinguishers, it is necessary to use personal protective equipment in accordance with GOST 12.4.011 to exclude the possibility of the composition getting on the skin, mucous membrane of the eyes and the gastrointestinal tract. 10.17. During operation and storage, it is necessary to take measures to prevent spillage of liquid components of charges. 10.18. Only a fully charged and sealed mobile fire extinguisher, equipped with a tag indicating the date (month and year) of charging, the date of the next control of the fire extinguisher parameters and the technical examination of the fire extinguisher, is allowed to be put into operation. 10.19. Fire extinguishing agents, expired warranty period storage or whose parameters do not meet the requirements of the relevant regulatory and technical documents must be subjected to regeneration treatment or disposed of. It is unacceptable to dump or drain the waste fuel without additional processing and pollute the environment. 10.20. Foaming agents that have lost their original properties and cannot be regenerated are recommended to be used as wetting agents when extinguishing class A fires or as aqueous solutions when cleaning contaminated metal surfaces. 10.21. It is recommended to neutralize biologically “hard” foaming agents by burning the concentrate in special furnaces or by burying it in a special landfill. 10.22. Substandard fire extinguishing powder compositions on a phosphorus-ammonium basis (Pirant-A, PF, P-2ASh, Vekson-AVS, etc.) or on a chloride basis (PKhK, Vekson-D) can be used as raw materials for fertilizers. Bicarbonate-based powder (PSB-ZM) can be used as an ingredient in cleaning products or to neutralize acidic wastewater. 10.23. Draining the remaining foam-forming charge solutions when washing fire extinguishers, foam communications, foam mixers, equipment, and storage containers into water bodies for domestic and drinking water use is not permitted. 11. List of references. GOST 12.1.007-76* Combustion solids |

|||||||||||||||||||||||||||||

|

Flammable liquids |

Combustion of liquid substances |

||||||||||||||||||||||||||||||

|

Flammable gases |

Combustion of gaseous substances |

||||||||||||||||||||||||||||||

|

Metals and metal-containing substances |

Combustion of metals and metal-containing substances |

||||||||||||||||||||||||||||||

|

Electrical equipment under voltage no more than... V |

The fire extinguishing object is under electrical voltage (the main picture of the pictogram is the sign “Caution! Electrical voltage» according to GOST 12.4.026) |

||||||||||||||||||||||||||||||

An example of a symbol for an air-foam fire extinguisher with a charge volume of OTV - 10 l, injection, intended for extinguishing fires of solid (class A fire) and liquid flammable substances (class B fire), model 01, with a hydrocarbon charge:

ORP- 10(3) - AB - 01 (UgPAV) according to GOST R 51057-2001.

Example of a symbol for a powder fire extinguisher charged with 5 kg of fire extinguisher, equipped with a high pressure cylinder used to create overpressure displacing gas in the body of a fire extinguisher designed to extinguish fires of solid (class A fire), liquid (class B fire) and gaseous flammable substances (class C fire), as well as live electrical equipment (class E fire), model 03, designed for use in mines:

OP- 5(6) - ABSE - 03 ( III ) according to GOST R 51057-2001.

An example of a symbol for a powder fire extinguisher charged with 2 kg of fire extinguisher, equipped with a gas-generating device used to create excess pressure in the body of the fire extinguisher, designed to extinguish fires of liquid (class B fire) and gaseous flammable substances (class C fire), as well as electrical equipment located energized (class E fire):

OP- 2(g)- ALL according to GOST 51057-2001.

An example of a symbol for an air-emulsion fire extinguisher with a fluorine-containing charge volume of 5 liters, with a high-pressure cylinder used to create excess pressure of the displacing gas in the body of the fire extinguisher, designed to extinguish the fire of solid (class A fire) and liquid flammable substances (class B fire) :

OVE- 5(6) - AB- 03 (Fluorosurfactant).

An example of a symbol for a water fire extinguisher with a fine spray, with a charge volume of OTV - 5 l, with a high-pressure gas cylinder used to create excess pressure of the displacing gas in the body of the fire extinguisher, intended for extinguishing fires of solid (class A fire) and liquid flammable substances (fire class B):

0V- 5(6) - AB "Borey" according to GOST R 51057-2001.

An example of a symbol for a carbon dioxide fire extinguisher with a charge weight of OTV - 2 kg, intended for extinguishing fires of liquid flammable substances (class B fire), gaseous flammable substances (class C fire) and fires of energized electrical equipment (class E fire):

INSTRUCTIONS FOR CONTENTS AND USE

PRIMARY FIRE FIGHTING MEANS

1. GENERAL PROVISIONS.

1.1. Industrial, administrative, auxiliary and warehouse buildings, structures and premises, as well as open production sites and areas must be provided with primary fire extinguishing means (hereinafter referred to as PSP) in accordance with the standards established by the Rules fire protection regime in the Russian Federation (approved by Decree of the Government of the Russian Federation of April 25, 2012 No. 390).

1.2. Primary fire extinguishing means are intended for use by employees of enterprises, organizations, personnel of fire departments and other persons for the purpose of localizing fires and are divided into the following types:

1.2.1. portable and mobile fire extinguishers;

1.2.2. fire hydrants and means to ensure their use;

1.2.3. fire equipment;

1.2.4. blankets to isolate the source of fire.

1.3. The use of primary fire extinguishing means, fire-fighting tools and fire-fighting equipment for household, industrial and other needs not related to fire-fighting is prohibited.

1.4. In addition to their direct purpose, it is permitted to use fire extinguishing agents in the localization and elimination of natural disasters and catastrophes, as well as for personnel training.

1.5. By order of measures in the organization, maintenance areas are distributed, assigned responsible persons to supervise and maintain good condition and keep all fire extinguishing equipment in constant readiness for use in the event of a fire.

1.6. The placement of fire extinguishers and fire equipment is established by the heads of structural units on the basis of design decisions, Fire Regulations in the Russian Federation and sets of fire safety rules.

2. FIRE EXTINGUISHERS.

2.1. The head of the organization ( ) provides the object with fire extinguishers according to the standards in accordance with Appendices No. 1 and 2 to the Fire Regulations in the Russian Federation.

2.2. Fire extinguishers are used to extinguish fires in their initial stages, as well as to fire protection small structures, machines and mechanisms.

2.3. Fire extinguishers are manual and mobile. Manual fire extinguishers include all types of fire extinguishers with a body volume that can hold up to 10 liters. charge. Fire extinguishers with a large charge capacity are classified as mobile fire extinguishers. To move them, the fire extinguisher bodies are mounted on special trolleys.

2.4. Fire extinguishers vary in design and type of extinguishing agent used.

Depending on the extinguishing agent used, fire extinguishers can be:

- aquatic;

— foam (chemical, air-foam, chemical air-foam);

— gas (carbon dioxide, freon, bromichladone);

- powder;

- air emulsion.

2.5. In places where fire extinguishers are installed, the ambient temperature must be at least 5 degrees C, with the exception of gas and powder fire extinguishers, which are operational at subzero temperatures.

2.6. Fire extinguishers must not be placed near heating or heating devices, as well as in places not protected from direct sun rays and atmospheric precipitation.

2.7. Each fire extinguisher installed at the facility must have an operational passport (hereinafter referred to as the passport) and a serial number, which is applied in white paint to the body of the fire extinguisher. The trigger or shut-off device of the fire extinguisher must be sealed with a disposable seal.

2.8. The following designations are applied to the disposable seal:

— individual seal number;

— date of charging the fire extinguisher, indicating the month and year.

2.9. A passport is issued for each fire extinguisher installed at the facility.

2.10. The fire extinguisher log book at the facility must contain the following information:

- brand of fire extinguisher, number assigned to it, date of its commissioning, location of its installation;

— parameters of the fire extinguisher during the initial inspection (weight, pressure, brand of charged fire extinguisher, notes on the technical condition of the fire extinguisher);

— date of inspection, identified comments on the condition of the fire extinguisher;

— date of maintenance with opening of the fire extinguisher;

— date of inspection or replacement of the OTV charge, brand of the charged OTV;

— name of the organization that carried out the recharging;

— date of verification of the indicator and pressure regulator, by whom they were verified;

— date of testing the fire extinguisher and its components for strength, name of the organization that conducted the test; date of the next scheduled test;

— the condition of the mobile fire extinguisher chassis, the date of its inspection, identified deficiencies, planned measures;

- position, surname, name, patronymic and signature of the responsible person.

2.11. Fire extinguishers must be regularly inspected and cleaned of dirt and dust. During visual inspections, it is necessary to check the integrity of the seal and tag. Fire extinguishers with faulty components, deep dents and corrosion on the body are not subject to further use and must be replaced with new ones.

2.12. Fire extinguishers used during a fire, as well as during personnel training, must be as soon as possible remove from the premises for subsequent charging.

To conduct classes using fire extinguishers, it is recommended to use fire extinguishers that have reached or are approaching their next recharge time.

2.13. Regular monitoring of the maintenance and maintenance of proper aesthetic appearance and constant readiness for action of fire extinguishers and other primary fire extinguishing equipment located in structural divisions must be carried out by responsible persons appointed by the relevant order for the organization,

2.14. The fire extinguishers used must be in good condition and always ready.

2.15. CARBON ACID FIRE EXTINGUISHERS (CAF).

For extinguishing fires various substances and materials, as well as electrical installations under voltage up to 10,000 V (10 kV), carbon dioxide fire extinguishers charged with liquefied carbon dioxide are used.

The principle of operation of carbon dioxide fire extinguishers is as follows: when the fire extinguisher is activated, carbon dioxide in the form of gas or carbon dioxide snow, directed into the fire zone, reduces the oxygen concentration and at the same time cools the burning substance and the environment.

Carbon dioxide fire extinguishers are effective at temperatures not lower than -25°C. At a lower temperature, the pressure of carbon dioxide in the cylinder drops, its release slows down, and the effectiveness of the fire extinguisher sharply decreases.

Carbon dioxide fire extinguishers are divided into manual and mobile.

The fire extinguisher must be replaced if the periodic inspection period for the cylinder has been exceeded, the seal has been broken, there is mechanical damage, or the fire extinguisher is incomplete.

Carbon dioxide fire extinguishers must be activated after directing the bell to the fire, since their action time is limited to a few seconds and at the first moment the main amount of carbon dioxide is released.

To activate OU-5, OU-8 it is necessary:

— using the transport handle, remove and bring the fire extinguisher to the burning site;

- point the bell at the combustion source and open the shut-off device (lever), having first broken the seal and pulled out the pin (the shut-off device allows you to interrupt the supply of carbon dioxide).

The working position of the fire extinguisher is vertical.

The stream of carbon dioxide emerging from the bell should be directed from the windward side to the place of the most active combustion, no closer than 1 meter from the source of combustion.

When extinguishing fires of flammable and combustible liquids, the carbon dioxide stream should be directed at an angle to the combustion surface, without allowing splashing, under the base of the flame from the edge and, as the flame is knocked down, move the carbon dioxide stream across the combustion area.

When extinguishing a fire, it should be borne in mind that when the fire extinguisher is operating, the temperature of the socket drops to -70°C.

After using carbon dioxide fire extinguishers in enclosed spaces, the latter must be ventilated.

2.16. POWDER FIRE EXTINGUISHERS (OP).

Powder fire extinguishers are used to extinguish fires and combustions of solid, liquid and gaseous substances, as well as electrical installations under voltage up to 1000 V.

To activate powder fire extinguishers OP-2, OP-5 and OP-10 it is necessary:

— bring a fire extinguisher to the fire;

- pull out the wedge or pin;

- press the lever and direct a stream of powder into the fire.

To stop the flow of powder, simply release the lever.

Repeated use and intermittent action are allowed.

In the working position, the fire extinguisher should be held strictly vertically, without turning it over.

Powder fire extinguishers are not allowed to be placed near heating appliances, where the temperature may be more than 50 degrees C, or in places exposed to direct sunlight.

Powder fire extinguishers should not be used to protect equipment that could be damaged by powder (electronic equipment, manifold-type electrical machines, etc.).

2.17. PLACEMENT OF FIRE EXTINGUISHERS.

Fire extinguishers should be located on the protected object in accordance with the requirements of GOST 12.4.009 (section 2.3), so that they are protected from exposure to direct sunlight, heat flows, mechanical influences and other adverse factors (aggressive environment, high humidity, vibration, etc.). It is preferable to place fire extinguishers near places where a fire is most likely to occur, along passageways, as well as near exits from premises, with the obligatory condition: fire extinguishers must be clearly visible and easily accessible. Fire extinguishers should not impede (obstruct the passage) the evacuation of people during a fire.

For placement of primary fire extinguishing equipment in industrial and warehouses, and also fire shields (points) can be installed on the territory of protected objects.

In rooms filled with production or other equipment that obscure fire extinguishers, indicators of their location must be installed. Signs must be made in accordance with GOST 12.4.026 and located in visible places at a height of 2.0 - 2.5 m from the floor level, taking into account the conditions of their visibility (GOST 12.4.009).

The distance from a possible source of fire to the nearest fire extinguisher is determined by the requirements of the rules; it should not exceed 20 m for public buildings and structures; 30 m - for premises of categories A, B and C; 40 m - for premises of categories B and D; 70 m - for premises of category D.

Fire extinguishers with a total weight of less than 15 kg must be installed so that their top is located at a height of no more than 1.5 m from the floor; portable fire extinguishers with a total weight of 15 kg or more must be installed so that the top of the fire extinguisher is located at a height of no more than 1 m. They can be installed on the floor, with mandatory fixation from possible fall due to accidental impact.

The distance from the door to the fire extinguisher should be such as not to prevent them from opening completely. Fire extinguishers should not create obstacles when moving people in the premises.

Powder and carbon dioxide fire extinguishers are allowed to be installed outdoors and in unheated rooms at a temperature not lower than minus 20 degrees C.

Freight and cars must be equipped with powder or halon fire extinguishers with a housing capacity of at least 2 liters (type OP-2 or OX-2).

Buses of an especially small class (such as Gazelle, RAF, etc.) are equipped with at least one fire extinguisher of the OP-2 type; small class buses (PAZ, etc.) - two OP-2 fire extinguishers; middle class buses (LAZ, LiAZ, MAZ, etc.) and other vehicles for transporting people - two fire extinguishers (one in the OP-5 cabin, the other in the OP-2 cabin).

Tankers for transporting petroleum products and vehicles for transportation dangerous goods must be equipped with at least two fire extinguishers of type OP-5: one must be on the chassis, and the second - on the tank or in the body with cargo.

Heavy-duty off-road dump trucks must be equipped with one fire extinguisher of the OP-5 type.

Mobile laboratories, workshops and other vehicles such as a van mounted on a car chassis must be equipped with two-liter fire extinguishers of the appropriate type, depending on the class of possible fire and the features of the mounted equipment.

On all vehicles, fire extinguishers must be located in the cab, in close proximity to the driver or in an easily accessible location. It is prohibited to store fire extinguishers in the trunk, body or other places that are difficult to access. Fire extinguishers located outside the cabin should be protected from exposure to precipitation, sunlight and dirt.

The design of the bracket must be reliable to eliminate the possibility of the fire extinguisher falling out of it when the vehicle is moving, as well as in the event of a collision or impact with an obstacle.

2.18. MAINTENANCE OF FIRE EXTINGUISHERS AND THEIR RECHARGE.

Fire extinguishers put into operation must undergo periodic maintenance, which ensures that the fire extinguishers are constantly ready for use and the reliable operation of all components of the fire extinguisher throughout its entire service life. Technical includes periodic inspections, inspections, tests, repairs and recharging of fire extinguishers.

Periodic checks are necessary to monitor the condition of fire extinguishers, control the location of their installation and reliability of fastening, the possibility of free access to them, as well as the presence, location and readability of instructions for working with fire extinguishers.

Maintenance of fire extinguishers must be carried out by an organization licensed by the Ministry of Emergency Situations.

Fire extinguishers taken out of service during repair, testing or recharging must be replaced with backup fire extinguishers with similar parameters.

Before putting the fire extinguisher into operation, it must be subjected to an initial inspection, during which an external inspection is carried out, the contents of the fire extinguisher and the suitability of its installation location are checked (the visibility of the fire extinguisher or the indicator of its installation location, the possibility of free access to it), as well as the readability and intelligibility of the instructions working with a fire extinguisher.

During the external inspection, the following is monitored:

— absence of dents, chips, deep scratches on the body, control units, nuts and head of the fire extinguisher;

— condition of protective and paint coatings;

— presence of clear and understandable instructions;

— condition of the safety device;

— serviceability of the pressure gauge or pressure indicator (if it is provided for in the design of the fire extinguisher), the presence of the necessary mark and the amount of pressure in the pump-type fire extinguisher or in the gas cylinder;

— the mass of the fire extinguisher, as well as the mass of the fire extinguisher in the fire extinguisher (the latter is determined by calculation);

— the condition of the flexible hose (if any) and the fire extinguishing agent sprayer (for the absence of mechanical damage, traces of corrosion, casting flash or other objects that impede the free exit of the fire extinguisher from the fire extinguisher);

— the condition of the chassis and the reliability of fastening the fire extinguisher body to the wall.

The test result is recorded in the fire extinguisher passport and in the fire extinguisher logbook.

The quarterly inspection includes an inspection of the installation site of fire extinguishers and approaches to them, as well as an external inspection of fire extinguishers.

An annual inspection of fire extinguishers includes an external inspection of fire extinguishers, an inspection of their installation site and approaches to them. During the annual inspection, the amount of leakage of expellant gas from a gas cylinder or fire extinguishing agent from gas fire extinguishers is monitored. The fire extinguishers are opened (full or selective), the condition of the filters is assessed, the fire extinguisher parameters are checked and, if they do not comply with the requirements of the relevant regulatory documents, the fire extinguishers are recharged.

When fire extinguishers are constantly exposed to such unfavorable factors as positive or negative ambient temperatures close to the limit value (according to the technical data for the fire extinguisher), air humidity of more than 90% (at 25 degrees C), corrosive environment, exposure to vibration, etc. ., inspection of fire extinguishers and control of fire extinguishers must be carried out at least once every 6 months.

If during the inspection it is discovered that any parameter of the fire extinguisher does not comply with the requirements of regulatory documents, it is necessary to eliminate the causes of the identified deviations in the parameters and send the fire extinguisher for recharging.

If the amount of leakage per year of the expelling gas or fire extinguisher from a gas fire extinguisher exceeds the limit values defined in GOST R 51057 or GOST R 51017, the fire extinguisher is taken out of service and sent for recharging.

At least once every 5 years, each fire extinguisher and propellant gas cylinder must be discharged, the fire extinguisher body must be completely cleaned of any residual fire extinguishing agent, an external and internal inspection must be carried out, and tests for strength and tightness of the fire extinguisher body, trigger head, hose and shut-off valve must be carried out. devices.

During an annual technical inspection, powder fire extinguishers are selectively (at least 3% of the total number of fire extinguishers of the same brand, but not less than 1 pc.) disassembled and the basic operational parameters of the fire extinguishing powder are checked ( appearance, the presence of lumps or foreign objects, flowability when poured by hand, the possibility of destruction of small lumps to a dusty state when they fall from a height of 20 cm, moisture content and dispersion). If the powder does not meet the requirements of regulatory and technical documentation in at least one of the parameters, all fire extinguishers of this brand must be recharged.

Powder fire extinguishers used for vehicle protection are fully tested at intervals of at least once every 12 months.

The inspections carried out are noted in the fire extinguisher log book.

Recharging fire extinguishers.

All fire extinguishers must be recharged immediately after use or if the amount of leakage of gas fire extinguisher or expelling gas per year exceeds the permissible value, but not less than the time specified in GOST R 51057 or GOST R 51017. The recharge time of fire extinguishers depends on the conditions of their operation and on the type of fire extinguisher used. .

When recharging, the housing of low or high pressure fire extinguishers is subjected to a hydrostatic test pressure test in accordance with the requirements of GOST R 51017 and GOST R 51057.

The housings of carbon dioxide fire extinguishers are subjected to hydrostatic pressure testing at least once every 5 years.

Powder fire extinguishers installed on vehicles outside the cabin or interior and exposed to adverse climatic and physical factors must be recharged at least once a year, other fire extinguishers installed on vehicles at least once every two years.