Classification of fire equipment. What is "fire class"

Necessities fire truck classification is needed for the best and well-coordinated organization of operational actions when extinguishing a fire by personnel of the Ministry of Emergency Situations. Before proceeding directly to the classification, it is necessary to understand what was the starting point, what characteristics and features were taken into account before classifying fire trucks.

Security fire safety objects and territories is observed not only due to preventive actions on the part of fire safety supervision and control authorities, but there are unfortunately cases when neglect of fire safety rules leads to sad consequences that are often accompanied by a fire.

Extinguishing a fire is already a direct robot of the combat fire departments of the Ministry of Emergencies, the implementation of which is possible only if there is good fire-technical equipment and fire rescue equipment. The use of fire and rescue equipment is necessary due to the fact that uncontrolled combustion (fire) contributes to the appearance of significant temperatures near the fire and, as a result, the appearance dangerous factors fire - smoke, soot, various toxic substances.

With this scenario, every minute is worth its weight in gold, so the elimination of a fire should be reduced to elementary destruction, due to the supply of a fire extinguishing agent to the fire.

Since burning can be subjected to different types substances with their physical properties, state of aggregation - fire extinguishing agents must be supplied under a certain pressure with a given intensity. The above qualities can be realized through the use of fire fighting equipment.

If we consider what fire equipment is, then we can say that this is a complex of technical means and devices of various configurations and structures used to extinguish fires (or ensure the conduct of fire extinguishing operations), fire localization, protection of people and material values.

To date, fire equipment is represented by a variety of means, ranging from an elementary fire extinguisher to a fire tank.

But if we consider the fire equipment necessary to ensure fire extinguishing, then we will consider in more detail classification of fire trucks.

Accordingly, with the tactics of extinguishing a fire during a fire, it is often necessary to produce robots to rescue the victims, open various structures using a manual rescue tool (,) or. The above-mentioned works can be carried out with the help of special fire equipment (cars) using a special fire tool.

Types of fire trucks

Thus, we will consider the following types of fire trucks, depending on the purpose: main, special and auxiliary.

Each of the types of fire trucks are designed to perform separate functions during fire fighting:

- basic fire trucks serve to transport to the place of emergency (fire) firefighters, water or other extinguishing agents to extinguish the fire and perform tasks as intended. In turn this group divided into cars:

- general purpose - for extinguishing fires in the residential and industrial sector of cities and towns (, fire pumps, first aid fire trucks);

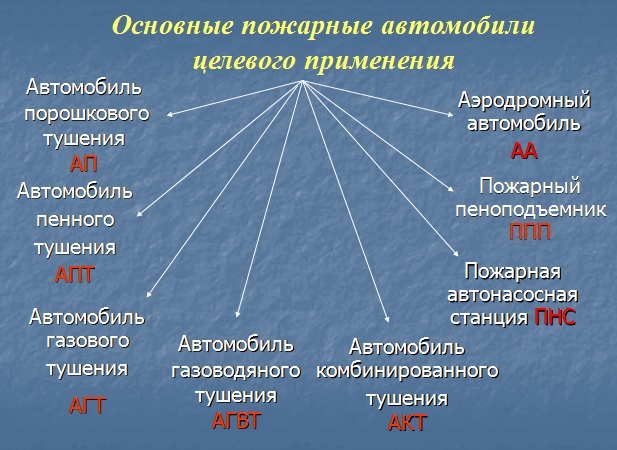

- purpose-built vehicles adapted for extinguishing fires at production facilities in the production of which substances can be used, the extinguishing of which must be carried out with special fire extinguishing compositions, departmental facilities of the chemical, oil production and oil refining industries (air-foam extinguishing vehicles, gas-water, combined extinguishing, pumping station and etc.)

- special fire trucks serve to ensure special work on fire (articulated lifts, cars of gas and smoke protection service, smoke removal, etc.)

- auxiliary vehicles these are vehicles that include vehicles for servicing fire trucks, delivering personnel, fire, special and rescue equipment of the Ministry of Emergencies (tankers, mobile auto repair shops, laboratories, buses, fuel trucks, etc.)

Symbols of fire trucks

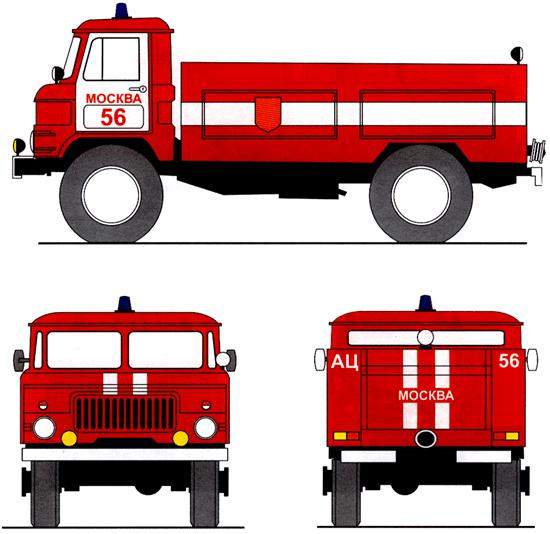

To facilitate the identification of all types of fire trucks, it is customary to use an abbreviation that indicates the functional affiliation of a fire truck to a particular type. Also, this abbreviation is usually denoted on the sides of cars.

For example: fire tank truck - AC, first aid fire truck - APP tank truck, - ASA, etc.

Also, for ease of remembering the characteristics of a fire truck, the basis special name it is customary to add the main parameters of a car to this car: characteristics, performance (for example, 40 l / s in AC-40 (130) 63B) or the lifting height of an articulating lift (30 m in AL-30 (4310)).

According to all fire trucks, it is customary to paint them red - which, as is commonly believed, symbolizes fire, danger, etc. For greater susceptibility, the red color is diluted with wide white stripes.

Same normative document the rule of placement of inscriptions and identification marks is regulated.

So the number of the fire department to which the car belongs and locality indicated on the door of the car, on the rear of the body the type of fire truck (AHR) is indicated.

To enhance the susceptibility of others and everyone's understanding that this is a fire truck, sound and signal beacons are also placed on it. Since the fire truck belongs to vehicles of increased care and importance, flashing beacons are placed on it of blue color.

Concerning sound signal, then today the sound notification of others is made from an electric siren, although there was an option to play a sound signal due to the exhaust gases of a car through a gas exhaust system - (which explains the specific sound of fire trucks in old feature films).

The classification of fire equipment is used to determine its purpose, scope, as well as to establish fire safety requirements for the operation of fire equipment.

Article 42. Classification of fire equipment

Fire equipment, depending on the purpose and scope, is divided into the following types:

1) primary funds fire extinguishing;

2) mobile fire fighting equipment;

3) fire extinguishing installations;

4) funds fire automatics;

5) fire equipment;

6) funds personal protection and saving people in case of fire;

7) fire tool (mechanized and non-mechanized);

8) fire alarm, communication and notification.

Article 43. Classification and scope of primary fire extinguishing means

Primary fire extinguishing equipment is intended for use by employees of organizations, personnel of departments fire brigade and other persons in order to fight fires and are divided into the following types:

2) fire hydrants and means of ensuring their use;

3) fire equipment;

4) blankets to isolate the source of fire.

Article 44. Classification of mobile fire extinguishing equipment

1. Mobile fire extinguishing equipment includes transportable or transportable fire trucks intended for use by personnel of fire departments when extinguishing fires.

2. Mobile fire extinguishers are divided into the following types:

1) fire trucks (main and special);

2) fire planes, helicopters;

3) fire trains;

4) fire ships;

5) fire engine pumps;

6) fitted technical means(tractors, trailers and tractors).

Article 45. Classification of fire extinguishing installations

1. Fire extinguishing installations - a set of stationary technical means of extinguishing a fire by releasing a fire extinguishing agent. Fire extinguishing installations must ensure the localization or elimination of a fire. According to the design, fire extinguishing installations are divided into aggregate and modular, according to the degree of automation - into automatic, automated and manual, according to the type of fire extinguishing agent - into water, foam, gas, powder, aerosol and combined, according to the method of extinguishing - into volumetric, surface, locally -volumetric and locally superficial.

2. The type of fire extinguishing installation, the method of extinguishing and the type of fire extinguishing agent are determined by the design organization. In this case, the fire extinguishing installation must provide:

1) implementation effective technologies fire extinguishing, optimal inertia, minimally harmful effect on the protected equipment;

2) actuation during a time not exceeding the duration of the initial stage of fire development (critical time of free development of a fire);

3) the required intensity of irrigation or the specific consumption of the fire extinguishing agent;

4) extinguishing a fire in order to eliminate or localize it within the time necessary for the commissioning of operational forces and means;

5) the required operational reliability.

Article 46

Fire automatics are designed to automatically detect a fire, alert people about it and manage their evacuation, automatic fire extinguishing and inclusion of executive devices of smoke protection systems, control of engineering and technological equipment of buildings and facilities. Fire automatics are divided into:

1) fire detectors;

2) fire control devices;

3) fire control devices;

4) technical means of alerting and managing evacuation firefighters;

5) fire notification systems;

6) other devices and equipment for building fire automation systems.

Article 47

1. Personal protective equipment for people in case of fire is designed to protect the personnel of fire departments and people from the effects of fire hazards. Means of rescuing people in case of fire are intended for self-rescue of personnel of fire departments and rescuing people from a burning building, structure, structure.

2. Personal protective equipment for people in case of fire are divided into:

1) personal protective equipment for respiratory and vision organs;

2) personal protective equipment for firefighters.

3. Means for saving people from a height in case of fire are divided into:

1) individual means;

2) collective funds.

Study questions:

General classification of fire trucks and their purpose, marking.

![]()

Symbol example

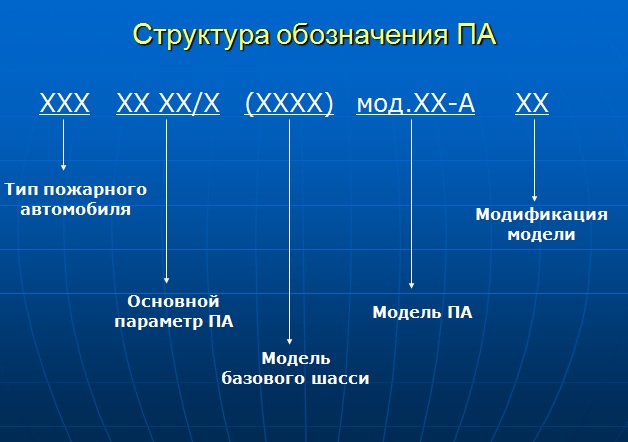

АЦ 3,0-40/4 (4331) model ХХХ-ХХ

With a capacity of 3 m3, a combined pump with a supply of 40 l / s (stage normal pressure) and 4 l/s (stage high pressure) on the ZIL-4331 chassis, the first modernization of the XXX model, modification of the XX.

The main fire trucks of general use.

- vehicles designed to deliver personnel to the place of call, extinguish fires and carry out rescue operations with the help of fire extinguishing agents and fire equipment transported to them, as well as for supplying fire extinguishing agents from other sources to the fire site.

Key Benefits of First Aid Vehicles

- small size and maneuverability in the conditions of the flow of urban transport;

- quick arrival to the place of call;

- effective extinguishing of local fires;

- the use of a high-pressure barrel allows to reduce the consumption of fire extinguishing agent;

- reduction of indirect damage from spilled water;

- economy of fuels and lubricants;

- versatility of equipment;

- the possibility of opening doors and bars window openings and garage doors

- possibility ;

- flushing of spilled oil products in case of an accident;

- providing first aid to victims of road accidents;

- effective in ensuring the safety of events with mass sojourns people;

- lower financial costs for maintenance and operation compared to AC.

The main shortcomings identified during the operation of the AMS

- when the spray barrel was supplied, due to a design flaw, the rubber hose was damaged at the point of attachment with a clamp to the motor pump;

- clearance (ground clearance) is very low, which makes it difficult to overcome even minor obstacles (curbs, etc.);

- not all models have an all-wheel drive chassis (4x4), which is necessary for the operation of the car in winter conditions;

- the length of the hose reel (50 meters) of the high-pressure barrel significantly limits the radius of work and complicates work in buildings with a complex layout;

- inaccessibility of equipment located on the roof of the car;

- compartments not tight;

- lack of a water intake system from water sources of all types.

The main target vehicles are for extinguishing fires at oil depots, timber processing, chemical, petrochemical, oil refining industries, at airports and other special facilities.

Powder fire trucks designed to extinguish fires of classes:

- A (Fires solids, mainly of organic origin, the combustion of which is accompanied by smoldering),

- B (Fires of combustible liquids or consumable solids),

- C (Gas fires),

- E (Fires associated with the burning of electrical installations)

- at industrial facilities of the gas, oil, petrochemical industry

Gas extinguishing vehicle

Machine for extinguishing local fires on nuclear power plants, transfusion points, warehouses for flammable liquids, in car parks, etc.

Provides elimination of fires in rooms with a volume of up to 5 thousand cubic meters, at elevators, in granaries and other premises where it is impossible to use other extinguishing agents leading to damage to expensive equipment and materials.

- Extinguishing agent - nitrogen

- Tank capacity, kg - 4000

- Fire monitor productivity, kg/s — 30

- Productivity of a manual trunk, kg/s — 2

Video about the main fire trucks

In accordance with the fire safety rules in the Russian Federation PPB-01-93, fires are divided into 5 classes.

Class A - fires of solid substances, mainly of organic origin, the burning of which is accompanied by smoldering (wood, textiles, paper, coal) and not accompanied by smoldering (plastic).

Class B - fires of flammable liquids or melting solids, insoluble in water (gasoline, ether, petroleum products), soluble in water (alcohol, methanol, glycerin).

Class C - gas fires.

Class D - fires of metals and their alloys.

Class E - fires associated with the burning of electrical installations.

Classification is necessary for the selection of fire extinguishing installations and primary fire extinguishing agents. The fire class is indicated in the passport of each fire extinguisher.

4 Classification of industries for fire hazard.

b, but do not explode, liquids with a flash point greater than 61°C.

5 Fire prevention

Fire prevention is based on the exclusion of the conditions necessary for combustion and the principles of safety.

Security can be achieved:

1) Measures to prevent fires

2) Signaling about emerging fires.

5.1 Fire prevention measures

organizational ( correct operation machines and intra-factory transport, the correct maintenance of buildings and territories, fire safety briefing employees, organization of voluntary fire protection, issuance of orders on fire safety issues);

technical (compliance fire regulations, standards for design, installation of electrical wires and equipment, heating, ventilation, lighting, proper placement of equipment);

regime (prohibition of smoking in unspecified places, production of welding and other hot work in fire hazardous premises, etc.);

operational - timely preventive inspections, repairs and testing of process equipment.

In accordance with the rules PPB-01-93, in order to prevent fires, it is important to place production in buildings of a certain fire resistance. Fire resistance is the resistance of buildings to fire.

According to fire resistance, buildings are divided into 5 degrees. The degree of fire resistance is characterized by the flammability of the substance and the fire resistance limit. The fire resistance limit of a building is the time, expressed in hours, after which the structure loses its load-bearing or enclosing capacity. The loss of bearing capacity means the collapse of the building structure in case of fire. The loss of the enclosing ability means the heating of the structure to a temperature, the increase of which can cause self-ignition of substances in adjoining room, or the formation of cracks in the structure, through which combustion products can penetrate into neighboring rooms.

In accordance with the degree of fire resistance and the category of fire hazard of production, the number of storeys of the building, fire breaks are determined.

Reducing the fire hazard of structures is of great importance.

Many rooms have wooden partitions, cabinets, shelving, etc. Increasing the flammability resistance of wooden structures is achieved by their plastering or cladding with fireproof or slow-burning materials, deep or surface impregnation with flame retardants, coating with fire-retardant paint or coating. Similar measures should be applied to other combustible structural materials.

The process of thermal decomposition of wood proceeds in two phases:

the first phase of decomposition is observed when the wood is heated to 250 (to the ignition temperature) and goes with the absorption of heat;

the second phase - the combustion process itself goes with the release of heat. The second phase consists of two periods of gas combustion resulting from the thermal decomposition of wood (flaming combustion phase) and the combustion of the resulting charcoal (smoldering phase).

The combustibility of wood is significantly reduced when it is impregnated with flame retardants. Heating wood leads to the decomposition of fire retardants with the formation of strong acids (phosphoric and sulfuric) and the release of non-combustible gases that prevent combustion and smoldering of the protected wood.

The most common flame retardants include ammonium phosphate, disubstituted and monosubstituted, ammonium sulfate, borax and boric acid. Bura and boric acid taken in a 1:1 mixture.

Thermal insulation materials include asbestos-cement sheets, gypsum-fiber, asbestos-vermiculite, perlite asbestos boards, various plasters. Protection with these materials is used only in enclosed spaces.

Paints, coatings consist of a binder, filler and pigment. The resulting film fire retardant paints serves both for flame retardant and for decorative purposes (due to the pigment).

Liquid glass, cement, gypsum, lime, clay, synthetic resins, etc. are used as a binder for fire-retardant paints and coatings. Chalk, talc, asbestos, vermiculite, etc. are used as fillers. Pigments include metopane, zinc white, mummy, ocher, chromium oxide, etc.

Basic ways flame retardant impregnation wooden structures and products can be superficial and deep. In some cases flame retardants applied to the surface, in others they impregnate the material in bathtubs or in installations for deep impregnation under pressure.

The effectiveness of a flame retardant is measured by the time after which a sample or structural element ignites from heat source. The cessation of combustion and smoldering after the removal of the heat source determines the quality of the flame retardant composition.

The flammability characteristics of building materials and structures have been established:

ignition time;

burning rate;

the time of cessation of combustion and smoldering after the ignition source is removed.

The burning rate is determined by the ratio of the percentage of sample weight loss during fire exposure to the test time. The study of flammability is carried out by testing standard samples of the material with conditioned heat sources, the position of these sources relative to the sample and the test time.

Fire extinguishers.

Fire extinguishing agents.

The impact of fire extinguishing agents on the fire site can be different: they cool the burning substance, isolate it from the air, remove the concentration of oxygen and combustible substances. In other words, fire extinguishing agents act on the factors that cause the combustion process.

Principles of cessation of combustion.

Isolation of the combustion chamber from air or reduction of the oxygen concentration by non-combustible gases to a value at which combustion cannot occur:

cooling the combustion chamber below certain temperatures;

intense speed deceleration chemical reaction in the flame;

mechanical breakdown of the flame by the action of a jet of gas or water;

creation of fire-blocking conditions.

To extinguish fires, water, aqueous solutions of chemical compounds, foam, inert gases and gas compositions, powders and various combinations of these agents are used.

Water is the main means of extinguishing fires. It is used in the combustion of solid, liquid and gaseous substances and materials. The exception is some alkali metals and other compounds that decompose water. Water for extinguishing is used in the form of solid (compact) jets, in atomized and mist (foggy) state, as well as in the form of steam.

The ability to extinguish a fire with water is based on its cooling effect, dilution of the combustible medium, formed during evaporation with water vapor and mechanical action on the burning substance (flame failure).

Foams are an effective and convenient fire extinguishing agent and are widely used to eliminate the burning of various substances, especially flammable and combustible liquids.

Foam is a cellular-film system consisting of a mass of bubbles (cells) of gas or air separated by thin films of liquid.

Fire-extinguishing foams are divided into two groups according to the method of formation: chemical and air-mechanical.

Chemical foam is obtained in large quantities in foam generators by contact with water of foam generator powders, consisting of an alkaline part (soda bicarbonate), an acid part (aluminum sulfate) and a foaming agent (substances of protein origin, synthetic, various surfactants, etc.).

In chemical foam fire extinguishers foam is formed by the reaction of aqueous solutions of sodium bicarbonate containing licorice extract, sulfuric acid and iron tanning agent.

Chemical foam is approximately 80% carbon dioxide, 19.7% water and 3% foaming agent.

Air-mechanical foam is formed in generators as a result of mechanical mixing of air, water and a foaming agent and can be of low, medium and high expansion. Depending on the type of foaming agent and the foam ratio, it is used to extinguish flammable liquids and combustible liquids.

Air-mechanical foam is economical, non-conductive, harmless to people, easily and quickly obtained during a fire, and, unlike chemical foam, does not cause metal corrosion and does not damage the equipment and materials on which it comes into contact.

The main fire-extinguishing property of foam is its ability to isolate the burning substance and materials from the surrounding air, reduce the oxygen concentration in the combustion zone, as well as its cooling effect.

Gas fire extinguishers. These agents include: water vapor, carbon dioxide (carbon dioxide), inert gases (nitrogen, argon), as well as fire extinguishing compositions based on halogenated hydrocarbons, which are gases or volatile liquids (ethyl bromide, chlorobromomethane).

Carbon dioxide in the snowy and gaseous state is used in various fire extinguishers and stationary installations to extinguish fires in enclosed spaces and small open fires.

Inert gases are used to fill volumes in which, when the oxygen concentration drops to 5% or lower, hot work can be performed (cutting, welding of metals, etc.).

Powder substances are dry formulations based on sodium carbonate and bicarbonate. Powders are used to extinguish metals and various solid and liquid combustible substances and materials.

Powder formulations are non-toxic, have no harmful effect on materials and can be used in combination with water spray and foam extinguishing agents. The negative property of powders is that they do not cool burning substances, and they can ignite again from heated structures.

STATIONARY INSTALLATIONS AND FIRE EXTINGUISHING DEVICES.

Stationary fire extinguishing installations consist of permanently installed devices and devices connected by a piping system for supplying fire extinguishing agents to protected objects.

Automatic fire extinguishing installations are classified depending on the use of extinguishing agents:

water - using solid, atomized, finely atomized water jets;

water-chemical - using water with various additives (wetting agents, thickeners, etc.);

foam - using air-mechanical foam;

gas - using carbon dioxide, halogenated hydrocarbons, inert gases;

powder - using fire extinguishing powders;

combined - using several extinguishing agents.

One of the promising areas that ensures the fire safety of facilities is the installation of fire-fighting automation - sprinkler and deluge installations (terms taken from English words: to sprinkle - splash and to drench - wet). These installations are used by many commercial warehouses.

Sprinkler installations are designed for quick automatic extinguishing and localization of the fire, when water can be used as an extinguishing agent. Simultaneously with the supply of sprayed water to the fire, the system automatically gives a fire signal.

In sprinkler installations, air-mechanical foam can also be used as an extinguishing agent.

Sprinkler installations adapted for extinguishing with air-mechanical foam are equipped instead of sprinkler heads SP-2 with special foam heads (foam sprinkler OP), which allow one head to protect a floor area of 20 - 25 m 2. For the formation of air-mechanical foam in the installations, a 3 - 5% solution of foam concentrate PO-1 is used.

Depending on the temperature in the protected premises, sprinkler installations are divided into water, air and air-to-water.

Water sprinkler installations are installed in rooms in which the temperature is constantly maintained above 4 ° C. the pipelines of this system are always filled with water. With an increase in air temperature or exposure to a flame, fusible locks of sprinkler heads are soldered, water comes out of the holes, irrigating the protection zone.

Air sprinkler installations are installed in unheated buildings. The pipelines of this system are filled with compressed air. In this case, there is compressed air upstream of the control and alarm valve, and water after the control and alarm valve. When the sprinkler head of the air system is opened, after the air has escaped, water enters the network and extinguishes the combustion source.

Air-to-water systems are a combination of air and water sprinkler installations. The sprinkler system is activated automatically by melting the fusible lock of the sprinkler head.

Drencher installations are designed for automatic and remote fire extinguishing with water. Distinguish drencher installations of automatic and manual action. In automatic deluge installations, water is supplied to the network using a group action valve. Under normal conditions, the automatic induction valve is held in the closed position by a cable system with fusible locks. In case of fire, the lock melts, the cable breaks, the valve opens under water pressure and water enters the drenchers. In a manual deluge installation, water is supplied after the valve is opened. Unlike sprinkler systems, water sprayers (drenchers) in deluge installations are constantly in the open state.

Fire extinguishers are designed to extinguish fires and fires in their initial stage. According to the type of extinguishing agent used, they are divided into foam, gas and powder.

Foam fire extinguishers are designed to extinguish small fires of solid materials and substances and flammable liquids. They are not used to extinguish fired electrical installations that are energized, because. chemical foam is electrically conductive.

Chemical foam fire extinguishers OHP-10, OP-M.

Air-foam fire extinguishers OVP-5, OVP-10.

Carbon dioxide fire extinguishers OU-2, OU-5, OU-8 are used to extinguish various substances and materials (excluding alkali metals), live electrical installations, vehicles, etc.

Carbon dioxide-bromoethyl fire extinguishers OUB-3A and OUB-7A are designed to extinguish small fires of various combustible substances, smoldering materials, electrical installations under voltage.

Powder fire extinguishers OP-1, OP2B, OP-10 are designed to extinguish small fires of combustible liquids, gases, electrical installations under voltage, metals and their alloys.

Automatic aerosol fire extinguisher SOT-1 is designed to extinguish fires of solid and liquid combustible substances (alcohols, gasoline), smoldering and solid materials, electrical equipment in enclosed spaces.

The principle of operation is based on the strong inhibitory effect of a fire-extinguishing aerosol composition of ultrafine products on the combustion reactions of substances in atmospheric oxygen.

Aerosol does not harmful effects per person, easy to remove. Disposable fire extinguisher.

The UAP-A fire extinguisher automatically detects and extinguishes a fire in enclosed spaces of small volume. The fire extinguisher is installed on the ceiling in the center of the room. In the event of a fire, the fusible element is destroyed, the capacity of the fire extinguisher is opened, and a substance (freon or powder) is ejected into the volume of the room, creating an environment that does not support combustion.

FIRE ALARM.

To fight fires importance has a timely message about the fire. To report a fire, use electrical and automatic system alarms.

Successful firefighting depends on the rapid and accurate communication of the fire and location to the local fire brigade. For this, electrical (EPS), automatic (APS), sound fire alarm systems can be used, which include a beep, a siren, etc. telephone and radio communications are used as a means of fire alarm.

The main elements of electrical and automatic fire alarms are detectors installed at facilities, receiving stations that register a fire that has begun, and linear structures connecting detectors with receiving stations. In receiving stations located in special premises of the fire department, round-the-clock duty must be maintained.

Basic requirements for a fire alarm:

should be located in places accessible for inspection;

sensors must be highly sensitive.

Sensors are applied thermal, smoke, ultrasonic and combined.

Sensors can be: maximum - they are triggered when the controlled parameters reach a predetermined value; differential - react to a change in the speed of a given parameter; maximally differential - they react to both.

The principle of operation of thermal sensors is to change the physical and mechanical properties of sensitive elements under the influence of temperature (fusible alloy). An alloy connects two plates. When heated, the alloy melts, the plates open the electrical circuit, and a signal is sent to the remote control.

Smoke detectors have two main methods for detecting smoke: photoelectric (IDP) and radioisotope (RID). The IDF detector detects smoke by registering light reflected from smoke particles with a photocell. The RID has an ionization chamber with a source of -particles as a sensitive element. An increase in the smoke content reduces the ionization rate in the chamber, which is recorded.

The combined detector (CI) reacts to both temperature rise and smoke.

A light fire detector (SI) registers the radiation of a flame against the background of extraneous light sources.

The ultrasonic sensor has high sensitivity and can combine security and alarm functions. These sensors respond to changes in the characteristics of the ultrasonic field that fills the protected room.

Currently, enterprises use beam and ring electric fire alarms.

Beam fire alarm TOL-10/50 is used at enterprises with round-the-clock stay of people and provides reception of signals, telephone call with a detector, start-up of stationary fire extinguishing installations.

Ring fire alarm system TKZ-50M is designed for 50 manual detectors. The station provides signal reception, fixing it with a recording device and automatic signal transmission to the fire department.

In rooms with non-round-the-clock stay of people, automatic fire detectors are installed. These detectors are triggered by smoke, heat, light, or both.

Reliable fire communication and signaling plays an important role in the timely detection of fires and the call of fire departments to the place of fire. According to its purpose, fire communication is divided into:

- wheeled and tracked vehicles,

- swimming and aircraft

- trains.

- main ,

- special,

- auxiliary .

- AC - tank trucks

- ANR - pump-hose

- APP - First Aid

- HPS - with high pressure pump

- AA - airfield

- AP - powder extinguishing

- APT - foam extinguishing

- ACT - combined extinguishing

- AGT - gas extinguishing

- PNS - pumping station

- AGWT - gas-water extinguishing

- AL - ladders

- APK - articulated car lifts

- AR - sleeve

- DU - smoke exhaust

- GDZS - gas and smoke protection service

- ASA - emergency vehicles

- ASh - staff

- fire trucks - AC;

- pump-hose fire trucks - ANR;

- fire trucks with high-pressure pumps - AVD;

- first aid fire trucks - APP.

- tank capacity, m 3;

- pump flow, l/s, at rated speed of the pump shaft;

- pump head, m w.c.

notification communication;

dispatcher communication;

Fires arise and develop wherever there are combustible materials and sources of ignition. Fire is uncontrolled burning. It is characterized by a high speed of flame propagation, accompanied by the release of a large number thermal energy and, consequently, a rapid increase in temperature near the combustion site.

In addition, combustion products contain: soot, oxides of various gases, toxic substances, etc.

Thus, fires are characterized by a rapid increase in . This creates a great danger to people's lives and leads to the rapid destruction of material values. Therefore, it is necessary to eliminate the fire and put out the fire as soon as possible, i.e. create conditions under which combustion processes cannot develop.

Materials of various aggregative states are exposed to combustion. Extinguishing them requires the use of fire extinguishing agents that provide a rational extinguishing mechanism. For its implementation, the necessary fire extinguishing agent with a certain intensity must be supplied to the combustion center.

Thus, in order to successfully extinguish fires, two basic requirements should be met: start extinguishing them as soon as possible and feed them to the combustion center with the required composition and with the required intensity. These two requirements are reflected in the technical characteristics of fire equipment.

fire fighting equipment- these are technical means of extinguishing a fire, limiting its development, protecting people and material values from it.

Currently, fire fighting equipment covers a large arsenal various means: primary fire extinguishing equipment, fire engines, fire extinguishing installations and communications.

Before the start of extinguishing fires, a number of special works can be performed: reconnaissance of a fire, removal of combustion products from premises, rescue of people, opening of structures, etc. To perform these works, a range of special fire engines with special equipment is required.

Fire engine is a transport or transportable vehicle designed to extinguish a fire.

For maintenance of personnel and fire equipment, especially on major fires, auxiliary fire engines are used.

Fire engines are created on the basis of various vehicles:

They are called: fire trucks (PA), fire boats, ships, helicopters, trains.

Fire trucks are equipped with divisions of the State fire service(GPS). Some of them use fire boats, helicopters, tanks.

Fire trucks are also equipped with fire departments of various ministries (railway transport, forestry, etc.).

Fire trucks consist of chassis, base vehicle, and a fire superstructure. It may include a cabin for combat crew, units for various purposes(, ladder mechanisms, etc.), containers for fire extinguishing agents, compartments for fire-technical equipment (PTV).

A variety of fires and fire extinguishing conditions, as well as the work performed during combat operations, required the creation of PA for various purposes.

According to the main types of work performed, PAs are divided into:

Basic PA, in turn, consist of PA general and target applications.

| Basic fire trucks | Special fire trucks | |

| general use | intended use | |

|

|

|

|

Main PA designed to deliver the personnel of the State Fire Service units, fire extinguishing agents and equipment to the fire site and supply fire extinguishing agents to the combustion zone.

PA general use designed to extinguish fires at urban facilities and in the residential sector.

PA intended use provide fire extinguishing at petrochemical industry facilities, airfields, etc.

The main PAs of general use are designated as follows:

They are characterized by a number of parameters. Fire safety standards have established that as the main parameters that determine functional purpose PA, are used:

The initial letters of the PA names and the main parameter of the PA type form the basis of their conventional designations.

Examples of symbols.

Example 1. AC-5-40(4310), model XXX. Fire truck, tank capacity 5 m 3 of water, water supply by a pump 40 l / s, chassis KAMAZ 4310, the first modification of the model.

Example 2. AKT-0.5 / 0.5 (131), model 207 - combined extinguishing vehicle, tank capacity for powder and foam concentrate 500 l (0.5 m), chassis of the ZIL-131 car, model 207.

Example 3. PNS-110(131)-131A - fire pumping station, pump flow 110 l / s, chassis of the ZIL-131 car, model 131 A.

Special PA are used to perform a variety of works: lifting to a height, dismantling structures, lighting, etc. As the main parameters, characteristics of the PA that determine the functional purpose, for example, the height of the ladders, the power of the generator of the emergency rescue vehicle, etc. are used.

Examples of symbols:

AL-30(4310) - fire tank truck with a height of 30 m ladder knees on the chassis of a KamAZ 4310 vehicle.

ASA-20 (4310) - rescue vehicle, generator power 20 kW on the chassis of the KamAZ 4310 car.

There used to be a term auxiliary vehicles(before the issuance of order No. 555 “On the organization of material and technical support for the system of the Ministry Russian Federation on business civil defense, emergencies and elimination of consequences natural Disasters, dated 09/18/2012”) ensured the functioning of fire departments. These included: trucks, tankers, mobile repair shops, etc.

To isolate PA from the general traffic flow in conditions of significant density and intensity traffic they must have a certain amount of information. It is carried out by the shape of the product, color, light and sound signaling.

All fire equipment products are painted red. To enhance the information content in the color-graphic scheme, a contrasting White color. Color-graphic scheme, inscriptions and identification marks, as well as. The breakdown of surfaces to be painted, the location of inscriptions and symbols are set in the order shown in the figure.

The number of the fire department and the city are indicated on the cabin door, on the stern - the type of PA, for example AC, - the tank truck and the number of the fire department. According to the color-graphic scheme, PA bumpers are painted white, the frame, wheel disks and visible parts of the running gear are painted black.

The knees of fire escapes, car and foam lifters are painted white or silver.

When performing an operational task, the information content of the PA is enhanced by sound and light signals.

The alarm light signaling of the PA is created by a blue flashing beacon. They operate from the on-board network with a voltage of 12 or 24 V, providing a flashing frequency of (2 ± 0.5) Hz, while the dark phase should not be less than 0.2 s.

Sound signal can be generated by sirens direct current, giving two or more alternating signals with a sound frequency from 250 to 650 Hz. The sound pressure level at a distance of 2 m from the siren should be in the range of 110-125 dB.

A siren activated by engine exhaust gases can be used as an audible signal.

By study guide"Fire Engineering", ed. 3, ed. M.D. Bezborodko