Rules for the placement and use of fire tanks. Reserve and regulation of water supply

Any fire water tanks are part of the overall fire fighting system on the object. Their purpose is to store a given volume of water in the absence of the possibility of connecting fire extinguishing equipment to the central water main, or to provide fire brigades with additional volumes of water.

By their design, ground fire tanks are represented by single-walled vertical or horizontal tanks. They can be either diamond-shaped or cylindrical. The bottom is usually cone-shaped.

Wherein vertical tanks can have a capacity of 100 to 5,000 cubic meters of water. Horizontal ones are less capacious - from 5 to 100 cubic meters.

There are fire tanks made of fiberglass or sheet steel. Inside they can be equipped with a special anti-corrosion coating. The material is selected based on the specific requirements at the facility, as well as the climatic features in the area. Inside the case there are special strong rings (ribs), which are designed to provide additional structural strength.

Tank placement

Fire tanks design and placement standards are very strict. They are determined by the rules of SNiP 2.04.01-85, as well as SNiP 2.07.01-89, SNiP II-89-80 and SNiP II-97-76 - depending on which facilities the tanks are installed on. According to these standards:

- tanks equipped with pumps are installed within a radius of 100 to 150 meters from buildings;

- in the presence of a pump - up to 200 meters;

- no closer than 10 meters from buildings of 1 and 2 categories of fire resistance;

- no closer than 30 meters from buildings of 3-5 fire resistance categories, as well as fuel and lubricants warehouses.

When designing the location of tanks, one should be guided by their availability at any time of the day for quick fire extinguishing.

When calculating the volume of tanks, it must be borne in mind that there are at least two tanks on one node. One of them should be in a filled state not less than half and should be instantly included in the work at the moment the other is empty.

The working volume of the tanks must provide at least 10 minutes of continuous extinguishing of both internal and external fires. It is allowed to use fire tanks for other needs, but at the same time, the tanks must be constantly filled with no less than 70 percent of their volume. ![]()

The installation of the tank itself is carried out on a specially prepared base. For its organization, concrete blocks, concrete pillows, as well as special supports made of durable metal. It should also be borne in mind that above ground tanks may need additional insulation measures - especially in harsh climates. It is assumed that there is:

- a special coil with a coolant supply from boiler rooms, or from heating mains;

- heating electrical installation for the pipeline and tanks directly;

- devices for providing artificial circulation of liquids inside the system in order to prevent its freezing.

The tanks must be without fail equipped with a pipeline for supply, a pipeline outlet system, overflow devices, a ventilation system, pipeline systems for complete drainage of water, it is necessary to provide water level indicators.

Tank operation

First of all, the filling of fire tanks should be carried out through special supply lines. This can be done from natural or artificial reservoirs. In the case of an artificial reservoir, a special protective grid should be equipped on the connecting pipeline from its side.

When additional use tanks for domestic and other needs, the complete renewal of water in them must occur no later than 48 hours. Sometimes this period can be extended up to 72 hours. Otherwise, the water in the tank becomes unsuitable for domestic use.

The maintenance team should regularly inspect the entire system. If any malfunction is found, it must be corrected immediately.

Once a year, a complete cleaning of the system should be carried out with the emptying of the tanks into special reservoirs or in sewerage. Reuse of water in this case is not allowed.

The maintenance team must also strictly monitor the water level inside the system.

Water intake from the reservoir for fire extinguishing purposes is carried out using a fire hose line and injection units provided for by the design. You can connect the hose line either through special connectors, or by simply immersing them in the tank.

Pressure tanks and water towers fire water pipelines high pressure need to be equipped automatic device to ensure their immediate shutdown in the event of starting fire pumps.

If all Norms and Rules are observed, then fire tanks are extremely effective means to ensure successful firefighting.

Fiberglass fire tank

Water Group Moscow designs and manufactures custom-made plastic containers and fire water tanks made of polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC) and fiberglass, designed for accumulation, storage and issuance of fire volume technical water or an aqueous solution of a foaming agent.

The production technology of the company Water Group Moscow (Water Group Moscow) allows the production of inexpensive plastic containers and plastic tanks for fire water supply (fire tanks, fire tanks) that meet all the requirements and standards of the fire system and counter fire safety types:

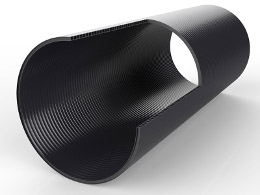

Underground execution (underground tanks allow the most efficient use of available space on manufacturing plant) for concreting or without concreting in the manufacture of fiberglass or polyethylene spiral pipes with ring stiffness SN2-SN16, depending on the depth of installation and the presence or absence of transport load at the installation site;

Ground execution of vertical and horizontal type from sheet plastics (polyethylene, polypropylene) in the basement and upper floors of industrial facilities and buildings, in special technical rooms and rooms with insufficient space and difficult accessibility.

The price of fire tanks made of plastic is constantly decreasing due to the development of manufacturing technologies.

At the request of the Customer, our company equips fire tanks and fire tanks (including underground tanks and tanks) with inlet and outlet pipelines, overflow devices, drain pipes, ventilation devices, stairs, manholes for people to access. To provide a more reliable and convenient access to the contents of the plastic container, the withdrawal and supply of the contents, we are ready to offer the installation of pressure seals that will ensure high-quality connection of the pipe with the wall of the plastic fire tank.

Advantages of plastic containers for fire water supply

Fire tanks, containers made of polymer materials have the following advantages:

. lightness, strength, tightness design

. excellent impact resistance

. wear resistance, long service life plastic containers

. not subject to corrosion, unlike containers and tanks made of metal

. 100% tightness, low water absorption and water permeability

. relatively low cost compared to tanks made of other materials

. ease of installation and convenience in further operation

Each material from which fire tanks are made has its own characteristics, and these features must be taken into account when designing and building. engineering networks. Our tanks are made of fiberglass, plastic sheet and spiral pipe.

Fire tanks, containers made of sheet plastic. Advantages:

. low cost;

. the ability to manufacture any shape and size;

. the possibility of manufacturing on site;

. a light weight;

. high service life.

Fire tanks, containers made of polyethylene spiral pipes. Advantages:

. low thermal conductivity due to the double wall;

. relatively low cost;

. low weight with high ring stiffness;

. the possibility of welding (assembly) in place.

Fire tanks, fiberglass tanks. Advantages:

. high mechanical strength;

. ease of repair;

. ease of installation.

Polypropylene fire containers

Plastic containers and reservoirs for fire water supply made of polypropylene, polyethylene or spiral pipes, custom-made by our company due to their high performance and inexpensive cost compared to similar products made of other materials, are in great demand in cases where obtaining the required volume of water, regulated for extinguishing a fire directly from a water supply source is technically impossible or impractical economic indicators, places where there are problems with the water supply or restrictions on the supply of water, and as a result, an emergency and fire supply of water is required.

Our company Water Group Moscow can manufacture plastic fire tanks locally at the customer's site!

When ordering from polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), fiberglass and spiral pipe tanks for fire water and fire tanks in our company, you get a guaranteed quality of plastic fire tanks in compliance with all parameters for strength, tightness and safety corresponding to all regulatory requirements and rules, low prices, installation in as soon as possible, attention, individual approach to each customer, the necessary technical recommendations for the further operation of the equipment, quality certificates for products. The production of plastic containers in our company guarantees you the receipt of functional, durable and reliable plastic products.

Plastic fire tank from the Water Group Moscow company - durable plastic fire tanks at a low price!

Water Group Moscow offers customers reliable and durable plastic fire tanks own production. We are one of the leaders Russian market tank products and equipment from modern species plastic and we have our own enterprises in the city of Moscow and in the regions of the country. The offered products have impeccable quality performance, are designed for a long service life and have all the necessary certificates of conformity. technical standards and SNIP standards regarding storage tanks for storage and distribution of water for extinguishing fires.

Plastic fire tanks: manufacturing features and main advantages

Products are manufactured according to projects developed by our design engineers using ready-made sheets made of modern polymeric materials (plastic or polypropylene). The joints of individual parts are connected by one of two welding methods- seamless (on special equipment) or a rod using hot air. Due to the unique performance characteristics of polymers, our plastic fire container has a number of advantages:

- absolute neutrality to any kind of impact environment(salts, aggressive chemicals, rotting bacteria, and so on);

- variability of the method of placement (underground or outdoor);

- complete tightness (eliminates any possibility of leakage);

- low weight even for overall products (provides ease of installation and transportation);

- moisture resistance;

- lack of constant monitoring of the current state;

- ease of maintenance;

- environmental Safety;

- durability;

- low cost (due to the simplicity of production technology, the pricing policy of our company and the possibility of selling without intermediaries);

Our plastic fire tanks can have both vertical and horizontal way placement, and are intended for those situations when it is technically impossible or economically impractical to obtain the necessary volume of water from centralized water supply sources to neutralize a fire.

Plastic fire tank in standard design and on order

In our catalog you can choose water tanks of the desired shape and overall dimensions, made according to standard projects our designers. If the offered product does not suit you, we can produce non-standard plastic fire container on order, which will require a personal meeting with our designers at the company's office (Moscow or regional offices).

Also, as an additional service, our company carries out the installation of water storage tanks with different option placement, supply and gadfly of pipelines, equipment with anti-overflow and ventilation devices, ladders, hatches and so on.

The fire tank is a container for storing liquid for localizing fires. This equipment is provided in cases where water intake from a water supply source is economically unprofitable, technically unfeasible, or its volume is not enough to eliminate the fire.

These tanks are installed in engineering system firefighting at enterprises with signs of heightened danger in manufacturing process. This category also includes gas stations, tank farms and warehouses of fuels and lubricants (fuel and lubricants).

Location rules

The placement of containers is based on the availability of buildings and structures, taking into account SNiP, not allowing the distances to be exceeded:

- with installed motor pumps - within a radius of 100 to 150 m;

- during the operation of autopumps - up to 200 m.

Distance to buildings of I and II degrees of fire resistance is not closer than 10 m; to buildings III; IV; V degrees and open warehouses of fuel and lubricants - 30 m. The equipment is located in such a way that the supply of the reagent can be carried out at any time of the day and at the right amount for extinguishing both internal fires and fires from outside.

Design features

Structurally, a fire tank is a single-walled vertical or horizontal tank of rectangular or cylindrical shape with a conical bottom. Horizontal fire reservoirs have a capacity of 5 cubic meters. up to 100 cubic meters

Vertical water storages are much more capacious - 100-5000 cubic meters. In addition, during installation, this design allows saving the area occupied by the territory.

Fire tanks are made of sheet steel with an internal anti-corrosion coating (or without it). Steel grades for manufacturing are selected in accordance with climatic features installation region. Internal annular stiffness diaphragms provide additional strength to the hull.

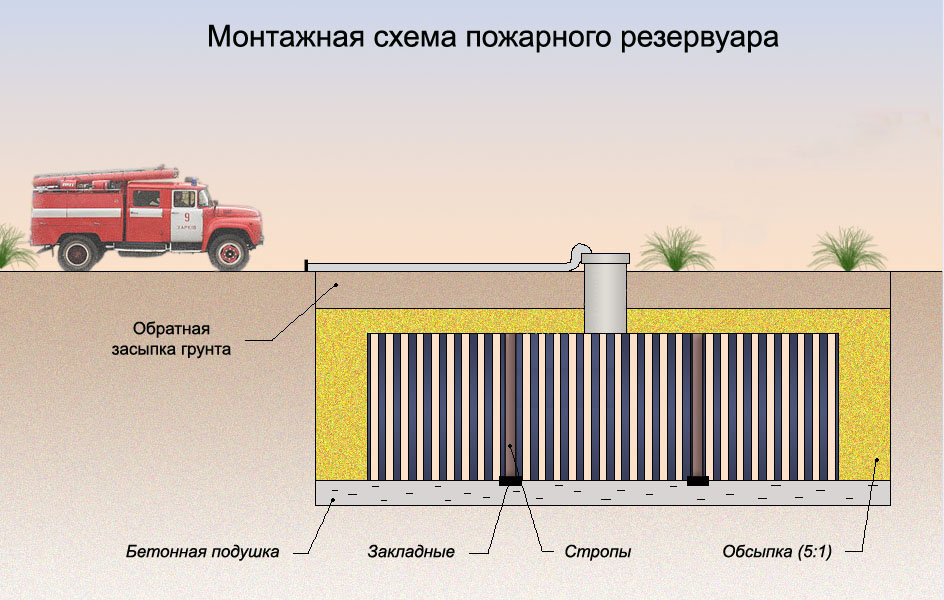

Installation of the structure is carried out on the base. Road blocks can be used for it, foundation slabs, concrete pad or special metal supports at a height from the ground from 3 to 7 meters. The container is fixed on anchor bolts through holes in the base. Installation can be ground or underground.

Ground structures in harsh climates need additional thermal insulation of the tank:

- installation of a coil with a coolant supply directly from the heating main or from the boiler room;

- installation of electric heating of pipelines of the system and the tank itself by means of fiberglass heaters;

- organization forced circulation liquids to prevent freezing.

Underground structures have an advantage over tanks located on the surface in terms of space savings and the absence of the need for insulation or heating of the internal cavity in winter period. Underground fire containment fluid storage can only be cylindrical.

The disadvantage of the underground location is considered to be a complex of expensive earthworks, the need for preparation and reliable fixing of the base. In addition, it is necessary external waterproofing as protection against ground water based on multilayer epoxy coating paintwork materials or polymers.

![]()

Filling occurs with the help of pumps through the hatch provided in the structure.

Kit structure

In accordance with the design, the set of the fire tank includes ladders or brackets for lifting and lowering personnel, observation platforms, sensors and liquid level control devices.

In the design of the entire system, modern requirements the following equipment must be provided:

- fill pipe. The filling of the tank occurs through the shut-off valve-pipeline;

- drainage well. It is needed to fill the fire truck with water. It connects the overflow tank to the storm sewer;

- suction pipe with valve. It is filled with fire pumps through it;

- drain pipe with shut-off valve for scheduled, emergency drains, as well as for draining during inspection, control or repair work;

- overflow pipe. It is connected to drainage well and sewerage in case of tank overflow.

The main factors in the selection and design of a fire extinguishing structure are the number of possible fires and their duration in time. Therefore, for correct selection reservoir, the estimated number of expected likely fires for a certain time period is determined. The length of time planned to eliminate the fire is also calculated.

Then installed optimal volume fire reservoir - with the condition of providing fire extinguishing water from internal fire hydrants, taking into account the needs of sprinkler and deluge installations that are not provided with their own reserve reserves. When calculating, the possibility of replenishing the stock of a fire tank during a fire from a common water supply system is allowed.

The number of required containers at this site is determined. The calculation should be such that in case of failure of one, the remaining ones must be filled with at least half of the emergency volume of water.

The levels of fire volumes in all tanks of the fire extinguishing system must be maintained at the same levels - both at the lowest and highest points.

It is necessary to provide free access to the tanks and wells for fire trucks on a hard road surface.

Reserve and regulation of water supply

In water supply systems, regulating and reserve water storage facilities include water towers, air-water boilers (hydropneumatic installations), which accumulate water volumes to regulate the operation of the entire system, as well as reserves in case of fires. The regulation of reserves consists in the accumulation of water in water towers when supplied in excess and in the intake from it when there is a shortage of water. common system water use.

The reserve of the fire volume of water is provided when it is technically impossible to obtain the optimal amount of water from plumbing system to extinguish fire. At the same time, there is a method for calculating the emergency reserve of fire-fighting volume. Creation of an emergency reserve for the localization of the source of fire is provided for up to 3 hours with a flow rate of 25 liters per second and up to 6 hours for a flow rate of more than 25 liters per second.

Expenditure of the emergency reserve of the water tower is allowed only upon receipt of a fire notice.

To extinguish fires, provide the necessary pressure of the supplied water. The pressures are calculated based on the conditions for creating jets from fire hydrants or the operation of special installations inside buildings.

The equipment of reserve tanks and water towers must ensure the constant availability of an emergency supply of water, even if in some cases pumping units compelled to work over time.

(No ratings yet)

Plant of polymer products Polex | Plast ® manufactures fire water tanks with volume from 10 to 200 m 3

Manufactured horizontal fire-fighting water tanks made of high-quality polymer are part of the fire-fighting water supply system used to store a regulated volume of technical water and fire extinguishing.

Polex Manufacturing Company | Plast serially produces horizontal fire tanks, vertical ones with the necessary additional equipment. As a rule, all construction projects in Russia are equipped with horizontal underground fire tanks with access hatches.

Application form

Fill out the form and our manager will contact you within 5 minutes.Benefits of partnering with Polex | Plast®

High quality standards

Own department of quality and labor protection.

On the market since 2006

GOST ISO 9001-2011 (ISO 9001:2008)

Application area

Polex Fire Tanks | Plast - PR are used at industrial and residential buildings to create an underground water storage of the required volume for fire safety and elimination of fires.

Fire tanks are part of the fire fighting system, according to SNiP (SNiP2.04.02-84 "Water supply. External networks and structures")

In order to correctly calculate and provide the required volume of water, it is recommended to use at least two tanks. If one of the tanks fails, the remaining tanks must contain at least 50% of the intended volume of water.

To ensure effective fire extinguishing, water must flow from the tank under pressure.

Production material

Sheet polyethylene  Polyethylene profile

Polyethylene profile  Polypropylene

Polypropylene

Characteristics of the materials used

Tank mounting options

The installation of a fire tank should be carried out on the basis of the installation steps indicated on the product passport. Installation of a fire tank for storing water underground is recommended to be carried out by special installation teams. Underground fire tanks are buried to a depth of 3000 mm. Installation should be carried out on a prepared concrete base, and backfilling with filling the container with water with phased sprinkling.

Forms of fire containers

Horizontal

Horizontal cylindrical fire tanks are today best solution to ensure the fire volume of the liquid.

These fire tanks do not require deep installation into the ground, unlike vertical tanks. The installation depth of the fire tank is from 1 to 2.5 m. For the installation of tanks at a shallow depth, the body of the polyethylene tank can be insulated.

The presence of raw materials and semi-finished products, components in the warehouse of the enterprise, allows you to produce any fire tank up to 80 cubic meters, in a short time with high operational characteristics for any building projects. Polyethylene fire tanks can be interconnected with branch pipes of various diameters on a flange connection to organize a large fire water supply of up to 500 cubic meters.

| Tank volume m 3 | Diameter, D mm | Length, L mm | Weight, kg |

|---|---|---|---|

| 1 | 1000 | 1300 | 89 |

| 1,5 | 1200 | 1350 | 105 |

| 2 | 1200 | 1800 | 169 |

| 3 | 1200 | 2800 | 258 |

| 4 | 1200 | 3600 | 294 |

| 5 | 1200 | 4500 | 340 |

| 6 | 1200 | 5600 | 395 |

| 8 | 1500 | 4500 | 490 |

| 10 | 1500 | 5650 | 680 |

| 12 | 1500 | 6800 | 597 |

| 15 | 1500 | 8500 | 690 |

| 20 | 2000 | 6400 | 1182 |

| 25 | 2000 | 8500 | 1445 |

| 30 | 2000 | 9600 | 1582 |

| 40 | 2000 | 12800 | 2044 |

| 50 | 2200 | 13200 | 3282 |

| 60 | 2800 | 10380 | - |

| 70 | 2800 | 12010 | - |

| 80 | 2800 | 13630 | - |

| 100 | 2800 | 16880 | - |

The main activities of the non-standard equipment plant "Mashprom-Equipment" are the design, manufacture and supply of non-standard equipment and machines for mining, metallurgical, chemical, oil refining and gas industries in Russia.

The products of the non-standard equipment plant include machines and equipment that require a non-standard approach and constructive solutions. "Mashprom-Equipment" has the ability to design and manufacture the following products:

- Conveyor equipment of all classifications with different angles is inclined and length from several meters to tens of kilometers, conveyor loaders.

- Crushing and screening equipment of all classifications under dimensions customer with an increased margin of safety, both in terms of performance and operating conditions, as well as agglomerators, sorption columns and other equipment for processing plants.

- Relining machines for mills, mechanized ore dumping complexes.

- Capacitive equipment with and without lining from 4m3 to 1200m3 with mixing devices, vats, sumps, silos, bunkers, feeders, storage tanks for liquefied gases.

- Heat exchange equipment.

- Products and parts for various industries based on technical specifications.

- Repair and restoration work of machines and equipment

- Steel structures for industrial and road construction

- Designing units and mechanisms for industrial sectors, converting drawings of foreign companies with adaptation to Russian standards and GOSTs of production.

The machines and equipment section presents the most interesting completed projects made for mining enterprises, which have gone from design to implementation into the final product.

At the core of our work, we are guided by the following principles:

- satisfaction of all requirements of our customer.

- comply with ISO 9001-2001;

- constantly update the quality system;

- comply with the requirements of industry standards and GOSTs

- maintain comfortable working conditions and improve the well-being of its employees;

- comply with environmental requirements of production.