The windows of the houses are carved platbands. Do-it-yourself carved wooden window frames. Varieties of products for wooden windows

This summer, a successful thought came to me - to make some kind of individuality in our country house to please the eye and be different from other houses.

I thought a little and found a solution, the more I gradually prepared for this. I have long been interested in the decoration of houses in the old days, revised a large number of sites on this topic. There was even a small collection of photos of platbands and decorative elements.

But there, mostly houses of timber or logs were finished, and our house is sheathed with siding, and I thought that you could not make such beauty using siding.

In a word, everything worked out and came up with, it remains only to do.

I apologize in advance that it is not enough detailed photos since at that time he did not yet know about the existence of the 7dach Club and did not take step-by-step photographs, but simply took pictures for his own interest.

I'll tell you how I made the platband, according to my technology and to the size of our window.

Used the tool:

- electric planer

- electric jigsaw

- drill

- feather drills of different diameters

- clamps - 4-6 pcs.

- drill D 4 mm

- a circular saw

- square

- pencil

- A4 paper - sheets 10

Material and consumables (for 1 platband):

- self-tapping screws 16 mm long - 8 pcs.

- self-tapping screws 70 mm long - 2 pcs.

- pre-dried board, 25 mm thick and 150 mm wide - 7-8 m

- dowels - 45 pcs.

- waterproof glue for wood

- sandpaper - about 10x20 cm

- plastic corner (the top 10 mm bracket is ideal for fastening mosquito net to the plastic window) - 2 pcs.

Preparatory stages

1. Creating templatesFrom the photos I have, I chose the one I liked and reworked it in my own way. You can, of course, draw your own individual platband, but first you need to read a little about the amulets of Russia, about the symbols of Bereginya, the Sun, etc. All this is present in Russian platbands.

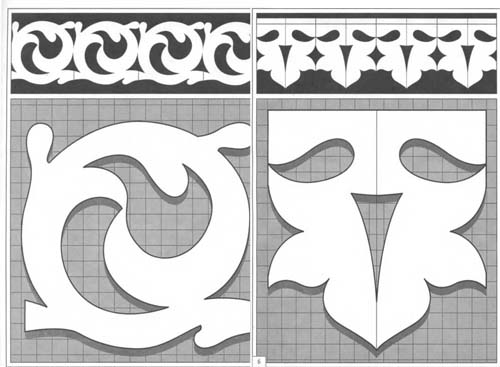

Photo used as source material

Our windows have an internal siding platband size of 88x88 cm. This was the starting point for the calculations. Therefore, the side parts should be exactly 880 mm in height and not wider than 140 mm (limited by the size of the board). The length of the upper and lower parts was determined by eye, the main thing is that they fit together beautifully. With the help of Photoshop I made a sketch of the casing in natural size.

2. Dividing a sketch into details in Photoshop

Amulet Bereginya - one of the elements of the casing

Some of the templates

Transferred the drawn details to thick paper and cut out templates.

3. Preparation of blanks

Sawed the board according to the length of the templates with a small margin. When sawing, it is imperative to select sections of the board without large knots. I sharpened these blanks to a thickness of 20 mm and drew the outlines of future patterns on them.

Sawed with an electric jigsaw with a narrow saw. The tilt adjustment of the saw blade must be set to "0", so there will be no burrs at the edges of the cut. Pay attention to the shape of the teeth, other teeth give a poor-quality cut with burrs along the edge, and cleaning it with sandpaper along all the bends is only a punishment for some kind of sin.

Jigsaw saw

Before you start sawing, you need to drill holes in the sawn places with a diameter of 8 mm to insert the file. Then drill out the round parts of the future voids with a suitable perforated drill. This is easier than cutting with a jigsaw, especially if the diameter of this part is small. You can't turn around with a jigsaw. And only after that you can start the main work with a jigsaw.

Assembling the sides of the casing

Each side of the casing consists of several carved parts, fastened together with glue and dowels. The assembled carved parts are fixed in the same way on rectangular slats.

Assembly

Dowels are glued into the carved parts, which, when assembled, are inserted into the mating sockets for glue.

Assembly

Assembly

Side part, composed of 4 parts

The black dot at the bottom is a hole (drilled in place) for attaching the platband to the wall.

Top part

The upper part consists of 6 parts. For clarity, the photo shows the joints of the parts and the location of the dowels. Two squares - attachment points for brackets with back side(described below).

The locations of the dowels are marked. Consists of 4 parts.

Assembled on a dry (without glue) platband

After assembling all sides, you need to paint them in the desired color. And only then produce final assembly platband.

Painting is the tedious part of the job for me. It is necessary to paint over each curl with a small brush in two layers with intermediate drying. I made the first platband for the attic window and painted it by hand, but now I have made a kit for the remaining 4 windows and will paint only with a spray gun.

bracket

The platband is attached to the window using brackets for plastic windows fastened with self-tapping screws to the upper part of the casing from the back side. With these brackets, the platband clings to the upper part of the siding platband like hooks and hangs on the window. From the bottom, in the side parts, one hole is drilled from the side, through them the platband is attracted to the wall with long self-tapping screws.

I made the dowels myself, I prepared about 200 pieces. Enough, a little more and left.

Pediment decoration.

It was with him that the whole venture with carved lace and platbands began. As the saying goes, appetite comes with eating.

Gable

By the way, about the financial side: 5 platbands cost me a little less than 2,000 rubles. Having rummaged on the Internet, I found about the same, but more unpretentious, at a price of 8500 rubles. for one set. So at least 40,000 rubles. remained in the family budget. Also a pleasant incentive.

The entry is posted in sections:

After installing windows in a wooden house, there is always a gap between the wall and window frame... The most in a simple way to eliminate it is to install platbands. In addition to functionality, they play the role of a decorative element that adorns the facade of the house and makes its appearance unique and complete. Some of the most beautiful are carved platbands made of wood.

Types of platbands made of wood

Today, platbands exist not only in wood, but also in wood-fiber, plastic and even ceramic. But the most demanded material for their manufacture is still wood. This is due to its environmental friendliness, affordable price and high aesthetic qualities. In addition, wood can be restored, thereby extending its service life.

Smooth or profiled from solid bars. If in the future the platbands are painted, then conifers are used, most often pine. When made from valuable breeds wood, they are varnished. Fasteners are nails, screws or liquid nails.

With figured carving from solid bars. They are mainly made of fine wood and varnished. They can be attached both to screws and to simple and liquid nails.

Smooth or profiled from glued bars. They can be produced already finished with laminated film or veneer of expensive wood species, which eliminates the need for additional finishing... But, there are also no finishing, intended for painting.

Stylized for a specific style. The most expensive type of platbands, which are made exclusively to order.

In addition, they are divided in appearance into flat, shaped and curly platbands.

Flat. The cheapest and simplest type of platbands. But it has a low aesthetic value.

Shaped... Most often they have a convex surface that has cuts, protrusions or grooves. They cost more than simple flat ones. This is due to the production technology, which requires the use of special equipment.

Curly wooden platbands... They are decorative elements and add personality to the house. They are produced on special machines equipped with vertical cutters. In this case, the desired pattern is programmed, and the machine automatically mills the surface. But despite the latest technology, the capabilities of such equipment are limited.

And only a master can make an openwork relief. Wooden platband price self made will depend on the complexity of the ornament and the type of wood.

But the main difference between manual milling and machine milling is that the machine does not make a through thread, but only applies a pattern to a certain depth of wood.

Wood for the manufacture of platbands

If it is necessary to make a flat or shaped casing, then a simple pine is used. To make carvings, you need soft wood, such as linden. It is easy to process even with hand tools and is easy to grind. But due to its high hygroscopicity, it needs high-quality topcoat... This involves the application of several layers of paint and varnish composition.

In regions where significant temperature differences are possible, as well as high humidity or, conversely, a dry climate, they make wooden platbands from dense and hard wood. These include birch and oak, which are extremely difficult to process, but they will last for more than a decade. Therefore, platbands from these types of wood are most often made on milling machines.

The only drawback of all types of wooden platbands is their high hygroscopicity, which eventually leads to their cracking and drying out. This can be avoided by periodically renewing the protective paint and varnish layer.

Tools required for the manufacture of carved platbands

Through thread most affordable way decoration of platbands for non-professionals. It does not require special skills, you just need to have patience, diligence and a sense of beauty.

A large number of companies offer, various platbands made industrially... But it is much more pleasant to make it yourself. As a tool, manual milling machines, conventional or electric jigsaws, different kinds drills, chisels and hacksaws.

Basic rules for the manufacture of platband

When making wooden platbands with your own hands, it is important to consider that after installation, they should not interfere with the normal opening of windows. So inner dimensions platbands are made more size window frame 2-3 cm.

The upper part of the casing is called "kokoshnik"; if necessary, it can be extended by fastening the parts with thorns. The lower part is called "towels" and is attached at an angle from the wall to drain water. It also has a thread that matches the style of the "kokoshnik" thread, but the bar for it should be 1 cm thicker than the top bar.

Before installing the platband, it is necessary to nail the slats around the perimeter of the entire window - this will completely close all the unevenness of the wall. The joints, however, must be carefully fitted.

All platbands are made in the same style.

Preparation for work

For the manufacture of a carved platband from wood, you should choose a board 3-4 cm thick. It is optimal for free opening window sashes... The width should be sufficient to cover the edges of the walls and protect them from moisture. Alder, linden, aspen or conifers can be used as wood.

The choice of small ornament is not the best good decision... It will be difficult to distinguish from a distance, and it will take more time and a special thin tool to manufacture. Therefore, the ornament should have large elements that are clearly visible from afar.

Location carved elements along the grain of the tree, protects the platband from cracking. This is especially true for wood. conifers.

Use simple patterns at first. The easiest for those new to carving are round elements patterns that are simply drilled with a drill. Below are sketches of samples of wooden platbands.

More details about their manufacture can be seen in the video.

Installation of platbands on windows

You can make stencils yourself or transfer a drawing from ready-made sketches. First, a pattern is applied to the workpiece, then a hole is drilled with a drill and the necessary ornament is cut from it with a jigsaw. Further, the cut out platbands must be well sanded with sandpaper.

After the carved blanks are made, they should be connected correctly. In total, there are two ways of connecting: on spikes or half-tree connection. The first method is much simpler and more popular, the second is used extremely rarely.

A special glue is used to fasten the platband. It is important that it is synthetic, since fungus can appear in the organic compound and moisture can collect. All this is very harmful to the wooden platbands.

If the elements are attached to nails, it is advisable to first grease all joints with glue, and only then fix them with nails. We should not forget about the glue treatment of all joints and especially the thorns.

Platbands are easiest to install on windows using wood screws. You can decorate their hats with sawdust mixed with glue, which will be painted over later. But even without this work, the screws will be practically invisible against the general background.

Finished platbands must be covered with a protective compound that will extend their service life by long years... For this, it is better to use special impregnations, which should be periodically renewed. The paint, no matter how high-quality it is, will begin to crack and peel over time, and it will be much more difficult to fix it.

When choosing a pattern for the future platband, it is very important to take into account the style of the whole house, because they should harmoniously complement it. Here are some examples of photos of carved wooden platbands.

In most cases, carved platbands are used to decorate windows. wooden houses... But in view of the fact that it is quite problematic to buy a ready-made platband today, it is easier to do it yourself.

Important! All platbands, albeit of the highest quality, have one significant disadvantage- they need protection from atmospheric precipitation. The manufacture of window frames traditionally begins with the preparation of everything you need.

Stage 1. Equipment

In the process, you will need the following tools:

Stage 2. Material selection

For ordinary platbands, it is better to use pine, while for carved products it is recommended to take soft rocks, for example, linden (the latter, moreover, is much easier to handle by hand).

Important! The only disadvantage of linden - hygroscopicity - can be easily eliminated by applying several layers of paintwork.

Hardwoods should be chosen in three cases:

- at high humidity climate;

- too dry air;

- in the presence of significant temperature fluctuations.

Hardwoods include birch and oak. They are quite difficult to handle. hand tools, therefore, a milling machine will be required, but such a tree will last several times longer than a linden.

Stage 3. Important points in the manufacture

Finished wooden platbands should not impede the opening of the sashes by at least 90ᵒ. With regard to other parameters, they are selected individually in accordance with the size of the opening. For fasteners, you can use spikes or connect the elements in half a tree.

Important! In the future, the upper part of the casing can be enlarged to apply large images to the surface. Spikes are used for fasteners, and the decoration itself is popularly called "kokoshnik".

The lower part of the product is made in the same carved manner and must include the bevel required for the drain. It is characteristic that the thickness of the lower part should exceed the thickness of the upper one by at least 1 cm.

Small slats are nailed on both sides of the opening - they will hide the differences in the walls (if any). The thickness of the strips should match the width of the gap, at least approximately. The final fastening is carried out only after careful adjustment of the joints.

Important! If the sash opens onto the street, then the platbands must be installed 3 cm above the window itself.

Stage 4. Pattern selection

Since ancient times, platbands have been decorated with the most bizarre patterns, which were believed to protect the house from evil spirits and the evil eye. Today, mainly skilled craftsmen are engaged in the manufacture of carved platbands.

Important! To dodo-it-yourself window frames, you first need to choose a good stencil that will allow you to create a pattern of any complexity, even without special skills in woodcarving.

Often the professionals themselves use stencils; without them, only one-time individual orders are carried out.

Stencils are freely sold today in enough wide range... They consist of the following components:

- lower bar;

- top bar;

- vertical slats.

In addition, there may be additional decorative details - hangers, and so on.

Step 5. Making the frame

First, a frame is formed from the pre-cut elements. Fastening is carried out using thorns, which are fixed in the hole with beads. A jigsaw is usually used to create the thorns, although a regular small-toothed hacksaw will do. A small knife is used to remove the sawdust.

The width of the finished frame, as well as the platbands described above, should not interfere with the free opening of the doors by 90ᵒ. The frame itself should be at least 2 cm larger than the window frame.

Stage 6. Manufacturing of platbands

Step 1. First, the drawing from the stencil is transferred to the tree by means of a carbon copy.

Step 2. Then a jigsaw with a thin blade is taken and small curly elements are cut out.

Step 3.C outside the contours of the pattern are cut so that the canvas runs along the edge of the workpiece.

Step 4. In any case, you will have to turn the saw in the workpiece. To do this is quite simple, you just need to use one of the two existing methods:

- upon reaching a turn, several parallel cuts are made (the saw should be able to turn to any angle inside the hole);

- you can go the other way - make a small loop that will allow you to enter from the back side.

Important! Modern jigsaws allow you to make cuts at an angle of 45-90ᵒ, so you can not only make the smallest cuts, but also give decorative element more saturated and voluminous form.

Step 5. If it is necessary to cut a closed shape in the center of the product, a hole is drilled in the middle of the part to be removed. After that, the jigsaw blade will be easier to move in one direction or another.

If the workpiece is thin enough, then when processing it, you can do without an electric drill. To do this, take a jigsaw and rests on the workpiece at a right angle. Then the tool is turned on and the hole is scratched, as it were, when the canvas is deepened into the wood.

These are all key aspects of the manufacture of window frames. Actually, the whole procedure comes down to repeated repetition of the actions described above, but their specific combination depends only on the skills and complexity of the pattern.

It should be noted that there are other manufacturing methods that differ from those described above. For clarity, we recommend watching a thematic video.

Video - Production of window frames

Find out which ones are better to choose, as well as consider the types and methods of installation, from our new article.

Prices for platbands and accessories for windows and doors

Platbands and extensions for windows and doors

Fundamental rules. What not to do

Below is a list of rules to help you avoid the most common problems.

- It is recommended to use a board 3-4 cm thick as a starting material.

- Don't jump on complicated patterns right away. It’s best to practice with regular round parts, which are easy to drill with a drill at first.

- The width of the workpiece must be such that it is sufficient to cover the ends of the walls and protect it from moisture.

- Carved elements should be placed along the grain of the wood to prevent cracking.

- When choosing a stencil, it is better to pay attention to patterns with large elements, since small ones will look crumpled, as a result of which the finish will not have the desired decorative effect.

Important! Before starting work, you should calculate the future costs of time and money, as well as the feasibility of the venture itself. In the absence of high skills in working with wood and interest in the process itself, it is easier to buy ready-made platbands.

Moreover, it is advisable to first familiarize yourself with the photos. different products... So you can find suitable option or to get inspiration for your own hand about creating something.

Step 7. Installing the product on the window

Now all that remains is to install ready-made carved platbands on the windows, for which special glue is used. It is important that it is not organic, otherwise, due to exposure to biological influences, it will harm the products themselves.

You can use and sanitary glue- there shouldn't be any problems with him.

Important! If the fastening will be carried out with the help of nails, then the spikes and joints should be greased with glue solution in advance.

Another option that can further simplify the installation procedure is to use self-tapping screws instead of nails. It will be easier, if only because there is no risk of damaging the platband or the surrounding surfaces with a hammer.

Important! The screw caps are very easy to disguise. Must be mixed sawdust with glue and the resulting mixture, spread the caps. It is advisable to do this even before painting the windows so that the hidden fasteners also acquire the required color.

The final painting procedure is also quite simple. On top of the finish, some kind of protective material is applied (not only paint, but also, for example, varnish, impregnation). It is advisable to do this in any case, since such a coating significantly extends the service life of the products.

The paint is known to peel off, so it is advisable to take it instead. It is much easier to periodically renew the impregnation than to remove cracked paint. And the latter, as you know, will surely crack.

As a conclusion

It is commendable that people strive to follow the traditions of their ancestors, because this is especially important in the current conditions of active urbanization. For self-made window frames will take a little time and the appropriate equipment. The procedure is complicated, but the result will more than pay off all the costs. Moreover, this way you can save a considerable amount of money, since the production of trims for one window to order will cost an average of 2.5-15 thousand rubles.

Video - Options for platbands

Platbands are an important component for any window. They are often associated with beautiful carvings, serving purely for decorative purposes. But they do not always have a catchy look, and they have much more functions. It is a versatile element that is essential for protecting windows and improving their insulating properties. Therefore, their installation is recommended in almost any wooden house.

What are platbands for?

The platband decorates the window and makes it much more colorful. But initially its purpose was defensive. Platbands are used as an external element of the window frame, which not only protects it from damage, but also closes the mounting gap between the frame and the wall of the house.

This approach provides:

- Reducing heat loss;

- Elimination of through holes;

- Dust and noise protection;

- Moisture protection.

Interesting ! Previously, platbands were also used as amulets. Because of this, they were given a colorful and non-standard look.

While these advantages are not so significant in concrete and brick structures, they are extremely important for timber houses. Over time, wood can dry out and deform, which leads to gaps between the frame and the rest of the structure. Platbands allow you to slow down this process, as well as reduce damage from existing holes.

Types of platbands

For houses, a lot of varieties of platbands are used. Often they differ in the material used, since they have a similar design. The main classification of platbands follows the installation method and marks two types of platbands:

- Overhead;

- Telescopic.

The overhead version is considered the most common, being the old type. It is installed simple method over the window frame, thereby blocking access to the sun and precipitation to the joint. Installation of this type is very simple and does not require much effort.

The telescopic casing is more modern. Its attachment does not require additional elements like screws or nails, because it is placed in the gap between the wall and the frame. As a result, it is securely fixed around the entire perimeter.

Use the telescopic mounting method as a priority. It is more convenient, because it more reliably covers the gap and prevents its deformation. However, its installation is complicated by the fact that for it it is necessary to completely remove the window, which is not always possible in wooden houses... In such cases, it is easier and more efficient to use the invoice platband.

Platband materials

Materials for platbands can be different. Wood is often used for these tasks, which is recommended for wooden structures. But here several options are allowed, including:

- Wood;

- Plastic;

Wood is a practical and natural option for any building. Due to its versatility, it can be given any ornament and style, and the use of the same type of material will allow it to perfectly complement.

Advice ! For better alignment, it is recommended to make platbands from the same wood as the structure. But if the texture is the same, then the color can be changed using special compositions.

Often it is chosen precisely because of the variety in the decor, because other materials require special processing on machines and rarely have such decorating elements.

While wood is reliable and durable, it has its drawbacks. These include vulnerability to moisture and high temperatures... In addition, frost also affects it negatively, destroying and deforming the structure.

Plastic in this regard is much more convenient. It is practical and reliable, and its wide production possibilities allow you to give it any texture, including woody. But at the same time, it does not deform from moisture and temperature extremes, and its lifespan is much longer. Another advantage of plastic is that it has fasteners in advance, which allows it not to spoil appearance platbands with nails or screws.

Perhaps the only drawback of plastic is its artificiality. Many owners do not want to complement their home artificial materials and reduce its environmental friendliness. The third option can help here.

MDF is a board made from wood waste. They are natural, but at the same time impregnated with special compounds, which significantly increases the life of the material and protects it from exposure external factors... Often, such platbands are laminated, which increases their lifespan and reliability. The only drawback of such elements is their relatively low strength compared to plastic and wood.

What material to take is a purely individual choice. Each of them has its own advantages, but there are also disadvantages.

Which wood is better

If the choice fell on wooden platbands, then it is important to note the choice of wood species. In fact, almost all options are suitable for this task, because they do not need to transfer any load. But here, too, there are some nuances.

The best option for platbands is oak or beech. It is a tough rock that can last a long time and will not deform from moisture or heat. But the problem is that it is extremely difficult to work with. It is extremely difficult to independently cut patterns on such material, and not every master will undertake this.

Advice ! The way out of this situation is special milling machines, the pattern on which is pre-loaded into the program.

If you need a softer and more inexpensive breed, you can choose a linden tree. It's easy to work with, but without careful handling, it will quickly collapse. It is necessary to use high-quality antiseptics and some kind of coating, which can worsen its appearance.

An intermediate option for such a task is birch or pine. It is a fairly sturdy strain that only requires basic maintenance. But at the same time it will be easy to work with her.

Preparing for installation

You must first take all measurements from the window. It is important to choose the appropriate dimensions so that the frame contour does not peep out from behind the platband and is reliably hidden. Further, the preparatory stages with the material are carried out.

If wood is used in the process of work, then you need to first cut out the blanks of the platbands, decorate them at your discretion and process. Plastic and MDF do not require processing, but wood needs impregnation protective compounds against moisture, as well as for protection from insects.

Important ! All work is carried out with dry lumber. If it is poorly dried, then deformation is possible after installation, which will ruin the whole work.

After measurements and processing, it is important to mark in advance the places of joints and fasteners on the platbands. All holes are pre-drilled. Platbands are carefully polished.

It is also important to prepare the place of work itself. Window joints are carefully insulated, because in the future access to them will be limited. If any insulation or repair work is planned, then they need to be done before installation.

You must first select the mounting method. It is not required for telescopic platbands, but there are several options for overhead trims. Among them, the most popular are:

- Nails;

- Deaf thorn;

- Through thorn.

The first option is the simplest, but spoils the overall picture and creates an extra load on the material during installation. Therefore, the cleats are more comfortable. A blind thorn implies the installation of small thorns on the window frame, and small holes are made in the casing for them. A through thorn implies the same technology, but a through hole in the casing.

If the house is built from a log house, then you need to make room for the platbands. To do this, it is worth cutting off the protruding edges, which can be done at an angle.

Installation of platbands in a wooden house

After carrying out all the preliminary procedures, the installation stage begins. To begin with, all the components of the casing are interconnected. To do this, you can use the same spike technology, nails or glue. But the latter is often used as an auxiliary component.

During installation, when using spikes, you need to do the following:

- Mark the future location of the studs on the frame and trim;

- Make or purchase spikes for this task;

- Drill the corresponding holes in the pre-marked places;

- Place the platband on the spike and fix it.

The first stage includes a preliminary marking of the perimeter, where the fasteners will be placed. It is important to evenly distribute the load, so they should be placed around the perimeter of the structure.

After the acquisition or manufacture of spikes, future holes are drilled for them. This is a simple stage, after which the installation process itself begins. The platband is neatly positioned so that all the spikes fall into the holes.

The task is quite simple, it is only important to accurately mark the future location of the fasteners. It is recommended to use glue during work in order to securely fix the structure after installation. This will reduce the risk of it falling and improve the insulation of the holes.

You can simplify the process by using ordinary self-tapping screws. Although they will degrade the appearance, their use greatly simplifies installation.

Upon completion of the work, it is worth treating the working holes with a composition so that they do not absorb moisture. Next, you just need to monitor the state of the structure and take care of it as needed.

The whole process is quite simple, it is only important to qualitatively connect all the elements and not neglect preparatory steps installation. Thanks to this, such a structure will last a long time, decorating the house and protecting residents from drafts and moisture.

Any owner dreams of making his home memorable and beautiful. If the house is no longer new, it is not so easy. One of the possibilities is carved platbands. They will even turn an ordinary "box" into a masterpiece.

Material for platbands

Carved platbands are made mainly of coniferous wood. The best option- pine, normally cut, inexpensive, durable due to its high resin content. In principle, you can use any other coniferous board, but it is better not to try with spruce: it is too fibrous, it is not cut even with the sharpest tool.

You can also make carved platbands from hardwood - linden (the softest), poplar, maple, oak, cherry, etc. But you need to know how to work with each species, get your hands on it, and there is no guarantee that something digestible will turn out, and hardwood is expensive. Therefore, window frames are often made of pine. You just need to pay attention to the quality characteristics.

Carved window trims - a way to make your home unique

If there is wood or a board that has lain for 3 years or more, you can use it: it is already definitely dry, only processing and calibration will be required. If there is no woodworking equipment at home (thicknesser and circular saw), you will need edged board... Wood of the first or top grade... This means that there should be no knots, chips, or resin pockets on the board. Take wood chamber drying, with a moisture content of no more than 8-12%. This is not for sale in the markets, you need to look for it at sawmills and in hardware stores.

Why chamber drying? Because it is dried in a special chamber, rapidly removing moisture. At the same time, some of the boards crack, bend - these go to rejection, the rest are sold. If you make carved platbands from oven-dried wood, they will definitely not be crumpled and they will not crack.

Tools

To make carved platbands with your own hands, you will need the following minimum set:

- drill with a set of drills;

- an electric jigsaw with a smooth start and a bunch of different wood saws;

- chisels;

- sandpaper with different grain sizes;

- petal disc of sandpaper on wood with a drill.

To reduce the time it takes to create carved patterns and grinding, it is better to have a router and sander.

One by one or in bulk?

Carved platbands usually consist of repeating elements. At least two vertical battens on each window are made the same. And since usually several windows are drawn up, many identical elements are required. If the platbands are going to be slotted, naturally there is a desire to cut out several pieces at the same time, folding the boards in a pile and somehow fixing them.

The desire is understandable, but difficult to realize, and the benefits in time are not as great as it seems. The first difficulty is that home craftsmen usually have jigsaws that are not too powerful. To cut through several planks, you have to move the file more slowly along the intended pattern. On straight lines the speed is still tolerable, on curves it is low. And, the smaller the bending radius, the slower you have to move the file. If you are working with one board, there are no such problems. So, in terms of time, the gain, if there is, is quite small.

One more point. Even thick, good, expensive files are deflected with a large thickness of the workpiece. So, when cutting several boards at the same time, the quality of the cut on the bottom (or two) remains a big question.

The procedure for making a platband with a slotted thread

Using a template, we transfer the desired drawing to the board (where to get it, how to enlarge it, how to make a template, read below). If necessary, we correct, draw the details well. Next, we will describe the procedure step by step.

We remove the wood in the slots of the picture

Since the carving will be looked at from afar, some inaccuracies are not fatal, but it's still worth striving for the ideal.

Making a curly edge

Some platbands have a straight edge. Then we skip this stage. If the edge is curly, you will still have to work with a jigsaw.

If the cut is difficult, it may not be very attractive places. This is not scary, then we will process them where necessary - with chisels, the same jigsaw, emery. When you are satisfied with the result, you can move on.

Final revision

The owners of wooden houses probably know everything about how to handle wood. But, just in case, let's repeat the general rules again.

Choice paints and varnishes very wide. Any for outdoor work. But keep in mind that opaque paints will have to be renewed periodically - just like that once a year. And that means - to shoot old paint, primer, paint again. The situation is simpler with oils for wood - they do not give a film on the surface of the wood, but are absorbed into the fibers. It is also necessary to renew the coating, but just remove dust and cover with a new layer. And the processing frequency is less. Cons of oil for wood - higher price, fewer flowers.

How to enlarge a template

Simple carved platbands can be made without templates. There will be several examples in the video - it shows how to outline, how to cut. But not everyone will be able to draw more or less complex patterns on their own. You need skill and talent. The easiest way is to find the diagram, print it in the right size, transfer to cardboard and cut out. This will create a pattern that you can trace.

The second way is to sketch from a photograph. Not all schemes can be found. Some, especially the old ones window frames, you won't find it anywhere. If you have at least some drawing ability, you can sketch them.

Even such an ornament can be drawn ... if you have the skill

Questions may arise about how to increase the size of the found schema or template. There are three options:

- Using any graphics editor. The simplest one - Paint - is on any computer running Windows (the "Image" tab, the "Resize image" line, select "centimeters" and in the box put desired length(height). The resulting file can be printed. If the printer is small, it may need to be split across multiple pages. Then they should be glued together and, according to the resulting picture, make a template.

- Using a photocopy. Copier has a zoom function.

- Taking graph paper, transfer the drawing to the desired scale. To do this, divide the original image into squares with a side of 0.5 or 1 cm (you can print it on a piece of paper in a cage). Then we transfer the lines to graph paper, increasing them in the required proportion.

The first two are faster. But when scaling, the picture may turn out to be fuzzy and blurry. It can be corrected by hand, you can draw in some kind of editor, for example, CorelDRAW. How to do this, see the video. Just an example of drawing a diagram for a thread.

Related Videos

Schemes, templates, patterns

The style is completely different ...