Warm water floor from a sauna stove. Warm floor in the bathhouse from the sauna stove. What materials need to be purchased

Among all heating systems, heated floors are very popular these days due to their technical specifications. Some residential buildings have to purchase electrical systems, but owners solid fuel stoves luckier, because they can install water circuit heating.

Warm floors from stove heating V wooden house- This is a great way to make the room temperature more comfortable and distribute it evenly throughout the entire area. In this particular embodiment, the element that heats the coolant is the furnace, and there is no need to install a boiler.

Features of a floor heating system using water from a stove

A heat exchanger must be installed directly above the firebox, because the stove will act as a heating element. For these purposes, an ordinary metal tank or welded pipes are suitable. It is from this that the water floor heating system will be installed in all rooms.

Based on the fact that it will not be possible to install a large-capacity heat exchanger into an ordinary stove, you will need to build a battery tank connected to the heat exchanger next to the stove. To prevent heat from escaping from the room through the base of the floor, foil thermal insulation is laid on it, which effectively reflects energy and helps normalize the temperature.

In addition, you will need a pump to return the cooled liquid back to the heating tank. The only exception is ovens that are located below floor level.

Attention! The auxiliary pump is installed on the general return, and not on the cycle that does not warm up well. If you install the pump separately on any of the wings, the water will circulate in a small circle.

The normal temperature for a heated floor is considered to be 40°C, and a brick oven, unlike a specialized boiler, does not have an automatic regulator, so the indicators may differ significantly from the norm. Therefore, in addition to the circulation pump, you will need to install a mixing unit.

If it is necessary to install several circuits for different rooms, a manifold is mounted between the boiler and the floor surface, to which valves with thermal heads and two- or three-way taps are connected to easily regulate the operation of the system.

Advantages and disadvantages of the system

A warm water floor in a wooden house under a screed from a stove is characterized by the following advantages:

- Saving on fuel, ease of maintenance and installation.

- The circuit is mounted inside the screed without reducing the usable area.

- Environmental friendliness.

- High heat transfer with relatively low energy consumption.

- Uniform heating of the room, absence of cold zones.

- Possibility of heating several rooms at once from one boiler or stove.

- Long service life.

The disadvantages of the system include the following:

- For rooms with a large square footage, a large volume of coolant is required, so it will take a lot of time to heat it up.

- If a wooden house is located outside the city and is used as a summer house, and not for permanent residence, then before leaving, you must drain the water, otherwise during severe frosts, frozen water can rupture the pipes.

Tip: To protect the system from freezing, you need to use polyethylene pipes and fill them with water with the addition of antifreeze. They should be placed at a distance of 20-25 cm to avoid warm and cold areas.

Types of device and materials used

The layout of a heated floor from a stove in a wooden house can be done in several ways:

- On a concrete screed - this is the cheapest, most reliable and moisture-resistant method. With its help, you can reduce the cost of building materials and do not require availability for work. practical experience. TO negative qualities This method involves the duration of the process - the floor becomes ready for use only a month after pouring. In addition, if the pipeline is damaged, determining the location of the leak without dismantling the entire coating will be problematic.

- On a screed using polystyrene boards having factory-ready recesses for fixing heating pipes. They are distinguished by ease of installation and a reflective layer of foil material to retain heat.

- On wooden base. Laying on logs is considered the most labor-intensive process, requiring precise calculation of the locations of the holes for laying the pipeline. On the other hand, the maintainability of such floors is much higher.

Tip: The height of the insulating layer (mineral wool, expanded clay, expanded polystyrene or polystyrene) should be 15-20 cm - this factor depends on climatic conditions location of the region.

Installation of a warm water floor from a stove in a wooden building

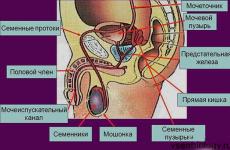

Water floor heating consists of the following layers:

- Waterproofing. It prevents condensation from settling on the structure.

- The thermal insulation layer prevents heat from escaping from the room through the bottom.

- Reinforced mounting mesh to protect insulation materials.

- A layer of thick foil to reflect heat.

- A pipeline lined with a snake or spiral to uniformly heat the surface.

- Leveling screed.

- Finish coating.

In some cases, when it is necessary to lay the floor directly on the ground, before laying the waterproofing layer, a “cushion” of gravel and sand is compacted and an expanded clay layer is poured. This is necessary to create additional thermal insulation conditions.

Heating system installation

Any work on laying heated floors, as well as other options, must begin with preparing the rough surface. It must be cleaned of old worn coatings, compacted or sanded to bring it to a perfectly smooth state. The height difference between the base in one room should not be more than 0.2 cm.

After preparation, you should begin laying the heating pipeline:

- To begin with, roofing felt is laid out in two layers perpendicular to one another as waterproofing. The joints of the sheets are carefully glued with mastic.

- The second step is flooring thermal insulation material and covering it with a mesh.

- The pipes are laid directly on top of the mesh.

After connecting the pipes to the system and checking it for defects, the screed is poured. For this purpose, a cement solution with fiber reinforcement or diluted ready-made dry mixtures are usually used.

The screed is poured evenly and leveled. Cement may slightly change volume during the drying process, so to prevent deformation of the finished coating around the perimeter of the room, damper tape should be applied before pouring.

After complete hardening (the drying process lasts about thirty days), you can begin laying facing materials.

The method of heating the floors of rooms using water from a stove is a simple method that, when the right approach and following all recommendations, will save money on the purchase of a heating boiler and electricity costs.

The properties of warm air are such that it rises, so it may be hot in the bathhouse, but the floor will remain cold.

Such changes are uncomfortable for many people, so you can make a heated floor system, which is widespread today.

It is easier and more expedient to make a heated floor in a bathhouse from a stove than to use electric floors. After studying the material in the article, you will be able to find out the features of the system and installation methods.

General information about the system

The water in the water circuit pipes will be heated by the stove

For a heated floor in a bathhouse, there is no need to install a boiler, since the heating will come from the stove. To do this, a heat exchanger should be made from a metal tank above the firebox.

From it it will be possible to lay water heating on the floor in those rooms where it is necessary. Additionally, you will need to install a pump to circulate water in the pipes.

Since it will not be possible to install a volumetric heat exchanger in the furnace, you should additionally place a battery tank next to it and connect it using steel pipes with heat exchanger. To reduce heat loss, insulation is laid on the floor so that it can properly reflect it and the rooms will have the required temperature.

The main problem with a water-heated floor from a stove is the inability to regulate the temperature. For heating, it is recommended to heat the floor to 40 degrees, but in the bath the water gets hotter and you will need to additionally install a mixing unit.

To protect the floor itself from moisture, a standard cement-sand screed, and as flooring tiles are used.

Before installing the system, you need to familiarize yourself with the pros and cons, which are given in the table:

| № | Advantages | Flaws |

|---|---|---|

| 1 | There is no electromagnetic radiation, unlike the electrical system. | In winter, it is necessary to drain the water so that the pipes do not burst from frozen water or the stove must be constantly heated. The best option– change the water to antifreeze. |

| 2 | Environmentally friendly and harmless to health. | Heating the battery tank will require a lot of heat, making the furnace less efficient for its main purpose. |

| 3 | Comfortable conditions are maintained in the bathhouse, the floor remains warm. | To heat floors in several rooms, you should install a large coolant, which will increase the warm-up time. |

| 4 | Economical. |

Warm floors can be made using several types of materials and devices, which are presented in the table:

| Name | Advantages | Flaws |

|---|---|---|

| Concrete screed - for a bathhouse perfect option. Filling is simple and does not require special skills. | Saves money on building materials, and due to cement, the floor will be resistant to moisture. | You can use the floor a month after pouring, but if the pipe is damaged, you will have to remove the entire screed to be able to determine the location of the leak. |

| Polystyrene boards are easy to use. | Each plate already has a layer of foil, which allows it to reflect heat, and they are also equipped with places for fixing pipes. | It is necessary to additionally fill the screed. |

| Heating pipes in a wooden floor. | High maintainability. | Accurate calculations are needed to determine the laying of the pipeline. |

To insulate the system, you can use any thermal material: mineral wool, expanded clay, polystyrene foam and other types.

Floor installation and preparation

A concrete screed is poured on top of the laid materials and pipes.

The warm floor in the bathhouse from the stove according to the scheme is made from the following layers:

- A layer of waterproofing that will protect the floor covering from condensation collection.

- The thermal insulation layer will retain the heat that can pass through the ceilings.

- To protect the insulation, a reinforcing mesh is laid.

- A layer of reflective materials with foil that will reflect heat into the room.

- A pipeline laid in the form of a spiral to uniformly heat the area.

- Screed for leveling surfaces with small slopes towards the drain hole.

- Laying the final floor covering.

If the floor will be laid on open land, then before the waterproofing layer you should pour a cushion of gravel and sand, and also lay a layer of expanded clay. Expanded clay will additionally perform a thermal insulation function.

Before any work, preparation is necessary. For a floor that will be heated by a stove, you should prepare a base and make a drain. The work is carried out as follows:

- It is necessary to remove the soil between the foundation, under the washing room and compact the surface. You will need to first lay a pipe in the wall to drain water into the sewer.

- A backfill of sand and gravel 15-20 cm high is made, after which the cushion is compacted.

- The base is insulated using expanded clay. The layer of material is 15-20 cm depending on the climate.

When preparing the surface, you need to remember the slope for the drainage.

Step-by-step installation instructions

Heating the floor in the bathhouse using the heat of the stove is a profitable step

The base of the bathhouse is ready, which means it’s time to start laying out the pipes. To do this you can use like copper pipes, and metal-plastic. The installation process is as follows:

- Initially installed waterproofing material. For this, roofing material is used, which is laid in two layers. Its joints are glued together with mastic, and all strips of material must be perpendicular to each other.

- Next, thermal insulation is laid.

- The next step is to lay the reinforcing mesh, which will protect the insulating materials.

- Pipes for floor heating are placed on top of the grid and connected to check their functionality and the presence of possible leaks.

- When all the materials are laid, you can begin to pour the screed over the entire area of the room. A damper tape is first glued around the perimeter of the rooms, which will prevent the floor from deforming due to temperature. Any type of mixture can be used for screeding.

- The floor filling is leveled along the beacons and the angle to the drain is maintained.

- The water-heated floor is almost ready; after the screed has completely dried, tiles or other floor materials that will be used should be laid. For more information about installing a water floor in a bathhouse, watch this video:

As you can see, it is not difficult to make a warm floor in a bathhouse using wood heating. IN end result the system will save money that could have been spent on purchasing a boiler and paying for electricity. By laying heating pipes under the floors, you can achieve a comfortable stay in the bathhouse, shower room and relaxation room.

The organization of heated floors in the bathhouse is necessary to create a comfortable microclimate in the dressing room. A wood stove can be used as a heat source. But for this you need to select a circuit and components.

Warm floor in the bathhouse from a buffer tank

A convenient, but labor-intensive option for heated floors in a bathhouse is the use of a buffer tank. This method is used when there are several heating circuits. Conditions – there is a place to install a buffer tank. Its capacity is 500-1000 liters. The advantage of the system is the ability to use warm water For shower.

- heated floor area – from 40 m²;

- power wood stove– from 15 kW;

- the ability to regulate the temperature of the coolant - mixing unit;

- system for quickly adding water to pipes.

The area of the room with a buffer tank is from 15 m². This is necessary for comfortable maintenance and repair of heating elements.

Scheme

To quickly heat water, install it in a wood-burning stove. It could be homemade design lattice or capacitive type. It should be located in the firebox, in the zone of highest temperature. The inlet and outlet pipes must be metal, installed shut-off valves, thermometer and pressure gauge.

Arrangement of underfloor heating elements, starting from the supply pipe.

- Connection to buffer tank.

- The tank contains a heat exchanger for indirect heating water.

- From the tank there is a supply pipe to the mixing unit.

- The mixing unit consists of a three-way valve and a circulation pump.

- From the collector comes the wiring of heating circuits - from 1 to 6 pcs.

- Return the cooled coolant to the storage tank.

To automate the operation, you can connect to a three-way valve. When the maximum temperature is reached, it will turn on, hot water will begin to mix with the cooled water from the return pipe.

To drain the coolant, a tap is installed in front of the collector. To add water to the system, a shut-off valve is placed on the supply pipe. It is mandatory to install safety systems - an expansion tank, a drain valve and an air vent.

Design Features

- small floor area;

- wood boiler power – up to 10 kW;

- need to save space.

The layout of pipes and installation of components depends on the design of the bathhouse - the location of the boiler, dressing room. It is compiled individually, but taking into account technical requirements and standards.

Scheme

A difficult task for such a scheme is installing the supply pipe into the boiler furnace. In or models you need to drill a hole with a diameter equal to the cross-section of the pipe. IN brick oven Part of the firebox is disassembled to install the pipe. It is important to ensure the tightness of the connection; there should be no gaps between the pipe and the wall of the furnace.

The order of the components.

- Coolant supply pipe.

- Thermometer, pressure gauge (optional).

- Air vent and water release valve.

- Circulation pump.

- Laying pipes in the floor.

- Connection to expansion tank.

- Return of cooled water for heating.

The pipes for connecting to the boiler are metal, diameter – 12-20 mm. It affects the heating area, and as a result, the rate of increase in coolant temperature. If the layout allows, you can make a mixing unit. This will allow you to automatically regulate the degree of heating of the coolant. But for this, the supply and return lines must be located nearby.

Advantages and disadvantages

The difficulty of such a warm bath floor is the inability to control the temperature of the water in the pipes. Due to the small area of the line in the furnace, heating occurs slowly; it can only be adjusted circulation pump. Prohibited use open system heating, as there is a possibility of air pockets. This will cause overheating and damage to the pipeline.

Advantages of single-circuit floor heating:

- Low consumption of pipes and components.

- No special tools needed and additional blocks– mixing, automatic addition of water to the system.

- Easy maintenance and repair.

To quickly increase the air temperature in the steam room, part of the pipeline can be located under the shelves. It should not come into contact with wooden elements.

Warm water floors from a wood stove in the house

This heating scheme can be implemented for a private home. Condition - the power of the furnace must ensure heating of the entire coolant for a long time. To do this, you need a good indirect heating tank of at least 1000 liters. Pipes made of cross-linked polyethylene with an oxygen barrier. Their installation is done on a special substrate.

Features of organizing a heated floor system from a stove in a private house:

- collector wiring is required;

- pressure stabilizer if two or more manifolds are installed;

- the maximum length of one circuit for a 16 mm pipe is up to 70 m.

It is important to ensure uniform heating of water in all circuits. To do this, we need collectors with thermostats for each section of pipelines.

How to organize a heated floor in a bathhouse? What features should you know about in advance and what should you avoid? All this is in our article!

The bathhouse will be much more comfortable if your feet do not freeze in the dressing room. Agree that this happens quite often, when the heated floor is only in the steam room, but in the dressing room the cold hits your legs. But this can be avoided.

Features of the flooring in the bathhouse

A bathhouse is a very specific room, which is characterized high humidity and temperature. In this case, water is collected or drained over the entire surface of the floor. This also adds a requirement for the materials used in finishing. Preference is given to wood, but tiles are also acceptable. And what is especially depressing is wood, a fairly good heat insulator.

Based on such a rigid framework, organizing a heated floor in a bathhouse is a multifaceted task, but has several implementation options.

- General heated floor. This is the most expensive option. To do this, lay the heat exchanger circuit with your own hands over the entire area of the bathhouse (excluding the steam room), according to all the rules, i.e. with a layer of insulation. A screed is poured on top, with a slope to drain water, and ceramic tiles are laid. The advantages of this method are that there is no differentiation of premises during the construction process. Everything is done the same way. But there are quite a lot of disadvantages:

- Extremely large investments in non-residential premises;

- Wet tiled floors with a slope are more dangerous;

- Monstrous inertia of the system. Warming up such a layer of screed will take longer than heating a firebox in a bathhouse;

- There is a danger of defrosting the system in winter if it is turned on irregularly;

- The need to allocate a separate corner to accommodate the heating system and control the water heated floor.

Conclusion: such floors are good for use in a large bathhouse, if not public, then corporate. In private housing construction, for ordinary person this option is very cumbersome

- Differentiated approach. In this case, you create two systems with your own hands that work independently: one heats the floor in the dressing room, the other in the washing compartment. This option is a priori better, because it allows you to solve problems of different levels of complexity independently. In particular, in the dressing room, infrared heated floors are quite appropriate, given that the humidity level there, although high, is an order of magnitude lower than in the washing department. In the bathhouse itself, creating a heated floor system faces a number of inconveniences, in particular:

- The thermal conductivity of wood and expanded clay is the same, i.e. these are equally good heat insulators;

- Tiled floors imply a general slope and require a fundamentally different approach when installing a sewer system in a bathhouse. Laying ceramic tiles impossible on a wooden base in rooms with high humidity and temperature. This means that it is necessary to organize a full-fledged “floor pie”, with excavation of soil to a depth of 60-70 cm.

In this article, we are trying to limit ourselves to considering personal baths. And these are used a couple of times a week. This means that the floor heating will be turned on a couple of times a week. And this is fraught with defrosting the system. In other words, a water heated floor in a personal bathhouse is very unprofitable. The same can be said about cable heating elements. In any case, they will be in the screed, which means the inertia of heating will not allow you to sincerely enjoy the delights of a heated floor.

The best solution to the problem

In a private bathhouse, it is much more pleasant to have a wooden floor under your feet. But the destructive effects of dampness are detrimental to wood. At the same time, heated floors in the bathhouse simply attract with their comfort. But there is a way out that allows the integration of one type of equipment to immediately obtain maximum benefit, in particular:

- Warm floor;

- Dry underground space;

- Drainage through leaking floors;

- Minimum capital investment.

All this is possible with organization of air floor heating. And another important advantage is the ability to organize uniform heating of the entire floor covering.

How to make a heated floor in a bathhouse

First you will need to organize the correct collection of water in the underground space. Therefore, the whole process will consist of the following steps:

- Organization of reinforced screed with a slope;

- Laying lags;

- Installation of heating system elements;

- Installation of flooring.

An important principle in creating a screed is its waterproofness and slope. Ensuring a uniform slope exactly at the level of the screed will make it possible to install floors without a slope, in which water will flow between the boards. These floors are safer.

Screed organization

The screed will be organized immediately under the entire bathhouse. The slope that must be maintained for natural water collection is 30‰. That is, 3 cm, at linear meter. It is recommended to drain in the center of the building. With this approach, it will be possible to avoid too large differences between opposite walls. For example, in a 4x5 m bathhouse, the height difference can be either 15 and 12 cm, or 7.5 and 6 cm, depending on the location of the drain hole.

The height of the floor of the underground space is not required to be too high; the minimum clearance will be 20 cm (along the walls). The pipe outlet to the septic tank is located in the center of the building. The pipe head is brought to the expected level and plugged. Before pouring the screed, you need to pour a cushion of a layer of sand - 5 cm, and a layer of crushed stone - 10 cm. Any sand can be used, it is poured in an even layer and compacted well. But crushed stone is required with low flakiness and a fraction of 20-30 mm. The crushed stone is filled from the center to the edges. In this case, the required slope must be taken into account.

IMPORTANT: The slope must be created by properly filling with crushed stone! In order to maintain the required degree, you can mark horizontal markings on the corners of the foundation. Crushed stone is also compacted, but this should be done without fanaticism.

The screed will be organized with a spill. That is, waterproofing is not provided between the crushed stone and the screed, and part of the solution will go into the lower layers. To minimize losses, the solution is mixed thick. The thickness of the screed is at least 5 cm. To calculate the required amount of the ingredient, it comes out that 1 m 2 of screed, 5 cm thick, weighs ≈ 72 kg. It will require 16 kg of cement, 48 kg of washed river sand and about 8 liters. water.

To increase waterproofing properties, for every 10 liters. add 1 liter of water. liquid glass!

Additionally, it is necessary to include polypropylene fiber in the solution. This component is used for dispersed reinforcement, but in addition it will give the finished surface exceptional smoothness.

After pouring the screed, you should wait 1.5-2 days, and iron the surface. To do this, it is sprayed with 10% liquid glass solution, and then sprinkled with a thin layer of cement. Then, it is thoroughly rubbed into the screed using grout. This operation will qualitatively increase the strength of the entire structure.

The time for complete maturation of the screed is 4-5 weeks. During this time, it must be sprayed with water daily and protected from direct sunlight.

Laying lags

A larch beam measuring 10 by 20 cm is perfect for bath logs. Before installation, it must be covered with two layers of drying oil. The beam is laid with a narrow edge on the ledge of the foundation. It is fixed with corners. Special strength is not required, because after installing the floor covering, the entire system will be monolithic and motionless.

The laying step is calculated based on the thickness of the floorboards. For the bath optimal choice there will be a board 30 mm thick. This means that the step between the logs should be 45-50 cm.

Heating system installation

The floor heating system will consist of a heat gun and a network of air ducts fixed to the joists. At the bottom of the pipes, it is necessary to drill holes ᴓ12-15 mm, in increments of 20 cm. The pipes are fixed with mounting clamps to the bottom of the beam. Flexible air ducts must be at least 12 cm. Almost all of them are designed to work with hot air. To connect them together, appropriate fittings are used: tees, nipples, diffusers. Therefore, it is better to purchase everything at once from one manufacturer.

The heat gun is installed with your own hands in the attic, and the central air duct pipe is led there. Placing the gun above the ceiling will serve as additional protection from noise. The choice of a heat gun should be determined by the presence of several operating modes and the shape of the outlet. In terms of performance, even something as simple as “Energoprom TPE-3 MKR” produces more than 40 l/s. And the air heats up to 40°C when operating in the weakest mode.

Flooring installation

Larch is ideal for the floor in the bathhouse. It will cost a little more than pine, but in terms of durability, it has no rivals. In addition, the following rule should be taken into account: The wood for the joists and decking must be of the same species.. Edged boards, 30x100 mm. The use of boards 10 cm wide is more preferable than 150 mm. They will be located more often, and there will be more gaps between them.

When laying, between each element a gap of 5-7 mm must be maintained. It will serve not only to drain water, but also to lift warm air. The easiest way to maintain such a clear boundary is to use crosses to lay tiles.

Before laying the flooring, prepare the drain pipe. Remove the plug and process the perimeter of the pipe silicone sealant and put a protective grill on the head.

To maintain a comfortable temperature in the main rooms of the bathhouse and ensure hot water supply, it is important to properly organize heating in the bathhouse from a heater located in the steam room, or use alternative sources. At the same time, each bathhouse owner can create an autonomous heating system independently, without involving outside help.

Need for additional heating

The classic option for heating a steam room for bathing procedures is a brick or metal heater. Wherein optional equipment used to maintain a given air heating temperature both in the steam room and in other rooms.

Ensure quick and uniform heating of the dressing room and rest room from sauna stove impossible.

And if in summer this does not cause problems, then in winter such a situation can lead to a decrease in comfort when organizing a bathing holiday. In this case, all the heat produced will be accumulated in the steam room, and other rooms of the bath will remain unheated.

Installation of additional heating equipment will ensure the maintenance comfortable temperature, necessary for a long stay in the waiting room.

Heating by stove-stove

For small baths, traditional heating remains the current heating option. In this case, it is enough to purchase or manufacture a heating unit of the required power.

Calculation of equipment power is determined by the formula: 1 kW of power per 1 sq. m of premises. To ensure a comfortable stay for visitors in the steam room, a thermal power reserve of 35 to 55% is additionally taken into account.

The popularity of the heating heater is explained by the following advantages:

- ease of installation and maintenance;

- accessibility of operation;

- using available fuel.

When giving preference to a sauna stove, do not forget about some of the disadvantages of the device:

- impressive dimensions and weight;

- inability to automate the process of heating rooms;

- high fire hazard;

- formation of fuel combustion products.

Modern heaters operate on wood, electricity, liquid and gaseous fuel. Choice suitable option depends on the financial capabilities and technical capabilities of the equipment.

To provide efficient heating heating the bath from the stove in the steam room is done as follows: the firebox is placed in the dressing room, the heater is in the steam room, and the tank with warm water in the washing department.

Heating by furnaces with heat exchangers

At the design stage of heating equipment with a heat exchanger, the following data is taken into account:

- dimensions of the building and area of premises;

- design features of the furnace;

- weight of heating equipment;

- number of heat exchangers;

- coolant volume;

- length and diameter of the chimney pipe.

The following options for connecting heating equipment using pipes are possible:

- to the expansion tank for hot water supply in the washing compartment;

- To heating radiators installed in functional rooms;

- to hot water supply and water heating system in the main premises of the bathhouse and residential building.

Heating stoves are equipped with internal and external heat exchangers. The internal element is located in the firebox, the external element is located around the chimney pipe.

Electric heating system

Electric heating is the simplest and most affordable option organizations autonomous system heating the bath. When organizing it, it is worth taking into account the electrical wiring diagram, the total load on the network and the cross-section of the wires in order to carry out high-quality installation work.

The electric heating system involves the use of the following types of equipment:

- electric stove;

- electric convectors;

- infrared film;

- electric heating cables.

Modern electric boilers of low power are equipped with automation capable of maintaining a given temperature in bath rooms. To heat the bath, it is allowed to use induction, electrode and stepped boilers with heating elements.

An electric heater for a bath can be used as a main and additional source of heating. If possible, it is most convenient to use electric convectors. As with boilers, convectors are equipped with thermostats to maintain optimal temperature in automatic mode.

The electrical system can be operated all year round, and there is no need for preparation and storage of fuel material. Significant disadvantage – high consumption electricity.

Gas heating system

When connected to a gas main, heating a bathhouse with gas is the fastest and most effective option systems.

The system has two implementation options:

- traditional heater equipped with a gas burner;

- gas boiler with installation of heating radiators and water pipes.

The undoubted advantage of such heating is the absence unpleasant odors, formation of soot and soot. Wherein gas equipment It has a compact body, low weight and does not require much space during installation. The power of a standard boiler reaches 45 kW, which is enough to heat a room up to 280 square meters. m.

Water heating system

A practical and affordable way to organize heating of a bathhouse in winter is to install a water system.

Water is used as a coolant, gas, electricity, liquid and solid fuel, as heating equipment - a stove or boiler.

Water heating provides quick and uniform heating of bath rooms with the possibility automatic maintenance set temperature.

There are the following options for arranging water heating:

- Radiator heating. Provides for laying pipes along the walls to which water radiators or convectors of the appropriate size and power are connected. The hot coolant from the boiler moves inside the system, providing space heating.

- Underfloor heating. Its operating principle is similar to that in the previous version. The only difference is that pipe installation is carried out in concrete base after its preliminary insulation and waterproofing. This design is of a non-removable type, and therefore requires compliance with installation technology.

Heating system with heated floors

Modern underfloor heating systems are represented by electric and water. Water floors - economical and affordable way heating of premises, requiring high-quality installation, since it is quite difficult to repair such a system.

To heat a rest room, dressing room or washing room, it is enough to install heated floors. All work can be done with your own hands. To do this, it is necessary to select pipes of a suitable diameter, calculate the operating resistance of the heating circuit and the required pump power, taking into account the area of the room.

Warm floors can be combined with radiator, electric and air heating.

Heating system from the heating main

A private bathhouse can be directly connected to the central heating main. To organize a similar heating option for a bath, you will need to install an additional circuit.

The circuit is connected to the heating main according to project documentation and permissions obtained from the relevant authorities.

Choice similar option comes with some difficulties:

- probability of accumulation groundwater in places where pipes are laid;

- necessity additional insulation heating mains;

- the need to attract professional installers.

Alternative and mixed heating options

Becoming in demand alternative options bath heating. These include the following types of equipment:

- heaters – ceramic and infrared;

- boilers – pyrolysis, pellet, diesel, long-burning;

- baseboard and ceiling heaters.

In cases where the bathhouse is rarely used, good option is the arrangement of a mixed heating system: a wood-burning stove combined with electric heating; pellet boiler with electric convectors. One type of equipment provides heating of rooms for bathing procedures, the other provides hot water supply and additional heating.

Combined heating system for bathhouse and home

If the residential building is connected to a central heating system, it is recommended to install auxiliary equipment for heating the bath.

Thus, the heating main from the house to the bathhouse is a practical and economical way to heat residential and functional premises.

In this case, the connection of the bathhouse to the heating system from the house is carried out through insulated pipes laid underground. In the bathhouse they are connected to heating radiators or convectors installed in all functional rooms. For heating the steam room and washing department a sauna stove is used.

At a short distance from the heating equipment installed in the house, up to bath room heat losses in such a system are insignificant.

In this case, the heating main of a residential building can be used for additional heating of the bathhouse, helping to maintain a comfortable temperature regime V winter period. This will prevent possible freezing of sewer lines, water pipes and buildings.

Choice suitable system heating depends on design features baths and financial capabilities of the owner.

Some owners prefer traditional electric or wood-burning heaters, which provide soft and even heating of the premises. Others choose combined systems or advanced heating technologies.

But if you know how to make heating in a bathhouse, following the rules and recommendations, the operation of the building is possible throughout the year under any climatic conditions.