What to smoke linseed oil. Proper use of wood for exterior and internal works. Ask your question

Wooden Cover: Cooking Coraished Lacquer, Oil and impregnation

All the beauty of the wood is that it looks perfectly in itself, just to show it to the texture. The kel can be used to get the desired shade. Sometimes, for example, a light wood need to darken slightly, it is in such a situation that the kel is useful.

Tree treated with melted oil

We understand the terms

Tinting varnish for wood (as well as verses, impregnation and other means) means the gradual addition of the dye until it acquires the desired shade. That is, the color is dye, which is gradually added to the solution.

Note!

Under each type of means for treating a tree, apply its type of flaper.

Otherwise, it may simply not dissolve when stirring, as a result we will get a suspension that cannot be used for processing.

As for what exactly to choose exactly, it is recommended to adhere to the map of colors when purchasing it. It is also not superfluous to know that the kel in which organic pigments are used is not particularly resistant to light. Therefore, for external work it is better to use a kel in which inorganic pigments were used.

In the photo - Map of colors for selecting the desired shade

You can consume a few hundred, only the common types of caller wooden stairs Include about 50-100 shades. But if suddenly the palette of colors is not enough, you can always mix 2 different colors And get your shade.

In this case, it is recommended to first experiment with a small amount of the coller and try out the resulting melted varnish or a veil on an unnecessary piece of wood. A sign that everything went well can be considered smooth surface After drying, the lack of drows and uniformity of the color.

First you need to test the melted lacquer or the veil on a piece of wood

How to compose

In a nutshell, the instruction on the caller is that the dye is slowly added to the veil, paint, etc., after which it is simply thoroughly mixed. The dye is added gradually and when the liquid reaches the desired shade, you can proceed to the trees processing. Nevertheless, there are a number of nuances, depending on what needs to be prepared - varnish, a simile or paint for wood.

Cooking the melted varnish

The main purpose of processing is to create a durable film on the surface of the wood, after drying the varnish it will protect the wood from penetrating moisture into it, the texture also appears. The melted varnish for a tree is different from usual topicsAfter processing, the wood texture is not just manifested, but also there is staining in the appropriate shade.

Sometimes even famous manufacturers may make mistakes in the color map, so it makes sense to take care of the preparation of varnish the desired shade with your own hands. Dyes are usually sold in the same stores as the wood processing agents. You can even try to negotiate with the caloring machine operator and the kel can cast into your container. It's simple perfect optionBut everything depends on the mood of employees.

The desired color can be obtained from the caloring machine operator

You can try to perform a tinting and with the help of priests. For example, there are references to the successful experience of adding an aqueous veil to the acrylic varnish (a kind of water varnish color). The solution obtained at the outlet is quite pale (even with a high concentration of the veil), so what is suitable in cases where the strong blackout is not necessary.

As for the processing process of a wooden product, it is recommended to adhere to such a sequence:

- the surface is thoroughly polished. Immediately before applying the lacquer layer, you need to wipe the surface to remove dust;

The surface should be perfect smooth

- then the first layer of the melted varnish is applied;

Note!

All the product is covered by varnish at once, in no case is it not recommended to break the surface to the sections.

If you cook the next portion of the varnish then, it is hardly possible to get the same shade, and the difference will be noticeable.

- tree tinting is performed at least 2 layers. But if the surface is quite porous, and the varnish itself turned out not very rich color, the number of layers can be increased to 3-4;

- the last layer is recommended to make colorless.

Code oil and impregnation

- ordinary oil paints. They can be mixed at room temperature;

- you can also gouache. But so that water does not interfere with the process will have a mixture to warm, water will evaporate;

You can use gouache

- in the past, people used both dyes as ordinary ash. For example, tinting oil for wood ashes will achieve dark gray or even black, it all depends on the concentration of the dye. Sozha, color clay and other natural materials can also be used;

Dark color can be obtained mixing with butter South or ash

- if you get a dry color and mix it with oil, we will get an analogue of purchased oil paint. Since the price is comparable, it makes no sense to mess with stirring oil and dye, it's easier to just buy paint.

It should be remembered that when working with an oil, a too large concentration of the dye gives a more rich color, but the oil properties are lost. That is, it is no longer so well protects the tree from moisture and over time the coating will need to be updated. So the tree for the wood can be added to the balance between the oil properties and color saturation.

In the case of impregnation, color after processing is usually secondary, but at this stage you can achieve the tree to have a noble view. If a part of the structure is processed, which will not be visible, then iron oxide can be added to the solution, just to be seen which part is processed, and which is not.

Iron oxide will give a bright red color wood

Calling impregnation for wood can be performed to simulate red or any other noble wood. YF, GO, KFI coalescent are used as dyes. By weight, the concentration of these substances does not take up to 4% of the impregnation mass. But here's a change in concentration even on the share of percent gives a spectrum of colors from camouflage green to the color of black chocolate, so that it is simply infinite for experiments.

Summarizing

Calling varnishes, oils and impregnations for wood - the process is creative, and therefore very exciting. By adjusting the concentration of the dye in the composition of a liquid or oil for wood processing, almost any shade can be achieved. As a result, even a simple pine looks sophisticated after processing.

This article shows an example of using acrylic varnishMounted by the usual veil on a water basis.

http://rubankom.com.

Impregnating oil - one of the easiest and at the same time effective ways Protective and decorative wood processing. Today it will be about the types of oils, differences in the compositions for internal and outdoor works, as well as the technique of performing the impregnation of wooden surfaces and wood products.

Wood oil - distinction and classification

Covering joinery oil can be called the most eco-friendly and exaggerated safe way Wood processing. All because the composition of oils enter either absolutely natural or inert chemical compounds. Immediately make a small reservation: there are oils for wood, which included volatile solvents, but after drying, such a coating remains absolutely harmless.

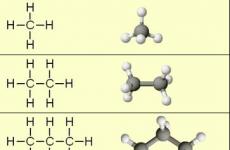

Almost all oils for wood are made on the basis of flaxseed oil, and if more precisely, linen or other natural oils. Characteristic feature This material is an extremely high tendency to polymerization. Clean oil for wood processing is almost never used. Oryol base can also be hemp, tung or other origin, mainly differences are expressed in conditions that contribute to thickening and polymerization.

Oils are very different in their technical characteristics: viscosity, density, type and content of dry residue, volatile solvents and special additives. All this not only affects performance Coatings, but also entirely determines the technique of applying and the nature of interaction with a certain breed of wood. On the other hand, the oil is classified and decorative effect, That is, according to such features, as the intensity of manifest texture and the depth of changing the color of wood.

Viscosity differences

In a joinery, there are about two dozen rocks of wood, characterized by density, porosity and vessel sizes. In each individual case, the oil must be selected individually, taking into account the size, shape and specific features of the product being processed. We note that you can regulate the viscosity of the solvents only when working with tung oil, other compositions cannot be categorically endured.

The more thick and viscous oil is used, the harder it is to apply a uniform layer before polymerization starts. Working with thick oils requires greater accuracy, the resulting fluthers subsequently remove very problematic. The advantages of thick oils are high drying speed, comparable to some species of varnishes. Also, due to the large content of solid particles, such oils form a stronger film, providing protection from both mechanical damage and contamination.

Liquid oils are used to treat products that either have a significant surface area, or abound in small parts with many details. hard to reach places. Low viscosity oils can be applied for quite a long time without fear of uneven drying. However, to gain high-quality protection, the product should dry long enough, besides, usually applying such oils is performed in 3 or more layers.

Decorative properties of oils

When choosing an oil paramount importance It has a visual effect of its application. From this point of view, the oil is divided into conditionally colorless and core. Why are colorless oils call only conditionally? Because in any case, they change the color of the tree surface in any case, but at the same time they retain transparency. Corrier oils include colloidal suspension of coloring pigment - from Belil to soot, which slightly muffle the contrast of the pattern of texture.

Transparent oils always exhibit wood texture. This is due, first of all, with a viscosity indicator. What it is lower, the smallest pores of the wood can be impregnated. Thick oils exhibit only a common pattern of fibers, more rare - small parts Textures. So, for the processing of oak surfaces, the oil must have a viscosity just below the average, while saturated thick compounds are recommended for alder.

The use of clarifier oils is largely sealed. Tooling of wood oil is quite rarely used as an independent processing technique. Much more often with the help of such compositions, the soft streaks between the solid fibers of the tree are emphasized or covered separate furniture elements. Corrupting oil after drying has a smaller glossiness than colorless.

It is not known whether such a property of oils as a smell can be attributed to decorative qualities. In fact, all oils smell absolutely different, from hayrokos to fried seeds. After drying, the smell of oil treatment turns into a very resistant, but hardly catchy fragrance, which can become a valuable part of the interior color.

The difference in the content of dry residue and wax

Despite the seemingly uniformity, oil for wood is a colloidal system consisting of liquid oil basics and suspend solid substances. As the latter, the products of partial oil polymerization are performed, special additives (sequivans in oils for external use), resins and natural wax. You are absolutely right if you suggested that the content of solid particles increases its viscosity and density.

The high content in oil is partially polymerized inclusions contributes to the elimination of the effect of raising the pile when weaving the tree. Using saturated thick oils, sometimes it is possible to completely avoid intermediate grinding or polishing. This traces one interesting trend: thick oils are perfect for large-sized wood, where the formation of a high pile is possible, while the flowing formulations are better to use for dense solid rocks, practically not inclined to "lochmatiness". On the other hand, due to the maintenance of the dry residue, the oil drying time is adjusted.

The inclusion in the dissolved wax pursues several other purposes. The wax helps to tightly clog the pores of the wood, providing it with excellent hydrophobicity. Such a fascination is used mainly in outdoor finish To protect the tree from the wetting and accumulation of dust in small pores. Another reason is that the wax is added to the oil, being dissolved in a turpite or other flying solvent. From here there is a problem persistent unpleasant odor, what in residential rooms Extremely undesirable. But there are oils in which the wax dissolves when heated. This mixture is unstable, the wax is often precipitated, which makes the use of oil more complex. However, due to the high ecology of such a composition, it is possible to carry out the fit of the interior details, but not for the purpose of protection, but to impart a light shade and gloss.

Protective properties of oils

In contrast to most protective equipment For wood, oil does not form a deaf film, while maintaining the vapor permeability of the material. At the same time, the hydrophobicity of the surface increases at times - with contact with liquid water, the absorption of the tree has almost zero. Nevertheless, the product from the tree remains susceptible to the drying and swelling, the oil coating does not save on these phenomena.

The protective effect of the oil lies in the sealing of the outer layers of the tree, due to which the penetration array of insect pests is eliminated. Due to the lack of ways to penetrate moisture, the tree becomes in the smallest extent susceptible to organic affect mold, fungus or blue.

Oil also retains the color of wood, especially it is important for exterior decoration at home. Cork oil formed on the surface effectively disperses sunlight And limits the influx of oxygen. Due to this, the speed of cellulose oxidation rate and the associated appearance of grayish raids is reduced.

All these properties are expressed stronger than the more thick oil is used for the coating and the more layers are applied. For oils, the separation of protection into two barriers is characterized: the internal, achieved impregnation, and the outer oil film forming on the surface during drying. It should be remembered that wood soaked wood has a higher thermal conductivity than dry.

Choosing in accordance with the wood

The oil for wood is always selected under the definite breed. It is recommended to have a trial segment of wood of the same type and quality of processing that are characteristic of wooden finish. Trial applying even on small sites It will help to quickly assess the behavior of the composition when contacting the tree, as well as the decorative effect.

It follows from the fact that all coniferous breeds Woods practically do not need impregnation with oil. Upon further need to use dense formulations applied in one layer. This is due to the presence in the pores of a large number of resins, which is why the tree loses the ability to absorb even fluid oils. Therefore, it is necessary to achieve rapid drying of the oil on the surface and in the surface layer.

Thick saturated oils are also used when processing wood with low density (linden, alder), especially fruit breeds having the most developed vascular system. There are no obstacles for impregnation with thick butter, while excessive flowing compositions will penetrate too deep and will forever remain in liquid state, having lost access to oxygen.

A completely opposite approach is used in the processing of beech, birch or plane. because of high density Such wood is impregnated with either non-light oil, or compositions with a solvent content. Often when working with solid dense rocks, their processing is performed by combined: first with oils that penetrate inside the wood, and after - thick compositions with a high proportion of dry residue and wax.

Features of applying and maintenance of oil finishing

The process of applying oil is extremely simple, it suffices to follow the instructions for the use of a certain composition. But there are general rules:

- Wood before applying oil should pass chamber drying (Humidity no more than 12-14%) and surface grinding to eliminate tactile roughness.

- Application is carried out strictly layered along the entire surface of the product, each layer must completely dry.

- Laying set time After applying the surplus, the oil is triturated with dry rags, distributing it between areas with uneven absorption.

- The oil is applied on all sides of the part in equal amounts, and the surface with an open slice of the fibers is no exception, despite the increased speed of absorbing.

- If, after drying the oil on the surface, a pile rose, before applying the next layer, it is necessary to carry out a preliminary grinding, otherwise the fibers from the vehicle will also be glad when rubbing the oily film.

Impregnation with oil retains operational qualities for 4-5 years indoors and 2-3 years outside. After these deadlines, the coating is updated, for which it is enough to thoroughly clean the surfaces and apply another layer of oil. The thickness of the oil is chosen depending on the degree of damage to the previous finish, it is usually sufficiently thick restoration compositions.

Parquet tinting is not at all such a simple process as it may seem to many. Many nuances and submarine stones are waiting for an inexperienced person. How to tint what technology and technique to apply what will happen at the output, and other answers are viewed on the Parquet Toning page.

In this article we will focus in detail on the possibility of using the melted varnish, widely offered in all building markets and other sites. The toned varnish for the parquet is sold everywhere, but those who are offered it, hardly ever tried to use it themselves! Toning lacquer It is difficult to call a wonderful tool for tinting parquet or geepboard.

Let's start with the fact that even on a colorless lacquer, the influx and adolescence are clearly visible after drying, although small differences In the thickness of applying are not noticeable. This is due to the fact that the eye captures only changes to the degree of gloss, but the color gamma does not change with the change in the thickness of the lacquer. When using a tinted varnish, everything is different, the thicker layer, the same is darker. Even small differences in thickness will explicitly stand out. Apply Nak large square Ideally evenly, without laying the layers unrealistic.

Explain on the fingers. Cover the shallow lamella in one movement of the brush and put it on the sample easily, but to roll it with a roller, and even more so apply a brush, without applying a part of the varnish of one passage to another is impossible. The melted varnish does not waste, and the places of transitions and jacks will be highlighted with dark spots and divorces.

See the example of applying a mounted varnish ticked with a brush and the consequences of this on the parquet tint error page.

Therefore, asking the question: why after white or colored varnish remains spots on the tree?, You most likely confuse stains with conventional divorces.

Toned lacquer is never used by real masters!

But still its use is possible. First, the use of melted varnish significantly reduces the process. If you know something, work without a rush, and a few dark spots There will be no tragedy for you, you can easily toned the floor in the country with such a means. Let's give some tips. Use only roller, and good quality. Cover the varnish only along the boards exactly by the width of the narrow section. Try to make hire from the wall to the wall in one movement. Do not climb anything to correct in the already lacquered part. By the next pass, in no case climb the already lacquered part. Competently, think over the outlet out of the room to lead the roller on the finish line, you could easily leave the room. Well, something like this.

But still its use is possible. First, the use of melted varnish significantly reduces the process. If you know something, work without a rush, and a few dark spots There will be no tragedy for you, you can easily toned the floor in the country with such a means. Let's give some tips. Use only roller, and good quality. Cover the varnish only along the boards exactly by the width of the narrow section. Try to make hire from the wall to the wall in one movement. Do not climb anything to correct in the already lacquered part. By the next pass, in no case climb the already lacquered part. Competently, think over the outlet out of the room to lead the roller on the finish line, you could easily leave the room. Well, something like this.

Yes, more! If the result of one of the layers satisfied you, use the colorless option for the following coatings!

The melted varnish is well used on completely "dead" floors in apartments and production rooms. It is well painted stains, rot and other damage. True, the structure is completely lost, and the floor acquires the kind of painted. The so-called "deaf" tinting of parquet. When applied several layers of tinted varnish, a completely homogeneous dark film is formed. In this case, the reflective ability varies and disappears the glass effect when all layers are viewed throughout the depth. In this case, the color differences in thickness are leveled, and the floor looks more or less homogeneous.

But such a coating is no longer toning in its true understanding, and rather called painting.

After reading this article, you can understand why it is not desirable to use the melted varnish to perform a parquet tint or board.

Ask a question by a repair specialist. Page number 1.

Before sending your question, check out service Rules! (see below)

You can ask a question to the expert on the subject of our portal, we will try to answer you on the pages of our site.

Rules:

- If the question does not match the subject of the section, then it can remain unanswered or just be deleted.

- Any accusations of experts or site administrators are categorically not allowed.

- It is strictly forbidden to add spam! IP addresses of all visitors who ask questions are recorded, and if necessary, it can be reported for a trial.

- The administration and experts do not guarantee you that your question will be awarded. But if all previous points of rules in the question are observed, then, as a rule, this question receives an answer.

Answer questions:

Statistics questions

Hello! Can you please tell me which paint can be painted floor to dry quickly and not much smelled?

Good day! Please tell me which brush is better to paint the wooden surface impregnation? Thank you in advance)

Good day. I ask you to help choose painting input street doors. The exterior side of the door is cleaned from old paint. to metal inner side Wooden. Q: What type of paint or enamel choose for painting entrance door From both sides? Sincerely, Alexander.

what varnish can be covered with paper color photo wallpapers Komar or any varnish acrylic water-based

Please tell me which resistance to 270m2

| boris, St. Petersburg | General issues January 22, 2012, 07:18 |

Good day. Tell me what "mourn", or varnish to cover the plywood door for furniture. I have a welfare beautiful wallMost likely of the tree, or plywood, the door broke out, offered to make a new one of the thick plywood. With all patterns, clippings and other things. The master says that if you cover it competently, then I don't remember this door, I don't remember exactly, but the door can not be distinguished from the old one. But I do not really do it, although the master is good with experience. I'm just surprised if everything was so simple, probably all people would not buy furniture, and they did from plywood. Thanks in advance. Boris.

Hello! What parquet varnishes can work on top of the lacquer tex luxury?

good day ... Can I ask a question on the bathroom?

Ask your question

Dear visitor! You are in the archive of the old Mastergrad.com website

collaborate ticcurila yacht. Is it possible to?

| Jazz. March 26, 2004. 10:02:12 |

Introductory is as follows. There is an oak parquet. Light, age - about 25 years. I plan to cycle, putty and three layers of ticcurila yacht chipmith. Varnish has already purchased. Correla varnishes for interiorsPutty will buy Pukkiti. Thank you. |

| Bobr. (Moscow) March 26, 2004. 10:09:50 |

Yacht varnish do not confuse with parquet. The latter is better than the "abrasion" and the load. And the yacht is more resistant to atmospheric influences. Cylish need to full removal Old varnish, then cover the impregnation, the color you need. (Dufa, Belinka or others. After drying, parquet (and not yacht) varnish in 2-3 layers. |

| Shilov. (Moscow) March 26, 2004. 10:52:40 |

Yacht is Unica Super? There, on the bank, the yacht is drawn, but it is generally parquet varnish. |

| Jazz. March 26, 2004. 11:06:40 |

Yes, Unica Super. Well, God is with you, let him be parquet :)) Although its basic quality is the weather resistance + protection against aggressive media. Decks, add-ons and other vessel parts. And how to collare something? :)) |

| zvyser. March 26, 2004. 11:15:33 |

Here look here http://www.finncolor.ru/cgi-bin/ank/tikkurila/search.cgi?a\u003dend&uid\u003d1805596404. |

| Bobr. (Moscow) March 26, 2004. 11:33:30 |

That's how! And I was explained on the market differently. And I bought a yacht for the porch - Unica Super for Balyasin, Perill, and for floor parquet: ((( And it is not necessary to collaborate the varnish. I think it is better to cover the floor with impregnation of the right color, and then varnish. I'm going exactly that way. And already Dupitex for these purposes bought. |

| Shilov. (Moscow) March 26, 2004. 12:26:22 |

By Tweets - I completely agree with Bobr - varnish do not touch, and the floor is impregnated. |

| Alex21. (Volga Volgograd region) March 26, 2004. 12:36:54 |

If the shade is needed light, it is quite possible to smoke the lacquer himself by universal collers. It is better to apply all three layers with melted - more than a shade will turn out. Only take into account that the intensity of the shade is growing with an increase in the number of layers. |

Wooden Cover: Cooking Coraished Lacquer, Oil and impregnation

All the beauty of the wood is that it looks perfectly in itself, just to show it to the texture. The kel can be used to get the desired shade.

Sometimes, for example, a light wood need to darken slightly, it is in such a situation that the kel is useful.

Tree treated with melted oil

We understand the terms

Tinting varnish for wood (as well as verses, impregnation and other means) means the gradual addition of the dye until it acquires the desired shade. That is, the color is dye, which is gradually added to the solution.

Note!

Under each type of means for treating a tree, apply its type of flaper.

Otherwise, it may simply not dissolve when stirring, as a result we will get a suspension that cannot be used for processing.

As for what exactly to choose exactly, it is recommended to adhere to the map of colors when purchasing it. It is also not superfluous to know that the kel in which organic pigments are used is not particularly resistant to light. Therefore, for external work it is better to use a kel in which inorganic pigments were used.

In the photo - Map of colors for selecting the desired shade

You can count the cololler to count several hundreds, only the common types of coloring wooden stairs include about 50-100 shades. But if suddenly the color palette is not enough, you can always mix 2 different colors and get your shade.

In this case, it is recommended to first experiment with a small amount of the coller and try out the resulting melted varnish or a veil on an unnecessary piece of wood. A sign that everything went well can be considered a smooth surface after drying, no drowshes and uniformity of color.

First you need to test the melted lacquer or the veil on a piece of wood

How to compose

In a nutshell, the instruction on the caller is that the dye is slowly added to the veil, paint, etc., after which it is simply thoroughly mixed.

Parquet Toning Malcified Lac

The dye is added gradually and when the liquid reaches the desired shade, you can proceed to the trees processing. Nevertheless, there are a number of nuances, depending on what needs to be prepared - varnish, a simile or paint for wood.

Cooking the melted varnish

The main purpose of processing is to create a durable film on the surface of the wood, after drying the varnish it will protect the wood from penetrating moisture into it, the texture also appears. The melted lacquer for the tree is different from the usual the fact that after processing, the texture of the wood is not simply manifested, but also staining in the appropriate shade.

Sometimes even famous manufacturers may make mistakes in the color map, so it makes sense to take care of the preparation of varnish the desired shade with your own hands. Dyes are usually sold in the same stores as the wood processing agents. You can even try to negotiate with the caloring machine operator and the kel can cast into your container. It is just an ideal option, but everything depends on the mood of employees.

The desired color can be obtained from the caloring machine operator

You can try to perform a tinting and with the help of priests. For example, there are references to the successful experience of adding an aqueous veil to the acrylic varnish (a kind of water varnish color). The solution obtained at the outlet is quite pale (even with a high concentration of the veil), so what is suitable in cases where the strong blackout is not necessary.

As for the processing process of a wooden product, it is recommended to adhere to such a sequence:

- the surface is thoroughly polished. Immediately before applying the lacquer layer, you need to wipe the surface to remove dust;

The surface should be perfect smooth

- then the first layer of the melted varnish is applied;

Note!

All the product is covered by varnish at once, in no case is it not recommended to break the surface to the sections.

If you cook the next portion of the varnish then, it is hardly possible to get the same shade, and the difference will be noticeable.

- tree tinting is performed at least 2 layers. But if the surface is quite porous, and the varnish itself turned out not very rich color, the number of layers can be increased to 3-4;

- the last layer is recommended to make colorless.

Code oil and impregnation

- ordinary oil paints. They can be mixed at room temperature;

- you can also gouache. But so that water does not interfere with the process will have a mixture to warm, water will evaporate;

You can use gouache

- in the past, people used both dyes as ordinary ash. For example, tinting oil for wood ashes will achieve dark gray or even black, it all depends on the concentration of the dye. Sozha, color clay and other natural materials can also be used;

Dark color can be obtained mixing with butter South or ash

- if you get a dry color and mix it with oil, we will get an analogue of purchased oil paint. Since the price is comparable, it makes no sense to mess with stirring oil and dye, it's easier to just buy paint.

It should be remembered that when working with an oil, a too large concentration of the dye gives a more rich color, but the oil properties are lost. That is, it is no longer so well protects the tree from moisture and over time the coating will need to be updated. So the tree for the wood can be added to the balance between the oil properties and color saturation.

In the case of impregnation, color after processing is usually secondary, but at this stage you can achieve the tree to have a noble view. If a part of the structure is processed, which will not be visible, then iron oxide can be added to the solution, just to be seen which part is processed, and which is not.

Iron oxide will give a bright red color wood

Calling impregnation for wood can be performed to simulate red or any other noble wood. YF, GO, KFI coalescent are used as dyes. By weight, the concentration of these substances does not take up to 4% of the impregnation mass. But here's a change in concentration even on the share of percent gives a spectrum of colors from camouflage green to the color of black chocolate, so that it is simply infinite for experiments.

Summarizing

Calling varnishes, oils and impregnations for wood - the process is creative, and therefore very exciting. By adjusting the concentration of the dye in the composition of a liquid or oil for wood processing, almost any shade can be achieved. As a result, even a simple pine looks sophisticated after processing.

This article shows an example of using an acrylic varnish, applied by the usual water-based versa.

http://rubankom.com.

Wood paint varnishes - selection tips

To protect wood and give her beautiful color And the brilliance during construction or repair is used by various LX.

Ticcuril water varnish: characteristics and subtleties of use

Wood paint varnishes are presented in such an assortment that the eyes are missing.

What you need to consider

Choosing a suitable LKM, consider several factors on which the final choice depends. What kind of wood are you going to cover? In what conditions will the product or surface be operated? Is it possible to handle the surface and pre-prepare it before work? Also note whether it is possible to re-process the tree, and whether the selected paint is compatible with the LKMs that are already applied.

The choice of wood protection means is so big that without pre-training You can not do. There are many primers, impregnations and various types of varnishes. All covers differ in appearance, which we can see when the work is completed. They also differ in the way of use, as it is necessary for all coatings. different conditions Application and drying.

Types of LKM for wood

Depending on the external species Selects such a lacquer paint for wood:

- dispersion paints;

- coverage of transparent color (sampling, impregnation, varnishes);

- enamel opaque.

A transparent coating may consist of pigments, the number of which varies, that is why they can maintain natural wood pattern. Such protection reacts well to moisture, steam, sun raysSo it makes old and loses its properties very slowly. Even if you want to re-paint the surface, you do not need to shoot old layer. Transparent coating can hold out several years.

Acrylic dispersion paints become increasingly. As a solvent, water is used, and the binding component in this LKM is acrylate components. After the coating is applied to the tree, the water completely dries, as a result on the surface we can see a solid film. It protects the material from moisture, external influences, fire. Such paint provides high level Resistance to any temperatures, and it is suitable for finishing outside or inside. If you do not like the original color, it can be toned and mixed with other shades, do not be afraid to experiment. last years Opaque enamel paints are no longer used in such a volume, as it was before. It is explained by toxicity and low resistance to fire. Compact "Docker Kemikal GmbH Rus" offers professional washes of varnishes of paints.

Natural wood of which is built by most houses and baths of manual logging or the usual widespread houses in the construction of houses and baths planed Bar. It has a pleasant light amber color. Many owners of houses and baths from logs and timber likes a natural shade of wood and its color scheme, so it is usually trying to save unchanged. The house of the hand-held logs, the walled log natural colors, natural shades of the wooden house from the bar are pleasant. Bright, sunny, amber, autumn, saturated or light spring tones of wood do not reduce the spatial volume of rooms in the house, cause positive emotions From the feeling of harmony with nature, do not annoy, harmonious and natural, like everything that is natural and not catchy.

But in certain cases, the need to change the original timber is due to any subjective or objective circumstances. The desire to change the timber color may occur or may be necessary under the following conditions:

- If wood has possible flaws that need to be hidden or made them less noticeable,

- If you wish to give a conventional wooden surface or a wooden object made of widespread and inexpensive wood effects wood effect of valuable breeds. Those. Create a visual effect from a wooden product made, for example, of pine, christmas tree or birch, indistinguishable visual effect of array of wood rare and expensive breeds, such as oak, beech, ash, cherry, tick or any exotic breeds wood

- During restoration wooden furnituremade of rare and possibly expensive wood varieties or to update the protective layer of special waxes or varnishes, which were previously applied to the wooden surface of the furniture, piece parquet., the massif of the floorboard and had a certain shade, but over time, in the course of operation we were worn out, laid out and need to be updated, partial or complete color,

- For design solutions When finishing a house where various color shades are provided at the request of the customer.

To facilitate the wooden home owner, the solution of the above tasks can be used. various options their implementation. But the most correct, in our opinion, the most realistic, inexpensive, economical and environmentally favorable solution can be the use of pigment and a caloring paste entered into oil or wax, i.e. Basic oil for wood, colored wax for wood, as well as color pigmented in various shades or applied by various colors of casting pastes of oils for wood. The oil and wax for the tree most corresponds to both close (relatively) wood structure, does not turn into a tree, not peeling unlike many varnishes, it is not extended, simply updated if there is a need for it, easily and quickly pigmeasies (painted) in almost any required The consumer shade and color will not fade for a long time, creates moisture-proof, but vapor-permeable protection of the surface of the log and timber, additionally enhances wood protection from UV. Evaluating the principal advantages, advantages and indisputable positive traits non-ferrous oil and colored wax are very many consumers, solving the question than to paint wooden housethan to paint a log house than paint the timber how to choose paint for wood, etc. Most often make choices and purchase colored oil for wood and colored wax oil.

If you want to get some color from the wooden surface or give the usual log, bruus or geepboard wood effect valuable breeds, use for these purposes a pigmented wood oil for wood, colored oil, colored wax for wood, which contains pigment, i.e. Already pigmented in standard oils and waxes, or add to dry, oil soluble or fat-soluble, which comes well. The process of obtaining non-ferrous oil and color wax you need the shade is simple and convenient for you. Any palette can be obtained practically at home by entering a small amount of high-concentrated color-resistant pigment into a conventional sucking oil with wax, to wood oil or in a colorless wood wax.

Another way to give the wood you need the color will be even easier and cheaper than the processing of a log, timber and floorboards with wax with wax. You can treat previously not treated with moisture-proof composition (the wood-processed wood should have open pores and the ability to absorb moisture!) Any wooden surface that you want to paint into a certain color of the usual on aqueous or alcohol basis. Water verses Sold almost in any economic store, it is not expensive, have different colors and easy to use. But this method has essential flaw Compared with the application of pigmented by the oil blown. The fact is that not all pigments possess increased color resistance. The most color-resistant - natural land, which are more preferable for administration in oil and waxes for wood. Natural land pigments and caloring pastes fade and change the color during operation, i.e. when they are used painted and treated with them wooden surface Long save the color you specified without significant changes. Some cheap pigments, including artificial, to implement from finished video In the form of veneers, they can simply be diluted with water to obtain a colored solution of different density and concentration. Low color resistance, the ability to quick and uneven burnout, inconsistency of the declared initial or change color Gamma. and the shade from the primary increases costs when they are frequently updated and reduce their time efficient work on protecting a wooden surface.

←

←

In detail about the advantages and disadvantages of different colors and pigmented impregnations, find out on the individual pages of our site by clicking on the links at the bottom of this page or choosing a ready-made answer to your question in the "" or "section in the header of the site. If there are difficulties in the selection of necessary impregnations, call the phones indicated on the site and get around the clock consultation from our specialists.

In detail about the advantages and disadvantages of different colors and pigmented impregnations, find out on the individual pages of our site by clicking on the links at the bottom of this page or choosing a ready-made answer to your question in the "" or "section in the header of the site. If there are difficulties in the selection of necessary impregnations, call the phones indicated on the site and get around the clock consultation from our specialists.

Learn detail All about finish protective impregnations, wood oil, wax, floor lacquer, paint and tree lazeri:

← Impact

←

Impact

←

"

←

"

←

, Wood oil, Furniture oil, Furniture oil, impregnation on linen oil

←

, Wood oil, Furniture oil, Furniture oil, impregnation on linen oil

←

. Wax for furniture. Furniture Wax. Liquid wax and solid wood wax. Wax mastic.

←

. Wax for furniture. Furniture Wax. Liquid wax and solid wood wax. Wax mastic.

←

, Lacquer for a log cabin and bar, floor lacquer, parquet varnish, wood paint. Azure.

←

, Lacquer for a log cabin and bar, floor lacquer, parquet varnish, wood paint. Azure.

←

←

Linen oil is a natural substance obtained by cold or hot spin of linen seeds. Clean oil can be used as an independent finishing coatingBut in the untreated state it is ineffective, due to the low ability to polymerization (drying).

Speaking about the impregnation of a tree linen OilUsually implies the use of olifa. This is the composition of thermal processing modified and the addition of chemical additives accelerating the polymerization process. Olif is also called "boiled" or "boiled" linseed oil.

Features of finishing with raw butter and oil

Processing wooden crafts clean linseed oil, you should be ready not only for long drying, which can take up to 3 days (for each layer), but also know a row important features. The crude product is actively absorbed into the structure of the tree, so the coating of wood with flaxseed oil has to be produced in 5-7 or more layers. Hyding outside, it is poorly polymerized inside, which is why the product can still leave oil spots for a long time. The effect of ultraviolet is significantly accelerating the drying process. In the Sun, the treated wood can dry in 6-8 hours, but the tone of the coating will change: it will become yellowish or even slightly brown.

Olife, due to the high velocity of polymerization, has completely different properties: dries quickly, it does not actively absorb, does not change its color. This makes it more practical in use. Regardless of the conditions, the answer to the question how much the olive is unequivocal - no more than a day (at 20 ° C). It distinguishes it from raw linen oil. Learning about this type Finishes, we will meant linen Olif.

Where is it better to apply such a finish?

Wood impregnation with flaxseed oil does not provide solid protective film, resistant to scratches and abrasion. But this species decorative finish They appreciate for others, first of all, environmental friendliness, antiseptic properties, ability to emphasize wood texture and keep it from cracking.

Linen Olif is used for finishing products used indoors. It is optimal for coating furniture surfaces that are not susceptible to intensive abrasion, wooden walls and ceilings. It is treated wooden dishes, Kids toys. As a decorative protective finish, linseed oil is appropriate to apply on the surface of the valuable wood for the maximum preservation of their natural qualities.

How to cover wood with linen oil?

Preparation. The oil is applied to the dry and ground surface. Wood moisture should be at least 15%. Works are recommended at relative humidity of air no more than 80%. When applying the composition on oily rocks of wood, the prepared surface is additionally wiped with White Spirit.

Application. For work, a brush, swab or not a darous tissue is used. The composition is evenly distributed on the surface, and give it to penetrate the structure of the tree for 15-30 minutes. Excess oils that are no longer absorbed, wipe on a rag or a tampon along the fibers. In order to avoid the formation of stains, follow the uniform distribution of oil on the surface.

Each new layer is applied after the total polymerization of the previous one with preliminary grinding. The number of necessary layers (in the case of olphoi from 1 to 4) depends on the features of the operation of the product and the type of wood (small-sized rocks require a smaller number of layers due to low absorption).

The time of complete drying of each layer is up to 24 hours.

How to restore oil coating?

Over time, the surface impregnated with flaxseed oil changes its color, starts look dry or erased. This coat Distributed, but this deficiency is compensated for simplicity of its recovery. When applying a repeated layer, the oil will hide all scratches and return the external attractiveness of wood. If desired, linseed oil can be toned with pigments, reaching the desired color shades. For products of non-intensive operation, the recovery procedure is carried out every two or three years.

What is oil wax and how to cook it yourself?

Linen oil with wax is an effective decorative protective coating that gives wood with high moisture protection properties and increases its wear resistance. Impregnation adds silky shine surfaces and emphasizes the natural advantages of wood. Suitable for processing light and dark rocks. Fully natural impregnation optimal for finishing wooden floors, stairs, doors, furniture and other items subject to intensive wear.

Linen oil and wax for wood will not be difficult to prepare themselves. The easiest way: in a heated water bath, grated beeswax is added and adjusted to a homogeneous consistency. Classic weight proportion - 1: 1. The ratio of wax and linseed oil can be varied, creating the compositions of varying degrees of viscosity: from thick mastic to liquid impregnations, penetrating deep into the wood structure.

How to avoid self-burning?

The process of oxidation of the oil during contact with air is accompanied by an increase in temperature, which can lead to self-burning of ferry-oil rags, tampons, sponges, etc. All consumables, which were used to wip the linen oil, should be carefully dried in the straightened state outside the room, and it is better to dunk in water or immediately burn. To store the dispenser and other tools in contact with oil use hermetic containers.