Sprinkler installations for water fire extinguishing. Sprinkler fire extinguishing from the company heat fire protection

Man has always strived to achieve perfection in almost everything. The real confirmation of this is the progress in the technical field. Today, the fire extinguishing system has reached a completely different level, a higher one. Modern ways elimination of fire allows you to save the lives of people in certain rooms, as well as protect their property. One of the options for fighting a fire is a sprinkler system, which eliminates a fire immediately after it occurs. If the object is equipped with this method of extinguishing open flame, then you do not have to wait for the arrival of special services, as well as use fire extinguishers.

Varieties of fire-fighting water supply

Today, sprinkler and deluge systems are being created for the purpose. The first are air, water and mixed. These systems are designed to be installed in rooms with or without heating. In water installations, pipelines are completely filled with liquid. Therefore, such systems are used only in heated rooms. IN air installations water enters the pipeline only after the control and signal valve has been triggered. They can be used in unheated rooms. The pipelines are initially filled with compressed air, so only after its release does the fire extinguish with water begins. Also, for rooms that do not have heating, mixed systems are used. In such installations, pipelines are filled with water in summer, and in winter they contain compressed air, since the liquid freezes at low temperatures.

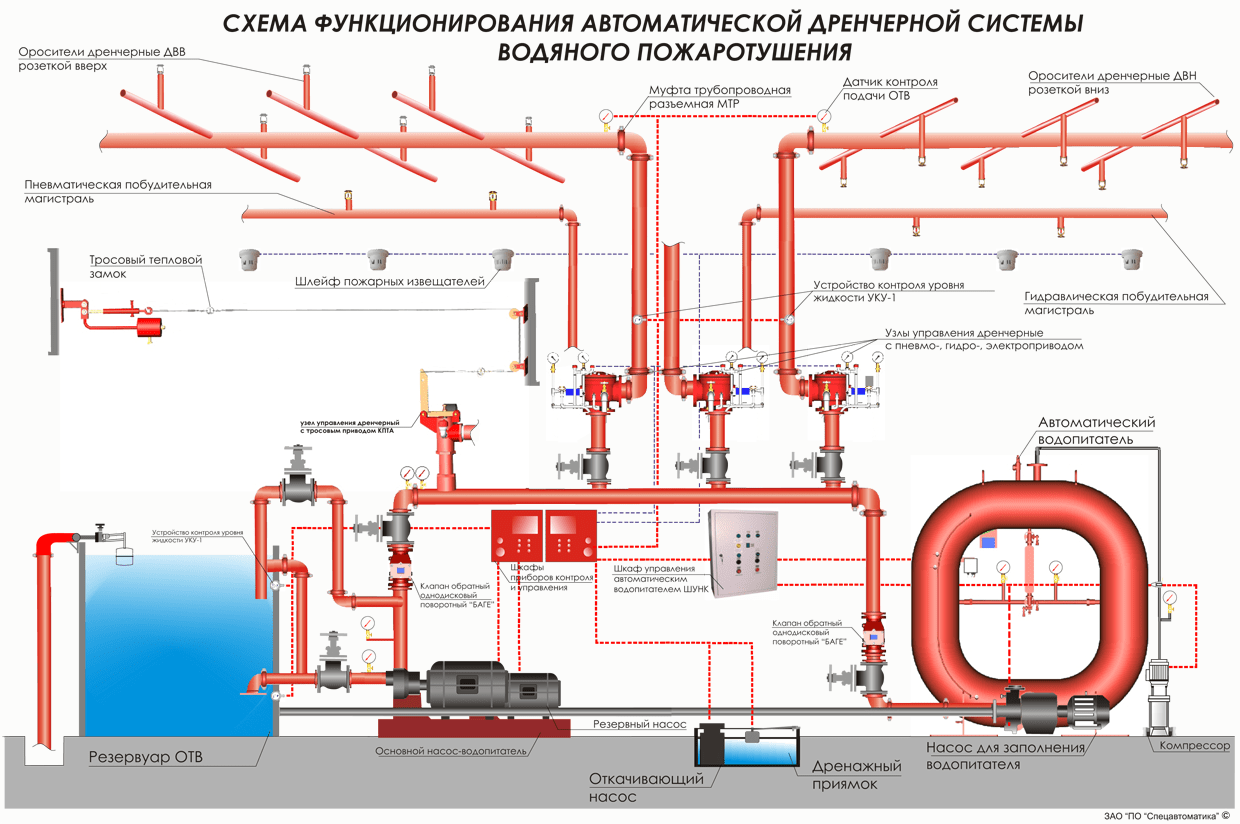

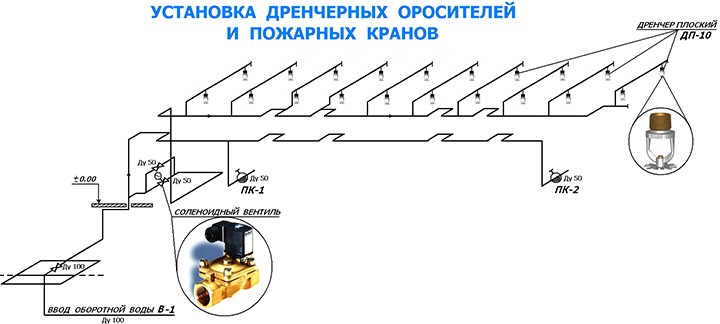

Deluge systems include heads that are equipped with holes with a diameter of 8, 10 and 12.7 mm. Such elements are used not only for, but also with their help, water curtains are created. They are designed to isolate fire sites. Such systems can be operated manually or automatically.

Features of the use of sprinkler-type installations

This type of fire extinguishing is fully automatic. The sprinkler system is being built in large facilities. A feature of these installations is the localization of open flames in closed areas, where the spread of fire is accompanied by a large amount of heat release. Most often, this method of extinguishing fires is used in crowded places, in parking lots with closed type, in numerous offices, retail and industrial premises.

Principle of operation

Any sprinkler fire extinguishing system consists of water supply networks. The principle of operation is that the installation is always ready to supply a substance that helps to eliminate the fire. It can be water or a special compound. The system operates under high pressure... Sprinklers are distributed over the entire area of a certain room, which are normally covered by sprinklers. They are special attachments made of light alloy material. When a fire breaks out, the valve is exposed to a high temperature, breaking the seal and supplying the extinguishing agent.

Design features

A sprinkler fire extinguishing system can consist of several separate sections. Each of them is equipped with an individual control and signal valve. Same separate section can be equipped with special devices that supply compressed air. This is necessary in order to increase the pressure in the pipelines. Such design features of fire extinguishing systems depend on the area of the object, as well as its configuration.

Types of equipment to be installed

Any sprinkler system has thermal locks. In most cases, they are triggered when the temperature reaches 79, 93, 141 or 182 degrees. The first two values refer to low temperature systems... They must be triggered no later than 300 seconds after a fire breaks out. This requirement is specified in GOST R 51043-2002. The following two values refer to high temperature systems. For them, the thermal lock must work no later than 600 seconds after the ignition started in the room.

Design and installation of a sprinkler fire extinguishing system

Initially, it is always necessary to complete the project. It will be needed for the correct placement of the equipment and pipelines of the fire extinguishing system at the facility. When developing drawings, the area of a specific room is always taken into account. It is also necessary to take into account the consumption of the substance required to extinguish the fire. Depending on the type of room, the location of each element of the system is determined, which are sprinklers, pipelines, and also the control unit. In this case, the height of the ceilings, the existing ventilation and the parameters at which the water supply will be carried out must be taken into account.

The installation of a sprinkler system consists of several stages. All are delivered to the site first. necessary materials and accessories. Then the cables are laid and the pipelines of the system themselves are laid. Further, the installation of other elements that are part of the fire extinguishing installation is carried out. At the last stage, commissioning tests are carried out.

Main element for fastening pipes

Sprinkler piping is suspended from horizontal surfaces. These are mainly the ceilings of the premises. For simplicity, a sprinkler clamp is used. Appearance such a device has a teardrop shape. Clamps are made, as a rule, of galvanized steel. They have different diameters, depending on the dimensions of the pipes used in the systems. There is a special hole in the clamps for fixing them to the ceiling. To carry out such a process, it is necessary to insert a threaded rod, which will be fixed with a nut. When using this installation method, it is possible to adjust the level of the pipeline. Usually, the required number of clamps is initially installed on the ceiling, after which the system itself is installed directly. Thanks to the use of such elements, the installation of pipelines is very fast. Clamps can be fastened using various means - they can be pins or threaded studs. ![]()

Maintenance of installations

The sprinkler system, like any other, needs regular maintenance. He has great importance to keep the installation in working order. One of the main elements are sprinklers, which must be constantly checked for physical damage. It is necessary to ensure that they do not have leaks, and also that there should be no traces of corrosion and destruction on such elements. If defects are nevertheless found, then it is imperative to replace the thermal locks, while the liquid is completely drained. After all work has been completed, the system is restarted. Also, the owner of such installations needs to know that their trouble-free operation is possible for 10 years after the installation.

Sprinkler system efficiency

Currently, in order to obtain reliable information about the operation of any equipment, they collect information from which statistics are formed. According to the latest data, a sprinkler fire extinguishing system effectively fulfills its tasks if at least one sprinkler is triggered in 10-40% of possible cases. Up to 80 percent of fires can be eliminated by simultaneously activating 10 valves. Moreover, such efficiency is observed over a large area. After completing the installation of the sprinkler system on the site, the owner of the premises will use a minimum amount Money... As a result, he will receive a fire extinguishing installation that will fully operate in automatic mode. At the same time, it does not depend on the connection to electrical network... All the listed advantages allow the sprinkler installation to occupy a leading position among all existing fire extinguishing systems.

Application automatic systems combating fire - the most reliable way property protection. Before choosing this or that fire structure, it is necessary to understand the features of each of them, and how the principle of operation differs from powder or deluge models.

The device and design of the sprinkler fire extinguishing system

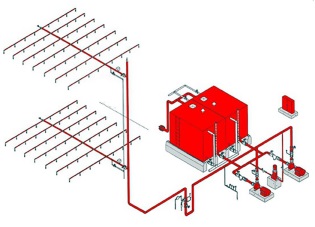

It is no coincidence that sprinkler-type fire-fighting devices are called systems, i.e. complex equipment, the action of which is based on the interaction of constituent assemblies and elements. The sprinkler fire extinguishing system device consists of:

- piping designed to transfer, distribute and spray water or foam;

- sprinklers (sprinklers) installed on pipes and spraying the incoming liquid over the area of the room;

- pumps to increase pressure when supplying water;

- water tanks and access to centralized plumbing system;

- sound and light warning devices.

The functions of control and signal sensors are performed by the sprinklers themselves, the heads of which are made of heat-sensitive materials.

In a large room, the pipeline consists of individual segments with autonomous system activation, which makes it possible to use it locally. Depending on the power and localization of the fire, it is connected different amount sprinklers located in the temperature rise zone.

The pipeline is constantly filled with water and is ready to start working. IN winter time, if the room temperatures are negative, then the water is drained from the pipeline, and inner space filled with pressurized air, which is easily displaced by water if necessary.

For spacious rooms with high ceilings, equipment with by hand activation, since the temperature during local ignition does not reach the critical values required for automatic melting of the sprinklers.

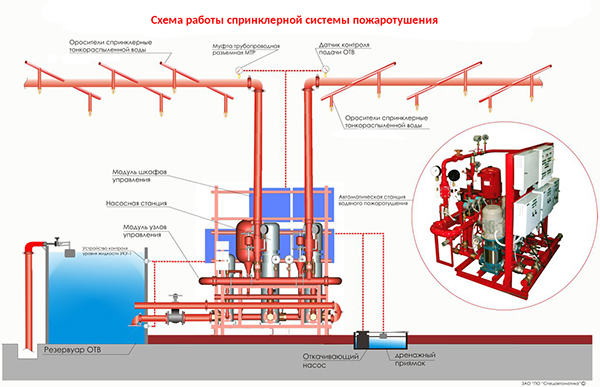

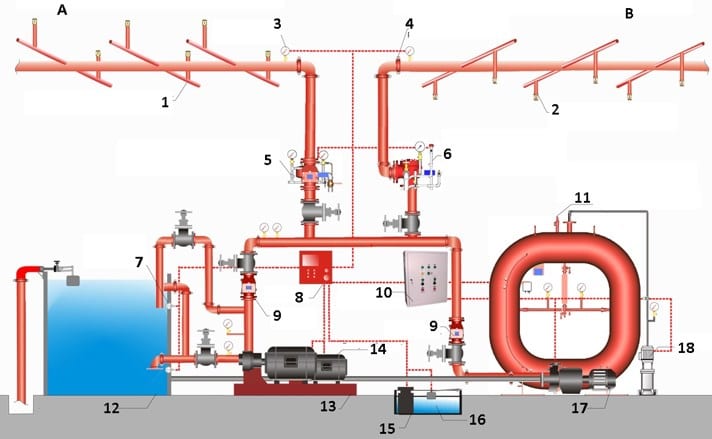

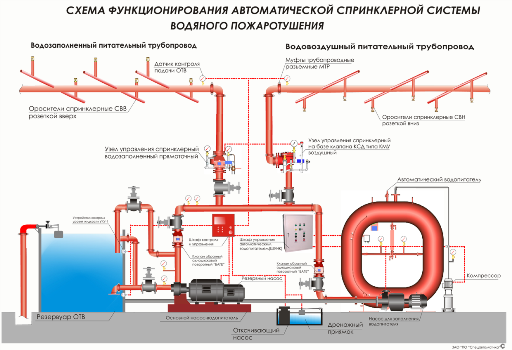

The scheme of the sprinkler fire extinguishing system provides ( see the diagram above):

- length and branching of pipelines

- the relative position of the sprinklers, taking into account the maximum coverage of the territory.

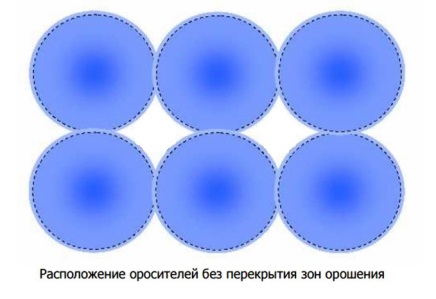

Methods of sprinkler placement with overlapping zones are used, which provides a reinforced water shower or without overlap, in which a minimum number of sprinklers are used.

For high premises possible use wall models sprinklers, which makes the structure more complex, but increases its efficiency and reduces water consumption and property damage during extinguishing.

Principle of operation

Like any fire-fighting equipment, sprinkler devices are designed to suppress fire by spraying extinguishing agents. The principles of operation of a sprinkler fire extinguishing system are based on the use of liquid, foam, gas or water-gas mixtures.

The main operating element is a sprinkler, which simultaneously acts as a sensor and a sprayer. In addition to this, other sensors that respond to temperature or air composition can be used. Such devices increase the speed of the system, but complicate the principles of its control. Another chain is added to the circuit, consisting of sensors and a control unit that activate the equipment before the sprinklers melt.

To a large extent, for a sprinkler fire extinguishing system, the principle of operation is based on the pressure difference inside the system and outside. In the passive state, these two pressures are balanced, and the shut-off valve hermetically shuts off the water supply to the sprinklers. After being under the influence high temperature the sprinkler heads dissolve, pressure differentials are created within the system, the valve opens and pressurized water is pumped into the room through the spray holes of the sprinkler.

How much pressure should a sprinkler fire extinguishing system be?

Pressure level requirements are formulated in SP 5.13130.2009 and other regulatory documents. The pressure in the sprinkler fire extinguishing system is indicated in the accompanying technical documents and must be observed during operation. Compliance with pressure standards is one of the mandatory questions of equipment performance checks.

The requirements of the joint venture indicate the permissible maximum and minimum indicators of what pressure in the sprinkler fire extinguishing system is considered acceptable.

Note!

So, the maximum pressure at the sprinkler can be no more than 1 MPa or 10 atmospheres, but other indicators are also allowed if they are fixed in the technical conditions for the protection of the property.

Optimal level pressure in two-pipe system automatic fire extinguishing is selected on the basis that the fire-fighting equipment must operate within a certain time, i.e. the inertia of the installation should not exceed 180 seconds.

For air sprinkler structures, the minimum pressure can be 0.01 MPa, with a further decrease, a signal is given to turn off the compressor.

Operating rules

The operation of the sprinkler fire extinguishing system must be maintained for a long time and constantly maintain the equipment in working order.

During operation responsible person is obliged to observe:

- system integrity;

- the level of its filling with water or other extinguishing solutions;

- connection to electrical equipment (pumps, pumps, alarms) and the presence of voltage in the electrical network;

- consistency of indicators technical specifications specified in the documentation for the equipment;

- arrange regular maintenance and checks on fire extinguishing capabilities

- in case of failure of at least one of the constituent elements, take care of the repair or dismantling of the equipment and replace it with a new model.

Conclusion

The principles on which sprinkler fire extinguishing devices work have made this equipment the most common and in demand due to its ease of operation and a high degree of reliability.

This article provides information on the principles of operation, advantages and disadvantages, differences, as well as how to use automatic fire extinguishing systems in sprinkler and deluge systems.

Sprinkler system characteristics

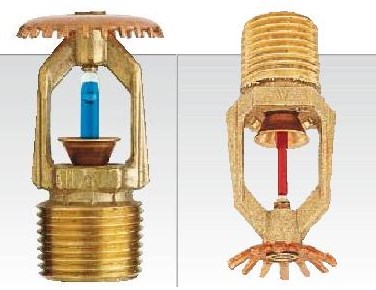

The principle of operation of a sprinkler fire extinguishing system is based on the operation of an automatic sprinkler with a built-in thermal lock. Upon reaching the threshold value of the critical temperature, the thermal lock, which is a thin-walled glass flask filled with a heat-sensitive substance, collapses and gives access to the fire extinguishing agent, which is under pressure in the pipeline network.

Historical reference: The first mentions of automatic fire extinguishing sprinkler systems were noted in the 19th century. System copper pipelines, in which there was water, was arranged at the spinning factories of Birmingham. Solid corks made of wax filled with chalk and sawdust were used as heat locks. Under the influence of high temperature, the wax melted, and the room was flooded with water. Naturally, the efficiency of such systems is rather low, since the wax softened when the fire was already raging in the room, and the temperature was very high.

The procedure for triggering the sprinkler system of automatic fire extinguishing

After the destruction of the thermal lock on one of the sprinklers, the following actions take place:

- The control system reacts to a pressure drop in the pipeline and activates the jockey pump to maintain required level extinguishing agent... The device turns off after automatic activation central fire pump supplying extinguishing agent from the tank;

- A message is sent about the operation to the central control room fire department;

- The fire warning system is activated: siren, flashing beacons, voice warnings;

- The ventilation system is turned off and the air ducts are blocked by special dampers;

- The smoke exhaust system is activated;

- If necessary and available, standby fire pumps are started.

IMPORTANT! The automatic fire extinguishing sprinkler system is designed to eliminate fires in the place of their occurrence on local areas. IN adjacent room where the temperature does not reach a critical value, the thermal lock will not collapse and triggering will not occur.

Advantages and disadvantages

The sprinkler-based fire extinguishing system has undeniable advantages:

- Relative ease of installation, low cost of installation and maintenance;

- Fast and effective elimination of the fire source;

- The ability to install in any room;

- Installation and configuration of the system is carried out promptly, does not require changing the layout of the room and cardinal destruction of partitions and load-bearing structures buildings;

- If the room contains suspended or stretch ceiling pipelines will not be visible and external aesthetic appearance will not suffer.

Flaws:

- Application a large number water for effective extinguishing of a fire can inflict no less damage to the property located in the room than fire;

- Sprinkler sprinklers are disposable devices that must be replaced after triggering and before re-bringing the system to readiness;

- The system may not be activated even after a smoke alarm has been triggered, since key indicator is the critical room temperature. The solution to this problem is the use of special sprinklers with a forced activation system, which leads to the need to lay an additional cable to each sprinkler.

- Cannot be used at subzero temperatures indoors. According to the standards, the minimum temperature in the building where the sprinkler system is installed should not fall below + 5 ° C.

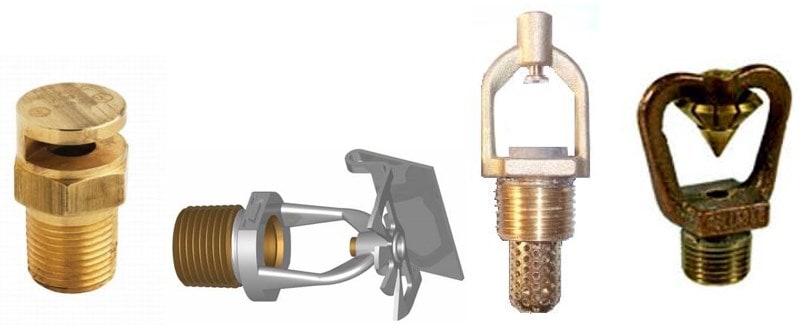

Device

- A sprinkler with a top-mounted outlet (UHV) cannot be installed in rooms with suspended ceilings;

- Sprinkler with bottom outlet - START;

- Pressure level sensor in the pipeline;

- Mounting elements of the pipeline - detachable couplings;

- Direct-flow control unit;

- Air control unit based on the SKD valve;

- Liquid level sensor in the tank;

- Sprinkler control device;

- Single-disc rotary check valve;

- Pumping equipment control cabinet;

- Automatic system for maintaining pressure in pipelines;

- Tank with water or other liquid extinguishing agent;

- The pump is the main one;

- The pump is back-up;

- Drainage pump - located in a controlled room to remove water;

- Drainage pit;

- The jockey pump is used to fill the water feeder;

- Compressor.

Sprinkler varieties

The main part of the automatic fire extinguishing sprinkler system on which the effectiveness of eliminating the fire source and the reliability of operation depends is the sprinkler sprinkler. The capsule with a thermosensitive liquid has a strictly defined critical response temperature, the operating range is within 57 ° C ... 343 ° C. Which operating threshold for each specific model can be easily determined by the color of the thermal lock:

IMPORTANT! The response time of low-temperature locks 57 ° С and 68 ° С should not exceed 5 minutes from the moment the room reaches the appropriate critical temperature. The optimal time is 2-3 minutes. For high-temperature thermal locks, the permissible response period is up to 10 minutes.

The following sprinkler head models have been designed to solve specific tasks fire extinguishing:

Positioning - the shape of the spray outlet for installing the device downward (EHV) or upward (UHV);

Directional jet - device with a reflector. Used to create a curtain of water, extinguish a specific localized meta or installation (for example);

Fine-dispersed flow - a device with a special nozzle for spraying water. Recommended for use in rooms where the use of large quantities of water can damage material values;

Early and / or forced actuation devices are used in rooms with high ceilings, where the critical temperature threshold can be reached for a long time.

Installation features

For the device of the piping system, only metal pipes with anti-corrosion coating. Fastening is carried out with clamps with a pitch of not more than 1.5 m. The connection of individual pipes can be carried out by welding or crimping using fittings and a special crimping pneumatic tool. The use of soldering even with the use of refractory solder is not allowed .

It is advisable to install a reservoir with a fire extinguishing agent and a pumping group in the basement of the house, and drain the drain pipes there. Place the control device in the room where all the controllers of the system are concentrated smart House.

IMPORTANT! To extinguish a fire in the control room, it is recommended to use autonomous modules of powder or gas fire extinguishing.

Features and differences of deluge systems

Unlike sprinkler systems, deluge automatic fire extinguishing installations are equipped with sprinklers that do not have thermal locks. Accordingly, the pipeline is not filled with a fire extinguishing agent, and the start of the fire extinguishing process occurs after the shut-off valve is opened, which blocks access to the central reservoir. Fire extinguishing is activated manually or after a fire alarm. In smart home systems, automatic fire extinguishing deluge systems are directly connected to the fire alarm control system. The process of extinguishing a fire can begin immediately after the detection of the source of fire or after confirmation of the command from the central control panel or remotely from the telephone.

Actuation and operating principle

- Detection of the source of fire is carried out, combustion or temperature) of the alarm and fire alarm system, after which the alarm signal is transmitted to the security console, mobile communication and control device to the owner of the house and to the central controller of the fire extinguishing system;

- The signal is checked against the threshold values stored in the controller's memory. Some systems with addressable detectors can be configured different meanings for different premises at home, depending on their purpose:

- for the kitchen, they limit the level of smoke,

- bathroom temperature level, etc. such customization is important to reduce the likelihood of false positives;

- When the fire extinguishing system is activated, the pumping station and unlocking several shut-off valves:

- From a propellant gas cylinder;

- From the pipeline network;

- The extinguishing agent is directed into the pipeline from an autonomous local reservoir or water supply system through a damper tank;

- Water sprayed over the fire zone can be saturated with fire-extinguishing chemical additives, which significantly increase the efficiency of fire extinguishing.

IMPORTANT! One of the main differences from a sprinkler installation is that water is sprayed over the entire area of the fire extinguishing system installation.

Main technical characteristics and advantages

Automatic deluge fire extinguishing systems have the following advantages:

- A quick reaction to the occurrence of a fire source, which can be determined by several parameters:

- Flame detector signal or infrared sensor heat. Usually, for residential premises in the smart home system, triggering is provided when the boundary temperature reaches 65-75 ° C or its abrupt, sharp increase by 15-20 ° C.

- For kitchens, it is advisable to use several methods of detecting fire (temperature, smoke, the presence of an open flame) in aggregate;

- Pumps of a standard installation can generate a liquid head of 100-600 m 3 / hour, which provides almost instant filling of even branched pipelines and a short response time of the system to fire detection;

- The system is able to control large rooms or buildings with a complex layout;

- The deluge installation does not require reconstruction, replacement of elements or additional adjustment after triggering. After restoring the position of the shut-off valves to the closed position and filling the tank with a fire extinguishing agent, the unit is ready for reactivation;

- The main advantage is the ability to use foam or gas as a fire extinguishing agent, which leads to minimization of material losses from exposure to water.

Installation and calculation rules

According to the current regulations, deluge automatic fire extinguishing installations for residential premises must comply with the following parameters:

- A separate drencher should control an area of no more than 9m 2;

- The distance between the nozzles is less than 3 m, from the wall is not less than 1.5 m;

- The volume of fire extinguishing agent based on water is not less than 0.5 l / sec per 1 m 2 of the room;

- The speed of water supply in the distribution lines is not less than 10 m / s, and in the pipelines supplying the sprayers at least 3 m / s;

- It is advisable to install shut-off nozzles with a directed jet in doorways to block the spread of fire;

- To create water curtains, drenchers with a socket divider and a hole diameter of 10, 12, 16 mm are used, and for extinguishing 12 mm in rooms, paddle drenchers.

Among all existing ways fire fighting, sprinkler fire extinguishing system stands alone. Its peculiarity is in its simplicity of design, the absence of complex automation.

Its action is based on the automatic opening of water. The system reacts to an increase in room temperature. When it reaches critical values, water is supplied from the sprinkler.

A bit of history

The first sprinkler systems were developed in the early 19th century. For such a long time, they have changed, but the principle of operation has remained the same. They owe their survivability to the simplicity of their design. There are no complex semiconductor or digital elements in them.

Simplicity also determines the reliability of devices. The main changes affected the materials used in the production of systems, increasing their capacity, installing modern elements. Only the basic principle of the sprinkler fire extinguishing system remains unchanged.

Structurally, the system looks like a branched pipeline with pressurized water. The outlet points of the working fluid are hermetically closed by caps that can be destroyed under the influence of high temperature. Simplified operation of the system can be described as follows. When a fire occurs in the room, the temperature rises, the hood material melts. Water splashes from the piping system. Constructive changes did not affect the principle of work, but its improvement. IN modern systems a sprinkler is applied. In fact, this is the sprinkler, thanks to which the extinguishing liquid is sprayed under pressure.

Advantages:

- Can be used in residential, office, administrative, industrial buildings.

- Fast reaction to fire.

Works well with smoke detectors. The latter increase the efficiency of the system due to timely notification of increased smoke levels. Their use without fire extinguishing devices is not justified, their effectiveness is not always high.

The decrease in efficiency is attributed to the following factors:

- The alarm signal may simply not be heard.

- People do not always have time to evacuate from a burning room.

The installation of a sprinkler fire extinguishing system together with smoke detectors can increase the efficiency of both elements significantly. Sensors give an alarm, and the fire extinguishing system instantly reacts to fires by splashing water.

Additional benefits are provided by the use of tap water as an extinguishing liquid:

- Low cost price.

- Lack of water shortages.

- Environmentally friendly, non-toxic.

- Safety for humans.

- Good extinguishing power.

Schemes of modern systems

Sprinkler fire extinguishing systems are developed based on the use of modern materials... For the installation of the pipeline, plastic pipes are used. This is an economically viable choice. The cost of arranging a plastic pipeline is several times lower than the cost of metal structures.

Installation of plastic pipes makes it possible to long years forget about any problems. No deposition on their inner surfaces limescale... The pipe clearance will retain its original values for a long time. Plastic pipes are lightweight, they do not increase the load on building construction... It is very easy to mount them.

The main disadvantage of water fire extinguishing is negative impact on many materials, for example, wood, paper. This required the development of systems that do not increase damage. Since the hood collapses under the influence of temperature, the use of modern materials has ensured a phased operation of the atomizers. The elements that are located as close as possible to the source of fire always begin to work first.

The fire extinguishing system piping is connected to water supply network... For supporting required pressure are established check valves... The result is a completely autonomous, non-volatile system, ready to run at any time. The triggering of one of the nozzles leads to a sharp drop in pressure. After that, the pressure sensors are triggered, starting pump equipment providing the necessary backup water supply.

Water sprinkler fire extinguishing is able to effectively protect the premises within a radius of 12m. If the triggered atomizer has not coped with the fire source, the air temperature continues to rise. Adjacent sprinklers are activated.

Restrictions

Automatic sprinkler fire extinguishing has some restrictions on its use. First, they are associated with the possibility of using water to extinguish fires of different classes. For example, for server rooms, industrial facilities, the choice of such a system is not justified, since water cannot be used to extinguish electrical equipment.

Other disadvantages include:

- Inertia of the system. The water in the piping cools the bell. Its destruction and operation of the system begins with a slight delay.

- Dependence on the reliability of the water supply system.

- The operation of the sprinkler system is dependent on the ambient temperature, which can increase not only as a result of a fire.

- Wetting the surrounding surfaces with water. This parameter can be considered both as an advantage and as a negative point in the operation of the system. On the one hand, water damages things. On the other hand, wetting surfaces prevents the spread of fire.

Dry systems

Classic sprinkler systems have restrictions on their use. They require water to work. If there is no possibility of continuous uninterrupted water supply, the system will be useless. Do not use sprinklers at low temperatures. Water freezes at low temperatures and can lead to complete destruction systems, pipe ruptures. Solving the problem of using additives that can lower the freezing point is not always possible. They form on inner surface tubes plaque, narrowing their lumen. Over time, pipes can become clogged to such an extent that the system will completely lose its functionality.

The development of dry systems made it possible to solve the problem. As long as the system is in standby mode, it is filled with compressed air. When the sprinkler is triggered, air escapes, a vacuum occurs. Under its influence, water is supplied to the valves of the water system and to the pipes. To speed up the work, devices are additionally installed that provide an almost instantaneous decrease in pressure and fast filling pipes with water.

Their work is as follows: when one sprinkler is triggered, other valves are automatically opened. As a result, the pressure in the system instantly drops and water is supplied faster.

Installation of dry systems is only possible with plastic pipes. Metal constructions destroyed by oxygen.

Despite the apparent simplicity, the sprinklers are in constant operation, in standby mode. As a result, the installation and maintenance of the system should be carried out by a specialized company licensed to carry out such work.

Deluge systems are a type of water fire extinguishing. Sometimes they are considered independent structures, sometimes called a type of sprinkler. Their main similarity is in the installation scheme of the pipeline in which the water is located. Drencher and sprinkler fire extinguishing systems differ in the way they are triggered. The signal for starting work in deluge fire extinguishing is given from a central control panel or a detector. This method of excitation made it possible to get rid of the main disadvantage of water systems - inertia.

This type can be mounted on any object. Their type and purpose do not matter. In unheated facilities, deluge systems are installed with dry pipelines filled with air.

Can't mount dry fire extinguishing at objects where there is a risk of explosion, intense ignition with a high rate of fire propagation.

Examples and prices

Sprinkler and deluge systems are some of the most affordable fire extinguishing equipment on the market. It is impossible to name a specific price for the device.

It consists of different components:

- Room area.

- Required number of thermal lock sprinklers.

- Pipes.

- Shut-off valves (check valves).

- Pump equipment.

- Back-up water storage.

The main pricing parameter is still the area of the premises. The amount of materials and components depends on it. Prices for the services of companies that design and install fire systems can also vary a lot.

On average, for a small room up to 500 sq. meters, project development and installation of all elements will cost 65,000 rubles.

Automatic deluge fire extinguishing system Maintain and maintain fire extinguishing systems

Automatic deluge fire extinguishing system Maintain and maintain fire extinguishing systems

No one would argue with the assertion that fire is one of the worst disasters that can happen in life, since its consequences are rarely minor. The task of automatic warning and fire extinguishing systems is to prevent a fire or its spread in order to protect the life and health of people, as well as material values and equipment. Nowadays, one of the most common are automatic sprinkler fire extinguishing systems, which will be discussed in this article.

What is a sprinkler system and how does it work?

In accordance with regulatory documents automatic installations extinguishing a fire should be provided in buildings of a certain purpose. These include various production, administrative and public buildings with a large crowd of people, the installation of such systems in private construction is not provided for by the norms. Despite this, some homeowners still equip their homes. fire alarm, and even fire extinguishing. For this, a sprinkler and deluge system is used, extinguishing the flame with water or other liquid formulations or gases.

The deluge scheme is designed to extinguish a fire in large areas with a large amount of water, therefore it is most often used in case of a fire to cool various dangerous objects that can easily ignite or in order to create between the fire and the rest of the room water curtain... The volume of water supplied per unit of time by the deluge system is so great that the consequences of its operation can exceed the damage from a fire. The peculiarity of this method is that fire pipelines are filled with water only after a fire, by a signal from an automation system or from a manual activation.

The deluge scheme is designed to extinguish a fire in large areas with a large amount of water, therefore it is most often used in case of a fire to cool various dangerous objects that can easily ignite or in order to create between the fire and the rest of the room water curtain... The volume of water supplied per unit of time by the deluge system is so great that the consequences of its operation can exceed the damage from a fire. The peculiarity of this method is that fire pipelines are filled with water only after a fire, by a signal from an automation system or from a manual activation.

In turn, a sprinkler fire extinguishing system is a network of pipelines with water sprayers installed on them that operate locally. Its main difference from the deluge one is that each water sprinkler (sprinkler) operates independently in automatic mode if there is a certain temperature in the area of its location. Thus, in the event of a local fire in the room, one or more sprinklers located in the high temperature zone will work, this is the principle of operation of the sprinkler fire extinguishing system.

Sprinkler system device

In a typical heated building, the piping to which all sprayers are connected are constantly filled with water or other pressurized compound. It is provided by a special pump, and in case of fire, it will pump water from the water supply network to maintain pressure or fire tank... In accordance with the norms, for these purposes, at least 2 or even 3 pumps are provided, one of which is working, and the rest are backup.

In unheated structures, the sprinkler installation provides for the emptying of the network in winter. To avoid freezing of water in the pipelines, they are filled with compressed air, which is quickly discharged from the system after the automatic valve is triggered during a fire, and the pipes are filled with a flame extinguishing agent. However, under such conditions, the time before the start of irrigation with water increases, which means that the probability of fire spreading increases.

Modern fire extinguishing systems can also be turned on manually. This is especially true in structures with high ceilings, where local fire does not always raise the temperature in the area where the sprinklers are located.

The tasks of calculating and designing these systems should be performed by specialized organizations that have all required permissions because the responsibility of this work is very high. As a rule, the following sprinkler systems schemes are used during development:

- with overlapping irrigation zones;

- without overlapping irrigation zones.

The first type of schemes is distinguished by reliable operation and involves the use of critical facilities, but requires a large number of sprinklers and, accordingly, water to extinguish the fire.

A scheme without overlapping zones also has the right to life, since it is more economical in installation and does not require a large water consumption.

The distance between the nozzles is determined depending on the chosen scheme, the height of the ceilings and technical characteristics devices. Typically, foam fire extinguishing sprinkler installations are located in the upper part of the room, under the ceiling, so that the flow of water or foam in the form of a torch is directed downward. However, there are also wall options sprinklers, they are used when too high ceilings industrial buildings or to protect valuable equipment. In addition, the circuits often involve the function of switching on at least two sprinklers in order to prevent false triggering.

Sprinkler design

As the name implies, water sprinkler fire extinguishing is based on the work of the main element of the circuit - the sprinkler. In simple words, this is an atomizer equipped with a so-called thermal lock, which plays the role of a trigger. Usually, a glass bulb with a liquid or a fusible link acts as a thermal lock. In standby mode, the lock restrains a compressed Belleville spring, at the end of which there is a valve cover that blocks the path of water. The sprinklers themselves and their parts are made of non-ferrous metals that are resistant to corrosion.

Glass bulb or fusible link designed for a specific temperature threshold environment... When this threshold is exceeded, the liquid inside the flask expands and destroys it, respectively, the fusible link loses its rigidity and the thermal lock opens. A spring is released, which lifts the valve cover and thereby opens up a stream of pressurized water. Further, the structure of the body ensures its high-quality spraying. At the same time, the water pressure in the system begins to decrease, which fixes the sensor and turns on the fire extinguishing pump.

Sprinklers fire protection systems must meet the following quality indicators:

Tightness. Since the device is constantly under high pressure, this indicator plays an important role. Leakage is unacceptable, because water can get on expensive equipment, documents, people, and so on.

Strength. A well-made sprinkler should not lose performance from external influences, such as high or low temperatures, the influence of aggressive media, and shock resistance. In addition, the outlet of the device must operate at a maximum pressure of the outgoing jet up to 1.25 MPa.

Reliable operation of the thermal lock. He must refrain from false switching on the sprinkler during sudden temperature changes.

Sensitivity and speed of response. For low-temperature sprinklers, the maximum turn-on time is up to 300 seconds, for high-temperature sprinklers - up to 600 seconds.

Irrigation intensity. This indicator should correspond regulatory requirements applicable to nozzles with different outlet diameters (from 8 to 20 mm).

Conclusion

As a method of local fire fighting, sprinkler fire extinguishing is the most effective, its work often prevents the intervention of fire brigades and, most importantly, harm to life and health of people.