Exhaust ventilation device for a gas boiler. The main types of ventilation in a private house and their features. Types of boilers and ventilation systems

Over the roofs of most country houses pipes are visible. But these are not ordinary chimneys of stoves, but only a small part complex design called ─ ventilation for gas boiler in a private house. Any heating equipment, including a gas boiler, requires a ventilation system device. The correct operation of the gas boiler depends on its correct installation.

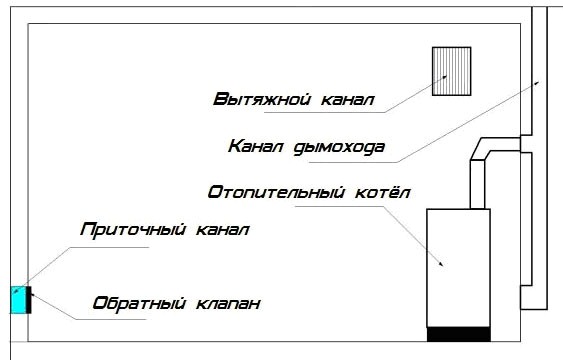

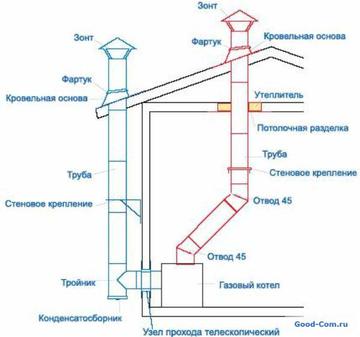

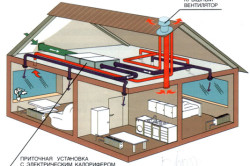

Ventilation scheme

The natural ventilation system for a gas boiler in practice does not show any special requirements... Combustion is impossible without oxygen, therefore, the air flow from outside must be sufficient both for the whole house and for its boiler room, in which it is most consumed. The draft and the output of combustion products also depend on the power of this inflow. For powerful heating units, an additional mass of air is required. It is provided by compulsory (artificial).

Types of ventilation

Ventilation system - a set of elements for cleaning, supplying and removing exhaust air. Ventilation systems for gas boilers differ in the following features:

- by the way of organizing pressure and air movement based on natural and artificial (mechanical) motivation;

- by designation ─ exhaust, supply and combined;

- by design ─ channel and channelless.

Ventilation for a gas boiler with natural induction of air exchange. This kind unorganized ventilation is based on the effect of air exchange, due to the difference in pressure of air masses inside and outside the building. It is also significantly influenced by the effects of wind through leaks and micro-crevices. wooden house, including when using vents, transoms and doors.

An organized natural ventilation is air exchange through artificially arranged supply and exhaust openings, manually adjustable. It occurs due to the pressure difference inside and outside the building. A deflector can be used to create a pressure change in the ventilation duct.

Ventilation for a gas boiler in a private house with mechanical induction of air exchange. In general, the functioning of this system is not much more complicated. natural ventilation and also depends on the difference atmospheric pressure... Two exhaust pipes are installed on the roof of the house, which are the basis of the air exchange system. One of them is intended for the introduction of atmospheric air into the house, the second is for the output of the exhaust outside. In contrast to natural ventilation, the inlet of this system is equipped with a fan with automatic on / off switch and a flow rate controller that regulates the operation of the system.

The ventilation ducts are routed so that Fresh air first enrolled in living rooms, and then into service (kitchen, bathroom, etc.). The other (exhaust) serves to remove oxygen-depleted air. It is usually equipped with a device called a built-in cooker hood. Both pipes are connected to the ventilation ducts of the service rooms. As a result, air from living rooms is pushed into service rooms, preventing the accumulation of moisture, musty smell in the House. Described scheme supply ventilation has high efficiency.

By purpose, ventilation is divided into:

- Supply ventilation for a gas boiler in a private house. This is the system by which a certain amount of air is supplied to the house mechanically... The air in it can be heated in winter and cooled in summer. Supply ventilation is organized artificially. She provides admission street air into the building due to excess pressure. At the same time, the exhaust air leaves through another ventilation duct.

- . It is installed to remove harmful emissions from the premises;

- Mixed ventilation. This ventilation performs the combined functions of the two systems described above.

The ventilation system by design can be carried out through branch channels and without them. The duct is arranged in cases when it is necessary to thoroughly filter the air from dust, moisture and steam. The work of channelless ventilation is organized through the wall openings of all ventilation ducts in the house.

Ventilation device

Let us ask ourselves the question, what elements does ventilation for a gas-fired heating boiler consist of? The device of the ventilation system for the boiler is labor-intensive and hard work and requires strict adherence to the technology of the selected scheme. Only a correctly calculated and installed circuit will function effectively.

Here are the basic requirements for installing ventilation for. It is carried out in this order:

- First of all, all the elements of the ventilation system are assembled.

- In the places where pipes pass through the structure of the building, special passage elements are installed to avoid damage.

- Thermal insulation is being installed. Its presence is mandatory at the joints of chimneys with the combustible material of the house structures.

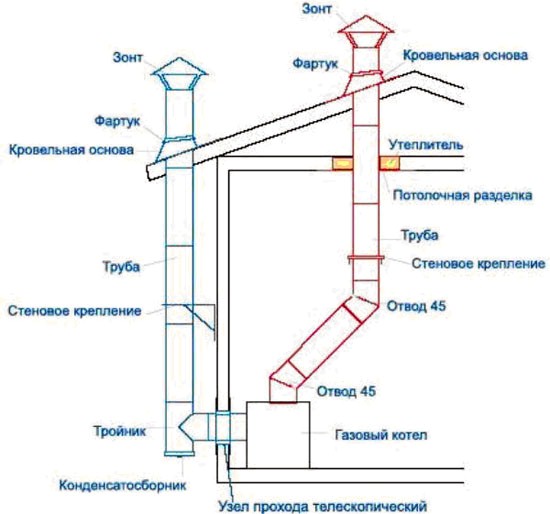

Ventilation for a gas boiler in a private house consists of a fairly large number of elements. Let's list the main ones:

- Adapter connecting the chimney with the outlet of the heating boiler;

- Revisioned tee fitting to aid in the removal of condensate;

- Mounting clamp for walls;

- Pass-through pipe;

- Channel pipes (telescopic);

- Bends installed near the beginning of the chimney in order to prevent a decrease in draft;

- A conical tip used in a flue gas boiler.

Heating gas equipment of any brand and design cannot be used without sufficient air exchange. Therefore, ventilation for a gas boiler in a private house is extremely important. There is no place for negligence, there is no place for the Russian "maybe"! It is about human health and life. Non-compliance correct selection ventilation scheme, its installation, may lead to penetration, as gas fuel and carbon monoxide in living quarters. The gas is colorless and odorless, although it is deadly to all living organisms. Moreover, its overabundance can lead to fire and explosion! The gas boiler room constantly needs special attention and care.

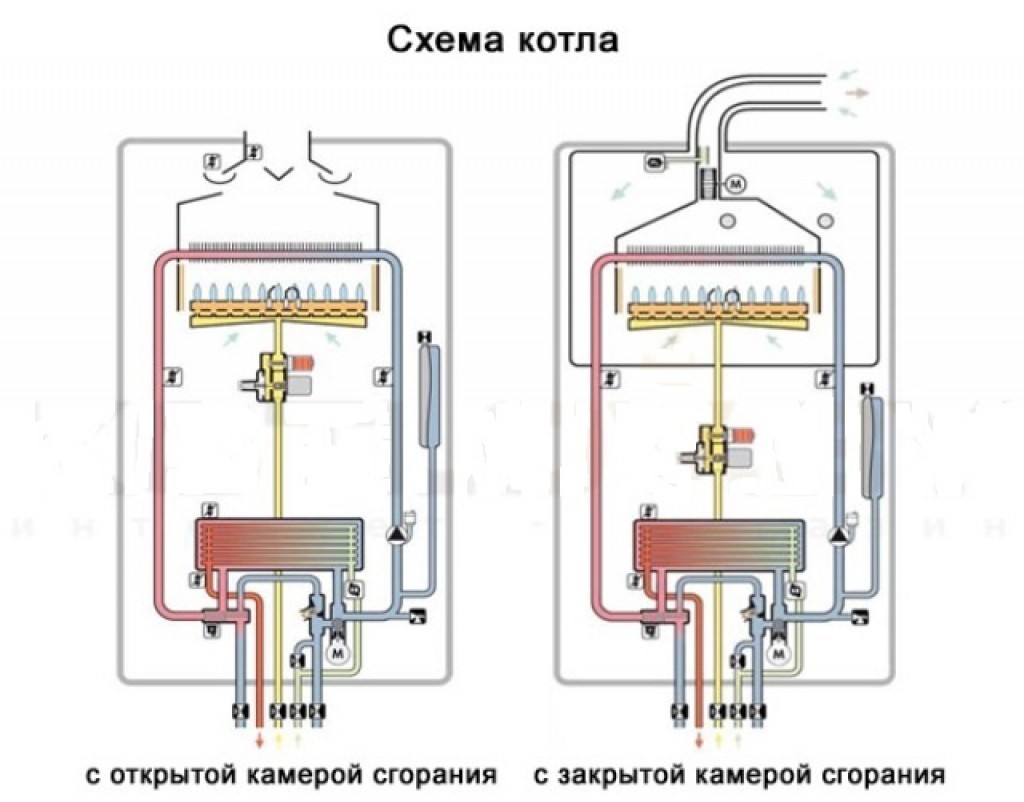

The most suitable and safest option is considered to be a turbocharged boiler with a double-circuit coaxial outlet to the outside in any version (floor-standing, wall-mounted, etc.). In such a case, air is taken from the outside and additionally warmed up along the outer radius, since at the same time the boiler is exhausted along the inner radius.

Experts recommend combining natural and forced ventilation, which, when the power supply is turned off, will make it possible to partially replace the work of the forced system. Also, the power supply will not be required if the fans are to be switched to the power generated by the wind turbine on the roof.

Today, the use of gas boilers in heating private houses is becoming more and more popular. You can understand this, because modern heating units are easy to use, economical, and most importantly, they create comfort and warmth in the home. but for maximum comfort, it is important to provide ventilation for a gas boiler in a private house. What is the best way to equip an exhaust system for a gas boiler? Let's talk about this in more detail.

The ventilation system of a room with a gas boiler in a private house is important and vital. necessary decision... This issue should be approached with full responsibility. Autonomous gas heating of a private house cannot do without ventilation.

Types of ventilation systems

There are different types ventilation ducts for a gas boiler.

- Depending on the principle of air exchange, ventilation is divided into artificial and natural.

- According to the purpose, the systems are of the supply, exhaust and mixed types.

- By the type of design of the system, channelless and channel ones are distinguished.

The artificial air exchange system is based on the operation of a fan, which is located in the same room as the boiler and is built into the ventilation grill. As for natural ventilation, it is achieved by the ingress of fresh air through the entrance doors and windows due to the pressure difference between the space of the room and the street. Nevertheless, it is better to equip such systems with a very small fan, which will ensure that the air circulation process is not disturbed.

Let us now touch on the supply ventilation for a gas boiler. Due to artificial induction, additional air enters the interior of the boiler room or kitchen, where the boiler is located due to the created excess pressure. Therefore, stale air will be removed through the ventilation duct.

V exhaust system ventilation air exchange is achieved by removing air masses through the ventilation shaft.

There is also a third type of ventilation, depending on the purpose - mixed or supply and exhaust. Its principle of operation combines the work of the two previous ventilation systems.

Channelless and duct ventilation

Channel type - supplying ventilation communications to the house. Especially important this system if the room needs to be thoroughly cleaned to remove moisture, dust or steam. Ventilation pipes for gas boilers are on the market in the widest range... There will be no problems with the choice.

Chimney for gas boiler

Checking the ventilation system for correct operation

Where to start checking the efficiency of a wall-mounted gas boiler hood?

For starters, it is important that the window in the room is open and the front door is closed. The next step is to apply a regular tissue to the vent. Due to the movement of air, the napkin will be carefully attracted to the opening, which means that ventilation works efficiently. If the napkin falls down, then the ventilation duct is clogged and should be cleaned.

How on their own calculate the performance of the ventilation system? You need to start with the calculation total area a building to be served by a fan. Then the area is multiplied by five. The result is summed up with twenty percent of it. As a result, a number is obtained, which will be the recommended performance of the ventilation system. The fan itself is then selected on it.

So the presence quality system ventilation in your house, and especially in a room with a gas boiler, is a guarantee of the health of the residents themselves. In addition, it guarantees reliable operation of the gas appliance.

Ventilation system of the room where the gas boiler is installed

Ventilation of a boiler room or kitchen, where there is gas equipment, can be either supply or exhaust. Let's talk about each type.

When installing this ventilation system, you should follow these steps.

- First of all, you need to draw a circle on the wall with a diameter of a couple of centimeters larger diameter plastic pipe.

- Then the perforator turns on, and holes are drilled according to the specified diameter of the hood for the gas boiler with a small step, as well as in the very center.

- Next, you need to use a chisel and a hammer to knock out all unnecessary from the inside of the circle, so that then you can easily mount the pipe into the cavity.

- After installing the pipe, you need to seal up the voids and cracks with polyurethane foam... The remains of this foam should be carefully removed from the walls until it has set.

- When everything is ready, a ventilation grill is installed, which will protect the ventilation system from debris, insects, and also give the system an aesthetic appearance.

Along with the exhaust ventilation, many felt the efficiency of the supply system as well. It quickly and smoothly changes the old dirty indoor air to clean and fresh air. In addition, the air that is supplied to the room with the gas boiler can be further processed, for example, humidified, heated and cleaned.

Each supply ventilation system has in its asset supply units using one hundred percent air flow from the street. Such systems can be used for both household and industrial purposes. The main advantage of this type of ventilation is a low noise level, which contributes to the creation of a calm and comfortable atmosphere indoors.

As is known, wall-mounted boilers should be installed on load-bearing walls... Moreover, each equipment is endowed with its own system for removing combustion products, which can be natural and forced.

The second option does not need a chimney. Such a boiler has a built-in fan. You just need to make a hole directly to the street for the outlet of the pipe through which the combustion products will flow. As a result, a forced draft for a gas boiler will effectively serve for many years.

As for the natural smoke exhaust system, products are brought out to the street by natural draft. A prerequisite for the installation of such gas units is the presence of supply ventilation or a water intake hole in the room.

Floor standing boilers must be installed strictly on the floor. No additional stands should be used for this. The removal of combustion products in them is carried out using an exhaust for a floor gas boiler, which is a special horizontal or vertical exhaust pipes.

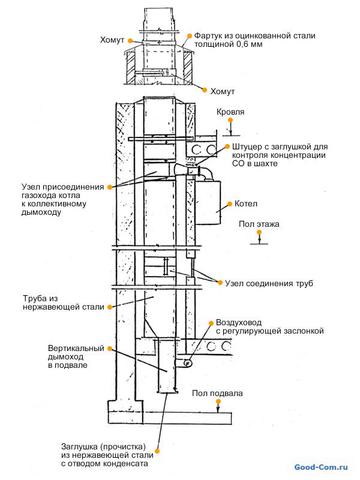

The entry of combustion products into the ventilation shaft should be carried out from different devices to different levels. The minimum distance is half a meter. When the inlets are located at the same level, there must be a special incision inside the chimney, having a height of at least half a meter.

Ventilation system gas equipment must be completely sealed, not allowing even the slightest volume of combustion products to pass through, which can lead to death. Each butt joint must be carefully sealed with a heat resistant sealant. In order to avoid a fire inside the boiler ventilation system must have an insulating layer.

When choosing a boiler, pay attention to such characteristics as equipment, type of heat carrier, electrical dependence, material of the main heat exchanger, type of exhaust for gas boilers, type of burner, method of preparation hot water, type of energy carrier and method of installation. The choice of all these characteristics depends on many factors, and they are very important. But of paramount importance is the installation of the boiler itself, since then all subsequent actions will be carried out from it. The fact where the boiler will stand, at least important aspect, the choice of further characteristics depends on this, for example, such as chimneys for gas boilers. From the place of installation of the boiler, it will depend on how to make the installation itself.

Important! When choosing a boiler, pay attention to the exhaust hood, boilers with forced exhaust are considered environmentally cleaner and safer.

Exhaust pipes for gas boilers

For safe work heating equipment it is necessary to ensure the outlet of combustion products. The safety of your family and the reliable operation of gas heating equipment will depend on how correctly the exhaust pipe for the gas boiler is installed. Taking into account the factor on which fuel your boiler will operate, and pipes for the exhaust are selected. For coal and gas boilers, the hoods are made from different materials. Gas pipes made of stainless steel are considered the leaders among pipes for heating equipment. They are cylindrical in shape.

The diameter of the chimney must not exceed the diameter of the flue. The chimney must have a soot cleaning hatch. There must also be an empty space under the chimney inlet where condensate can drain and accumulate. If something accidentally gets into the chimney, this hole serves to prevent the chimney from blocking.

The chimney itself must be resistant to the effects of combustion products and be sealed. What does resistance to combustion products mean? This is when the pipe is resistant to heat load and to the effects of combustion products. Exhaust pipe gas heating boiler must be made of heat-resistant materials that are resistant to corrosion, such as: aluminum, enamelled, galvanized and stainless steel... Make sure there is good draft in the chimney. You can check the draft by turning on the water heater and opening the hatch under the chimney. Next, you need to bring up the fire: the flame should stretch into the inside of the pipe and go out.

Forbidden! Do not use ventilation ducts to remove combustion products.

Features of the Russian market

Today, for the use of household heating devices, the consumer is provided with a large selection: wall-mounted, floor-mounted, with a closed combustion chamber and an open one, with a copper, cast-iron and steel heat exchanger, electric, solid and liquid-fuel, gas, double and single-circuit. The difference between them is price and functionality.

For the Russian consumer, there are two important factor, according to them, the type of this or that heating equipment is determined. The first factor is the price, sometimes it has great importance when buying a boiler, and the second factor is the type of heating system that exists. It's no secret what is being built and operated a large number of housing with open system heating, and it is simply impossible to use an imported high-tech boiler. Therefore, Russian gas boilers- the best and only option for gas heating equipment.

![]()

Floor boiler heating system Russian production includes the following elements: circulation pump, expansion tank, coolant, heating radiators, pipeline accessories, pipes and heating boiler. The heart of the entire system is, of course, the boiler. It heats up the coolant in order to give off heat through heaters... In order to reduce the resistance during the movement of the coolant, large pipes are needed, all slopes must be maintained.

For autonomous electrically independent heating and hot water supply systems of industrial and domestic premises, floor-standing heating systems... For example, for workshops, workshops, houses, cottages and summer cottages. Such boilers are almost identical to each other, made in the form of a floor-standing rectangular or cylindrical cabinet. On the front there is a door for starting the boiler and adjusting the heating modes.

Installing a gas boiler in the kitchen

Today, apartment residents and owners of old private houses prefer to install a gas heating boiler in the kitchen. Such a solution can save space, which is often not enough. This is relevant in the case when the area of the room does not allow to allocate a separate room for the boiler room, especially since modern heating gas boilers have an excellent design and compact dimensions that fit most interiors. When planning to install a gas boiler in the kitchen, consider the rules, such as: the presence of a window with a window (so that air flows into emergency cases), ventilation grill or doors with a gap between the floor. Mandatory presence of a ventilation duct. Please note that the kitchen area must be at least 7.5 kV meters, and minimum height ceiling - not less than 2.5 meters.

There is a necessary standard for the walls on which the gas heating boiler will be installed. The distance between the boiler and the walls must be at least ten centimeters; a heat-insulating screen is also required, which must be made of roofing metal in combination with asbestos. The walls in the room, if possible, need to be made of non-combustible materials, but if there are no such walls, it is still allowed to install the boiler.

What requirements must be observed when installing a gas boiler?

According to all safety rules, it is forbidden to install boilers in living rooms; there must be a separate room for the equipment. In the boiler room, the height of the ceilings must be at least 2.2 meters, and the width of the doorway must be at least 0.8 m. The floor must be flat, made of non-combustible materials, and the walls must be plastered (wall decoration is not allowed with flammable materials). The windows must correspond to the calculations of 0.3 sq. m per 10 cubic meters. m. premises. It is necessary to carry out communications into the boiler room: sewerage, water, gas and electricity supply.

There must be a ventilation outlet on the ceiling of the boiler room, which is connected to the entire ventilation of the building. Air supply can be either through the grill of the boiler room door, or from the street. Two chimney channels are made through the wall. One channel for mounting, the other, just below, for technological cleaning. The chimney must be gas-tight, the ingress of combustion products into the boiler room is unacceptable. The exhaust opening must be at least as large as the area of the unit. To prevent air leakage through the chimney and to ensure complete removal combustion products, the upper cut of the chimney must be above the roof ridge or at the level. The boiler must be accessible from all sides; it must be installed far from open sources of fire.

Forbidden! When using reduced gas, the gas boiler must not be installed in the basement or on basement floor.

The use of materials is permitted only if there is an indexed link to the page with the material.

Comments:

- The main types of ventilation in a private house and their features

- How to check the ventilation of a gas boiler in a private house?

- Choosing a ventilation system for a private house

- Arrangement of supply ventilation in a private house with a gas boiler

Currently, a lot of homeowners use gas boilers for heating. This allows you not only to create a comfortable and cozy atmosphere in the house, but also helps to save money. However, it must be remembered that when using this heating method, ventilation is required in a private house for a gas boiler.

The importance of ventilation systems cannot be overemphasized. With absence necessary ventilation in homes where it is used natural gas for heating and cooking, residents may experience health and well-being problems. This is due to the fact that during the combustion of gas, combustion products and water vapor enter the air, and insufficient removal of combustion products leads to insufficient removal of moisture. An increased level of humidity leads to the appearance of mold, which also negatively affects the microclimate at home and the health of residents. Mold and gas combustion products are especially dangerous for the elderly and people who suffer from pulmonary diseases. Poor ventilation negatively affects the condition of the skin, there is a state of increased fatigue, drowsiness and headaches.

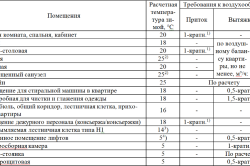

Ventilation in a private house must provide the required intensity of air circulation that meets sanitary and hygienic standards.

To determine the sanitary and hygienic standards, the capacity of the house, the number of people living and the type of their activity are taken into account. With insufficient air exchange, the air becomes heavy and there is a desire to open the windows for ventilation. Because of this, the air temperature inside the house begins to drop and the requirements for heat consumption, which is necessary for heating, increase. From this it can be concluded that air exchange affects not only the sanitary and hygienic state of the house, but also energy costs. In older houses, the ratio of the amount of heat required for ventilation to the total cost of heating is about 15%. In new homes, this ratio is much higher.

The main types of ventilation in a private house and their features

- Ventilation by air exchange is divided into two types: artificial and natural. Artificial ventilation can be created by installing a fan that is built into the air exchange system. It is usually installed in the bathroom. Natural ventilation is provided by the intake of fresh air from the windows and the front door. When using this system, it is advisable to install a small fan, which will not disturb the process of air circulation.

- Ventilation for the purpose is subdivided into supply ventilation, exhaust ventilation and mixed ventilation. Supply ventilation is created artificially. With its help, an additional supply of fresh air to the house is achieved, due to which overpressure... At the same time, the old air comes out through specially created ventilation ducts. Exhaust ventilation works by exhausting old air through ventilation shafts. Mixed ventilation combines both modes.

- By design, ventilation for a gas boiler can be with or without a channel. The duct is used in cases when it is required to clean the air as well as possible from dust, importance and steam. Ventilation without a duct is carried out through the wall openings of all ventilation ducts in a private house.

Back to the table of contents

How to check the ventilation of a gas boiler in a private house?

To check the operation of the system, you must open a window or front door, pick up a regular paper napkin and bring it to the opening ventilation shaft... If the napkin does not adhere well to the hole, it means that the ventilation system is not working well. Most often this happens due to a clogged channel or an improperly equipped ventilation system.

To calculate the performance of the ventilation system, calculate the area of the house, multiply the result by 5 and add 20%. The obtained value is the recommended performance of the fan, which should be installed in a private house.

Back to the table of contents

Choosing a ventilation system for a private house

Most often, a ventilation system in a private house is designed during construction. However, if this moment has been missed, it is never too late to rectify the situation. When building a house, three types of air exchange systems are usually used: natural ventilation, supply and supply and exhaust. Natural system air exchange in a private house in which there are plastic windows, does not work, as they completely block the normal air circulation. In addition, the principle of operation of natural ventilation is based on the use of the temperature difference inside and outside the house. Since there is no such difference in the summer period, the system cannot work either.

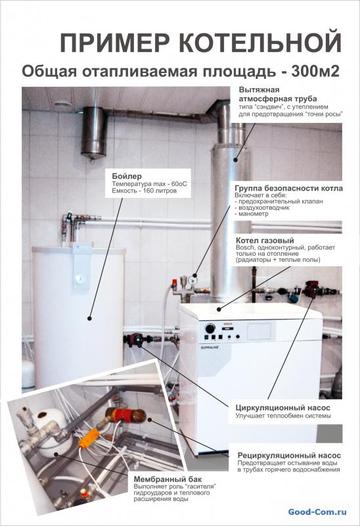

In a private house in which a gas boiler is installed, it is best to install a ventilation system that will be able to pump and remove air. That's why the best option there will be a supply and supply and exhaust system. Supply system perfect for a house with an area of no more than 300 m². If the area of the house is much higher, then it is better to install a supply and exhaust system.

Back to the table of contents

Arrangement of supply ventilation in a private house with a gas boiler

Figure 1. Scheme of supply ventilation of a private house.

The principle of operation of the supply ventilation system is very simple. On the roof of the house (usually above the kitchen, where the gas boiler is installed), 2 exhaust pipes are installed. They form the basis of the future air exchange system. The first pipe will serve to introduce fresh air into the house, and the second pipe will serve to output. The first pipe is equipped with a special fan, which has an automatic on and off system and an additional power controller that will regulate the operation of the system. The supply ventilation diagram can be seen in Fig. 1.

Ventilation passages should be designed so that fresh air (for example, from the bedroom) enters other living rooms, and then goes to the kitchen, corridor and bathroom, where there are vents. The second chimney is used to exhaust the air. It usually has a built-in hood. The second exhaust pipe is connected to the outgoing ventilation ducts, which are laid in the kitchen and bathroom. Thus, fresh air begins to flow from the room and is then pushed into the bathroom and kitchen, which prevents moisture accumulation and bad smell in the House. This method arrangement of ventilation has a high efficiency.

Even with a closed firebox in a gas boiler room, an exhaust hood is required: gas leakage is possible and, as a result, poisoning of residents. In the worst case, an explosion. Therefore, a hood for a private house in accordance with SNiP is necessary: it ensures the safety of people and effective work equipment.

The exhaust device for gas in a private house is determined by the location of the boiler room: on the basement, in the annex, in a separate building, in the attic, in a separate room in the house (). For equipment on liquefied gas the boiler room in the basement is not suitable. This fuel has more mass than air.

If a leak develops, gas will start to accumulate at the bottom of the house and may explode.

For powerful models, a boiler room device with forced ventilation for a gas boiler is mandatory).

A wall-mounted low-power unit (within 30 kW) may be placed in the kitchen if it meets the following conditions ():

- an area of at least 15 square meters;

- ceiling from 2.2 meters high;

- glazing from 3 square centimeters per cubic meter;

- there are transoms or vents on the windows;

- the boiler is placed 10 cm from the wall, the wall is sheathed with non-combustible material;

- there are air vents at the bottom of the door.

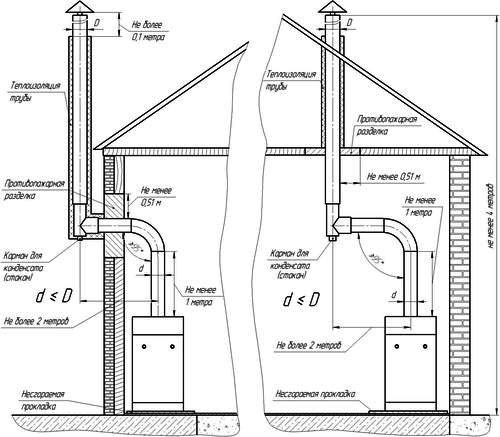

In accordance with 2.04.05 II-35 SNiP, ventilation for gas boilers in private houses is mandatory. The outlet of the ventilation duct is located in ceiling slab... An inspection channel for cleaning is made 30 cm under the chimney. The amount of air required for ventilation depends on the capacity of the unit: 1 kilowatt requires 8 sq. see airflow, if the air comes from the street, 30 sq. cm - if from the next room.

Exhaust options

Ventilation in a boiler room with a gas boiler is natural and artificial. The first involves the creation of conditions under which the air in the boiler room will be renewed by itself.

With an artificial exhaust from a gas boiler in a private house, the air flow is forced by fans. Let's consider the features.

Natural

How to make a ventilation duct in a private house for a gas boiler: with a unit power of up to 30 kW, it is enough to perform in the lower part outer wall supply air with a diameter of 15 centimeters. A piece of plastic pipe of the appropriate section is placed in the hole, and the outside is covered with a grid to protect it from dirt, mice, and birds.

From the inside, put on the pipe check valve... Its purpose is to prevent street cravings. An opening for supply ventilation for a gas boiler in a private house is punched in the immediate vicinity of the fuel compartment so that the air passes directly into the firebox.

How to make an exhaust hood for a gas boiler in a private house: bring the ventilation duct for a gas boiler outside, install a protective canopy over the pipe. From the inside, you can also put a valve to exclude reverse thrust... The exhaust pipe in a private house for a gas boiler is placed directly above it.

The natural ventilation device for a gas boiler is simple and cheap, but does not always meet the standards. Building regulations require that the air in the boiler room is completely renewed three times per hour.

Guarantee this when natural air exchange it will not work, it is uncontrollable - it depends on the season, outside temperature, wind speed and direction.

Artificial

How to make ventilation in a boiler room with a gas boiler with artificial draft: the ventilation duct is equipped with a fan, the power of which is selected depending on the channel section plus a margin of 20-30 percent. When choosing, take into account the length and geometry of the duct pipe, the number of turns. It is possible to install the fan only on the inlet or only on the outlet, but it is preferable to equip both.

How to properly make a hood for a gas boiler in a private house: triple the volume of the room (multiply the height, width and length of the room) - you get the amount of air required for pumping. In accordance with this figure, one or two fans are selected.

You can increase the efficiency of air exchange by using automatic system control: the controller turns on the fans simultaneously with the boiler, when it stops, it turns off ().

The role of the chimney in the ventilation process

Regardless of the presence / absence of fans, the bulk of the gases in both directions pumps the chimney (). Its design can be different, the choice is due to the characteristics of the boiler itself. For example, condensing units require installation coaxial chimney ().

For any pipe design (coaxial, conventional), for any orientation in space (vertical, horizontal), the cross-section must correspond to the cross-section of the corresponding boiler nozzle.

The instructions for the unit usually indicate the required parameters and type of chimney, as well as recommendations for installation. Subject to these recommendations and SNiP rules, the hood for a gas boiler in a private house and the air flow to the burner work efficiently, combustion products do not penetrate into the room, soot and dirt do not accumulate in the channel.

If the chimney is vertical, the chimney should rise above the ridge by at least 0.5 meters, flat roofs- per meter. The number of knees is minimal (no more than three). The chimney is equipped with an inspection window for cleaning, a condensate drain, a protective canopy against rain.

Video on how to make a ventilation duct in the house.