House made of porous bricks. Houses made of ceramic blocks. Ceramic brick by appointment

Ceramic brick has been one of the most popular and widespread building materials for many years. It is based on clay, and it is added various impurities that give the finished product certain properties. When it comes to building walls and various buildings, then the first thing they think about is this reliable material. In this article we will talk about the pros and cons of a house made of ceramic bricks.

Popularity

Its main advantage is that this material is quite durable, resistant to moisture, a strong drop in temperature, and conducts heat well. For developers, ceramic bricks have earned mostly positive reviews during the construction of the house. That is why such material now occupies one of the leading positions, despite the huge variety of other masonry products.

Projects of houses made of ceramic bricks come in different heights and designs. This material is used not only bearing walls, but also interior partitions. Houses made of ceramic bricks are not only durable, but also undeniably environmentally friendly. All this is achieved due to the fact that during the manufacture of these building materials only natural substances are used that do not harm humans. But the projects of houses designed for ceramic bricks have their pros and cons.

Specifications

The main advantages that this material has are considered:

- High density of each brick;

- The structure of ceramic products is relatively porous;

- The ability to maintain its properties even with a large drop in temperature (very important for houses in our country);

- Good strength of the constructed walls;

- Houses made of red ceramic bricks are distinguished by high thermal conductivity and water absorption.

The density of the material is characterized by a mass of 1 m³. This indicator is inversely proportional to porosity, and also affects the thermal conductivity factor of the wall of a house made of ceramic bricks. There is a large assortment of this material in specialized stores. Density can be from 1000 kg/m³ if the base is hollow up to 2100 kg/m³ for clinker ceramic bricks. The main types are shown in the photo below.

During the development of a house construction project, it is necessary to calculate the amount of material with different properties. Some walls (especially interior partitions) can be built from cheaper, but less dense ceramic bricks, which also have many positive reviews, as well as analogues with indicators of 2100 kg / m³.

During the construction of a house, each person is looking for a way to save money while not reducing the final quality of the building. To do this, even at the stage of project development, several options for materials from which walls can be erected are considered. Each of them has its pros and cons. It is best to get feedback from people who regularly deal with these substances. If you decide to build a house of ceramic bricks, then you need to remember about its main advantages and disadvantages. The video below describes the basic principles of building walls from this material.

Advantages

If you are thinking about building a house from ceramic bricks, then remember the following advantages of this material:

- In its form, it has a small size, which allows you to build buildings from it. different types and external design. Even on the Internet, it is easy to find drawings and calculations of houses and ceramic bricks, as shown in the photo below. Turning to the developers, you will always pick up turnkey solution, which can best meet your requirements;

- When your house is ready, there will be no problems with its exterior finish. Besides the fact that this brick looks good on its own, it can be coated with any decorative material. If desired, it is easy to finish the structure with wood panels;

- A house made of this material will always be very durable and reliable. It can withstand strong temperature changes, adverse weather conditions. Some doubt whether it is possible to build a house of ceramic bricks in stripes with a cold climate, but do not worry, even a very strong cold is not terrible for such a structure;

- Great durability. The structure of this material has a long service life. Even in 100 years, such a house will not be needed overhaul. The main thing is to comply with all norms and rules during construction;

- Ceramics has great heat and noise insulation;

- The material is completely environmentally friendly and does not contain substances harmful to human health.

Flaws

But it is worth remembering the main disadvantage that such a brick has:

- It's quite expensive. If you decide to build big house from this material, then be prepared for the fact that it will cost you a fairly large amount;

- In addition, he requires strong foundation. If you decide to make a two-story building, then get ready to lay a serious foundation that can withstand such a heavy structure;

- It should also be borne in mind that the small size of the bricks stretch the process of building a building for a longer time.

These both minuses and pluses must be taken into account while you are going to build a house from ceramic bricks.

Porous brick quickly gained popularity among builders and buyers due to its special properties. You can find a lot of positive feedback about this material, but many try to ignore the shortcomings.

Porous brick is not ideal, but its distribution in Europe and Russia is in no way associated with some disadvantages. In most cases, they are subjective and based on the private opinion of users.

Building a house from porous bricks also has a number of features that should be taken into account, ranging from a well-designed project to the qualification level of builders. By contacting our specialists, you can quickly and efficiently carry out brick house construction . Years of experience construction of cottages and private houses allows the InnovaStroy team to create structures of any complexity from the material you choose.

Porous brick house: material properties

First of all, it should be noted that the described material has a lot of positive qualities. "Porous" means the presence of microscopic pores in the mass, which give the blocks and bricks their unique properties. Let's consider them in order.

Strength

The most important indicator that is considered when choosing building materials. The special structure with internal voids ensures that enough high pressure on any side of the brick - up to 150 kg / sq. cm. In this case, the internal pores serve as additional local foci that counteract the pressure on the material. Construction of a private house from porous bricks– a guarantee of its service for more than 100 years. This has been proven by numerous experiments and practice in Europe.

Environmental friendliness

Porous brick blocks are made from clay and organic impurities. After firing at 1800°C, all fine fractions burn out and form the famous pores in the mass of the material. Except natural ingredients The block should not contain anything.

Insulation

We combine this term with sound and heat insulation. Thanks to internal voids and pores, brick blocks provide ideal protection. The resulting air barrier prevents penetration sound waves and reduces heat transfer three times, compared with gas blocks. Construction of cottages from porous bricks in InnovaStroy is provided minimal cost for additional external coating with heat insulators.

physical characteristics

The industry has several standard sizes for porous brick blocks. All of them are quite large and voluminous, replace from 15 standard bricks. This reduces the amount of building material in the construction of walls and ceilings, reduces transportation costs. With its dimensions, for example, 250x120x128 mm, or 260x250x215 mm, it weighs around 4-6 kilograms. They are easy to carry and install. At the same time, the construction of a wall takes 2-2.5 times less time than when laying with ordinary bricks. Building a house from porous bricks is facilitated by the fact that the side faces have zigzag keys that do not require cement mortar. They create an additional air barrier in areas of greatest heat loss - at the seams.

Saving

Due to its low weight, the entire structure of the cottage is quite light. This means that such a house can be built on any soil and use light foundations. It is enough that the width of the support in the strip foundation is equal to the width of the bearing wall, and you can build a cottage. Also significant savings are obtained on the solution. Porous brick blocks require only 2 mm joints between rows. Taking into account that the seams themselves are 5 times less than with brickwork the savings are tangible.

Construction of a private house from porous bricks: disadvantages

All cons this material are technical in nature and can be easily leveled if order an individual house project from the professionals of our company and entrust them with the construction of a cottage. To evaluate the effectiveness of using porous bricks, the disadvantages also need to be voiced:

- Price. The price for each block is quite high due to the peculiarities of production. All natural materials require financial contributions. Although, if you reduce all the points described above with savings, then the final estimate looks quite attractive. Of course, if it was compiled by our specialists who care about your every ruble.

- Complexity of processing. Despite their positive properties, porous brick block has a certain level of brittleness. That is, to cut off the floor of the block or create a curly cut, you need to use special equipment. If the construction will be carried out by our company, then this drawback can be ignored.

- Floor limit. According to the practice of the company, it is worth noting that porous bricks are enough to build a cottage on three floors. He will normally cope with the functions of load-bearing structures. If a more serious building is required or your cottage should have a unique shape, then it is better to use a monolithic frame, and build walls and partitions inside the house from porous bricks. This is also a dubious drawback, but to many it seems very significant.

Does it make sense to build a house of porous bricks?

The answer may seem predictable, but all the advantages of the material described above confirm that there is a point in building, especially since the porous brick block has been popular in private construction abroad for many years. With its main disadvantage - the price, the material has so many advantages that it covers any shortcomings. With proper design and rational budgeting, you can ensure that the cost of the cottage will be very profitable.

Do not discount the fact that a well-built porous brick house can last more than 100 years. It will be a reliable stronghold for your family, children, grandchildren and future generations.

Order the construction of a porous brick house now

The InnovaStroy company has vast experience in the construction of structures from porous brick blocks in any region of Russia. Competent design and use of the latest computer programs help to create technically correct documentation for the full construction of your cottage. Attracting only qualified builders and reliable suppliers guarantees high quality construction. Taking into account all the wishes of the customer and the positive characteristics of the material will provide an excellent result when building a cottage from environmentally friendly material.

Porous ceramic brick is a special building material that combines all the advantages of classic red brick and aerated concrete, but is completely devoid of their disadvantages. It is not for nothing that the second name of such a material is warm ceramics, which fully corresponds to the qualities of porous bricks. It is characterized by the highest strength, low weight, and this allows you to reduce the load on the foundation, improve thermal insulation without the use of additional layers of insulation.

Porous brick or, as it is also called, “warm ceramics”, has improved thermal insulation, low weight and high strength.

Houses made of porous bricks are distinguished from other analogues by reliability, warmth, efficiency, attractiveness, high comfort and energy saving. Let's find out how the masonry from this building material differs from others, how to calculate the amount.

Advantages of residential buildings made of porous bricks

Increased block sizes significantly speed up construction and save cement mortar.

A modern porous brick building has numerous advantages:

- The highest strength of porous ceramic bricks allows the material to withstand loads up to 150 kg per square meter. see This allows you to build a residential building up to nine floors high. For example, the strength of ordinary aerated concrete is only up to 50 kg per square meter. cm, foam blocks - only up to 200 kg per sq. see, which significantly limits the possibility of conducting construction works. Ordinary ceramic or silicate grades M-75 and M-100 also have lower rates: only 75 and 100 kg per square meter. cm.

- Convenient sizes. Often, instead of the expression “porous brick”, “porous stone” is used. This is due to the fact that the dimensions and shape of the porous product are very different from the standard. Its dimensions can range from 260*250*219 to 510*250*219 mm. Such increased dimensions greatly speed up construction. It takes a lot less material to build a house.

- Light weight. Despite the fact that the dimensions of the porous product are larger than usual, its volumetric weight is less, it is only 80 kg per cubic meter. m, and this can be compared with materials such as foam concrete or aerated concrete. For comparison: the density of traditional ceramic red brick is 2000 kg per cubic meter. m, which is almost two and a half times more.

- The low density of the material gives real opportunity greatly reduce the load on the foundation of the house. This advantage allows you to make the foundation not so massive, you can save significant funds on its construction. At the same time, the house retains its strength characteristics, remaining reliable and stable.

- Thermal insulation. Porous brick is characterized by low thermal conductivity, which allows you to build very warm house, without arranging an additional layer of thermal insulation. It is enough to lay walls with a thickness of only 40 cm in order to fully meet all the requirements for energy saving at home.

- Fire resistance. Masonry from a porous product is non-combustible, such a house is able to withstand open flame within 3-7 hours.

How else is a porous brick house effective?

When a house is built from ordinary foam concrete, silicate or traditional ceramic bricks, heat loss can be carried out through the seams. When using porous bricks, in order to reduce such losses, not an ordinary cement mortar is used, but a special glue. At the same time, the masonry has a joint thickness of only 2 mm, which makes it possible to seriously minimize "cold bridges". Of the features, it should be noted that the masonry is carried out without the use of mortar for vertical joints, which are tightly connected due to the presence of the groove-comb system.

High resistance even to the most adverse weather conditions. The porous brick perfectly endures numerous freeze-thaw cycles, up to a maximum of one hundred such cycles is possible. This is a biologically inert material, that is, during operation, fungus and mold will not form on its surface, which eliminates damage to the material.

The use of this material in the construction allows you to create an excellent comfortable microclimate in the house. Such buildings have the best sanitary and hygienic characteristics among others.

During construction, you can use a wide range of materials colors offered by manufacturers today. The difference between this brick construction technology lies in the fact that the surface can be faced with any materials, including plastering and much more.

Cons of using

Ceramic porous bricks also have some disadvantages. The main disadvantage is quite high price compared to conventional and other building materials. For example, lightweight concrete is three times cheaper. But, as is often the case, the shortcomings are offset by some other factors.

Using a brick, you can save on material for facade decoration, not worrying about the number of storeys, in this case there are no restrictions.

Such disadvantages as the price, in comparison with ceramic or silicate bricks, are perfectly compensated by the fact that the construction requires a smaller amount of material, and the construction itself in this case is much simpler and faster. For porous ceramic bricks, there is no need to arrange an additional layer of thermal insulation, and this is also a significant savings.

How to calculate the amount of material?

Building houses from porous bricks is a rather responsible process, like the construction of any building. In order for the work to be of high quality and fast, it is necessary at the beginning to correctly calculate the amount of building material. The first thing that affects the design indicators is the thickness of the wall that can be laid out:

- in half a brick, while the house will have a wall 120 mm thick;

- in one, the wall thickness will be 250 mm;

- one and a half, the thickness of the walls will be 380 mm;

- laying in two bricks, the wall will have a thickness of 510 mm;

- if the masonry is two and a half, the wall will have a thickness of 640 mm.

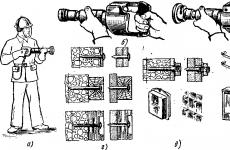

Masonry made of bricks and ceramic blocks: a - chain ligation of masonry made of bricks 65 mm thick; b - also, from a brick 88 mm thick; c - multi-row dressing of brick masonry 65 mm thick; g - the same, made of brick 88 mm thick; e - from hollow ceramic stones.

After that, it is necessary to determine what is the area of the walls, for which the perimeter of each wall is multiplied by the height. To obtain the value of the net area, it is necessary to subtract the area of windows and doorways from the obtained value.

Now, to get the amount of ceramic bricks, you need to multiply the number of bricks 1 sq. m of masonry walls on the perimeters of the building. For example, subject to masonry in two bricks, that is, with a wall thickness of 510 mm, given the presence of a seam, in order to build a house, for every 1 sq. m masonry you need this:

- single - 204 pcs.;

- one and a half - 156 pcs.;

- double - 104 pcs.

If the walls are laid out ceramic material with a laying of two and a half, that is, with a wall thickness of 640 mm, then taking into account the presence of a seam for every 1 sq. m surface will have to:

- single - 255 pcs.;

- one and a half - 195 pcs.;

- double - 130 pcs.

What does the cost of the house include?

Before you start building a house, you need to calculate the cost of this process in order to understand how profitable it will be to use this particular material. It is recommended that such calculations be carried out using special program, which can be easily found on the net, or contact a specialist. But you can get the basic numbers yourself. So, a house made of this material includes:

- the price of the site where the construction will be carried out;

- the total cost of all building materials and tools that will be needed during the construction process;

- payment to the architect, foreman, workers;

- the cost of engineering networks, such as gas supply, electricity, water supply, sewerage;

- transportation costs for the delivery of materials, etc.;

- other expenses that may arise during construction.

The use of ceramic bricks for the construction of today is back in vogue. Especially often recently, porous, which is also deservedly called warm ceramic, has begun to be used.

It has many advantages over traditional building material: light weight, high strength, high thermal insulation performance, which allows you to do without additional insulation, that is, save on materials during construction.

Modern technologies and stages of building a brick house practically do not differ from the old ones: builders lay the same even rows, walls are erected layer by layer. The shape has changed a little, large-format blocks, a cellular structure, new materials have appeared. Manufacturers have improved processes, accelerated production, improved performance, but otherwise the modern one differs from the century-old building only in style. In the article we will talk about the stages of building a brick house from scratch to finished housing, we will dwell in more detail on the materials, features and technology of erecting stone buildings.

Stages of building a brick house

1. Site analysis

It is important to determine the features of the territory, the influence of the landscape and conditions on the upcoming construction. Experts evaluate the relief, access roads, distance to the nearest buildings, the presence and location of communications, land use features (security zones, the position of red lines, site development rules). The results of the inspection are analyzed and taken into account in the development of the project.

2. Removal of the building spot

We bring the position of the future home to the area. After the precise definition of the boundaries, it becomes clear how to organize the construction, in which direction to turn the cottage.

3. Geological studies of the soil in the building spot

Before the development of the QOL project (reinforced concrete structures), geological and geodetic studies are carried out. You can’t rely on outdated data, results on neighboring sites - GOOD WOOD always conducts research for a particular house. This is how you avoid trouble stone house weighs a lot, so the foundation must be calculated as accurately as possible.Standard work list:

- we measure the site, enter information about the relief, the location of objects, neighboring buildings into the topographic plan;

- explore geological structure ground, depth ground water;

- we carry out test drilling to determine the characteristics of the soil, possible difficulties in the construction of the foundation.

4. Development of design documentation

According to the results of the geological survey, the designer calculates desired type foundation, then prepares project documentation.

5. Building a foundation

For the construction of stone walls required solid foundation- the foundation must withstand the weight of building stone, reinforced concrete floors, roofs. Lung Options wooden buildings won't fit. Minimum requirement - strip foundation with a sufficient foundation depth, but more often a grillage on piles or a classic slab is used.

In GOOD WOOD stone cottages, a reinforced concrete slab or grillage on driven piles with prefabricated floor slabs is laid as a foundation, depending on the results of geology and geodesy, the recommendations of designers for of this type soil and relief of the site or the wishes of the customer.

Tracks engineering communications lay before filling monolithic slab or laying a floor slab when the foundation is pile-grillage. The foundation receives technical supervision - the engineer arrives three times, evaluates the correctness of the preparation, pouring, and accepts hidden work.

FOUNDATION OF THE HOUSE: we do it without mistakes.

6. Construction of walls and ceilings

Blocks are placed strictly according to the project, taking into account the features of the technology. Waterproofing is laid under the first row - bituminous protection is 10 cm wider than the wall itself. Before installation, if necessary, level the foundation in order to start laying from a horizontal surface with a deviation of up to 20 mm to the area to be checked.

If in a house from ceramic block it is planned to finish with facade bricks, reinforcing mesh is laid.

For connection use the appropriate masonry material - a mixture of Porotherm TM. The mixture is applied only on a horizontal surface - this reduces consumption by a third.

The walls also accept GOOD WOOD technical supervision. Sometimes representatives of Wienerberger come to the site - they check the correct operation construction firms with Porotherm blocks.

Wienerberger representative for construction site GOOD WOOD

On stone walls you can install any overlap - assemble lightweight construction on wooden beams, lay ready-made reinforced concrete slabs, pour a prefabricated monolithic structure. The weight limit is 70 tons per meter of wall.

7. Roofing

Simultaneously with the installation of the roof pie, we install skylights, ventilation outlets, chimneys, output communications.

In most serial projects, a conventional gable is used; for individual design, you can order a single or flat roof, a multi-level structure with steps, a change in the angle of inclination.

8. Installation of windows, doors

Work occurs simultaneously with laying finish coat roofs. The side surfaces are laid using additional elements of the desired width or fitting standard blocks. Rows above the opening are held with a solid or prefabricated lintel.

Jumper design options:

- Reinforced concrete. Heavy prefabricated concrete product, used in most brick buildings.

- Porotherm ceramic concrete lintels. The product is mounted, poured with concrete. After laying 2-3 rows on the lintel, the upper part of the opening gains its final strength.

9. Exterior finish

The type of facade design is planned at the stage of architectural design, so that nothing interferes with finishing. The architect needs to know in advance whether the house will be decorated with bricks, decorative plaster or hanging panels.

Finish option combined houses

Finish option combined houses

Finishing option for combined houses

Finishing option for combined houses

Finishing option for combined houses

Finishing option for combined houses

10. Laying communications

Workers lay wires and pipelines in walls and ceilings, connect permanent electricity, a septic tank, and water supply. If required, we equip the caisson on the well, mount the septic tank.

11. Finishing walls, ceilings, floors

In GOOD WOOD, you can order the development of interior design in any style - from classic to high-tech. We take into account the wishes of the owner, modern tendencies in design country houses, choose quality materials, we follow the finishing technology. Simultaneously with the design of the premises, we install end devices (electrics, plumbing, lighting).

12. Blind area, drainage, finishing work

All stages of the construction of a brick house are carried out with the participation of technical supervision: the engineer is present at hidden work, performing critical stages. The customer, if desired, can also come and check whether the builders are doing everything right.

Advantages of brick houses

GOOD WOOD uses Porotherm ceramics, products of Wienerberger AG, the largest manufacturer of bricks and tiles in Europe. Porotherm is a modern version of the "red" brick. Large-format, small-mesh porous blocks are made from clay, they retain the advantages of ceramic bricks and add a few extras:

- High strength. It is possible to build load-bearing walls of multi-storey buildings from bricks with reinforced concrete floors. The limit for Porotherm is 10 floors.

- Environmental Safety. Brick is produced with a minimum of chemical additives. Porotherm is made using clay and fine sawdust to create pores within the material.

- Ceramics tolerates freezing, moisture, retains strength indefinitely. One of the advantages of building a brick house is the durability of the building. The service life of brick buildings is 100-150 years.

- Any architectural solutions. We build cottages with bay windows, balconies, complex roof, terraces on the second floor.

- Construction is speeding up. One large block replaces up to 14 bricks, reduces assembly time, construction time brick house decrease.

- No insulation required. When using Porotherm 38 Thermo, 44 and 51 blocks, it is sufficient decorative finishes walls.

- Costs are being reduced. It takes less to build walls adhesive solution(the solution is not applied to the side surfaces), the customer pays less to masons (construction is faster), installation of insulation is not needed, the material itself is cheaper.

Projects of brick cottages

Serial

GOOD WOOD architects have developed convenient projects of stone houses:

- . Simple design: no stairs, "extra" rooms. layout one-story houses universal - the classic arrangement of rooms suits most customers.

Project SK-1

Project SK-1 Project TK-2

Project TK-2 - . Two design options are possible - attic floor or a cold attic and ceiling. In houses with an attic, you can install windows in the roof, in cottages with a cold attic in all rooms - a flat ceiling of the same height.

- . Made in chalet style.

Any ready-made drawing can be modified for yourself: add, remove or change balconies and terraces, adjust the layout, size and location of windows, the height of the premises. For significant changes, you will have to recalculate the parameters, others (for example, mirroring, changing the height of the ceiling) are included in the drawings for free.

Individual

Bring your own sketches, tell the architect about your wishes for planning and design, what styles you prefer in architecture - the specialist will develop suitable project. The stages of building brick houses according to an individual project include several stages of coordination - it is important to make sure that the result will not disappoint the customer. We develop and build small cottages and huge estates, high-tech houses, modern classic, minimalism, chalet.

Valid for all built cottages official guarantee GOOD WOOD - 50 years.

How to order the construction of a brick house

Find a suitable serial or individual project in the catalogue, arrange a meeting with the architect and the technical supervision engineer on the site. Specialists will make rough plan works, help you choose a place for construction, tell you how to quickly build a brick house and what is needed for this. Consultation on the site removes 100% of questions about the upcoming construction.