Primary fire extinguishing equipment in administrative buildings. Fire safety of warehouses

Many are interested in the question of where the primary fire extinguishing means should be located in order to quickly use them at the right time. Such interest is also due to the fact that sometimes the means are used for other purposes, they ignore the rules of content. Should they be locked, or can they be left in a conspicuous place? What is the order of their content?

General rules

Boards and cabinets are provided to accommodate the primary means of fire fighting. It is in them that the well-known fire extinguishers, buckets, shovels and other equipment are kept.

Shields are installed in warehouses, back rooms, transit points for the transportation of goods, garages, in the yards of enterprises and organizations. The placement is carried out in such a way that the funds are not exposed to direct rays of the sun, rain and snow. Shields covered with a net are used if they are located in places where many people pass, including strangers. The placement of open boards takes place in the areas of enterprises, where entry is prohibited to unauthorized persons or is provided by passes.

Boards, cabinets and fire extinguishing means are painted in signal colors, in accordance with the requirements of GOST "Signal colors and safety signs".

It is recommended that the placement of primary fire extinguishing equipment be in rooms, offices and warehouses where the likelihood of fire is highest. They are installed near electrical equipment, in laboratories, storages with flammable liquids, for example, with fuel. Fire extinguishing media are installed near escape routes in public buildings. At the same time, care must be taken that such placement does not interfere with the movement of people.

All must be constantly in working order, and must be inspected, cleaned of dust, renewed paint.

Their service is monitored by people who know the rules and regulations for the maintenance of fire extinguishing equipment. If there are no such at the enterprise, then they contact a licensed company that helps to organize the correct content and Maintenance funds.

Sand storage

To extinguish flammable liquid and to prevent its spreading, use sand. Sand boxes are placed next to fire shields, on which one more useful remedy- a shovel. Sand can be collected with a shovel or with a bucket hanging on the shield.

The sand must be dry and free from dirt and impurities. At least twice a year it is stirred, lumps are broken so that it can be easily raked up. For storage, boxes or shortened barrels are used. They must be closed so that excess moisture does not get inside.

Fire fighting hand tools

An important extinguishing agent is a cat or fire-resistant cloth. They are extinguished with a nightmare electrical devices, devices and burning clothes. To accommodate felt, fire-resistant capes and use cabinets, shields or ordinary shelves in rooms where fire is possible.

The placement of axes, hooks and shovels takes place on fire shields. The requirements for their content are as follows. They must be clean, correctly sharpened, free of corrosion, with intact cuttings. Placement on the boards is carried out by hanging, so that any primary fire extinguishing agent can be quickly and easily removed without resorting to additional tools.

Maintenance consists of straightening the crowbars and metal hooks of the hooks if they are bent after use. The broken handle of the shovel is replaced. Inspect the conical bucket, making sure that it is intact without strong dents or changes in shape.

There should be 2 fire extinguishers on each floor of a public building. Other premises also require their placement, in accordance with fire safety rules.

Since there are quite a few types of fire extinguishers, the order of their maintenance must be observed in accordance with the technical documentation. But there are also basic requirements for placement and content, common to all species.

- Each item must be numbered and signed. Use white paint or tags.

- There must be a seal on the manual release mechanism.

- The location of fire extinguishers is chosen away from heating devices and direct sunlight.

- Do not choose too damp places for placement in order to prevent rapid corrosion of the body and the starting device.

- Make sure that the primary fire extinguishing agent can be freely approached.

- The inventory must be visible; it must not be hidden in niches, on mezzanines and cabinets that are not intended for storing primary fire extinguishing equipment.

- The correct placement is such that the top was at a height of 1.5 m and no more. If the mass of the fire extinguisher is 15 kg or more, then the mark drops to 1 m.

In accordance with the maintenance procedure, a scheduled check of primary fire extinguishing equipment occurs once every six months. Unscheduled checks are carried out after each exercise or firefighting application. Defective or empty cylinders are replaced with new ones.

Primary fire-extinguishing equipment must be secured at the locations so that they do not fall from an accidental shock. The position of any object must be stable.

How are fire extinguishers serviced

All primary extinguishing media, including fire extinguishers, in mandatory must undergo maintenance. It includes inspection, repair, testing and refueling.

Examine externally, checking that there are no dents, deep damage. The body of the primary extinguishing media must be painted a uniform red, free from rust. It should show clear instructions on how to use the product.

If there is a pressure gauge on the body of the primary fire extinguishing agent, then check its serviceability, the date of the last verification, and control the pressure inside. The fire extinguisher is weighed and the mass of its contents is determined by calculation.

Assess the condition of the spray gun and hose (if present). Nothing should prevent the extinguishing agent from escaping.

For manual fire extinguishing equipment, check their location and attachment to the wall or in the fire cabinet. For mobile fire extinguishers, check the serviceability of the chassis, attachment to the trolley.

Fire extinguishers are randomly opened during annual inspection. Evaluate them working condition and, if necessary, carry out recharging or full replacement for new copies.

Once every 5 years, all fire extinguishers are discharged, and the cylinders are cleaned and checked for strength and tightness. They inspect the seals, assess the integrity of the coating, check the locking devices, starting heads. Recharge of extinguishing agents occurs in the event of scheduled inspection, detecting a gas leak, more than normal, or after use in a fire. Do not patch the case or weld holes. Damaged balloon fire extinguishing means are removed from service.

Fire hydrants are an important primary extinguishing agent. They are housed together with sleeves and nozzles in fire cabinets. The sleeves are carefully rolled up. The placement of cabinets should be 1.35 m above the ground or floor. They are made with ventilation holes. Equipment should be kept dry and clean. The sleeve is rewound once a year, changing the edge of the bed. Every 6 months, it is planned to check the taps by unscrewing them and monitoring the water pressure. The results of the check are recorded in a journal specially provided for such purposes.

Warehouses are the most important integrated part of any logistics system, performing the function of accumulating and redistributing goods.When placing goods in warehouses, it is necessary to consider not only them optimal combination on physical and chemical properties and temperature requirements, but also the ability to ensure proper fire safety of the facility.

fire safety in the warehouse

Classification of warehouses by fire hazard

Depending on the potential hazard of materials stored in the warehouse (Fire safety standards Airbag safety 105-03), all warehouses are subdivided into categories

- А (increased fire and explosion hazard) - warehouses for storing flammable gases and flammable liquids (with a flash point up to 28 ° C), as well as substances that can explode and (or) burn when interacting with atmospheric oxygen, excess moisture or with each other;

- B (explosion and fire hazard) - storage facilities for the content of flammable bulk and dusty substances, fibers and flammable liquids (with a flash point of more than 28 ° C), as well as substances capable of forming explosive dust and vapor-air mixtures;

- В1-В4 (standard fire hazard) - warehouses containing flammable and hardly combustible liquids, fibers and materials (including loose and dusty ones), capable of burning when interacting with water, air oxygen or with each other, but not exploding;

- Г (moderate fire hazard) - rooms in which non-combustible substances and materials are temporarily located, as a result of processing, are in a molten or incandescent state, as well as storage rooms heated by the combustion of solid, liquid or gaseous fuels;

- D (low fire hazard) - storage facilities that contain non-flammable substances and materials at a standard storage temperature.

It should be noted that this classification of warehouse premises often does not reflect the specifics of the organization of storage processes, does not take into account the architectural type of warehouse (open, semi-open or closed) and its number of storeys, as well as the degree of fire resistance of the building structure itself.

Fire resistance of warehouses - passive fire protection

The fire resistance of any building is its ability to withstand fire until the loss of operational properties. Fire resistance is characterized by two indicators - the fire resistance limit and the fire propagation limit.

The least fire resistant are wooden buildings, the ignition temperature of which is only 150 ° C, therefore, the fire protection of wooden warehouses should be given the most close attention... Traditionally, their fire resistance is increased by applying plastering and impregnation with special flame retardants.

Fire protection treatment

Metal structures can also be plastered, finished with concrete or ceramic tiles. Nice results showed the processing of metal with special intumescent paints, which, in the event of a fire, form a porous layer of a slow-combustible material on the surface, increasing in volume 40 times. This treatment can significantly increase the time to reach the critical temperature (120 minutes instead of 40).

In order to improve the fire resistance reinforced concrete structures, they are treated with special compounds, the basis of which can be expanded vermiculite or a composition of gypsum, lime and an alkaline solution of sodium silicate (water glass).

In addition to processing structures, passive fire protection implies the obligatory processing of windows, the cracking of which during a fire causes increased combustion due to the flow of air into the room. Reinforcement of windows with a polymer film increases the fire resistance of a conventional window from 5 to 10 minutes, and the use of special glass blocks - up to 60 minutes.

Barriers to the spread of fire will be and fire doors, which are made of refractory steel or aluminum with the obligatory filling of the frame with a non-combustible material inside.

Along the perimeter, such a door is equipped with a fire-prevention tape-seal, which prevents the penetration of smoke and burning into the room.

Active fire safety systems

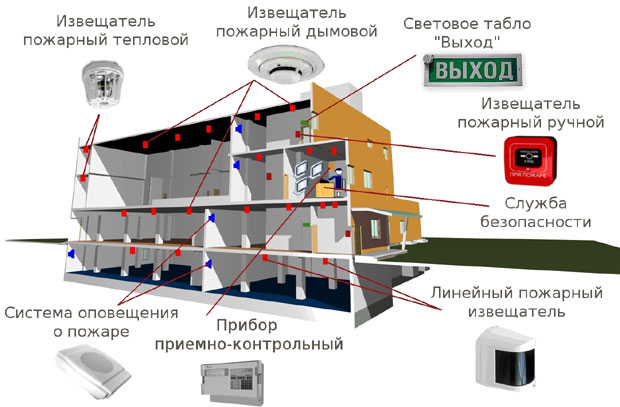

Active fire protection systems include systems fire alarm usually including

- that react to combustion products that appear in the air (smoke, carbon monoxide) or to an increase in temperature. There are sensors that react to the appearance open flame, they are used in warehouses where a fire may occur without a smoldering stage (fuel and lubricants warehouses);

- an electronic control panel that analyzes the readings of the sensors and, if necessary, starts the fire extinguishing system;

- an indication unit that reflects the state of the system and the processes occurring in it;

- a source uninterruptible power supply, allowing the system to remain operational in the absence of electricity.

In addition, a fire alarm system in a warehouse is usually supplemented with manual fire detectors, which are a device that manually triggers a fire alarm by pressing a signal button. Manual sirens should be installed in a place of easy access and protected by a light cover against accidental activation.

active fire safety systems

In addition to fire alarm systems, active fire safety equipment includes automatic fire extinguishing systems, which in record time since maximum efficiency allow you to localize the sources of fire in warehouses... Currently used to prevent fires

- traditional water system fire extinguishing, the cheapest and most affordable;

- sprinkler and deluge sprinklers. It can be called a modification of a water-based fire extinguishing system. They imply the presence of a pipeline with a supply of water, a main and reserve pump and a special head with a fusible nozzle that provides fine atomization of liquid under pressure. They are triggered automatically, without human intervention.

- , which is capable of feeding fine-grained powder into the fire site. In this case, it is possible remote control extinguishing the fire. It is used in the case when fire extinguishing with water is not possible (extinguishing the fire of gasoline, some chemicals). Powder mixtures have a long shelf life, without loss of functional properties and can be used in wide temperature ranges (-50 ÷ 50 ° C);

- modules gas fire extinguishing are distinguished by ultra-high-speed fire localization (no more than 30 seconds). They can be used to extinguish the fire of combustible gases, oil products, oils, paints and varnishes. They do not form a corrosive film, when they come into contact with the equipment, they do not spoil the stored materials;

However, whichever fire extinguishing system you choose, it should be remembered that strict adherence to fire requirements and fire safety techniques at the enterprise will help to avoid a fire in the warehouse.

General fire requirements for warehouses

All warehouses must be completed automatic system fire alarm and primary fire extinguishing equipment that have passed certification. To equip warehouses without an internal fire water supply with primary fire extinguishing means, fire shields are completed. Regulatory documents the following number of fire shields in warehouses is determined:

All fire shields should be located in easily accessible places, within sight. The best option their location will be as close as possible to the exit from the premises. Storage fire fighting equipment must be supplied with a luminous sign.

All persons admitted to work in storages and warehouses must undergo an initial briefing on ensuring the fire safety of the facility. The briefing is carried out directly at the workplace, while the employee must be familiarized with the fire extinguishing equipment located at the facility and the algorithm for practical actions in the event of a fire. Repeated briefings are carried out as needed, but at least once every 6 months.

In warehouses, it is mandatory to place an evacuation plan (diagram) from the building, made in accordance with GOST R 12.2.143-2009 and a plate with the designation of the person responsible for the fire safety of the facility, including initials, position and telephone numbers. Luminescent signs must be present on the walls of the warehouse, providing an emergency evacuation route for personnel in the event of a power outage.

Outside the warehouse, on a wall made of non-combustible material, there should be devices for turning off the electricity. Moreover, they are placed in a niche or cabinet, which must be closed and sealed.

Forbidden in warehouses of any category

- smoking, using open fire;

- the presence of plug sockets, household electric heating and heating devices, gas stoves, emergency lighting (lighting during off-hours).

- laying of transit cable lines and ventilation systems;

- use of luminaires with fluorescent lamps with reflective caps made of combustible material;

- storage of materials and substances with unknown fire hazard properties;

- storage of used containers and packaging materials.

All vehicles used for loading and unloading operations must be removed from the warehouse outside of working hours.

Warehouse planning

The primary task of planning warehouse premises is the correct zoning and determination of the location of racks or stacks, aisles between them, as well as the organization of sorting yards and work areas. Since it is precisely because of errors in the layout of the premises that enterprises incur losses.

It is forbidden to install racks close to the walls and columns of the room or place spacers.

- The minimum distance between the stack and the wall ( heating devices, column) - not less than 0.7 m,

- between the rack and the floor ( metal truss) - 0.5 m,

- between the stack and the lighting fixture - 0.5 m.

In warehouse without sectional premises with a width of up to 30 m and an area of up to 700 m2, a passage must be provided with a width of at least 1.5 meters opposite emergency exits... If the area of the room exceeds 700 m2, in addition to the passage, an additional 1.5 m wide passage is provided along the entire room.

The territory of the warehouses is isolated by a fence made of non-combustible material at a distance of at least 5 meters from the walls of buildings, structures, places of storage of petroleum products. The height of the fence is standardized at least 2 meters. All access roads to the fuel and lubricants warehouse must have sufficient illumination, their outer coating must undergo timely inspection and periodic repairs. V winter time access roads to fuel and lubricants depots should be constantly cleared of snow and ice. Fuel storage areas should be fenced with a strip of plowed land, at least 2 meters wide.

All covered warehouses of fuels and lubricants and oil depots must have at least 2 exits, which are located at opposite ends of the room, while the doors must open outward. It is forbidden to occupy the aisles with containers and foreign objects.

The equipment used for the acceptance, storage and shipment of petroleum products is equipped with control, protection and blocking devices. All electrical appliances, lamps and wiring, electrical fittings and equipment must be in good working order, in a special explosion-proof design. It is necessary to provide emergency lighting lines at oil depots and warehouses of fuels and lubricants. It is undesirable to use mercury lighting for fuel and lubricants warehouses, as it is morally obsolete and dangerous. It is preferable to choose as lighting fixtures LED modules. Any equipment is subject to operation only during its service life, and after that it requires replacement.

At renovation work, when opening the hatches of tanks, only copper-plated tools should be used, which do not cause a spark during use.

Stationary equipment for receiving and storing petroleum products (tanks, reservoirs, tanks) is installed on a solid fire-resistant foundation. In this case, the containers must be protected from atmospheric electricity and from exposure to direct sunlight. Reservoirs with shrinkage cracks are not used.

If the warehouse stores oil products in barrels, then the distance between the tiers should be at least 1 meter. All barrels are stored with corks facing up, in special wooden spacers that prevent them from rolling out. When stacking drums, wooden spacers are used between them, which prevent the formation of sparks in case of accidental impacts. All empty containers should be washed, steamed and only in this form should be further stored.

Since it is impossible to extinguish oil products with water, all fuel and lubricants warehouses must be equipped with a sufficient number of foam or acid fire extinguishers. In addition, each autonomous room of the fuel and lubricants warehouse must have an accessible telephone or radio connection, which, if necessary, makes it possible to inform the person on duty about the fire. fire department or the appropriate dispatching service.

Fire extinguishers should be located on the protected object in such a way that they are not exposed to direct sun rays, heat flows, mechanical influences and other unfavorable factors (vibration, aggressive environment, high humidity, etc.). They must be clearly visible and easily accessible in the event of a fire. It is preferable to place fire extinguishers near the places where fire is most likely to occur, along the paths of the passage, as well as near the exit from the premises. Fire extinguishers should not interfere with the evacuation of people in the event of a fire.

For the placement of primary fire extinguishing equipment in production and storage facilities, as well as on the territory of protected objects, fire shields (points) must be equipped.

In rooms saturated with production or other equipment that obscure fire extinguishers, indicators of their location should be installed. Signs should be located in visible places at a height of 2.0-2.5 m from the floor level, taking into account the conditions of their visibility.

The distance from a possible fire source to the nearest fire extinguisher should not exceed 20 m for public buildings and structures, 30 m - for rooms of categories A, B and C, 40 m - for rooms of categories C and D, 70 m - for rooms of category D.

It is recommended that portable fire extinguishers be installed on hanging brackets or in special cabinets. Fire extinguishers should be located so that the main inscriptions and pictograms showing the order of their activation are clearly visible and facing outward or in the direction of the most likely approach to them.

The locking and starting device of fire extinguishers and cabinet doors (if placed in the cabinet) must be sealed.

Fire extinguishers with a total mass of less than 15 kg must be installed in such a way that their upper limit is located at a height of no more than 1.5 m from the floor; Portable fire extinguishers with a total mass of 15 kg or more must be installed so that the top of the fire extinguisher is located at a height of no more than 1.0 m from the floor. They can be installed on the floor, with the obligatory fixation against a possible fall in case of accidental impact.

The distance from the door to the fire extinguisher should be such that it does not interfere with its full opening.

Fire extinguishers should not be installed in locations where temperatures are outside the temperature range indicated on the extinguishers.

Water and foam fire extinguishers installed outdoors or in an unheated room and not intended for operation at subzero temperatures should be removed during the cold season (air temperature below 1 ° C). In this case, information about the location of the fire extinguishers during the specified period and the location of the nearest fire extinguisher should be placed in their place and on the fire panel.

The use of primary fire extinguishing means for household and other needs not related to extinguishing a fire is not allowed.

Maintenance of fire extinguishers should be carried out in accordance with the instructions for use and using the necessary tools and materials by a person appointed by order for the enterprise (organization), who has passed in the prescribed manner the knowledge test of regulatory and technical documents on the design and operation of fire extinguishers and the parameters of fire extinguishers, capable of independently conducting necessary work on the maintenance of fire extinguishers.

Table 6.1. Timing of checking the parameters of fire extinguishers and recharging fire extinguishers

|

Type of OTV used |

Term for checking the parameters of OTV |

Fire extinguisher recharge time |

|

Water (water with additives) |

Once a year |

Once a year |

|

Once a year |

Once a year |

|

|

Once a year (optional) |

Every 5 years |

|

|

Carbon dioxide (carbon dioxide) |

Weighing once a year |

Every 5 years |

|

Weighing once a year |

Every 5 years |

Powder fire extinguishers used to protect vehicles must be checked in full at least once every 12 months.

Powder fire extinguishers installed on vehicles outside the cab or salon and exposed to adverse climatic and (or) physical factors must be recharged at least once a year, other fire extinguishers installed on vehicles - at least once every two years.

Fire extinguishers intended for charging into a fire extinguisher must be hermetically sealed, have clear marking and the necessary accompanying technical documentation, and also pass incoming control to check the compliance of their main operational parameters with the requirements of regulatory documents.

When recharging fire extinguishers, it is not allowed to use the unspent OTV residue (after using the fire extinguisher) without qualifying its properties for compliance with NTD requirements. Charge water and foam fire extinguishers completely replaced with fresh.

It is not allowed to mix powder formulations. different types, since this leads to a significant deterioration in their operational properties and to a decrease in fire extinguishing ability.

It is forbidden to charge the fire extinguisher into the body of the fire extinguisher in excess of the permissible value (especially water and foam), as this can lead to its destruction when blown up.

The bodies of powder and gas fire extinguishers must be dried before charging the OTV. The presence of moisture in them is not allowed.

An appropriate mark is made about the recharging of the fire extinguisher on the body of the fire extinguisher (using a label or tag attached to the fire extinguisher), as well as in its passport.

Automatic fire extinguishing installations (AUPT) are designed for automatic detection and extinguishing of a fire in its initial stage with simultaneous fire alarm signaling. They protect buildings, premises in which flammable and combustible substances are stored or used, valuable equipment and raw materials (warehouses of oil products, varnishes, paints), book depositories, museums, rooms for electronic computers, etc.

By the type of used extinguishing agent AUPT is subdivided into water, steam, foam, carbon dioxide, nitrogen, freon and powder.

In agricultural enterprises, the most widespread are sprinkler (English sprinkle - to spray, drizzle) and drencher (English drench - to wet, irrigate) water and foam fire extinguishing installations.

The sprinkler installation consists of a branched pipe system 7 located under the ceiling and filled with water under pressure created by an automatic (auxiliary) water feeder 4. Sprinklers (sprinklers) are screwed into the pipes every 3-4 m 8, the outlet openings of which are closed with glass or metal fusible locks. When a fire breaks out and the air temperature in the room reaches a certain value (for various sprinklers it is 72, 93, 141, 182 or 240 ° C), the locks are destroyed and water, sprayed, enters the combustion zone. At the same time, the control and signal valve 5 is triggered, the main water feeder turns on 2 (pump) that takes water from the water source 1 (main tank or fire water pipe) and a fire alarm is triggered.

When protecting unheated buildings, where there is a danger of water freezing, sprinkler installations of the water-air system are used, filled with water only up to the control and signal valves, after which there is compressed air in the pipelines with sprinklers. When the heads are opened, air first comes out, and then water begins to flow.

Drenchers of deluge installations, unlike sprinklers, do not have fusible locks, and their outlets are constantly open, and the water supply network itself is closed by a group-action valve that opens automatically at a certain temperature. Manually operated deluge systems are also used.

Sprinkler installations irrigate only that part of the room in which the sprinklers were opened, and drencher installations irrigate the entire calculated part at once. These installations are used not only to extinguish a fire, but also to protect building structures, equipment and raw materials from fire. The estimated area of irrigation by one water sprinkler or drencher type is from 6 to 36 m 2, depending on their design and the diameter of the through hole.

To increase the efficiency of AUPT, wetting agents, halocarbons and other substances are added to the water.

Sprinkler and deluge foam fire extinguishing installations, unlike water ones, are equipped with foam-forming sprinklers or devices for mixing the foam concentrate with water (foam generators). only in the area of the fire). They are charged with liquid carbon dioxide, nitrogen, argon, freons and other compounds. Gas installations are less complicated and cumbersome than foam ones, and more efficient in operation, less damage to raw materials, equipment, materials, etc.

To extinguish small foci of combustion in tanks, tanks, to protect individual units and equipment, automatic local powder fire extinguishing systems are often used. When the thermal sensor is triggered 1 Control block 4 through the switch 3 includes a flame suppression device 2, from which a fire-extinguishing powder is thrown into the combustion center under the pressure of gases formed during the combustion of a special gas-generating charge.

Automatic fire extinguishing installations, depending on the design, have different response times: from 0.1 to 3 minutes.

Automatic fire alarm systems (A – UPS) are designed to detect a fire in the initial stage, report the place of its origin, and, if necessary, for the introduction of AUPT and smoke removal. The most common is an electrical fire alarm. It consists of fire detectors (sensors) installed in controlled areas and responding to changes in any physical parameters in the room in the event of a fire, and a fire control station, which receives signals from the detectors via electrical wires, transmits them to the central fire station. communication, includes light and sound alarms, and, if necessary, AUPT.

Automatic fire detectors are subdivided: according to the reactive factor - into heat (react to temperature rise), smoke (react to the appearance of smoke), light (react to a change in the luminous flux) and combined (react to several factors); according to the principle of action - to maximum (react to the achievement of the maximum level of any factor), differential (respond to the rate of change of the parameter) and maximum differential.

Warehouses for flammable and combustible liquids (area from 100 to 500 m 2), for storage in containers of mixed feed, grass flour, etc. (from 200 to 1000 m 2), grain (200 m 2 and more ), as well as the premises of workshops for the production of vitamin grass flour, dry starch, for processing seeds (from 200 to 1500 m 2), packaging and packaging of vegetables, fruits in combustible containers (200 m 2 and more) and many other production and administrative household premises.

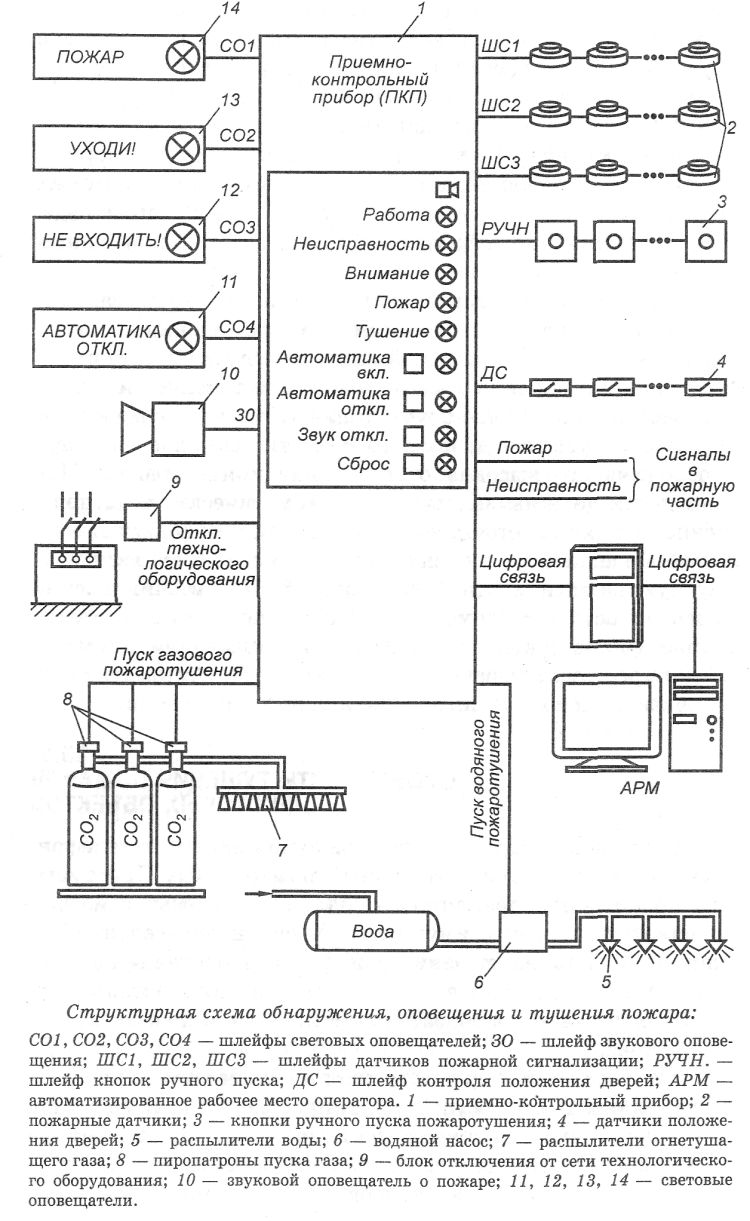

The figure shows one of the universal schemes for automatic fire detection and extinguishing. If a combustion source occurs in one of the rooms, after two or more fire alarm sensors are triggered 2, the signal from them is sent to the control panel 1.

This device sends a signal to the fire department, turns on light annunciators 14 "Fire" located outside and inside the building, and the pump 6 water fire extinguishing or detonates squibs 8 start-up of a gas fire extinguishing system. In addition, the AWP program can provide for the simultaneous de-energization of technological equipment through the disconnecting unit 9, activation of light annunciators 12 "Do not enter" installed outside the building and light annunciators 13 "Go away" installed indoors.

The system program can also set the option of a certain delay in the start of the fire extinguishing system for preliminary evacuation of people from the zone of release of fire extinguishing gas (from the combustion room), if the gas is toxic and dangerous for workers. In some cases, the program can also delay the release of gas until all doors are completely closed, when a high fire extinguishing concentration is required. In this case, the doors should close automatically, and their position is monitored by sensors. 4. If necessary, the fire warning and extinguishing system can be turned on manually by pressing one of the buttons 3. In the event of a malfunction in the automation system, a corresponding signal is sent to the fire department. When automatic mode is deactivated, the sirens light up 11 "Automation disabled" located in the protected area.

Many of us only know about a fire extinguisher that its place is in the far corner on the wall or in the trunk of a car. We also know that with the help of this balloon it is possible to extinguish the fire. But in order for a fire extinguisher to justify its cost and purpose in a critical situation, this knowledge is not at all sufficient.

What is the inspection of fire extinguishers?

The annual inspection of fire extinguishers should include a visual inspection of the fire extinguisher, as well as the place where it is installed and the approaches to it. In addition, the leakage volume of the propellant gas is monitored. The bodies of fire extinguishers are opened (selective or complete, the condition of the filters is assessed, the parameters of the fire extinguisher are checked, and if they do not coincide with the requirements of regulatory documents).

Where should the primary extinguishing equipment be located?

On the territory of enterprises and in the construction area, primary fire extinguishing equipment should be placed on special fire shields or posts. While in small rooms, single placement of fire extinguishers is also permissible. The location of the fire extinguisher should not be determined by the project, but by the management of the organization or facility, taking into account industry fire safety rules. The placement of fire extinguishers and firefighting equipment, as well as their number is not determined by the project, but is established by the management of the relevant divisions of the facility or organizations, on the basis of industry fire safety rules and norms for calculating primary fire extinguishing equipment.

What automatic installations fire extinguishing?

Automatic fire extinguishing installation - an installation designed for fire extinguishing, which is automatically triggered when the automatic sensors react to fire factors. The following types of such installations are used: water, sprinkler, deluge, foam, as well as gas, aerosol and powder.

Sometimes we do not know the answer to even the simplest question: do we need a fire extinguisher?

At first glance, it may seem that a fire extinguisher is not needed at all. It hangs on the wall of the office long years not in demand. However, this is a very common misconception that can lead to dire consequences. Nowadays, when the majority office space is private property, the damage from the fire is felt by concrete people, not an abstract state. Lack of elementary fire extinguishing means is costly.

And if we continue this thought, then the owners of apartments, houses and cottages also need a fire extinguisher. Each of us has something that requires protection, which means there must be special means for this.

Is a fire extinguisher really effective as a means of protection? Won't we spend more money for the purchase of this cylinder, how would you pay for the damage caused by the fire?

An elementary calculation will help to answer this question. Check the prices for fire extinguishers, then evaluate your own property and compare the two numbers. You can safely bet that a fire extinguisher will cost you much less.

Will I or my family members or my employees use the fire extinguisher at the right time?

The mere presence of a fire extinguisher does not guarantee fire protection. It is necessary to use it correctly in time. A fire extinguisher is not the best complex device in the world. To use it correctly, you should carefully, and most importantly, read the instructions in advance and study the device of the cylinder. It would be desirable to practice in its application, then in a critical situation a fire extinguisher will really save property, and possibly life.

Moreover, there are automatic fire extinguishers that work without human intervention.

What fire extinguishers are there and which one is better to choose?

The old chemical-foam fire extinguishers (OHVP-10) are long gone. They were replaced by powder (OP) and carbon dioxide extinguishers (UO), which are distinguished by their high ability to extinguish fire and are quite aesthetic appearance... This allows you to place fire extinguishers in any room without the fear that they will ruin the interior.

A new generation of fire extinguishers is used to extinguish electrical installations under voltages up to 1000 W and operate in the temperature range from - 400 to + 500 C. These fire extinguishers need to be serviced only once every 5 years.

Inside a dry powder fire extinguisher there is a special powder that covers the fire and prevents the flow of oxygen to it. Powder fire extinguishers are suitable for use in industrial, warehouse, garages and cars. They are very effective in extinguishing flammable liquids and gases.

In residential buildings, offices, archives and rooms where computers, office equipment and other valuable equipment are located, it is worth using carbon dioxide fire extinguishers. They are distinguished by a cleaner action when used, since the extinguishing agent (carbon dioxide) evaporates after extinguishing, leaving no traces.

Fire extinguishers also differ in the volume of the fire extinguishing agent charge. And the price of a fire extinguisher depends on this factor. So, OP-2 (s) - powder fire extinguisher with a charge volume of 2 liters has a mass of 4.5 kg, and OU-5 is carbon dioxide with a charge volume of 5 liters weighs 13.5 kg. There are also mobile fire extinguishers with a volume of 100 liters and a weight of up to 240 kg, used in large production and storage facilities and at gas stations.

Fighting fires in electrical installations. Primary funds fire extinguishing

Particularly important when fighting fires in energy enterprises has the ability of personnel to use primary fire extinguishing equipment.

In accordance with the Fire Safety Rules, industrial and service buildings, structures and premises, as well as open production sites must be provided with the necessary primary fire extinguishing means.

Primary fire extinguishing means include:

- all types of portable and mobile fire extinguishers;

- equipment for fire shields;

- boxes with powder formulations (sand, perlite, etc.), as well as fire-resistant fabrics (asbestos cloth, felt, felt, etc.).

Primary fire extinguishing equipment is located in easily accessible places and should not interfere with the evacuation of personnel from the premises.

It is prohibited to use fire-fighting equipment and other fire-extinguishing means for needs other than extinguishing fires and personnel training.

Used or faulty fire extinguishers must be immediately removed from the protected area and replaced with serviceable ones.

For the placement of primary fire extinguishing equipment in industrial premises, as well as on the territory of enterprises, as a rule, special fire shields should be installed.

Single placement of fire extinguishers in small rooms is allowed.

The location of fire extinguishers and fire fighting equipment and their number is determined on the basis of the safety and security standards and the norms for calculating primary fire extinguishing equipment.

Fire shields are designed to concentrate and place hand-held fire extinguishers, fire-fighting equipment and tools used in the elimination of fires in a certain place.

The doors of the panels are sealed and must be opened without a key and with great effort.

Fire extinguishers

Fire extinguishers are designed to extinguish combustion centers in their initial stage, as well as for fire protection small structures, machines and mechanisms.

Fire extinguishers are hand-held and mobile.

TO hand-held fire extinguishers includes all types of fire extinguishers, containing up to 10 liters of charge.

Fire extinguishers with a large charge volume belong to mobile(their bodies are installed on special trolleys).

Depending on the fire extinguishing agent used, fire extinguishers are divided into:

- aquatic;

- foamy(chemical, chemical air-foam, air-foam);

- gas(carbon dioxide, freon, bromkhladonovye);

- powder.

In places where fire extinguishers are installed, the temperature environment must be at least 5 0 C.

Fire extinguishers are not allowed to be placed near heating and heating devices, as well as in places not protected from sunlight and precipitation.

The shut-off valves of fire extinguishers (taps, valves, handles, etc.) must be sealed, a tag must be attached to it indicating the date of charging and the person who made it.

Fire extinguishers should be regularly inspected, which checks the condition of the membranes and the spray (for foam fire extinguishers), the integrity of the seal and the tag.

Fire extinguishers must be recharged periodically. It is not allowed to send more than 50% of fire extinguishers for recharge at the same time. at which the recharge time has come.

Chemical foam fire extinguishers

Chemical foam (ОХП-10) and chemical air-foam fire extinguishers (ОХВП-10) are designed to extinguish various burning solid materials and flammable liquids.

The OHP-10 charge consists of an aqueous solution of alkali (sodium bicarbonate) and sulfuric acid.

The charge of OHVP-10 consists of the same substances as that of OHP-10, but 500 cm 3 of a foaming agent was added to the alkali solution to increase the foam yield and increase its efficiency during extinguishing.

The design and arrangement of fire extinguishers ОХП-10 and ОХВП-10 are shown in Fig. 1 and 2.

Their external difference lies in the fact that a foam nozzle is installed on the OHVP-10 to increase the rate of the outgoing foam.

To activate a fire extinguisher OHP-10 or OHVP-10, you must:

- using the side handle, bring the fire extinguisher in an upright position to the fire;

- install the fire extinguisher on the floor and clean the spray with a hairpin (suspended from the handle of the fire extinguisher), if it is not covered with a safety membrane;

- turn the handle (7) 180 0 from the initial position;

- grasp the side handle with one hand and lift the fire extinguisher off the floor, then, holding the bottom of the fire extinguisher with the other hand, turn it upside down;

- direct the outgoing foam stream to the fire.

For better foaming at the initial moment of the fire extinguisher's action, it is recommended to shake its body, which will ensure better interaction of the acid and an aqueous alkali solution.