Check fireproof water supply. Tests of internal fire fighting water supply

Check fireproof water supply necessary element Preventive actions by persons responsible for fire safety at enterprises, factories, etc. Also, checking fireproof water supply is an extremely necessary point of verification of the oversight of the Ministry of Emergency Situations.

When the fire supply test is conducted

External inspection - Once in a six months of the guard of the guard on the fixed site and the supervision authorities (inspection) during the survey of objects (SP-31-13330-2012). Accordingly, all these rules can take themselves at the notes of the person responsible for fire safety at their facilities.

Checking fire protection networks sets

- the existence of access paths to water sources (the width of the entrance should be at least three meters per car), the entrance to the fire water source must be solid (desirable performance of asphalt or concrete), and ensure the impelled passage and turn of fire cars;

- the presence and condition of the outer cover of the hydrant well (in winter time The hydrant cover must be cleaned from ice and covered with a warming drawer)

- technical condition of the well hydrant (in summer);

- the presence and condition of the firefighter reservoir, hydrant, etc.;

- the depth of the reservoir (wet well) in a place intended for immersing the suction mesh of the car and the fence of water for the needs of fire extinguishing;

- control of dry terrestra, the state of firefighters, filling firefighters;

- the presence of safety side fences and reference timber on the fire pier.

When departing on duty guard for fire, testing operational plans And fire extinguishing cards must be checked by the nearest firewalls by external inspection with a mark in the check log.

With launch of water - It is necessary to spend twice a year (April-May, September-October) by the personnel of the guard of the guard in the presence of a plumbing service or an object.

When checking is carried out:

- external inspection, checking the availability of water and pressure on the network by setting the column to all fire hydrants with a mandatory start of water (it is strictly prohibited when checking the use of end keys and other devices);

- Checking the health and performance of the device for the descent of water from the hydrant;

- the presence and verification of the coordinate correspondence on the established indicators of the water sources;

- checking the state of the coating of the fire pier, its carrier structures, lateral fences;

- Checking self-helping wells and their power by installing vehicles with fence and waters.

Tests of water supply water supply lines for waterproof

During the operation of the water supply, pipe diameters are reduced due to deposits on their corrosion walls, therefore, to determine the actual water expenditures from fireproof water pipes Tests it on water production.

one . The following water supply networks are subject to water testing:

- plumbing networks that are on the most distant distance from pumping stations;

- networks that have the smallest diameter pipelines;

- dead-end networks and low pressure networks;

- in the most fire-hazardous production facilities, which requires high water consumption.

2. Plots plumbing networks which are tested for waterproof, must be agreed with the staff of the water supply services.

3. Hydraulic tests of water supply networks are carried out with a worker of exploitation of water supply networks during the maximum consumption hours of 1 time in 5 years.

4. The external water supply network is tested for the possibility of supplying a calculated water consumption with a minimal pressure of 10 m of a water column in accordance with the norms.

Firewater Hydraulic Test Methodology

- Determine according to SNiP 2.04.02-84, or by the project, the required water consumption for the outer fire extinguishing (Q H), for this object or settlement.

- Mark on the external water supply network fire hydrants from which you can get the required calculated amount of water.

- Secure the time of hydraulic testing of the water supply network.

- Mentally create a "fire" and turn on the pumps at the pump station.

- Calculate the calculation of the actual flow of water for fire extinguishing (Q Φ) is one of the proposed methods.

- Compare the necessary and actual water consumption ( prerequisite Q N.< Q ф или Q н = Q ф) , сделать вывод о соответствии устройства водопровода с нормативными требованиями.

Test results are made in acts ( table 3.), which are compiled in 2 copies: 1 - for fire protection, 2 - for water circular. The act should be made a clear conclusion on the compliance or non-compliance of water revenues of the proven water sewing needs of fire extinguishing.

In case of inconsistency of verified water supply networks established by the standards, fireguard Together with the VKA service are being developed technical events By providing the necessary water reproduction for the needs of fire extinguishing (replacement of water pipes, an increase in their diameter, ringing networks, etc.).

Methods for testing water supply networks for water production for the needs of fire extinguishing

1. Volume method

Water consumption is calculated using a measuring tank with a capacity of at least 0.5 m3. The time of filling the tank with water is determined by the testimony of the stopwatch.

Then: Q f \u003d w / t,

where q f is the actual water consumption, l / s;

W is the capacity of the measuring tank, l;

T is the time of filling the tank with water, p.

2. Using the trunk-water meter.

The barrel-water meter is an ordinary fire barrel, additionally equipped with a pressure gauge and replaceable nozzles with a diameter of 13 to 25 mm.

In order to determine the flow of water use the following calculated formulas:

Q f \u003d p √h or q f \u003d √h / s

where r - the patency of the nozzle

3. With the help of water meters

For this, water meters large diameters Tools with transitional pipes and connecting heads and include in sleeve lines.

four . Using fire column

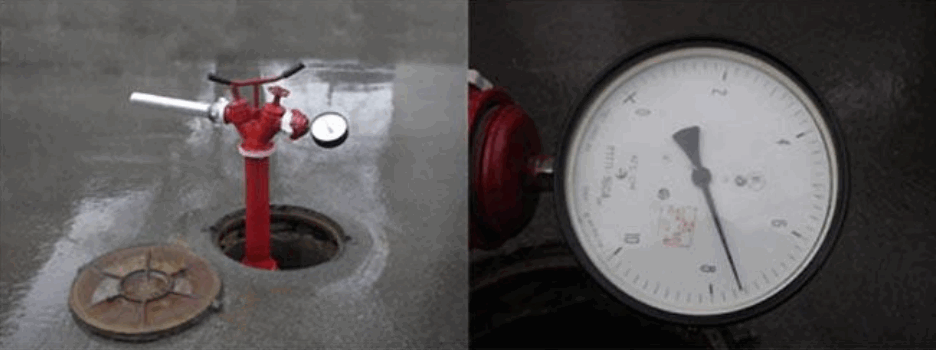

For such a test, it is necessary to equip two straight segments of pipes with a length of 500 mm, a diameter of 66 mm and the connecting heads, and on the body of the column, install a pressure gauge ( fig.1). According to the testimony of the pressure gauge and the data given in Table No. 2 determine the actual water consumption.

Water reproductive lines depends on the type of line (ring or dead), pipe diameter, water pressure in the line, and is determined by table 2..

Table 2.

Water reproductive lines

|

Pressure in line to fire, kPa |

aquifer |

Consumption in l / s with pipe diameter in (mm) |

|||||

|

tupic ring |

|||||||

|

tupic ring |

|||||||

|

tupic ring |

|||||||

|

tupikov kіltsev |

|||||||

|

tupic ring |

|||||||

Fig.1. Measurement of the actual water flows from the water supply station during the pressure of the fire column nozzle 1 - column, 2 - pressure gauge, 3 - smooth pipe.

To be confident in the performance of the fire extinguishing system, it is necessary to periodically check it. There is a method for testing internal fire fighting water supply, in which it is described in detail how to check which tools to use and so on. It will be useful to consider the main stages of tests.

What tests are carried out

Tests are carried out on determining the health of the water supply. All fire cranes must be good, so each of them passes inspection. With a water ratio, the situation is a bit different.

Waterproof is called the volume of water, which gives a tap per unit of time. It is compared with the normative indicator, and so determine the availability of the water supply to work. Only extreme fire cranes are experiencing on the waterproof. They are also called dictating, they are located on (above) of all from the supply source. If they perform the norm, then other cranes will also provide firefightening water, giving the required amount of water.

Determine the pressure from the valve or the manual trunk and the height of the jet. If the tests have not passed at least one crane, then the fireproof water supply is considered unequiscover and needs to be repaired.

As for the test of fire water supply in good condition, then the locking valves of fire cranes are checked here. There should be no leakage, the flywheel should be easily rotated, and the valve shut-off part is freely moved to the side and to another. If a diaphragm is provided in the fire crane, then check whether its diameter corresponds to the design requirements. Check results are displayed in the act.

How to check for waterproof

To test the water production of the internal fire fighting water supply required special devicecalled a hydrotest. Its main part is a pressure gauge that measures pressure. The pressure gauge should take calibration to confirm the shelf life once every 2 years.

Includes are also present:

- nozzles;

- adapter;

- valve;

- cut of the hose;

- key for fire heads;

- the key to attach fire sleeves to fittings.

Equipment different models Hydrometers may differ, but it is the main parts to carry out tests on the taps with the heads of any diameter.

In the general case, the device is an insert with a pressure gauge. Checking the fire crane is based on the placement of inserts between fire sleeves and barrel (or valve), followed by the removal of the testimony.

When the verifier opens the crane, a strong jet of water is formed. You can direct it in sewage Stock Or to the street. If it is impossible, the receiving tank is used. Its volume is determined in each case separately, since it depends on the expenditure rate of the water supply.

Test data is entered into the appropriate log. Then they are treated, that is, they produce calculations. The measured pressure must be at least the normative or project specified in the test method. Knowing pressure, length and diameter of the sleeve, it is possible to determine the water consumption per unit of time (waterproof) and the height of the jet.

Measured water supply parameters are interconnected. If the pressure does not correspond to the norm, then it is possible to be sure that the height (length) of the jet, as well as the waterpart, will not be normal. However, they must be calculated to understand how large deviations from the norm.

When and who spends

The fire-fighting system should be checked at a positive temperature. The norms set the temperature + 5 ° C or higher. Internal and external water supply are inspected in autumn (September-October) and spring (April-May) - 2 times a year. Checking the fireproof crane takes place at such a time of day so that water consumption on household or production needs in the system has been maximum.

According to the rules of O. fire fireThe head of the organization or enterprise is responsible for the health of the fire station. He organizes tests or assigns responsible person For verification events.

To carry out the testing of the fire water supply, it is not necessary to have a license or special permission. The methodology states that the verifier must be instructed to use the fire crane and check for knowledge of safety rules. A verification is confirmed by signed acts and protocols.

But to properly do all the measurements, skills and knowledge are needed. In addition, the cost of the hydrotestter to test the fire pipeline, reaches 20-30 thousand rubles. Each organization will want to carry additional spending on its purchase.

That is why the leaders turn to firms that specialize in conducting tests of fire water pipes. They have the necessary equipment, and make measurements as quickly as possible, saving time. There is no need to delve into calculations, study in detail the sequence of actions. It is only necessary to attend measurements. commissioner manwho confirms the fact of testing the water supply.

Documentary confirmation

Tests must be confirmed documented. Such documents is an act of checking internal fireproof water supply. Subject points It is the date and time (hours, minutes) of the test, as well as the crane number according to the approved scheme. The document indicates the name of the organization that performs the test and organization operating the water supply. Indicate the results of water testing and the health of the cranes.

Ministry Russian Federation By Affairs civil Defense, emergency situations and elimination of the effects of natural disasters

Federal State Institution "All-Russian Order" Honor Sign "Research Institute of Fire Defense"

of May 23, 2011 N 12-3-03-2636EP

On the appeal to clarify the parameters given in the SP 10.13130.2009 and in the "method of testing internal fire-fighting water supply" (VNIIPO, 2005; NSC N 2 (42) -2010) - hereinafter referred to as the "Methodology" text, - we inform the following.

1. It is necessary to be guided by the methodology.

2. Instructions for testing fireproof water pipes are intended only for objects of OAO Gazprom, and in terms of testing of internal fireproof water supply (HPV) it affects the measurement of pressure, flow and height of the compact part of the jet. Having tests for the consumption and height of the compact part of the jet according to the methodology is not required. The methodology is in more detail and methodically more correctly stated by the Algorithm for Testing HPV for Water Locations. In addition, the basic rules for testing the EHP on the performance and tests of the fire cranes valves for health are set.

3. Skuffers in Table 3 SP 10.13130.2009 For trunks with a diameter of the outlet 13 mm and valve 50 mean the inappropriateness of using fire cranes with these technical means, because At a pressure of less than 0.21 MPa, the flow rate will be less than 2.6 l / s.

4. If the objects are used at 13 mm trunks, fire sleeves with a diameter of 51 mm and a length of 20 m, then, therefore, the pressure on the dictating valve of the fire crane should be p ~ 0.19 MPa.

5. In the methodology there is no information about the proportionality ratio between the height of the jet and its compact part, because There is no need to test the height of the compact part of the jet.

6. When using a stem 13 mm of fire sleeves 20 m long pressure cannot be below 0.19 MPa (see P.4).

7. Note 1 Table 1 SP 10.13130.2009 does not apply to the hostel. Under the phrase "and other equipment" implies valves, connecting heads or connecting fittings.

8. In EHF, it is allowed to use only those plastic and metal plastic pipeswho have passed the corresponding tests for fire resistance.

9. The advantages of the technique to the other previously existing techniques is precisely in the absence of measurements of the flow and height of the compact part of the jet.

Full information on the ERW device, its technical means, the main parameters of the EHF, the hydraulic calculation algorithm and various types His tests and his technical means Followed in an educational and methodological manual "Internal fireproof water supply: educational and methodical manual / L.M.Meshman, V.A. Bulkinkin, R.Yu.Gubin, E.Yu.Romanova / Under total. Ed. N.P. Kopillaova . - M.: VNIIPO, 2010. - 496 p. "

Head of NIC PST.

S.N. Kopilov

Electronic document text

prepared CJSC Codex and drilled by:

mailing.

General

Due to the fact that during the operation of water supply networks, the pipe diameter decreases due to corrosion and deposits on the walls, it is necessary to test for the detection of actual consumption in order to determine their maximum water reserves.Water supply networks are tested during the maximum water consumption hours in the residential sector (from 7 to 9 hours), in industrial facilities, if there is an economic and drinking water supply (in the climbers), in the presence of production and fire water supply (in the clock of its maximum use).

Tests first must be subject to the plotting of the water supply network:

Method 1.

Tests are carried out by fenced water from a water supply network by fire vehicles. The fence is made through the sleeves with a diameter of 80 (65) mm and trunks with a nozzle diameter 19 mm and more.For testing, it is necessary to know the water production of this water supply network (Table 1):

| Head in the network, m | Type of water supply network | Water reproduction of the network, l / s, with the diameter of the pipe, mm | |||||||||||||

| 100 | 125 | 150 | 200 | 250 | 300 | 350 | |||||||||

| 10 | Tupic | 10 | - | 20 | - | 25 | - | 30 | - | 40 | - | 55 | - | 65 | - |

| Ring | - | 25 | - | 40 | - | 55 | - | 65 | - | 85 | - | 115 | - | 130 | |

| 20 | Tupic | 14 | - | 25 | - | 30 | - | 45 | - | 55 | - | 80 | - | 90 | - |

| Ring | - | 30 | - | 60 | - | 70 | - | 90 | - | 115 | - | 170 | - | 195 | |

| 30 | Tupic | 17 | - | 35 | - | 40 | - | 55 | - | 70 | - | 95 | - | 110 | - |

| Ring | - | 40 | - | 70 | - | 80 | - | 110 | - | 145 | - | 205 | - | 235 | |

| 40 | Tupic | 21 | - | 40 | - | 45 | - | 60 | - | 80 | - | 110 | - | 140 | - |

| Ring | - | 45 | - | 85 | - | 95 | - | 130 | - | 185 | - | 235 | - | 280 | |

| 50 | Tupic | 24 | - | 45 | - | 50 | - | 70 | - | 90 | - | 120 | - | 160 | - |

| Ring | - | 50 | - | 90 | - | 105 | - | 145 | - | 200 | - | 265 | - | 325 | |

| 60 | Tupic | 26 | - | 47 | - | 55 | - | 80 | - | 110 | - | 140 | - | 190 | - |

| Ring | - | 52 | - | 95 | - | BY | - | 163 | - | 225 | - | 290 | - | 380 | |

| 70 | Tupic | 29 | - | 50 | - | 65 | - | 90 | - | 125 | - | 160 | - | 210 | - |

| Ring | - | 58 | - | 105 | - | 130 | - | 182 | - | 255 | - | 330 | - | 440 | |

| 80 | Tupic | 32 | - | 55 | - | 70 | - | 100 | - | 140 | - | 180 | - | 250 | - |

| Ring | - | 64 | - | 115 | - | 140 | - | 205 | - | 287 | - | 370 | - | 500 | |

Based on the waterproof, determine the number of fire cars required for testing. Cars are installed on adjacent hydrants, a sleeve line 20 m long with a barrel with a nozzle diameter of at least 19 mm is laid from each pump nozzle.

The work of the trunks is considered normal if the compact jet range is at least 17 meters and the pressure on the nozzle is at least 40 meters.

If, while on the pump there is a pressure pressure sub-pressure (determined by the pressure gauge on the suction pipe of the pump), the nozzles in one of the trunks is folded. If the jet range and pressure on the trunk remains within the established limits, the nozzles are collapsed in the next barrel. The test continues until the suborition on the pump becomes equal to 10 m.

Depending on the diameter of the water supply and the type of water supply network (annular, deadlock), the number of trunks can vary. With small diameters of networks or deadlocks, it is possible to use the "b" stems or various combinations "A" and "B".

The water production of the water supply network is determined by the amount of the flow rate of the stems (Table 2):

| Head in the trunk, m | Water consumption, l / s, from the barrel with a diameter of the nozzle, mm | ||||||

| 13 | 19 | 25 | 28 | 32 | 38 | 50 | |

| 20 | 2,7 | 5,4 | 9,7 | 12,0 | 16,0 | 22,0 | 39,0 |

| 30 | 3,2 | 6,4 | 11,8 | 15,0 | 20,0 | 28,0 | 48,0 |

| 40 | 3,7 | 7,4 | 13,6 | 17,0 | 23,0 | 32,0 | 55,0 |

| 50 | 4,1 | 8,2 | 15,3 | 19,0 | 25,0 | 35,0 | 61,0 |

| 60 | 4,5 | 9,0 | 16,7 | 21,0 | 28,0 | 38,0 | 67,0 |

| 70 | - | - | 18,1 | 23,0 | 30,0 | 42,0 | 73,0 |

| 80 | - | - | - | - | - | 45,0 | 78,0 |

Tests are carried out, both under normal pressure and with the inclusion of boost pumps.

Method 2

Produced using a fire column and control measuring device. The test is carried out by one of the parties (the Notebook or the GPS subdivision) in the presence of attorney and certified equipment.For testing it is necessary: \u200b\u200bInstall the fire column on the hydrant;

- connect to the connecting heads of the pressure gauge and the smooth nozzle of the measuring instrument (Figure 1);

- open the fire hydrant until full overlapping its drain canal;

- open the valve of the valve column of the feed water to the pressure gauge and measure its pressure (Figure 2);

- open the valve of the valve column of the feed water to the smooth pipe and measure the pressure (Figure 3);

- according to the established pressure of water and the secondary indication of the pressure gauge, as well as the table data shown in Table No. 3, determine the water production from the hydrant at the beginning of the plotting, then repeat similar tests at the end of the water supply site. The arithmetic average of the two values \u200b\u200bobtained during the test will be

being a water reproduction of a water supply network.

Fig.1. Device for testing a water supply network for waterproof

Technical experts GK " Fire safety"Conduct the performance of the performance and waterproof of the internal fire water supply networks. The company's employees are studied in detail the water supply network for risers, fire cranes, electromagnetic valves, etc.

As a rule, it is carried out before accepting the lrugs into operation, upon completion of the repair work. The tests of the HPV on the waterproof should be carried out at least twice a year: once in the spring and once in the fall, and the temperature ambient It should not be descended below 5 ° C. Waterproof tests are carried out with minimal pressure in the mainstone. external network. For example, testing at the facility should be carried out at that time of the day when the building in which the HPV test occurs, the water consumption of the relevant services is observed.

According to the results of verification of the technical condition and testing of internal firefare water supply on water production, appropriate acts are drawn up in 2 copies.

Rolling of fire hoses, water testing tests

GC "Fire Safety" will quickly and efficiently work on the pumping of fire hoses in a double ride, on a new edge with the design of all the necessary documents.

To ensure the constant readiness of fire sources of water supply and successful use, the following basic measures should be ensured:

- systematic control over the state of water sources;

- timely preparation of fireproof water supply to operating conditions in spring-summer and autumn-winter periods;

- testing of water supply networks on water production and drawing up acts according to water production;

- accurate accounting of the entire fireproof water supply;

- establishing an operational relationship with plumbing services of the city, districts and objects.

The test of the internal fireproof water supply (fire crane) on the waterproof, the pumping of the fire hose to the new ride. Validating performance check

Fire Crane is one of the components of the internal fireproof water supply and applies in cases of occurrence on a fire facility, as primary tool Fire extinguishing, before the arrival of fire units. Therefore, the fire crane should always be in good condition, for which the annual periodic water testing tests are produced, checking the efficiency of the ruling pumps (fire pumps), and is also transferred to a new rack of fire hoses. It should be noted that such tests and inspections have the right to hold only a specialized organization that has an appropriate fire safety license.

Checking the internal fireproof water supply (fire cranes) are held in order to establish health shut-off valvesmounted on fire cranes, as well as verification of the compliance of the main hydraulic parameters (pressure when the height of the water jet, the flow rate of the fire trunk) requirements of the joint venture. 10.13130.2009 and SNiP 2.04.01-85 *.

Our specialists qualified and quickly check your internal fireproof water supply on working capacity and water production (it also includes tests of fire cranes and testing fire hydrants). Checking the fire station is a prerequisite for the norms and rules for ensuring security in the event that in the enterprise, factory or other institution fire situation. Fire fiber water supply allows you to provide the first help before the arrival of the firefighters and EMERCOM employees, which is why its serviceability must be regularly checked.

Upon completion of checks and testing internal water pipes, the necessary acts and test protocols are drawn up, your fire sleeves roll up on a new sputure of the rod, the heads of the sleeves join the fire crane. The fire pipe, which should be conducted regularly allow you to not worry about fire safety, and thereby ensure quality conditions for your work. In addition, the check should be carried out by a specialized organization with a license for this species work.

Remember that the fire pipeline plays a very important role to ensure your own security and security of those who are with you nearby. Employees of GC "Fire Security" will be prepared fire equipment and internal fireproof water supply to autumn-winter and spring-summer period of operation.

The cost is calculated depending on the number of fire cranes on the facility. In any case, the price level allows you to say that we offer services at a profitable and attractive price, both for government customers who are limited in budget and financing and for private customers. Checking the fire station is made in the shortest and convenient time for you. When conducting work on the test of fire water pipeline, modern equipment is used, the works are performed qualitatively and with maximum accuracy. The technique allows you to check and test the internal fireproof water supply to return without unnecessary water consumption.

| No. p / p | Types of jobs | Price | Notes | |

| 1 | Rolling of fire hoses on a new edge (rut) | from 450 rubles per unit. | Upon completion of the work, an act of rewinding is issued, the tag with a duty of rolling is attached to the sleeve | |

| 2 | Check fire cranes for waterproof | from 900 rubles per unit. | ||

| 3 | Verification of pump pumps | 5000 rubles for units. | According to the inspection, an act is issued | |

| 4 | Testing roof fences | up to 100 pm | from 150 rubles for 1 pm | According to the inspection, the act and protocol is issued |

| from 100 or more | from 100 rubles for 1 pm / m | |||

| 5 | Test stairs | According to the inspection, the act and protocol is issued | ||

| Staircase vertical | up to 10 pm | 3000 rub. | ||

| from 10 to 20 pm | 4300 rub. | |||

| from 20 pm | 6000 RVB. | |||

| Transition staircase (on the roofs) | up to 7 pm | 3000 rub. | ||

| more than 7 pm | 3600 rub. | |||

| Staircase marching (section) | up to 2 marches | 3600 rub. | ||

| from 3 to 4 marches | 6000 rubles | |||

| more than 4 marches | 2000 rubles. For march | |||

| Minimum cost of work on testing stairs and fences 12 000 rubles | ||||

Our customers are satisfied with the quality of the services provided, you will not have to clean up after testing, as often happens in other organizations. The fire fighter plumbing performs important roles for any room and the question of its health can not be postponed. Everything necessary equipment And we bring the tanks on the test of the water supply on their own.

We are ready to answer all your questions and promptly perform a set of work to ensure your fire safety.

All work is carried out in accordance with modern fire safety standards: the methodology for testing internal fireproof water pipes is approved by the Ministry of the Russian Federation on the Russian Federation; SP 10.13130.2009 System Rules Set fire protection. Internal fireproof water supply. Fire safety requirements.

Mandatory condition for fire checks is the inspection of fire hydrants for waterpart. This event allows you to identify the serviceability of the equipment, and other moments of which fire safety may depend directly. Responsibility for the condition of fire cranes carries a local water volokanal or the organization they are attributed.

If the organization is not listed on the balance of water, then this event The company conducts with the help of specialized companies that have a relevant license.

Based on the established fire safety regulations in the Russian Federation, fire hydrants should always be working and ensure due consumption of water to repay the fireplace.

Checking fire hydrants on waterproofing will include:

- superficial inspection of fire hydrants;

- checking cranes for waterproof;

- new rack of fire hoses.

The goal that the inspection of fire hydrants on waterproof is pursued - determining the cost of water to extinguish the focus of ignition and compliance with them to all standards and requirements. The test of hydrants is usually carried out before they are commissioned, after repair and every six months (autumn and spring) during inventory. In addition, pumps, valves, as well as pipelines for tightness are checked.

The fire hydrant is designed to take water from the water supply network to extinguish and eliminate fire. With periodic two times a year, all fire hydrants must be checked. GC "Fire Safety" has accreditation for this type of work and specialists who have extensive experience in the MES system.

The list of works on the inspection of the fire hydrant includes:

- Hydrant mass;

- Hydrant housing;

- Hydrant height, overall and connecting sizes;

- The inner diameter and size of the square hydrant rod;

- Valve stroke and its size;

- Spindle's gap and backlash back;

- Fastening the lid of the hydrant;

- The quality of castings, deviations of the size and mass of castings;

- The number of the remaining water in the hydrament;

- Diameter and threads of the drain canal;

- Thread nipple;

- Fastening nipple.

Responsibility for the health of fire hydrants carries an organization that controls the operation of water supply and sewage.

Checking the fire hydrant on waterproof includes:

- Water consumption;

- The number of rod speeds to the full opening of the valve;

- Hydraulic resistance;

- The rotating time of opening and closing the valve key.

The service life of hydrants is determined on the basis of the analysis of operational observations. Tests of hydrants on:

- Operating pressure;

- Tightness;

- Probability of trouble-free work;

- Pressure pressure of the pressure in front of the hydrant and at the output of it;

- Mechanical strength Valve and its drive.

Conducting the inspection of fire hydrants is a very important point, since when the fire occurs, it is impossible to extinguish the fire with a faulty hydrant. Only qualified specialists should conduct such checks. GK "Fire safety" in the most short time Will the necessary tests of fire water supply on water production. Checks all fire system - This is a prerequisite for security in enterprises and other institutions. A working fire hydrant allows you to quickly eliminate the focus of ignition. Regular carrying out of such work will increase the quality of work and not worry about their safety when the fire occurs. If the fire hydrant malfunctions are detected by our employees can be held repair work to eliminate breakdowns. The technique used by us makes it possible to test hydrants for water production without unnecessary water consumption.

We also provide everything you need to check the equipment and according to the test results we give all required documents (Acts) for waterproof and efficiency.