Wooden floor beams: types, calculation and features of choice. Metal floor beams: types and properties General information about the device and purpose

The flat and monotonous "smoothed" landscape of the steppe zone is brightened up and enlivened by their picturesque outlines, it is they - the beams. How is this landform formed? What is a beam, and what are its main features? In this article, we will try to answer all these questions.

Fluvial relief - what is it?

The relief formed by surface watercourses (permanent or temporary) is usually called fluvial (from the Latin word fluvio - “flow, flow”).

Any water flow performs a certain geological work, namely: it destroys solid blocks of rocks (erosion process), transfers the product of destruction and deposits it in a new place (accumulation process). As a result of this work, many different forms of relief are formed on the earth's surface: meanders, gullies, ravines, alluvial cones, trails, and others.

Fluvial processes are possible only under certain climatic and geological conditions. The most suitable terrain for the formation of fluvial landforms is a flat area composed of "soft" rocks, with sufficient moisture and sparse woody vegetation. In other words, these are steppe or forest-steppe natural zones.

The classic series of erosional landforms created by surface streams looks like this:

- Furrow (erosive).

- Gulp.

- Ravine.

- Beam.

- River valley.

Moreover, this series is evolutionary. That is, each of these forms eventually passes into the next in exactly that order.

What is a beam? Where and under what conditions is it formed? In what follows, we will describe this form of fluvial relief in more detail.

What is a beam?

Beams, ravines, valleys - without all these objects it is impossible to imagine the classical steppe (Ukrainian, Russian or Moldavian). By the way, it is in the cultural heritage of these peoples that these landforms are often mentioned - in fairy tales, stories, songs and legends.

However, the word "beam" has several meanings. In addition to the above-mentioned relief form, this term also denotes a structural element made of wooden beam, serving as a support for something. In addition, the beam is another part of the car suspension.

The definition of a beam in geography is as follows: it is negative, linear elongated shape relief formed by temporary water flow. At the same time, its bottom can be dry, or filled with a small stream. The beam is a typical "product" of erosional geological processes.

The main features of the beams

The slopes and bottoms of the gully are covered with dense herbaceous and shrubby vegetation (sometimes with small areas forests). This feature distinguishes it from the ravine, the bottom of which is not turfed and is more prone to erosion. Most often, the beam develops precisely from the ravine, but not always. Under certain conditions, it can bypass the gully stage of "fluvial evolution".

In the steppe relief, the beam, as a rule, is clearly and vividly expressed. Very often, rocky outcrops and outcrops of deeper rocks protrude on its slopes. This is especially true for the beams of the Donetsk Ridge.

The bottom of the beam is most often flat and expanded. However, the closer to the upper reaches, the narrower it becomes. Unlike ravines, ravines are characterized by a branched structure. In terms of their shape resembles a branchy young tree or bush. Some especially developed beams are complicated by longitudinal side terraces - leveled stepped platforms, composed of alluvial sediments.

Structure, dimensions and types of beams

Beam parameters can be different:

- Length - from several hundred meters to several tens of kilometers.

- Width - from 50 to 500 meters or more.

- Depth - from several meters to several tens of meters.

The structure of any beam includes the following elements:

- Brovka.

- slopes.

- Bottom.

- Thalweg (line of maximum depth, measured along the bottom).

According to the shape in the plan, all beams are divided into straight, curvilinear and tree-like; by size - small, medium and long; according to the complexity of the organization - into single and branched.

Examples of famous beams

So, what is a beam, we have already figured it out. This form of relief is typical for the steppe zone of Ukraine and temperate latitudes of the European part of Russia. Let's get acquainted with the most famous examples of beams in the territory of these two states.

The Severnaya Krasnaya gully is located on the outskirts of the Ukrainian city of Krivoy Rog (see photo). Its total length is 36 km, the maximum depth is 30-40 meters. Today, the territory of the beam is declared a protected area. On its slopes there are outcrops of ferruginous quartzites, whose age is estimated by geologists at 3-3.5 billion years.

Kamenny Log is one of the most beautiful beams in Russia. It is located in the vicinity of the village of Koshlakovo, Belgorod Region. Dozens of Red Book plant species grow within the beam - yellow and perennial flax, feathery feather grass, Cretaceous thyme and others.

Sotera is one of the most picturesque beams of the Crimea. It is located near Alushta and the village of Solnechnogorsk. The beam attracts the attention of a huge number of tourists due to its natural monuments - the unique "Stone Mushrooms" and the Grazer waterfall.

Despite cost reductions in construction industry, consumed still make a pretty decent revenue for firms that produce building materials. Many people are now buying the right materials for self construction, the same applies to metal beams, metal is one of the most durable and affordable bases for the foundation and frame of a building.

What are beams and what are they made of

Beam is important element in the design, it is placed to increase stability and strengthen the structure. metal beams are made most often of steel, their action is directed to bending. If the structure is too massive, then the beam is made of an I-beam, it looks like two connected letters t. With this section, the load on the material is distributed evenly and resistance increases.

Beams are not only made of metal joints, there are also wooden ones, they are used in more simple construction, they cannot be manufactured with different types sections, so they are ordinary timber With different length and width.

Types and properties

Beams are distinguished by size, they are assigned numbers by which you can select the desired characteristics individually for construction:

- Size "10" - the smallest by standards, is used as a ceiling, strengthens moving elements in buildings. It can be installed as a guide structure for lifts, provided that they are small.

- "12" - the beam will be slightly larger, and, accordingly, can withstand more pressure. Most often used as the basis of frames, installed in mechanisms and machines.

- Number "14" is more massive and helps to create more loaded floors, it is subject to installation in reinforced concrete structures, such are often installed in industrial construction.

- The "16" beam is distinguished by its strength and can already be a full-fledged support; it is installed not only to ensure the stability of the gran-beams, but also for the movement of shop transport along rail lines.

- Beam "18" can be used specifically in the construction of buildings, creating a reliable support. If you need to support large mechanisms or ensure the stability of wide areas.

- "20" number is already included in the number large beams, it can be the base for columns or frames for engineering.

- "25" - is no longer so often used in the construction of houses, but it will be a reliable time for any lifting mechanisms, even large cranes.

- "30" number is also used as the basis for lifting, but unlike "25" it is made wider and longer, this provides higher resistance under heavy loads.

Aluminum and steel floors, their pros and cons.

Often used in construction aluminum, more precisely its alloys, it quite resistant to environmental influences, but does not know how to be so stable under weight load. Compared to steel, they are lighter and thinner, but most often they have to be thickened for extra strength. In the construction of structures, both materials can be used, depending on the volume of construction, since industrial production is a more voluminous work with strong fortifications, but small buildings can be assembled from aluminum, it is economical and easy to use.

There is one important feature - metal when exposed high temperatures melts, literally melts, creating a homogeneous mass that cannot be restored, while aluminum, when heated, does not turn into a melted puddle, but, on the contrary, when the temperature decreases, it is restored to its normal form. Of course, not in every production environment has a temperature of 80 degrees, so there will be no deterioration with normal heating. From the side of chemical designations, iron has more noble compounds, and aluminum has not received recognition from chemists.

There is such a thing as the modulus of elasticity, it is responsible for the resistance of the material to regeneration after strong pressure, that is, if the action of the beam is directed to bending, then it should not bend, so than more pressure, the higher the modulus of elasticity should be. Aluminum alloys have an elastic modulus of 70.000 MPa, which is three times less than the same indicator for iron. It is on the basis of this that a plan for the location of the beams is built, their bearing capacity is calculated.

Shapes, thickness and height

The difference in shape and size is determined in accordance with the numbers of the manufactured beams, they can be either small and narrow with a solid shape, or massive I-beams, which are easily recognized as a support for large working cranes. Individual production allows you to order the basis for movable structures with specific indicators and shapes. The most important thing is that the height must always be increased by 1.5 times, this will shrink and other construction work.

Usage

The main purpose of metal floors - industrial engineering, it is different from civil special requirements. Most often, developers for these buildings already have ready plan, therefore, there will be no problems with sketching the project, but for such an industry, the material must have all the certifications, because the structures will be used for mass gatherings of people or large factories that are tested for strength by government agencies.

At the same time, complex metal constructions really large customers can afford it, their price is quite high, and aluminum is most often used in civil engineering, although it is not so durable, but it is not necessary to spend money on additional anti-corrosion treatment, and the material can withstand the standard load of a residential building.

Technologies modern construction industrial buildings and residential buildings today, as before, among the structural elements of structures, various kinds of structures are used, united by one name - a beam. According to its purpose, this element of the building is designed to play the role of a bearing mechanism. Located on two or more pillars of the building, such an element takes on the load and allows you to create interfloor ceilings, to connect spans, is one of the main elements roof structure building.

Traditionally, in the construction of buildings, beams are used that correspond to the type and purpose of buildings, and therefore there are different kinds classifications of these elements. Most often, the classification is carried out according to the type, purpose, form and material of this structural element.

General information about the device and purpose

In construction, beams are classified, first of all, depending on how many supports it lies on:

Structurally, the simplest beam used in low-rise frame-panel housing construction for the device attic floor, is a solid beam rectangular shape, but for more demanding installations than simple country house elements that are somewhat different in shape and capable of withstanding heavy loads are required:

Moreover, special requirements apply to the materials of construction:

The most popular in construction, in the construction of roofs of industrial facilities, are used T-shaped or I-shaped profiles, they are the main elements of roof structures here. This is due to the fact that this form works most efficiently under bending loads.

I-beams - in their form cross section resemble the letter "H". Each element has its own name - the vertical parts of such a letter "H" are called shelves, and the dash connecting them is called a wall. Due to this shape, the profile is able to withstand greater loads than a rectangular material in cross section. In addition, I-beam structures allow the use additional methods increasing the strength of the structure:

- for the most critical sections of the roof, I-profiles with a thickened wall are used;

- for secondary sections, crossbars are used, the inner edges of the shelves, which are parallel to each other;

- to increase the rigidity of the structure, profiles with a slope on the inner edges are used.

Materials and technologies for the manufacture of floor elements

Depending on the purpose of the building, the technology of its construction and the conditions for its subsequent operation of the roof, the beams are classified both by the type of material used and the method of manufacturing the finished element:

- Reinforced concrete structures:

- are made by the method of monolithic mold casting with the obligatory use reinforcing cage in the factory, as a rule, these are T-sections of a complex frame structure;

- monolithic structures - produced by mold casting directly on construction site in the construction of buildings using monolithic-frame technology.

- Metal:

- metal elements made by the method of hot rolling of metal of the finished form;

- special types of products individual elements connected by welding;

- products from light alloys for special types of roofing - stadiums, concert halls, exhibition centers.

- Wooden:

- from a solid bar of various sizes;

- composite crossbars made of separate parts, interconnected adhesive method using like natural wood, and materials based on wood - plywood, fiberboards.

Classification and marking of steel elements

The classification of steel structures is carried out and has its own alphanumeric code. Such coding makes it possible to carry out the necessary classification and take into account the elements necessary for the parameters in construction even at the stage of developing design and estimate documentation.

The basis for this type of classification are officially approved state standards and specifications, according to which all types of beams are classified, regardless of the material of manufacture or manufacturer.

So, in the marking of steel I-sections, in addition to indicating their dimensions, and the height can be from 100 mm to 1000, an alphabetic code is also indicated, which indicates, for example, the dimensions of the edges of the shelves:

- "B" - means that the product has a normal width of parallel faces;

- "W" - indicates that the shelves have an increased width and are classified as "wide-shelf" products;

- "K" - says that such a profile can be used as a column support.

The use of wooden elements in various roof structures

In low-rise housing construction, during the construction of the roof, beams are used as elements of various purposes and sizes:

The most suitable for performing such functions are I-glued wooden elements, which have great strength, can withstand heavy loads and are light in weight compared to solid wood lumber. feature of all kinds wooden structures used in the construction of the roof of a building is the use of lumber conifers for the device of rafters, struts, frame partitions and hard wood for the device of the attic floor.

Sergey Novozhilov - expert in roofing materials with 9 years of practical experience in the field of engineering solutions in construction.

I-beam or I-beam is one of the established standard profiles of structural building elements. Its name comes from the Latin word taurus, which in translation means - a bull. This is most likely due to the fact that in its cross section the I-beam has the shape of two connected letters T or the letter H, and, therefore, has two horns. The main purpose of such building element is the reception of a vertical (less often horizontal) load, which creates it with separate parts of the structure. After that, due to its design, the I-beam evenly distributes it to the rest of the supporting areas or transfers this load to load-bearing elements designs. An I-beam is usually made from rolled ferrous metal, but there are also wooden I-beams. For rolling, carbon and low alloy steels are usually used. In the cross section of an I-beam, as a rule, a wall and two shelves located at the ends of the wall are distinguished.

Types of I-beams and their scope.

The main area of application of I-beams is the overlapping of multi-storey buildings. In addition, the I-beam is widely used in the construction of bridges, less often in mechanical engineering and car building. It is not uncommon to use an I-beam for reinforcing passages in mines.

The main area of application of I-beams is the overlapping of multi-storey buildings. In addition, the I-beam is widely used in the construction of bridges, less often in mechanical engineering and car building. It is not uncommon to use an I-beam for reinforcing passages in mines.

I-beams are divided according to the following parameters:

- By wall thickness;

- According to the location of the shelves: parallel and with a slope.

Parallel, in turn, distinguish:

- B - normal.

- D - mid-shelf.

- K - columns.

- U - narrow-shelf.

- Ш - wide-shelf.

I-beams with a slope are also divided into:

- M - ordinary, in which the shelves have a slope of the inner edges of up to 12%. They are usually used for overhead tracks.

- C - special, in which the shelves have a slope of the inner faces of more than 16%. Such I-beams, as a rule, are used to reinforce mine shafts.

There are also wooden I-beams. They are mainly used in frame housing construction. Their use can significantly reduce the installation time of the building and its total weight. In addition, the use of an I-beam eliminates such phenomena in scrap as shrinkage, shrinkage, shifts, cracks, etc.

I-beams- this is the main component of any work site in the construction of bridges, ceilings, industrial buildings. The use of beams can significantly reduce loads and reduce metal consumption. Beams allow you to recreate the shape of the supports, and their use leads to a significant reduction in the weight of metal structures.

According to the accuracy of rolling, the I-beam is divided into:

B - increased;

B is normal.

I-beam

The modern era is notable for the fact that before our eyes there is a widespread displacement of large-block reinforced concrete structures monolithic building. It has a whole range of advantages - starting from the strength of the structure, which primarily depends on the quality of the connection of the elements. The monolith has practically no connections, so it happens that during an earthquake, the monolith house tilts or even collapses on its side, but does not crumble into pieces.

For casting horizontal slabs, a unified formwork is used, one of the main parts of which is the slab beam. Resting on vertical posts, the beam directly supports the deck of docked plywood boards, on top of which is poured and solidifies concrete mortar with pre-assembled fittings.

Practice has shown that the most rational is wooden beam double section.

Features of an I-beam.

The I-section, which has the form of the letter “H” lying on its side, is the most rational profile from the point of view of the resistance of materials. It consists of 3 elements, while having rigidity and strength for deflection and twisting, which are not much inferior to a full-bodied rectangular beam, at the same time being much lighter. Besides quality boards from the same volume of raw wood you can get more than a bar of the same quality - less culling for natural defects.

This makes the I-beam a much more economical type of tooling. An I-beam correctly glued from several parts is less susceptible to warping when the wood dries out, and under conditions concrete works this is not uncommon.

In addition, as already mentioned, the lower weight compared to solid timber makes the formworker's work less difficult and less traumatic.

A rented I-beam will help you out!

Courage architectural solutions poses difficult tasks for modern builders, including providing the construction site with the necessary equipment. A reasonable solution is often to rent I-beams and other construction equipment from specialized companies that have sufficient resources to satisfy their customers. This is our "ArendaStroy". We have a fleet of quality timber I-beams for formwork. Sign a lease agreement with us - and a number of issues will be safely closed.

Beam types

A beam is a solid element that works mainly on transverse bending and perceives the load located in the span, transferring it to the supports.

Most common in steel structures have split beams due to the certainty of their work, as well as ease of manufacture and installation.

The most suitable beam cross-sectional shape for bending, as you know, is an I-beam. It is not excluded the possibility of using a channel profile as well, if it is structurally convenient.

Beams are rolled and composite. If possible, one should strive to use rolled beams as less labor-intensive. However, due to the limited range of rolled beams, powerful beams that perceive large moments have to be designed as composite welded or riveted beams.

Welded beams are made up of three sheets: one vertical, called the wall, and two horizontal, called, which are welded to the wall.

Riveted I-beams are made up of a vertical sheet - a wall - and belt corners that are riveted to the wall. If it is necessary to use powerful riveted beams, then horizontal sheets are riveted to the corner shelves to increase the moment of resistance.

Welded beams are more economical than riveted beams. Therefore, the latter have limited use, mainly in heavy structures, as well as in structures subjected to large dynamic or vibration loads.

"Design of steel structures",

K.K. Mukhanov

A flat sheet metal deck is positioned and welded to the flanges of the beams. The thickness of the flooring is assigned by calculation, most often depending on the accepted allowable deflection, since full use stress in the sheet for a given deflection is not always possible. Therefore, the calculation of sheet flooring is carried out according to standard loads. The peculiarity of sheet flooring is that, by the nature of its…

The general dimensions of the beam are its calculated span and section height. The calculated span of the beam l is the distance between the centers of the supporting parts; thus, the actual length of the beam ld is always slightly larger than the calculated span. The distance l0 is called the distance in the light; it is usually determined by the operating conditions of weapons and is justified by economic considerations. The general dimensions of the beams The section height h is assigned, ...

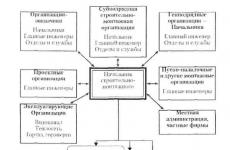

When designing beam structures, as a rule, it is necessary, depending on the purpose of the beams, to draw up a diagram of their location, outline the general dimensions and determine the load on the beams. If it is necessary to cover a certain area, the beams supporting the ceiling are usually located in two directions. This construction, which sometimes consists of whole system intersecting beams is called a beam cage. On a beam cage can ...